Analytical Investigation of Cyclodextrin Complexation Using the Co-Grinding Technique in the Case of Terbinafine Hydrochloride †

Abstract

:1. Introduction

2. Experiments

2.1. Materials

2.2. Methods

2.2.1. Preparation of Co-Ground Mixtures

2.2.2. Differential Scanning Calorimetry (DSC)

2.2.3. X-ray Powder Diffractometry (XRPD)

2.2.4. Fourier-Transform Infrared Spectroscopy (FT-IR)

2.2.5. Raman Spectroscopy

2.2.6. Dissolution Rate Studies

3. Results and Discussion

3.1. Differential Scanning Calorimetry

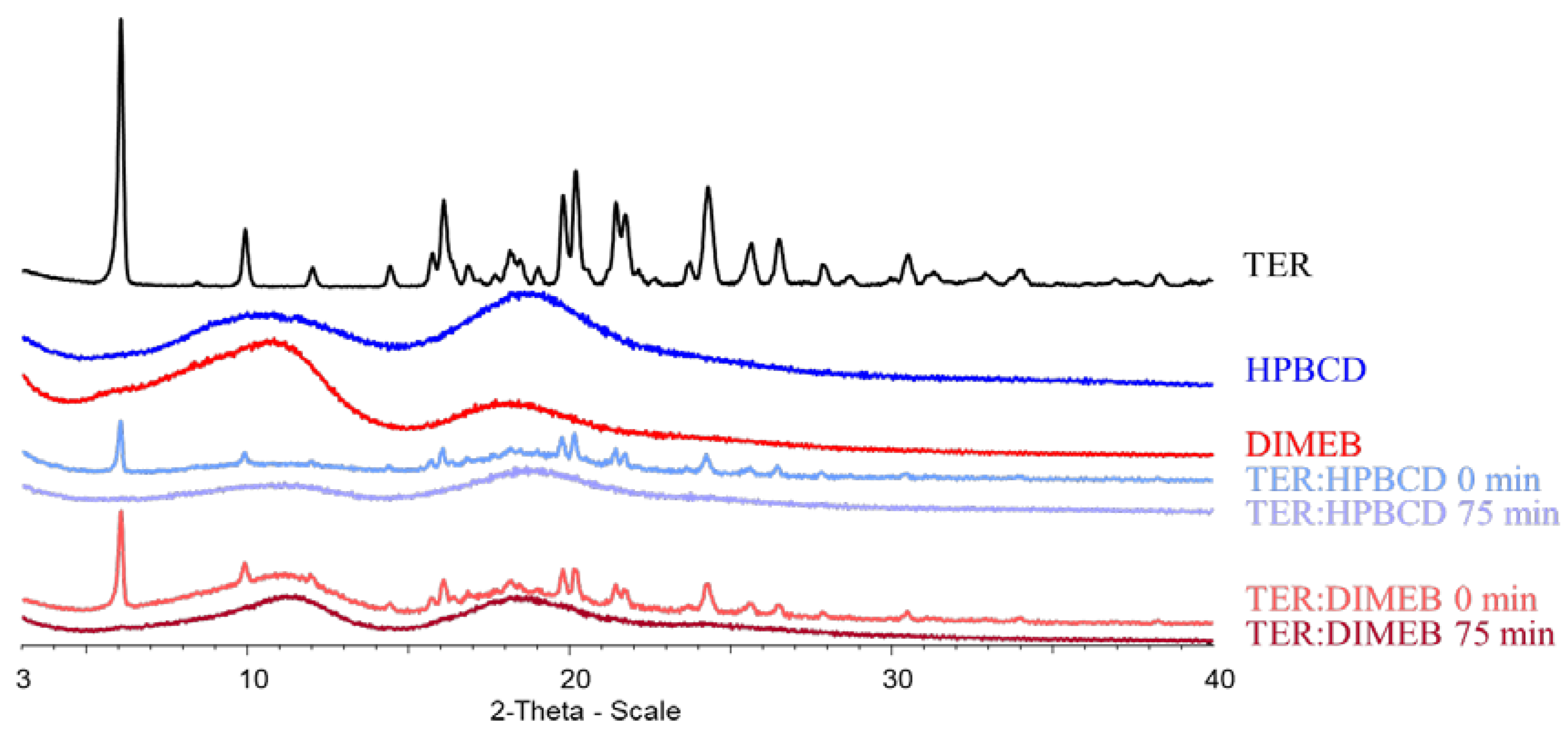

3.2. X-ray Powder Diffractometry

3.3. Hot-Humidity X-ray Powder Diffractometry (HOT-XRPD)

3.4. Fourier-Transform Infrared Spectroscopy

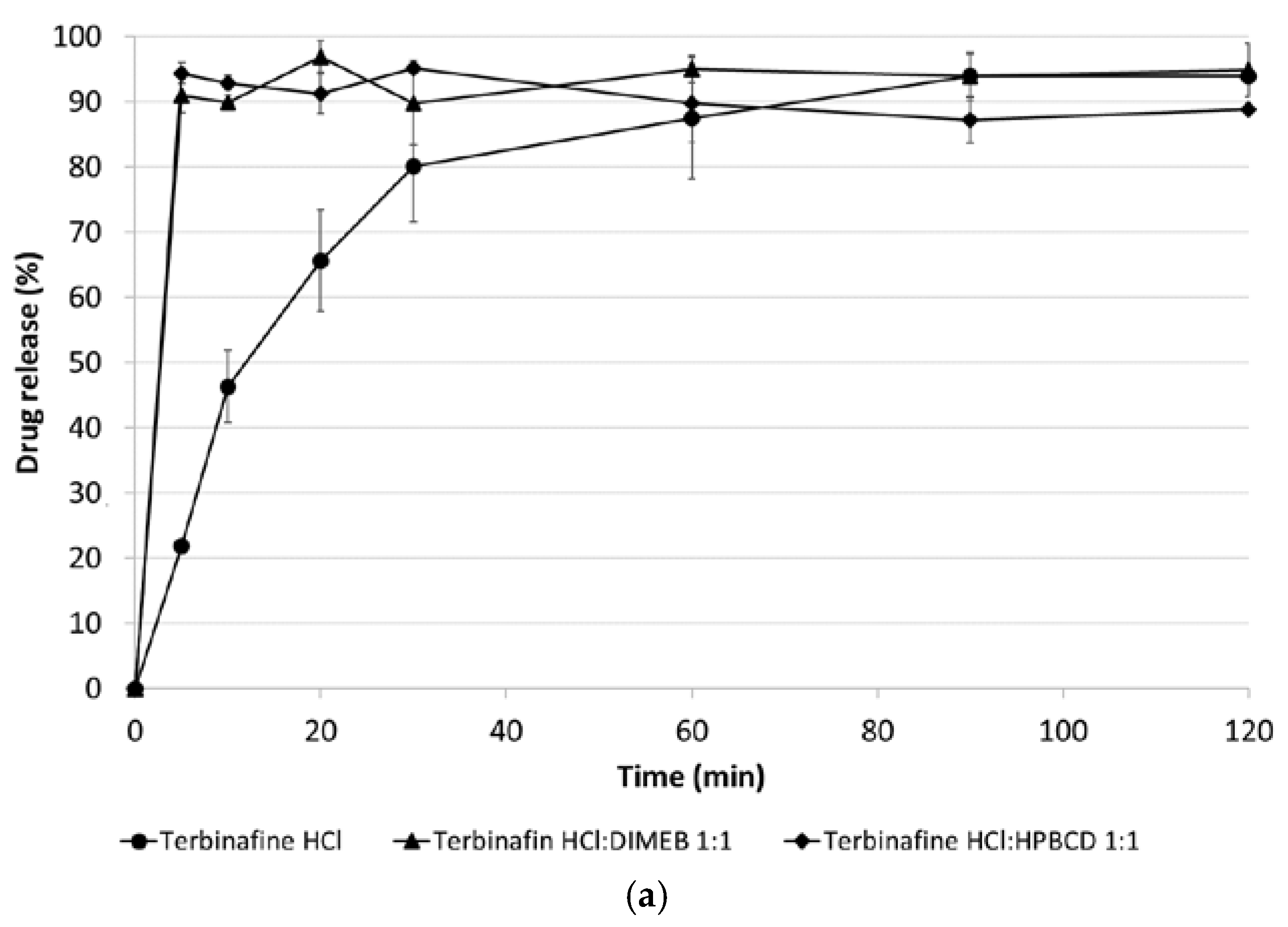

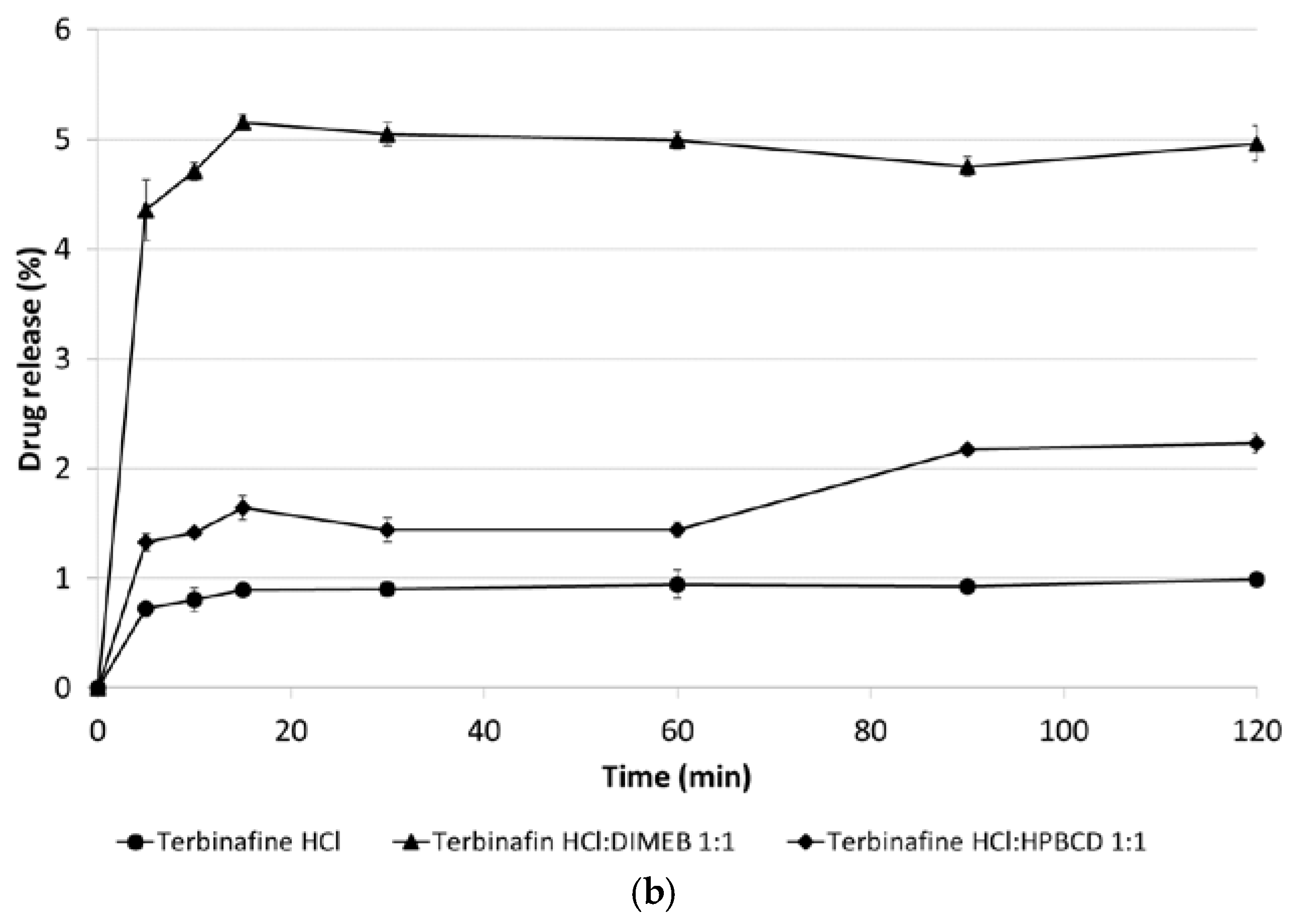

3.5. Dissolution Studies

4. Conclusions

Author Contributions

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BCS | Biopharmaceutics Classification System |

| CD | cyclodextrin |

| TER | terbinafine hydrochloride |

| HPBCD | hydroxypropyl-β-cyclodextrin |

| DIMEB | heptakis(2,6-di-O-methyl)-β-cyclodextrin |

| DSC | differential scanning calorimetry |

| XRPD | X-ray powder diffractometry |

| HOT-XRPD | hot-humidity stage X-ray powder diffractometry |

| FT-IR | Fourier-transform infrared spectroscopy |

References

- Kurkov, S.V.; Loftsson, T. Cyclodextrins. Int. J. Pharm. 2013, 45, 167–180. [Google Scholar] [CrossRef]

- Loftsson, T.; Jarho, P.; Másson, M.; Järvinen, T. Cyclodextrins in Drug Delivery. Expert Opin. Drug Deliv. on Drug Delivery 2005, 2, 335–351. [Google Scholar] [CrossRef] [PubMed]

- Hedges, A.R. Industrial Applications of Cyclodextrins. Chem. Rev. 1998, 98, 2035–2044. [Google Scholar] [CrossRef]

- Jug, M.; Mura, P. Grinding as Solvent-Free Green Chemistry Approach for Cyclodextrin Inclusion Complex Preparation in the Solid State. Pharmaceutics 2018, 10, 189. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kondoros, B.A.; Laczkovich, O.; Berkesi, O.; Aigner, Z. Analytical Investigation of Cyclodextrin Complexation Using the Co-Grinding Technique in the Case of Terbinafine Hydrochloride. Proceedings 2021, 78, 19. https://doi.org/10.3390/IECP2020-08714

Kondoros BA, Laczkovich O, Berkesi O, Aigner Z. Analytical Investigation of Cyclodextrin Complexation Using the Co-Grinding Technique in the Case of Terbinafine Hydrochloride. Proceedings. 2021; 78(1):19. https://doi.org/10.3390/IECP2020-08714

Chicago/Turabian StyleKondoros, Balázs Attila, Orsolya Laczkovich, Ottó Berkesi, and Zoltán Aigner. 2021. "Analytical Investigation of Cyclodextrin Complexation Using the Co-Grinding Technique in the Case of Terbinafine Hydrochloride" Proceedings 78, no. 1: 19. https://doi.org/10.3390/IECP2020-08714

APA StyleKondoros, B. A., Laczkovich, O., Berkesi, O., & Aigner, Z. (2021). Analytical Investigation of Cyclodextrin Complexation Using the Co-Grinding Technique in the Case of Terbinafine Hydrochloride. Proceedings, 78(1), 19. https://doi.org/10.3390/IECP2020-08714