Gelled Emulsions Based on Amaranth Flour with Hemp and Sesame Oils †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Gelled Emulsion Preparation

2.3. Instrumental Color Analysis

2.4. Texture Profile Analysis

2.5. Gelled Emulsion Stability

2.6. Lipid Oxidation

2.7. Statistical Analysis

3. Results and Discussion

3.1. Color Measurement

3.2. Textural Properties

3.3. Gelled Emulsions Stability

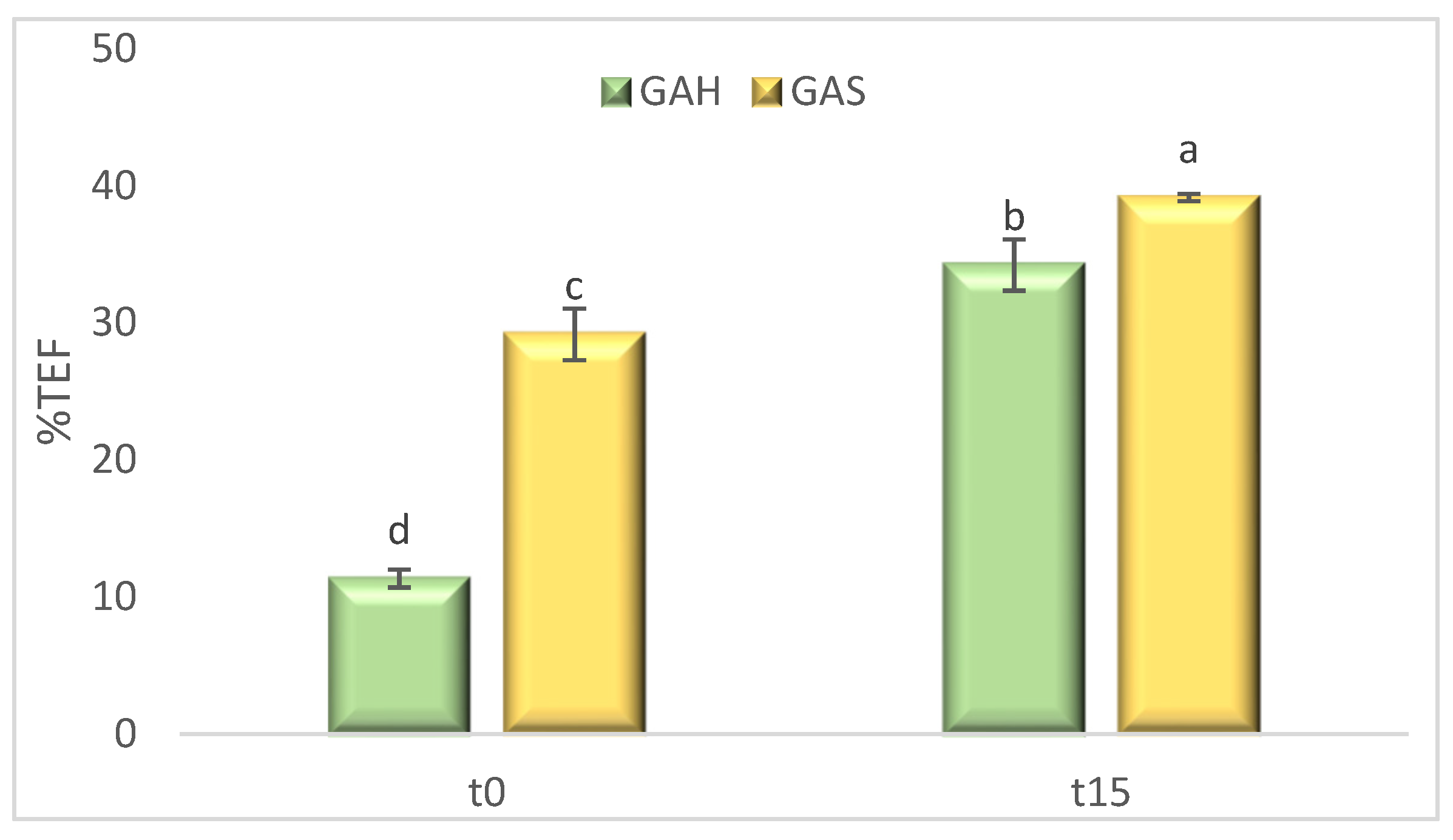

3.4. Lipid Oxidation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sandrou, K.M.; Arvanitoyannis, I.S. Low-fat/calorie foods: Current state and perspectives. Crit. Rev. Food Sci. Nutr. 2000, 40, 427–447. [Google Scholar] [CrossRef] [PubMed]

- Jimenez-Colmenero, F.; Salcedo-Sandoval, L.; Bou, R.; Cofrades, S.; Herrero, A.M.; Ruiz-Capillas, C. Novel applications of oil-structuring methods as a strategy to improve the fat content of meat products. Trend Food Sci. Technol. 2015, 44, 177–188. [Google Scholar] [CrossRef]

- Delgado-Pando, G.; Cofrades, S.; Ruiz-Capillas, C.; Jimenez-Colmenero, F. Healthier lipid combination as functional ingredient influencing sensory and technological properties of low-fat frankfurters. Eur. J. Lipid Sci. Technol. 2010, 112, 859–870. [Google Scholar] [CrossRef]

- Horita, C.; Morgano, M.; Celeghini, R.; Pollonio, M. Physico-chemical and sensory properties of reduced-fat mortadella prepared with blends of calcium, magnesium and potassium chloride as partial substitutes for sodium chloride. Meat Sci. 2011, 89, 426–433. [Google Scholar] [CrossRef] [PubMed]

- Paglarini, C.d.S.; Vidal, V.A.S.; Martini, S.; Cunha, R.L.; Pollonio, M.A.R. Protein-based hydrogelled emulsions and their application as fat replacers in meat products: A review. Crit. Rev. Food Sci. Nutr. 2020; in press. [Google Scholar] [CrossRef]

- Dickinson, E. Emulsion gels: The structuring of soft solids with protein-stabilized oil droplets. Food Hydrocol. 2012, 28, 224–241. [Google Scholar] [CrossRef]

- Lam, R.S.H.; Nickerson, M.T. Food proteins: A review on their emulsifying properties using a structure-function approach. Food Chem. 2013, 141, 975–984. [Google Scholar] [CrossRef] [PubMed]

- Schultz, S.; Wagner, G.; Urban, K.; Ulrich, J. High-pressure homogenization as a process for emulsion formation. Chem. Eng. Technol. 2004, 27, 361–368. [Google Scholar] [CrossRef]

- Ahmed, I.A.M.; Uslub, N.; Özcan, M.M.; Al Juhaimi, F.; Ghafoor, K.; Babiker, E.; Osman, M.A.; Alqa, H.A.S. Effect of conventional oven roasting treatment on the physicochemical quality attributes of sesame seeds obtained from different locations. Food Chem. 2021, 338, 128109. [Google Scholar] [CrossRef] [PubMed]

- Hughes, E.; Cofrades, S.; Troy, D.J. Effect of fat level, oat fiber and carrageenan on frankfurters formulated with 5.12 and 30% fat. Meat Sci. 1997, 45, 273–281. [Google Scholar] [CrossRef]

- Rosmini, M.; Perlo, F.; Pérez-Alvarez, J.; Pagán-Moreno, M.; Gago-Gago, M.; López-Santoveña, F.; Aranda-Catalá, V. TBA test by an extractive method applied to pate. Meat Sci. 1996, 42, 103–110. [Google Scholar] [CrossRef]

- Pintado, T.; Ruiz-Capillas, C.; Jiménez-Colmenero, F.; Carmona, P.; Herrero, A.M. Oil-in-water emulsión gels stabilized with chia (Salvia hispanica L) and cold gelling agents: Technological and infrared spectroscopic characterization. Food Chem. 2015, 185, 470–478. [Google Scholar] [CrossRef] [PubMed]

- Rezler, R.; Krywdzinska-Bartkowiak, M.; Piatek, M. The influence of the substitution of fat with modified starch on the quality of pork liver patés. LWT-Food Sci. Technol. 2021, 135, 110264. [Google Scholar] [CrossRef]

- Choi, Y.S.; Lee, M.A.; Jeong, J.Y.; Choi, J.H.; Han, D.J.; Kim, H.Y.; Lee, E.S.; Kim, C.J. Effect of wheat fiber on the quality of meat batter. Food Sci. Anim. Resour. 2007, 27, 22–28. [Google Scholar] [CrossRef]

- Turhan, S.; Sagir, I.; Ustun, N.S. Utilization of hazelnut pellicle in low-fat beef burgers. Meat Sci. 2005, 71, 312–316. [Google Scholar] [CrossRef] [PubMed]

- Fernández-Ginés, J.M.; Fernández-López; Sayas-Barberá, E.; Sendra, E.; Pérez-Álvarez, J.A. Lemon albedo as a new source of dietary fiber: Application to bologna sausages. Meat Sci. 2004, 67, 7–13. [Google Scholar] [CrossRef] [PubMed]

- De Nuñez Gonzalez, M.T.; Boleman, R.M.; Miller, R.K.; Keeton, J.T.; Rhee, K.S. Antoixidantprperties of dried plum ingredients in ra and precooked pork sausage. J. Food Sci. 2008, 73, 63–71. [Google Scholar] [CrossRef] [PubMed]

- Bonnes-Taourel, D.; Guérin, M.C.; Torreille, J. Is malonaldehyde a valuable indicator of lipid peroxidation? Biochem. Phar. 1992, 44, 985–988. [Google Scholar] [CrossRef]

- Trindade, R.A.; Mancini-Filho, J.; Villavicencio, A.I. Effects of natural antioxidants on the lipids profile of electron beam-irradiated beef burgers. Eur. J. Lipid Sci. Technol. 2009, 111, 1161–1168. [Google Scholar] [CrossRef]

- Jacobsen, C.; Timm, M.; Meyer, A.S. Oxidation in fish oil enriched mayonnaise: Ascorbic acid and low pH increase oxidative deterioration. J. Agric. Food Chem. 2001, 49, 3947–3956. [Google Scholar] [CrossRef] [PubMed]

- Taherian, A.; Britten, M.; Sabik, H.; Fustier, P. Ability of whey protein isolate and/or fish gelatin to inhibit physical separation and lipid oxidation in fish oil-in-water beverage emulsion. Food Hydrocol. 2011, 25, 868–878. [Google Scholar] [CrossRef]

| Samples 1 | Water | Flour | Gel Instant | Gellan Gum | Hemp Oil | Sesame Oil |

|---|---|---|---|---|---|---|

| GAH | 47 | 10 | 1.5 | 1.5 | 40 | - |

| GAS | 47 | 10 | 1.5 | 1.5 | - | 40 |

| Samples 1 | Day | L* | a* | b* |

|---|---|---|---|---|

| GAH | 0 | 69.45 ± 1.91 a,b | −1.03 ± 0.21 d | 23.52 ± 0.54 a |

| 15 | 61.83 ± 2.30 c | −0.52 ± 0.28 c | 23.22 ± 1.62 a | |

| GAS | 0 | 71.47 ± 0.95 a | 0.71 ± 0.08 b | 12.72 ± 0.22 b |

| 15 | 67.37 ± 0.65 b | 0.75 ± 0.09 a | 13.04 ± 0.44 b |

| Samples 1 | Firmness (g) | Work of Shear (g.s) |

|---|---|---|

| GAH | 536.67 ± 21.28 a | 460.00 ± 8.17 a |

| GAS | 466.67 ± 11.45 b | 366.67 ± 13.42 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Botella-Martínez, C.M.; Fernández-López, J.; Pérez-Álvarez, J.Á.; Viuda-Martos, M. Gelled Emulsions Based on Amaranth Flour with Hemp and Sesame Oils. Proceedings 2021, 70, 98. https://doi.org/10.3390/foods_2020-07713

Botella-Martínez CM, Fernández-López J, Pérez-Álvarez JÁ, Viuda-Martos M. Gelled Emulsions Based on Amaranth Flour with Hemp and Sesame Oils. Proceedings. 2021; 70(1):98. https://doi.org/10.3390/foods_2020-07713

Chicago/Turabian StyleBotella-Martínez, Carmen María, Juana Fernández-López, José Ángel Pérez-Álvarez, and Manuel Viuda-Martos. 2021. "Gelled Emulsions Based on Amaranth Flour with Hemp and Sesame Oils" Proceedings 70, no. 1: 98. https://doi.org/10.3390/foods_2020-07713

APA StyleBotella-Martínez, C. M., Fernández-López, J., Pérez-Álvarez, J. Á., & Viuda-Martos, M. (2021). Gelled Emulsions Based on Amaranth Flour with Hemp and Sesame Oils. Proceedings, 70(1), 98. https://doi.org/10.3390/foods_2020-07713