Avocado-Derived Biomass: Chemical Composition and Antioxidant Potential †

Abstract

:1. Introduction

2. Methods

2.1. Raw Material

2.2. Extraction and Chemical Characterization

2.3. Total Phenolic Content (TPC)

2.4. Total Flavonoids Content (TFC)

2.5. Antioxidant Activity

3. Results and Discussion

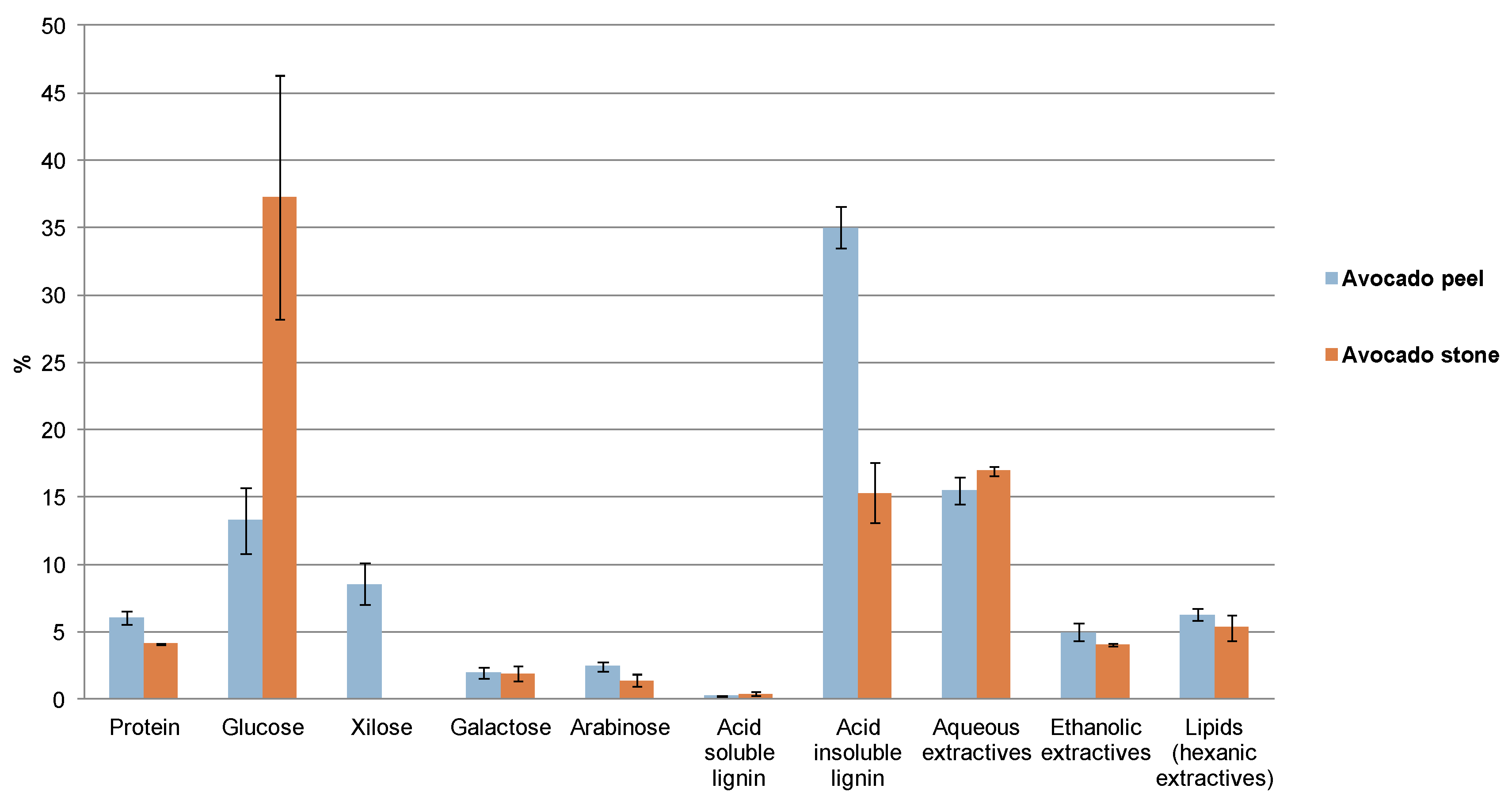

3.1. Chemical Characterization of Avocado Waste

3.2. TPC, TFC and Antioxidant Activity

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nations (FAO). FAOSTAT-2020. Available online: http://www.fao.org/faostat/en/#data/QC/visualize (accessed on 10 October 2020).

- Bet, C.D.; Waiga, L.H.; De Oliveira, C.S.; Lacerda, L.G.; Schnitzler, E. Morphological and thermoanalytical study of modified avocado seeds starch with lactic acid. Chem. J. Mold. 2017, 12, 13–18. [Google Scholar] [CrossRef]

- Krumreich, F.D.; Borges, C.D.; Mendonça, C.R.B.; Jansen-Alves, C.; Zambiazi, R.C. Bioactive compounds and quality parameters of avocado oil obtained by different processes. Food Chem. 2018, 257, 376–381. [Google Scholar] [CrossRef] [PubMed]

- Barbosa-Martín, E.; Chel-Guerrero, L.; González-Mondragón, E.; Betancur-Ancona, D. Chemical and technological properties of avocado (Persea americana Mill.) seed fibrous residues. Food Bioprod. Process. 2016, 100, 457–463. [Google Scholar] [CrossRef]

- Permal, R.; Leong Chang, W.; Seale, B.; Hamid, N.; Kam, R. Converting industrial organic waste from the cold-pressed avocado oil production line into a potential food preservative. Food Chem. 2020, 306, 125635. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Ash in Biomass; Technical Report NREL/TP-510-42622; Laboratory Analytical Procedure (LAP): Golden, CO, USA, 2008. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass. Technical report NREL/TP-510-42618 Analytical Procedure; Laboratory Analytical Procedure (LAP): Golden, CO, USA, 2012. [Google Scholar]

- Ferrentino, G.; Ndayishimiye, J.; Haman, N.; Scampicchio, M. Functional activity of oils from brewer’s spent grain extracted by supercritical carbon dioxide. Food Bioprocess Technol. 2019, 12, 789–798. [Google Scholar] [CrossRef]

- Lama-Muñoz, A.; Contreras, M. del M.; Espínola, F.; Moya, M.; de Torres, A.; Romero, I.; Castro, E. Extraction of oleuropein and luteolin-7-O-glucoside from olive leaves: Optimization of technique and operating conditions. Food Chem. 2019, 293, 161–168. [Google Scholar] [CrossRef] [PubMed]

- Medfai, W.; Contreras, M. del M.; Lama-Muñoz, A.; Mhamdi, R.; Oueslati, I.; Castro, E. How cultivar and extraction conditions affect antioxidants type and extractability for olive leaves valorization. ACS Sustain. Chem. Eng. 2020, 8, 5107–5118. [Google Scholar] [CrossRef]

- Perea-Moreno, A.J.; Aguilera-Ureña, M.J.; Manzano-Agugliaro, F. Fuel properties of avocado stone. Fuel 2016, 186, 358–364. [Google Scholar] [CrossRef]

- Páramos, P.R.S.; Granjo, J.F.O.; Corazza, M.L.; Matos, H.A. Extraction of high value products from avocado waste biomass. J. Supercrit. Fluids 2020, 165, 104988. [Google Scholar] [CrossRef]

- Saavedra, J.; Córdova, A.; Navarro, R.; Díaz-Calderón, P.; Fuentealba, C.; Astudillo-Castro, C.; Toledo, L.; Enrione, J.; Galvez, L. Industrial avocado waste: Functional compounds preservation by convective drying process. J. Food Eng. 2017, 198, 81–90. [Google Scholar] [CrossRef]

| Element 1 (%) | Peel | Stone | Element 1 (%) | Peel | Stone |

|---|---|---|---|---|---|

| N | 0.97 ± 0.07 | 0.66 ± 0.01 | H | 5.71 ± 0.02 | 5.58 ± 0.02 |

| C | 49.83 ± 0.42 | 42.05 ± 0.05 | O | 42.2 ± 2.62 | 50.79 ± 1.56 |

| Ash | 3.81 ± 0.05 | 2.76 ± 0.28 | Humidity | 70.9± 0.2 | 52.0 ± 0.4 |

| Part | TPC | TFC | TEAC | FRAP | ||||

|---|---|---|---|---|---|---|---|---|

| AE | EE | AE | EE | AE | EE | AE | EE | |

| In terms of biomass weight (g GAE or g rutin or mmol TE/100 g, d.w.) | ||||||||

| AP | 4.13 ± 0.56 | 0.60 ± 0.12 | 5.35 ± 1.36 | 0.75 ± 0.09 | 17.48 ± 3.12 | 0.47 ± 0.05 | 15.20 ± 2.02 | 1.49 ± 0.34 |

| AS | 0.31 ± 0.06 | 0.18 ± 0.03 | 0.45 ± 0.13 | 0.67 ± 0.02 | 1.66 ± 0.31 | 0.32 ± 0.08 | 1.29 ± 0.32 | 0.66 ± 0.05 |

| In terms of extract weight (g GAE or g rutin or mmol TE/100 g, d.w.) | ||||||||

| AP | 26.56 ± 2.77 | 12.60 ± 3.17 | 34.23 ± 6.90 | 15.63 ± 1.25 | 112.15 ± 13.35 | 9.67 ± 2.11 | 97.78 ± 7.83 | 37.77 ± 1.68 |

| AS | 1.81 ± 0.34 | 4.39 ± 0.88 | 2.66 ± 0.82 | 16.49 ± 0.80 | 9.85 ± 2.03 | 7.84 ± 2.04 | 7.71 ± 1.93 | 16.31 ± 1.62 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Vargas, M.C.; Contreras, M.d.M.; Gómez-Cruz, I.; Romero-García, J.M.; Castro, E. Avocado-Derived Biomass: Chemical Composition and Antioxidant Potential. Proceedings 2021, 70, 100. https://doi.org/10.3390/foods_2020-07750

García-Vargas MC, Contreras MdM, Gómez-Cruz I, Romero-García JM, Castro E. Avocado-Derived Biomass: Chemical Composition and Antioxidant Potential. Proceedings. 2021; 70(1):100. https://doi.org/10.3390/foods_2020-07750

Chicago/Turabian StyleGarcía-Vargas, Minerva C., María del Mar Contreras, Irene Gómez-Cruz, Juan Miguel Romero-García, and Eulogio Castro. 2021. "Avocado-Derived Biomass: Chemical Composition and Antioxidant Potential" Proceedings 70, no. 1: 100. https://doi.org/10.3390/foods_2020-07750

APA StyleGarcía-Vargas, M. C., Contreras, M. d. M., Gómez-Cruz, I., Romero-García, J. M., & Castro, E. (2021). Avocado-Derived Biomass: Chemical Composition and Antioxidant Potential. Proceedings, 70(1), 100. https://doi.org/10.3390/foods_2020-07750