A Characterization Study of Morphology and Properties of Poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH)/Aloe Vera Fibers Biocomposites: Effect of Fiber Surface Treatments †

Abstract

:1. Introduction

2. Experiments

2.1. Materials

2.2. Extraction Procedure and Chemical Composition of Bio-Fibers

2.3. Chemical Modification of Fibers Surface

2.3.1. Alkaline Modification

2.3.2. Chemical Modification Using TMOS

2.3.3. Combined Alkaline–Organosilane Treatment

2.4. Preparation of PHBH/AVF Biocomposites

2.5. Characterization Techniques

3. Results

3.1. Morphological Analysis of Modified PHBH/AVF by SEM

3.2. Rheological Measurements

3.3. TGA Data

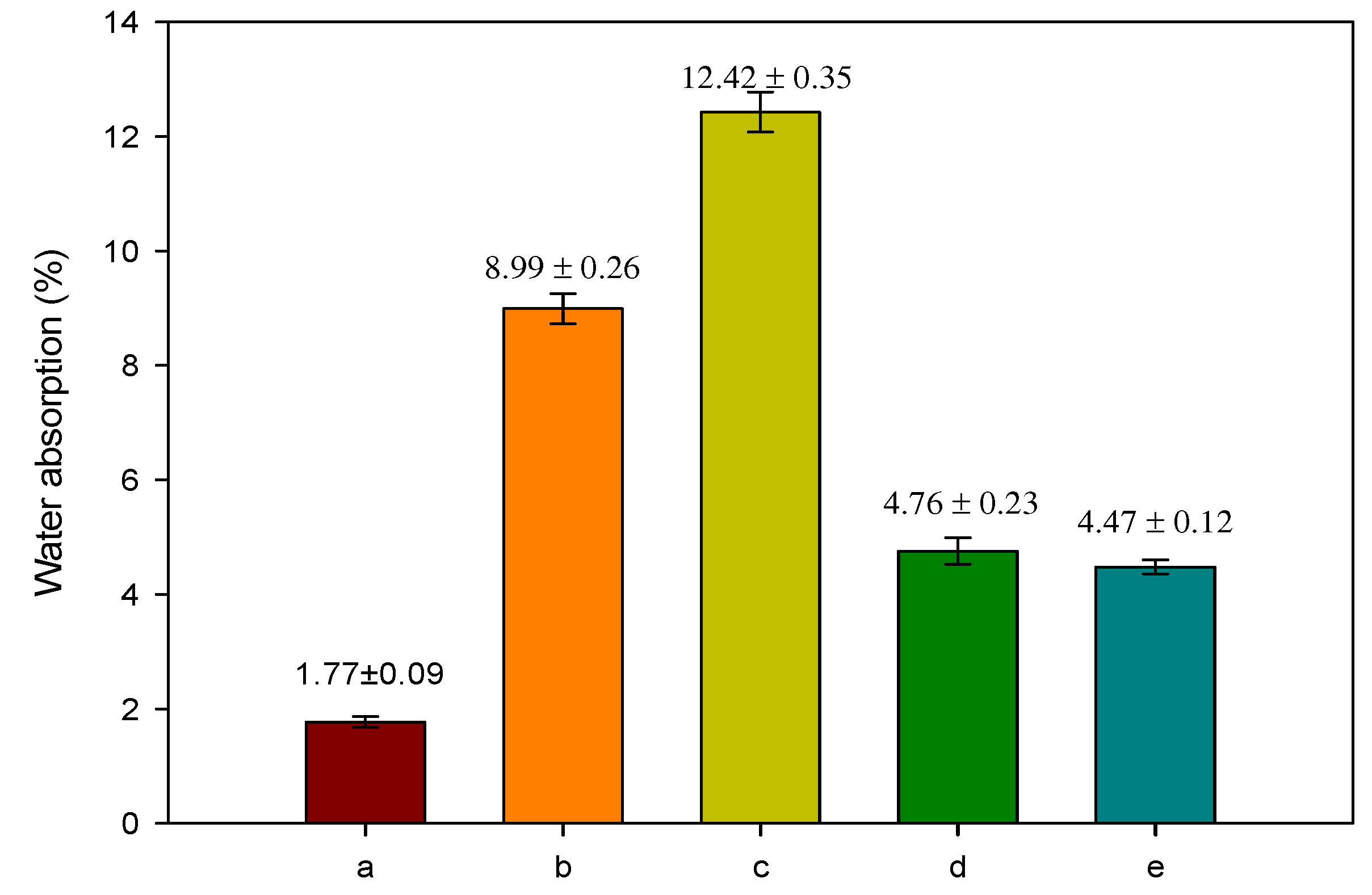

3.4. Water Absorption (WA)

4. Discussion

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Abbreviations

| PHBH | poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) |

| Aloe Vera Fiber | AVF |

| ATR-FTIR | Attenuated total reflectance-Fourier transform infrared spectroscopy |

| SEM | Scanning Electron Microscopy |

| TMOS | Trimethoxy-octadecyl-silanes |

| NTAVF | Not treated Aloe Vera fiber |

| A-AVF | Alkaline treated Aloe Vera Fiber |

| S-AVF | Organosilanes treated Aloe Vera Fiber |

| AS-AVF | Combined alkaline organosilanes treated fiber |

| TGA | Thermogravimetric analysis |

References

- Bharath, K.N.; Basavarajappa, S. Applications of Biocomposite Materials Based on Natural Fibers from Renewable Resources: A Review. Sci. Eng. Compos. Mater. 2016, 23, 123–133. [Google Scholar] [CrossRef]

- Murphy, C.A.; Collins, M.N. Microcrystalline Cellulose Reinforced Polylactic Acid Biocomposite Filaments for 3D Printing. Polym. Compos. 2018, 39, 1311–1320. [Google Scholar] [CrossRef]

- Kennouche, S.; Le Moigne, N.; Kaci, M.; Quantin, J.-C.; Caro-Bretelle, A.-S.; Delaite, C.; Lopez-Cuesta, J.-M. Morphological Characterization and Thermal Properties of Compatibilized Poly (3-Hydroxybutyrate-Co-3-Hydroxyvalerate)(PHBV)/Poly (Butylene Succinate)(PBS)/Halloysite Ternary Nanocomposites. Eur. Polym. J. 2016, 75, 142–162. [Google Scholar] [CrossRef]

- Ivorra-Martinez, J.; Verdu, I.; Fenollar, O.; Sanchez-Nacher, L.; Balart, R.; Quiles-Carrillo, L. Manufacturing and Properties of Binary Blend from Bacterial Polyester Poly (3-Hydroxybutyrate-Co-3-Hydroxyhexanoate) and Poly (Caprolactone) with Improved Toughness. Polymers 2020, 12, 1118. [Google Scholar] [CrossRef]

- Raza, Z.A.; Abid, S.; Banat, I.M. Polyhydroxyalkanoates: Characteristics, Production, Recent Developments and Applications. Int. Biodeterior. Biodegrad. 2018, 126, 45–56. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites Reinforced with Natural Fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Balaji, A.N.; Nagarajan, K.J. Characterization of Alkali Treated and Untreated New Cellulosic Fiber from Saharan Aloe Vera Cactus Leaves. Carbohydr. Polym. 2017, 174, 200–208. [Google Scholar]

- Chaitanya, S.; Singh, I. Novel Aloe Vera Fiber Reinforced Biodegradable Composites—Development and Characterization. J. Reinf. Plast. Compos. 2016, 35, 1411–1423. [Google Scholar] [CrossRef]

- Chaitanya, S.; Singh, I. Ecofriendly Treatment of Aloe Vera Fibers for PLA Based Green Composites. Int. J. Precis. Eng. Manuf. -Green Technol. 2018, 5, 143–150. [Google Scholar] [CrossRef]

- Mannai, F.; Elhleli, H.; Ammar, M.; Passas, R.; Elaloui, E.; Moussaoui, Y. Green Process for Fibrous Networks Extraction from Opuntia (Cactaceae): Morphological Design, Thermal and Mechanical Studies. Ind. Crop. Prod. 2018, 126, 347–356. [Google Scholar] [CrossRef]

- Li, S.; Xu, S.; Liu, S.; Yang, C.; Lu, Q. Fast Pyrolysis of Biomass in Free-Fall Reactor for Hydrogen-Rich Gas. Fuel Process. Technol. 2004, 85, 1201–1211. [Google Scholar] [CrossRef]

- Varma, A.K.; Mondal, P. Physicochemical Characterization and Pyrolysis Kinetic Study of Sugarcane Bagasse Using Thermogravimetric Analysis. J. Energy Resour. Technol. 2016, 138, 052205. [Google Scholar] [CrossRef]

- Joyyi, L.; Thirmizir, M.Z.A.; Salim, M.S.; Han, L.; Murugan, P.; Kasuya, K.; Maurer, F.H.; Arifin, M.I.Z.; Sudesh, K. Composite Properties and Biodegradation of Biologically Recovered P (3HB-Co-3HHx) Reinforced with Short Kenaf Fibers. Polym. Degrad. Stab. 2017, 137, 100–108. [Google Scholar] [CrossRef]

- Orue, A.; Jauregi, A.; Unsuain, U.; Labidi, J.; Eceiza, A.; Arbelaiz, A. The Effect of Alkaline and Silane Treatments on Mechanical Properties and Breakage of Sisal Fibers and Poly (Lactic Acid)/Sisal Fiber Composites. Compos. Part A: Appl. Sci. Manuf. 2016, 84, 186–195. [Google Scholar] [CrossRef]

- Georgiopoulos, P.; Kontou, E.; Georgousis, G. Effect of Silane Treatment Loading on the Flexural Properties of PLA/Flax Unidirectional Composites. Compos. Commun. 2018, 10, 6–10. [Google Scholar] [CrossRef]

- Dehouche, N.; Idres, C.; Kaci, M.; Zembouai, I.; Bruzaud, S. Effects of Various Surface Treatments on Aloe Vera Fibers Used as Reinforcement in Poly (3-Hydroxybutyrate-Co-3-Hydroxyhexanoate)(PHBHHx) Biocomposites. Polym. Degrad. Stab. 2020, 175, 109131. [Google Scholar] [CrossRef]

- Wu, C.-S. Assessing Biodegradability and Mechanical, Thermal, and Morphological Properties of an Acrylic Acid-Modified Poly (3-Hydroxybutyric Acid)/Wood Flours Biocomposite. J. Appl. Polym. Sci. 2006, 102, 3565–3574. [Google Scholar] [CrossRef]

- Berthet, M.-A.; Gontard, N.; Angellier-Coussy, H. Impact of Fibre Moisture Content on the Structure/Mechanical Properties Relationships of PHBV/Wheat Straw Fibres Biocomposites. Compos. Sci. Technol. 2015, 117, 386–391. [Google Scholar] [CrossRef]

- Komal, U.K.; Lila, M.K.; Singh, I. PLA/Banana Fiber Based Sustainable Biocomposites: A Manufacturing Perspective. Compos. Part B: Eng. 2020, 180, 107535. [Google Scholar] [CrossRef]

- Vandi, L.-J.; Chan, C.M.; Werker, A.; Richardson, D.; Laycock, B.; Pratt, S. Extrusion of Wood Fibre Reinforced Poly (Hydroxybutyrate-Co-Hydroxyvalerate)(PHBV) Biocomposites: Statistical Analysis of the Effect of Processing Conditions on Mechanical Performance. Polym. Degrad. Stab. 2019, 159, 1–14. [Google Scholar] [CrossRef]

- Rachini, A.; Le Troedec, M.; Peyratout, C.; Smith, A. Comparison of the Thermal Degradation of Natural, Alkali-Treated and Silane-Treated Hemp Fibers under Air and an Inert Atmosphere. J. Appl. Polym. Sci. 2009, 112, 226–234. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Kaci, M.; Djidjelli, H.; Boukerrou, A.; Zaidi, L. Effect of Wood Filler Treatment and EBAGMA Compatibilizer on Morphology and Mechanical Properties of Low Density Polyethylene/Olive Husk Flour Composites. Express Polym. Lett 2007, 1, 467–473. [Google Scholar] [CrossRef]

- Ali, A.; Shaker, K.; Nawab, Y.; Jabbar, M.; Hussain, T.; Militky, J.; Baheti, V. Hydrophobic Treatment of Natural Fibers and Their Composites—A Review. J. Ind. Text. 2018, 47, 2153–2183. [Google Scholar] [CrossRef]

- Gogoi, R.; Tyagi, A.K. Surface Modification of Jute Fabric by Treating with Silane Coupling Agent for Reducing Its Moisture Regain Characteristics. J. Nat. Fibers 2019, 1–10. [Google Scholar] [CrossRef]

| Formulations | PHBH (wt %) | AVF (wt %) | Designation |

|---|---|---|---|

| PHBH | 100 | - | Matrix |

| NTAVF | 80 | 20 | PHBH/non treated AVF |

| A-AVF | 80 | 20 | PHBH/alkaline treated AVF |

| S-AVF | 80 | 20 | PHBH/organosilanes treated AVF |

| AS-AVF | 80 | 20 | PHBH/combined alkaline and organosilanes treated AVF |

| Sample | (Pa.s) | G’ (Pa) | G” (Pa) |

|---|---|---|---|

| PHBH | 4100 | 6.18 | 258 |

| PHBH/NTAVF | 111,000 | 5100 | 4760 |

| PHBH/A-AVF | 835,000 | 50,500 | 14,000 |

| PHBH/S-AVF | 228,000 | 9610 | 10,600 |

| PHBH/AS-AVF | 1,240,000 | 66,500 | 40,800 |

| Samples | T10 (°C) | T50 (°C) | Tmdr (°C) | Residue (%) |

|---|---|---|---|---|

| PHBH | 280 ± 0.5 | 294 ± 1.8 | 295 ± 1.1 | 0.2 ± 0.05 |

| PHBH/NTAVF | 274 ± 0.8 | 288 ± 1.9 | 288 ± 0.8 | 4.2 ± 0.6 |

| PHBH/A-AVF | 260 ± 0.7 | 274 ± 1.7 | 276 ± 0.9 | 4.3 ± 0.4 |

| PHBH/S-AVF | 278 ± 0.4 | 293 ± 1.3 | 293 ± 0.3 | 1.9 ± 0.1 |

| PHBH/AS-AVF | 277 ± 0.2 | 289 ± 1.1 | 292 ± 0.3 | 1.6 ± 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Idres, C.; Kaci, M.; Dehouche, N.; Zembouai, I.; Bruzaud, S. A Characterization Study of Morphology and Properties of Poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH)/Aloe Vera Fibers Biocomposites: Effect of Fiber Surface Treatments. Proceedings 2021, 69, 38. https://doi.org/10.3390/CGPM2020-07183

Idres C, Kaci M, Dehouche N, Zembouai I, Bruzaud S. A Characterization Study of Morphology and Properties of Poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH)/Aloe Vera Fibers Biocomposites: Effect of Fiber Surface Treatments. Proceedings. 2021; 69(1):38. https://doi.org/10.3390/CGPM2020-07183

Chicago/Turabian StyleIdres, Celia, Mustapha Kaci, Nadjet Dehouche, Idris Zembouai, and Stéphane Bruzaud. 2021. "A Characterization Study of Morphology and Properties of Poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH)/Aloe Vera Fibers Biocomposites: Effect of Fiber Surface Treatments" Proceedings 69, no. 1: 38. https://doi.org/10.3390/CGPM2020-07183

APA StyleIdres, C., Kaci, M., Dehouche, N., Zembouai, I., & Bruzaud, S. (2021). A Characterization Study of Morphology and Properties of Poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH)/Aloe Vera Fibers Biocomposites: Effect of Fiber Surface Treatments. Proceedings, 69(1), 38. https://doi.org/10.3390/CGPM2020-07183