Recyclable Insulating Foams for High-Temperature Applications †

Abstract

:1. Introduction

2. Experiments

2.1. Materials

2.2. Extrusion Foaming Process

2.3. Foam Characterization

3. Results and Discussion

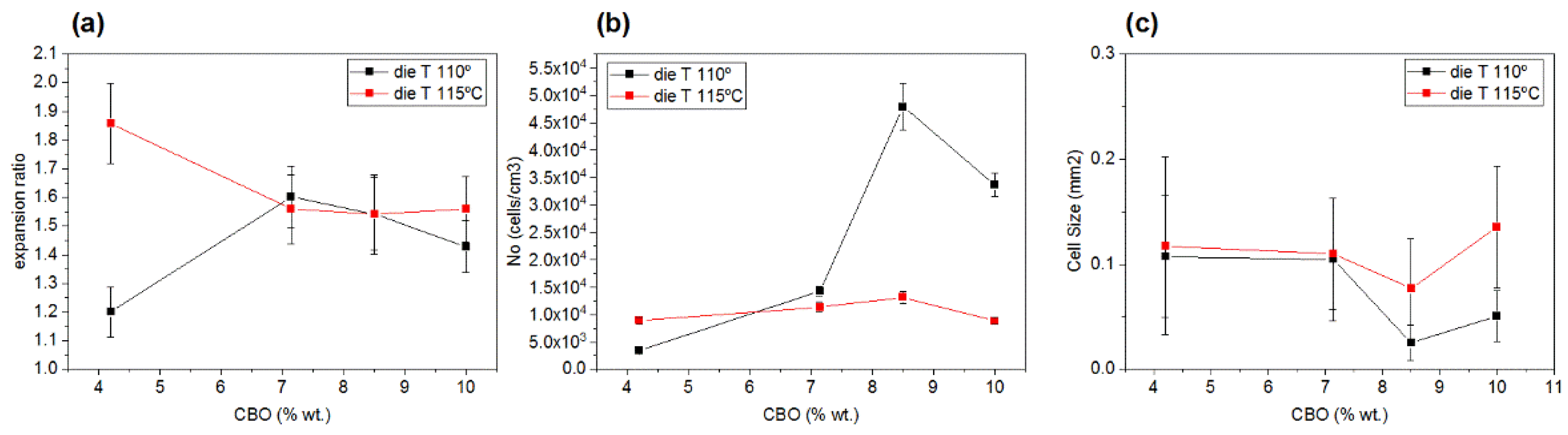

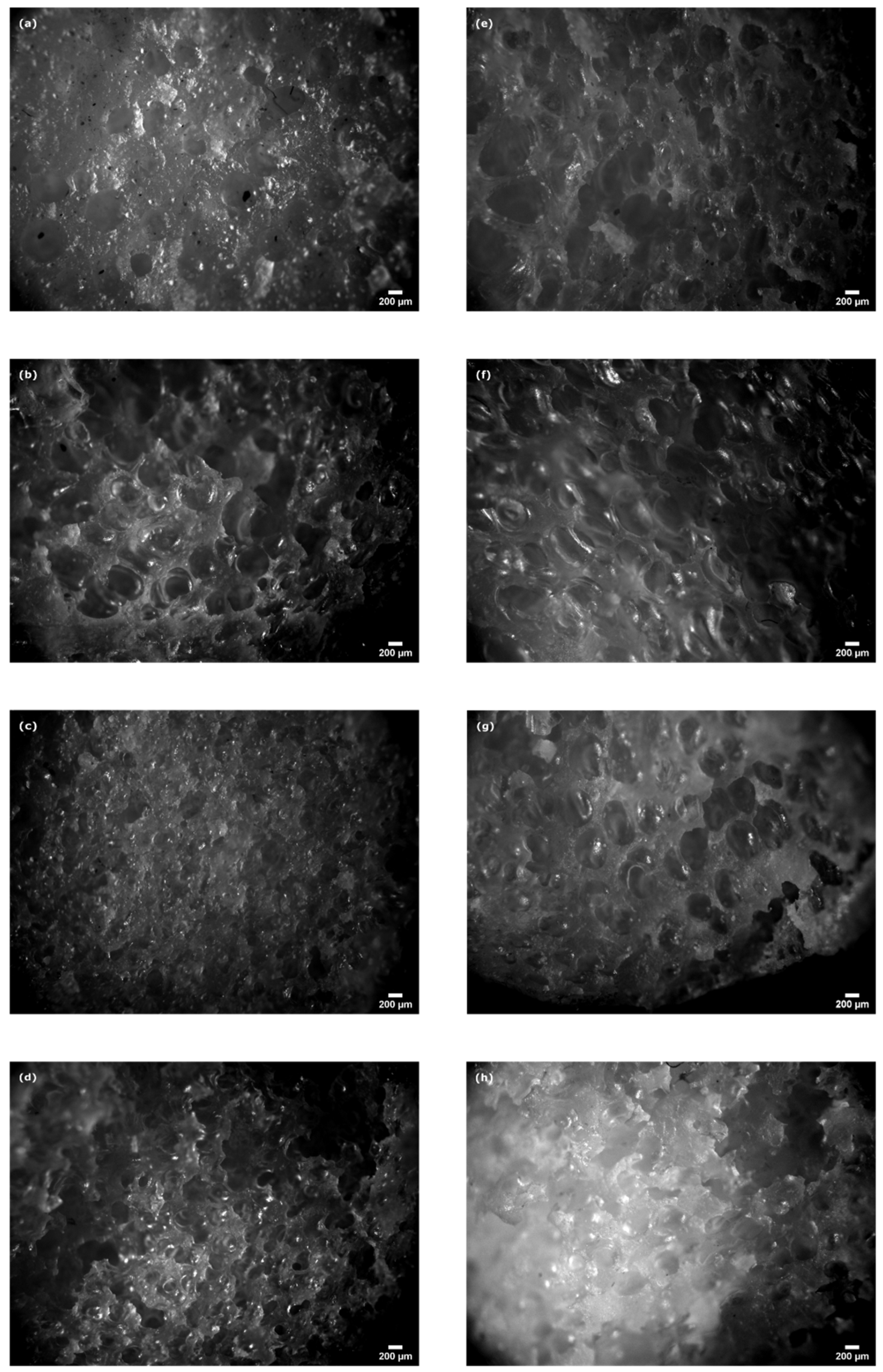

3.1. Microstructural Characterization and the Relationship with the Process Conditions

3.2. Effect of Process Conditions on the Volume Expansion Ratio

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Abbreviations

| PB-1 | Polybutylene |

| ESCR | Environmental stress cracking resistance |

| DH | District heating |

| PU | Polyurethane |

| TDI | Toluene diisocyanate |

| MDI | Methylene diphenyl diisocyanate |

| EU | European Union |

| CLP Regulation | Classification, labelling and packaging of substances and mixtures regulation |

| REACH | Registration, evaluation, authorisation and restriction of chemicals |

| CBA | Chemical blowing agent |

| wt. | Weight |

| T° | Temperature |

References

- Nilsson, S.F. New developments in pipes and related network components for district heating. In Advanced District Heating and Cooling (DHC) Systems; Elsevier: Amsterdam, The Netherlands, 2016; pp. 191–214. ISBN 9781782423744. [Google Scholar]

- Kurańska, M.; Prociak, A. Bio-Based Polyurethane Foams for Heat-Insulating Applications. In Nano and Biotech Based Materials for Energy Building Efficiency; Pacheco Torgal, F., Buratti, C., Kalaiselvam, S., Granqvist, C.-G., Ivanov, V., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 357–373. ISBN 978-3-319-27503-1. [Google Scholar]

- The European Parliament and the Council of the European Union. CLP Regulation; (EC) No 1272/2008. Off. J. Eur. Union 2008.

- Commission Regulation (EU). 2020/1149 of 3 August 2020 Amending Annex XVII to Regulation (EC) No 1907/2006 of the European Parliament and of the Council Concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) as Regards Diisocyanates: (EU) 2020/1149. Off. J. Eur. Union 2020. [Google Scholar]

- Wypych, G. Handbook of Plasticizers, 3rd ed.; Chemtec: Toronto, ON, Canada, 2017; ISBN 9781895198973. [Google Scholar]

- Olabisi, O.; Adewale, K. Handbook of Thermoplastics; CRC Press: Boca Raton, FL, USA, 2016; ISBN 1466577223. [Google Scholar]

- Lee, S.-T.; Park, C.B. (Eds.) Foam Extrusion. Principles and Practice, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2014; ISBN 9781439898598. [Google Scholar]

- Jeong, B.; Xanthos, M.; Seo, Y. Extrusion Foaming Behavior of PBT Resins. J. Cell. Plast. 2006, 42, 165–176. [Google Scholar] [CrossRef]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Liu, W.; Liu, B.; Zhou, H.; Wang, W. Reactive Modification of Poly(ethylene terephthalate) and its Foaming Behavior. Cell. Polym. 2014, 33, 189–212. [Google Scholar] [CrossRef]

- Reignier, J.; Gendron, R.; Champagne, M.F. Autoclave Foaming of Poly(ε-Caprolactone) Using Carbon Dioxide: Impact of Crystallization on Cell Structure. J. Cell. Plast. 2007, 43, 459–489. [Google Scholar] [CrossRef]

- Kaewmesri, W.; Lee, P.C.; Park, C.B.; Pumchusak, J. Effects of CO2 and Talc Contents on Foaming Behavior of Recyclable High-melt-strength PP. J. Cell. Plast. 2006, 42, 405–428. [Google Scholar] [CrossRef]

- Matuana, L.M.; Faruk, O.; Diaz, C.A. Cell morphology of extrusion foamed poly(lactic acid) using endothermic chemical foaming agent. Bioresour. Technol. 2009, 100, 5947–5954. [Google Scholar] [CrossRef]

- Guo, Q.; Wang, J.; Park, C.B.; Ohshima, M. A Microcellular Foaming Simulation System with a High Pressure-Drop Rate. Ind. Eng. Chem. Res. 2006, 45, 6153–6161. [Google Scholar] [CrossRef]

| Die T (°C) | CBA% wt. | Density (g/mL) |

|---|---|---|

| 110 | 4.2 | 0.740 ± 0.032 * |

| 110 | 7.1 | 0.5 ± 0.017 * |

| 110 | 8.50 | 0.598 ± 0.031 * |

| 110 | 10 | 0.53 ± 0.034 * |

| 115 | 4.2 | 0.50 8± 0.122 * |

| 115 | 7.1 | 0.508 ± 0.036 * |

| 115 | 8.50 | 0.488 ± 0.178 * |

| 115 | 10 | 0.601 ± 0.089 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Doyle, L.; Weidlich, I. Recyclable Insulating Foams for High-Temperature Applications. Proceedings 2021, 69, 29. https://doi.org/10.3390/CGPM2020-07200

Doyle L, Weidlich I. Recyclable Insulating Foams for High-Temperature Applications. Proceedings. 2021; 69(1):29. https://doi.org/10.3390/CGPM2020-07200

Chicago/Turabian StyleDoyle, Lucía, and Ingo Weidlich. 2021. "Recyclable Insulating Foams for High-Temperature Applications" Proceedings 69, no. 1: 29. https://doi.org/10.3390/CGPM2020-07200

APA StyleDoyle, L., & Weidlich, I. (2021). Recyclable Insulating Foams for High-Temperature Applications. Proceedings, 69(1), 29. https://doi.org/10.3390/CGPM2020-07200