Influence of Residual Stresses of Sputtered Thin Film Electrodes for Dielectric Elastomer Applications †

Abstract

:1. Introduction

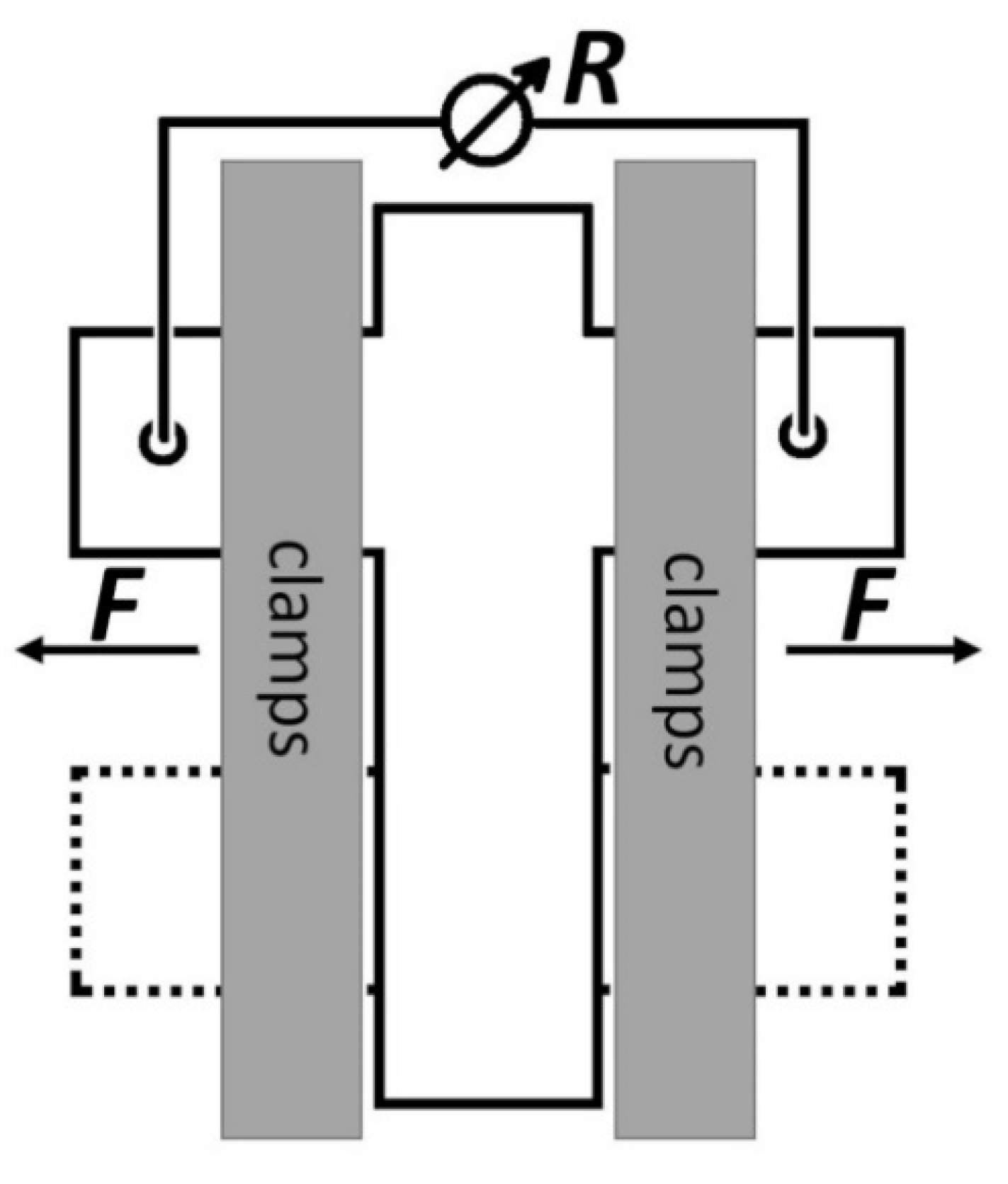

2. Materials and Methods

3. Results and Discussion

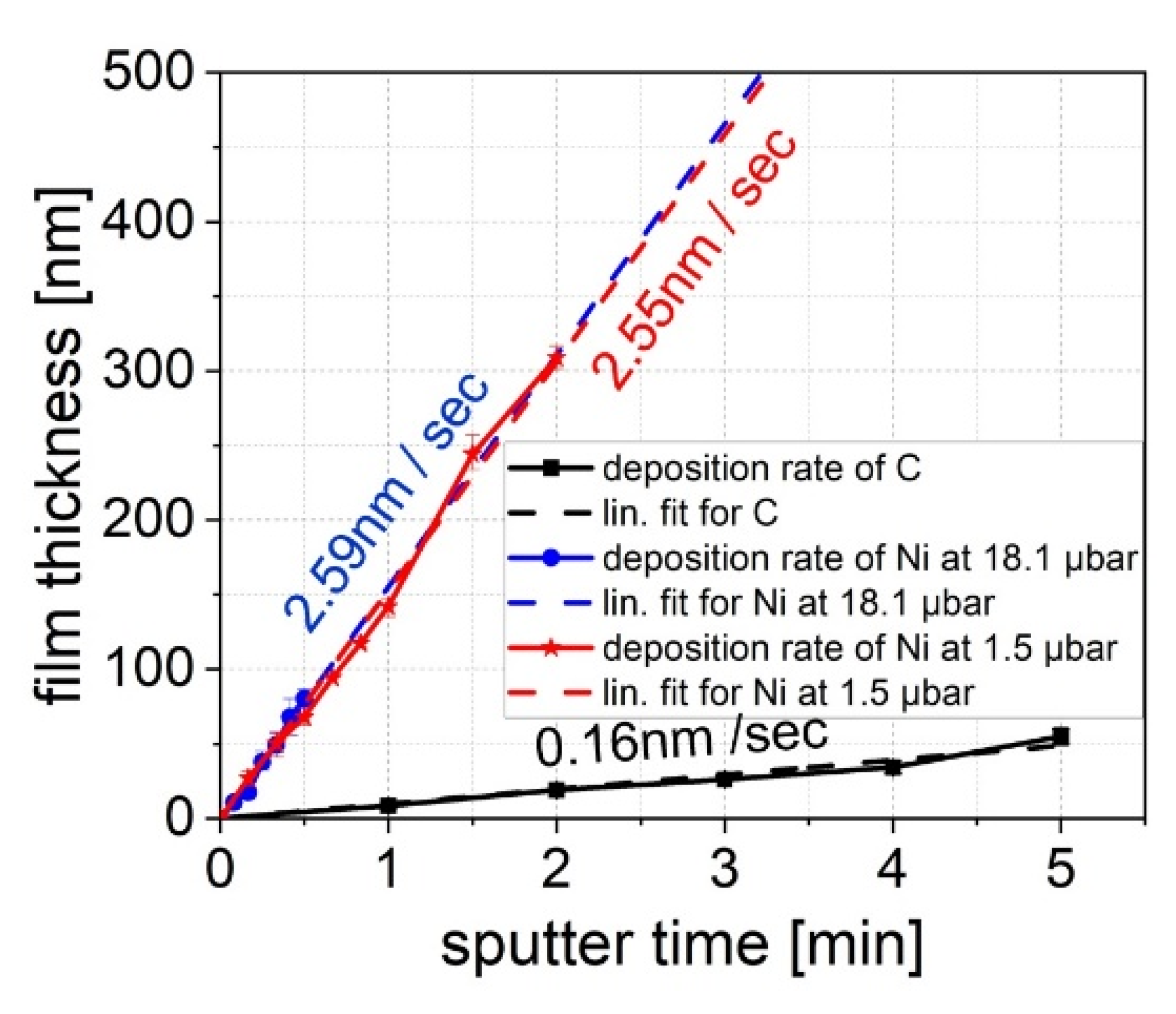

3.1. Deposition Rate

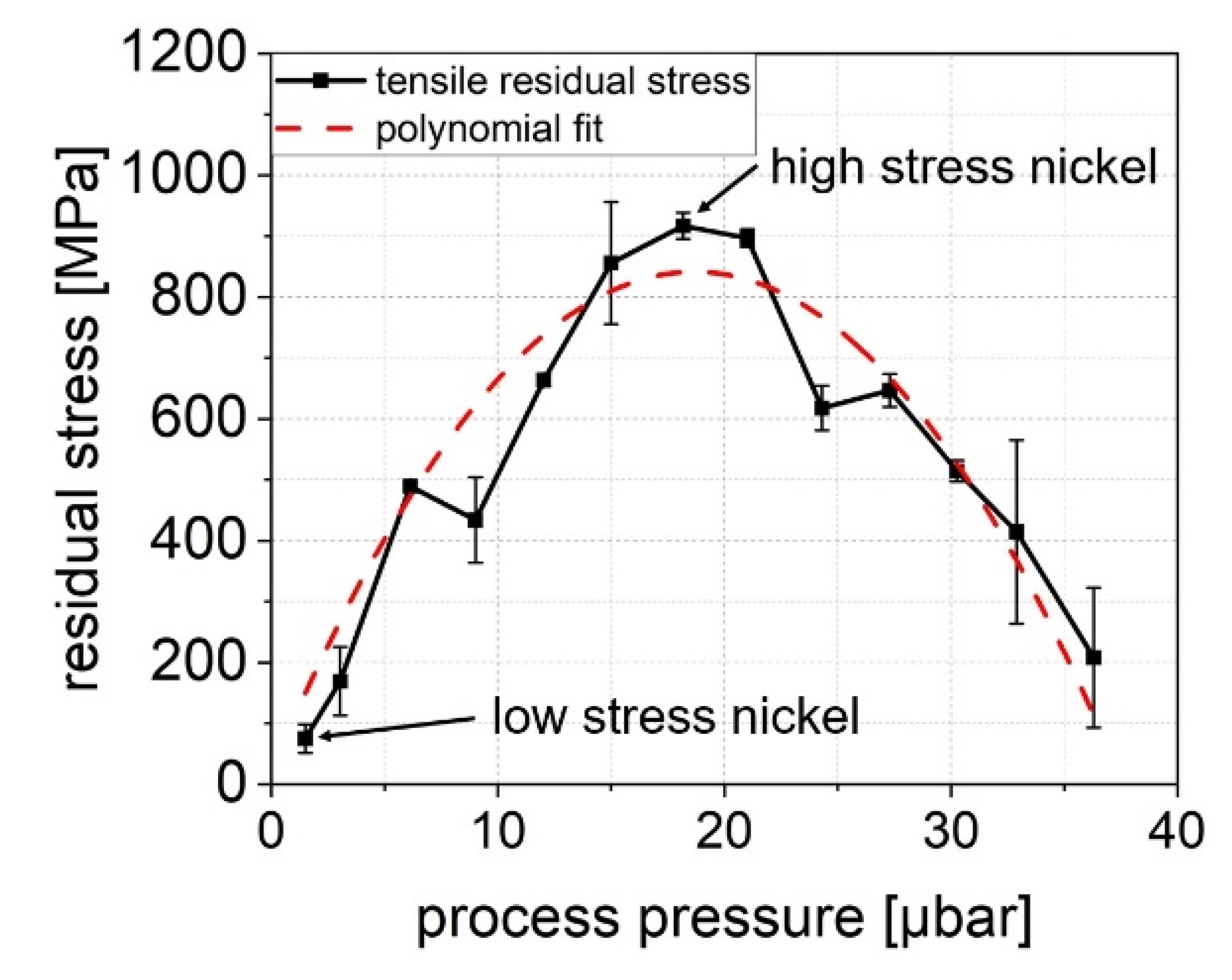

3.2. Residual Stress Analysis

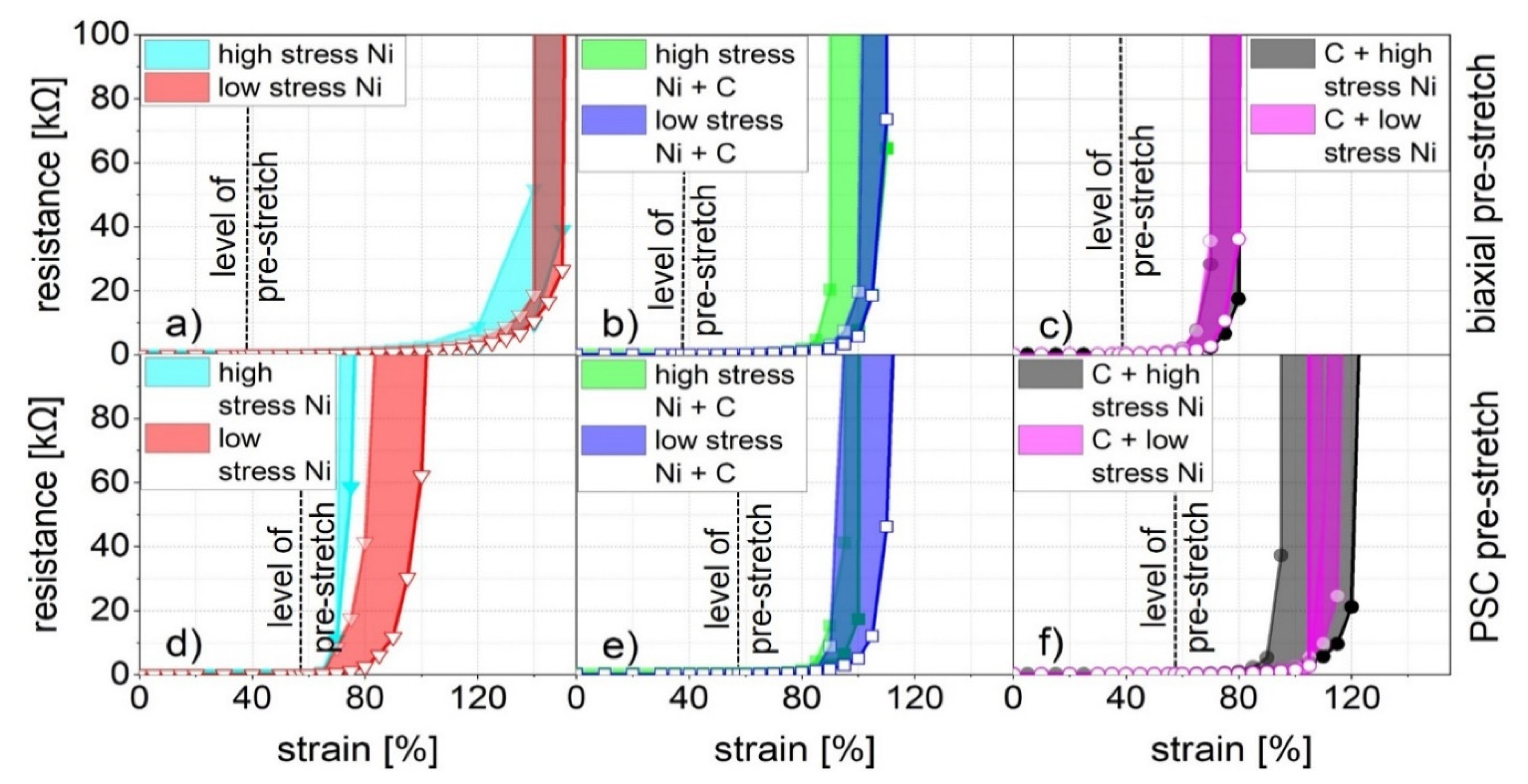

3.3. Resistance vs. Strain Measurements

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rosset, S.; Shea, H.R. Flexible and stretchable electrodes for dielectric elastomer actuators. Appl. Phys. A 2013, 110, 281–307. [Google Scholar] [CrossRef]

- Romasanta, L.J.; Lopez-Manchado, M.A.; Verdejo, R. Increasing the performance of dielectric elastomer actuators: A review from the materials perspective. Prog. Polym. Sci. 2015, 51, 188–211. [Google Scholar] [CrossRef]

- Hau, S.; Rizzello, G.; Seelecke, S. A novel dielectric elastomer membrane actuator concept for high-force applications. Extrem. Mech. Lett. 2018, 23, 24–28. [Google Scholar] [CrossRef]

- Linnebach, P.; Simone, F.; Rizzello, G.; Seelecke, S. Development, manufacturing, and validation of a dielectric elastomer membrane actuator–driven contactor. J. Intell. Mater. Syst. Struct. 2019, 30, 636–648. [Google Scholar] [CrossRef]

- Pelrine, R.E.; Kornbluh, R.D.; Joseph, J.P. Electrostriction of polymer dielectrics with compliant electrodes as a means of actuation. Sens. Actuators A Phys. 1998, 64, 77–85. [Google Scholar] [CrossRef]

- Fasolt, B.; Hodgins, M.; Rizzello, G.; Seelecke, S. Effect of screen printing parameters on sensor and actuator performance of dielectric elastomer (DE) membranes. Sens. Actuators A Phys. 2017, 265, 10–19. [Google Scholar] [CrossRef]

- Benslimane, M.; Kiil, H.-E.; Tryson, M.J. Electromechanical properties of novel large strain PolyPower film and laminate components for DEAP actuator and sensor applications. In Proceedings of the Electroactive Polymer Actuators and Devices (EAPAD 2010), San Diego, CA, USA, 7–11 March 2010; p. 764231. [Google Scholar]

- Lacour, S.P.; Wagner, S.; Huang, Z.; Suo, Z. Stretchable gold conductors on elastomeric substrates. Appl. Phys. Lett. 2003, 82, 2404–2406. [Google Scholar] [CrossRef]

- Pelrine, R.; Kornbluh, R.; Joseph, J.; Heydt, R.; Pei, Q.; Chiba, S. High-field deformation of elastomeric dielectrics for actuators. Mater. Sci. Eng. C 2000, 11, 89–100. [Google Scholar] [CrossRef]

- Verplancke, R.; Bossuyt, F.; Cuypers, D.; Vanfleteren, J. Thin Film stretchable electronics technology based on meandering interconnections: Fabrication and mechanical performance. J. Micromech. Microeng. 2012, 22, 15002. [Google Scholar] [CrossRef]

- Huang, S.; Liu, Y.; Zhao, Y.; Ren, Z.; Guo, C.F. Flexible Electronics: Stretchable Electrodes and Their Future. Adv. Funct. Mater. 2019, 29, 1805924. [Google Scholar] [CrossRef]

- Akbari, S.; Shea, H. Arrays of 100μm x 100μm dielectric elastomer actuators to strain the single cells. Procedia Eng. 2011, 25, 693–696. [Google Scholar] [CrossRef]

- Cheng, T.; Zhang, Y.; Lai, W.-Y.; Huang, W. Stretchable Thin Film Electrodes for Flexible Electronics with High Deformability and Stretchability. Adv. Mater. Weinheim. 2015, 27, 3349–3376. [Google Scholar] [CrossRef] [PubMed]

- Kaltenbrunner, M.; Sekitani, T.; Reeder, J.; Yokota, T.; Kuribara, K.; Tokuhara, T.; Drack, M.; Schwödiauer, R.; Graz, I.; Bauer-Gogonea, S.; et al. An ultra-lightweight design for imperceptible plastic electronics. Nature 2013, 499, 458–463. [Google Scholar] [CrossRef] [PubMed]

- Hubertus, J.; Fasolt, B.; Linnebach, P.; Seelecke, S.; Schultes, G. Electromechanical evaluation of sub-micron NiCr-carbon thin films as highly conductive and compliant electrodes for dielectric elastomers. Sens. Actuators A Phys. 2020, 315, 112243. [Google Scholar] [CrossRef]

- Schultes, G.; Schmid-Engel, H.; Schwebke, S.; Werner, U. Granular metal–carbon nanocomposites as piezoresistive sensor films—Part 1: Experimental results and morphology. J. Sens. Sens. Syst. 2018, 7, 1–11. [Google Scholar] [CrossRef]

- Koppert, R.; Uhlig, S.; Schmid-Engel, H.; Göttel, D.; Probst, A.-C.; Schultes, G.; Werner, U. Structural and physical properties of highly piezoresistive nickel containing hydrogenated carbon thin films. Diam. Relat. Mater. 2012, 25, 50–58. [Google Scholar] [CrossRef]

- Ardigo, M.R.; Ahmed, M.; Besnard, A. Stoney Formula: Investigation of Curvature Measurements by Optical Profilometer. AMR 2014, 996, 361–366. [Google Scholar] [CrossRef]

- Stoney, G.G. The tension of metallic films deposited by electrolysis. Proc. R. Soc. Lond. A 1909, 82, 172–175. [Google Scholar] [CrossRef]

- Hodgins, M.; York, A.; Seelecke, S. Systematic experimental characterization of dielectric elastomer membranes using a custom-built tensile test rig. J. Intell. Mater. Syst. Struct. 2017, 28, 2117–2128. [Google Scholar] [CrossRef]

- Carpi, F.; Anderson, I.; Bauer, S.; Frediani, G.; Gallone, G.; Gei, M.; Graaf, C.; Jean-Mistral, C.; Kaal, W.; Kofod, G.; et al. Standards for dielectric elastomer transducers. Smart Mater. Struct. 2015, 24, 105025. [Google Scholar] [CrossRef]

- Seshan, K. Handbook of Thin Film Deposition Processes and Techniques: Principles, Methods, Equipment, and Applications, 2nd ed.; Noyes Publications: Norwich, NY, USA, 2002. [Google Scholar]

- Priestland, C.R.D.; Hersee, S.D. The effects of pressure on the deposition rate in rf sputtering process. Vacuum 1972, 22, 103–106. [Google Scholar] [CrossRef]

- Farooq, M.; Lee, Z.H. Optimization of the Sputtering Process for Depositing Composite Thin Films. J. Korean Phys. Soc. 2002, 40, 511–515. [Google Scholar]

- Schott, A.G. Homepage Schott AG: Mechanical Properties Borosilicate. Available online: https://www.schott.com/borofloat/german/attribute/mechanical/index.html (accessed on 11 September 2020).

- Lacour, S.P.; Chan, D.; Wagner, S.; Li, T.; Suo, Z. Mechanisms of reversible stretchability of thin metal films on elastomeric substrates. Appl. Phys. Lett. 2006, 88, 204103. [Google Scholar] [CrossRef]

- Lambricht, N.; Pardoen, T.; Yunus, S. Giant stretchability of thin gold films on rough elastomeric substrates. Acta Mater. 2013, 61, 540–547. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hubertus, J.; Croce, S.; Neu, J.; Rizzello, G.; Seelecke, S.; Schultes, G. Influence of Residual Stresses of Sputtered Thin Film Electrodes for Dielectric Elastomer Applications. Proceedings 2020, 64, 2. https://doi.org/10.3390/IeCAT2020-08492

Hubertus J, Croce S, Neu J, Rizzello G, Seelecke S, Schultes G. Influence of Residual Stresses of Sputtered Thin Film Electrodes for Dielectric Elastomer Applications. Proceedings. 2020; 64(1):2. https://doi.org/10.3390/IeCAT2020-08492

Chicago/Turabian StyleHubertus, Jonas, Sipontina Croce, Julian Neu, Gianluca Rizzello, Stefan Seelecke, and Günter Schultes. 2020. "Influence of Residual Stresses of Sputtered Thin Film Electrodes for Dielectric Elastomer Applications" Proceedings 64, no. 1: 2. https://doi.org/10.3390/IeCAT2020-08492

APA StyleHubertus, J., Croce, S., Neu, J., Rizzello, G., Seelecke, S., & Schultes, G. (2020). Influence of Residual Stresses of Sputtered Thin Film Electrodes for Dielectric Elastomer Applications. Proceedings, 64(1), 2. https://doi.org/10.3390/IeCAT2020-08492