Effect of Mechanical Loading and Increased Gap on the Dynamic Response of Multiple Degree of Freedom Electrostatic Actuator †

Abstract

:1. Introduction

2. Methods

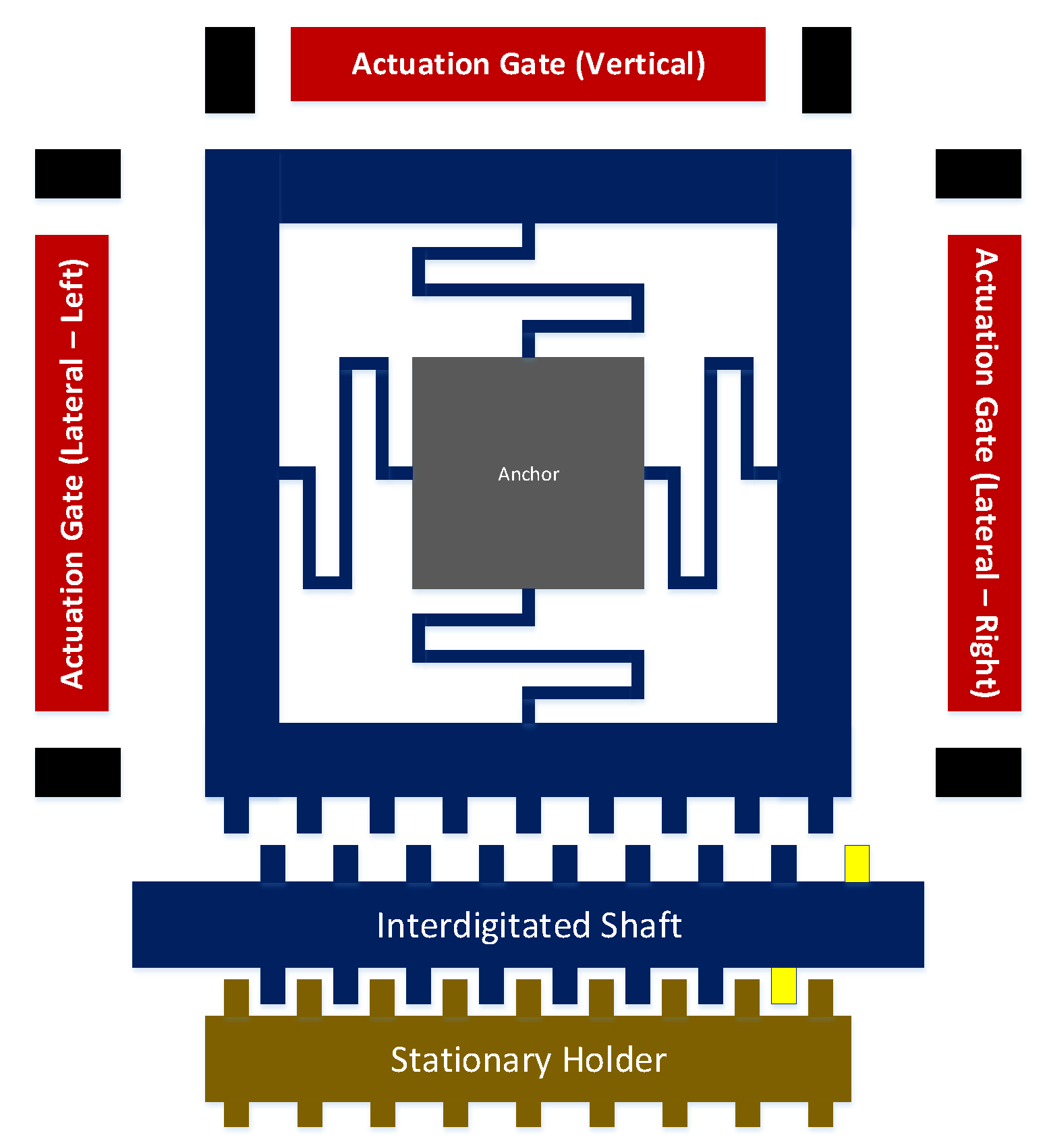

2.1. Structural Design and Operation Concept

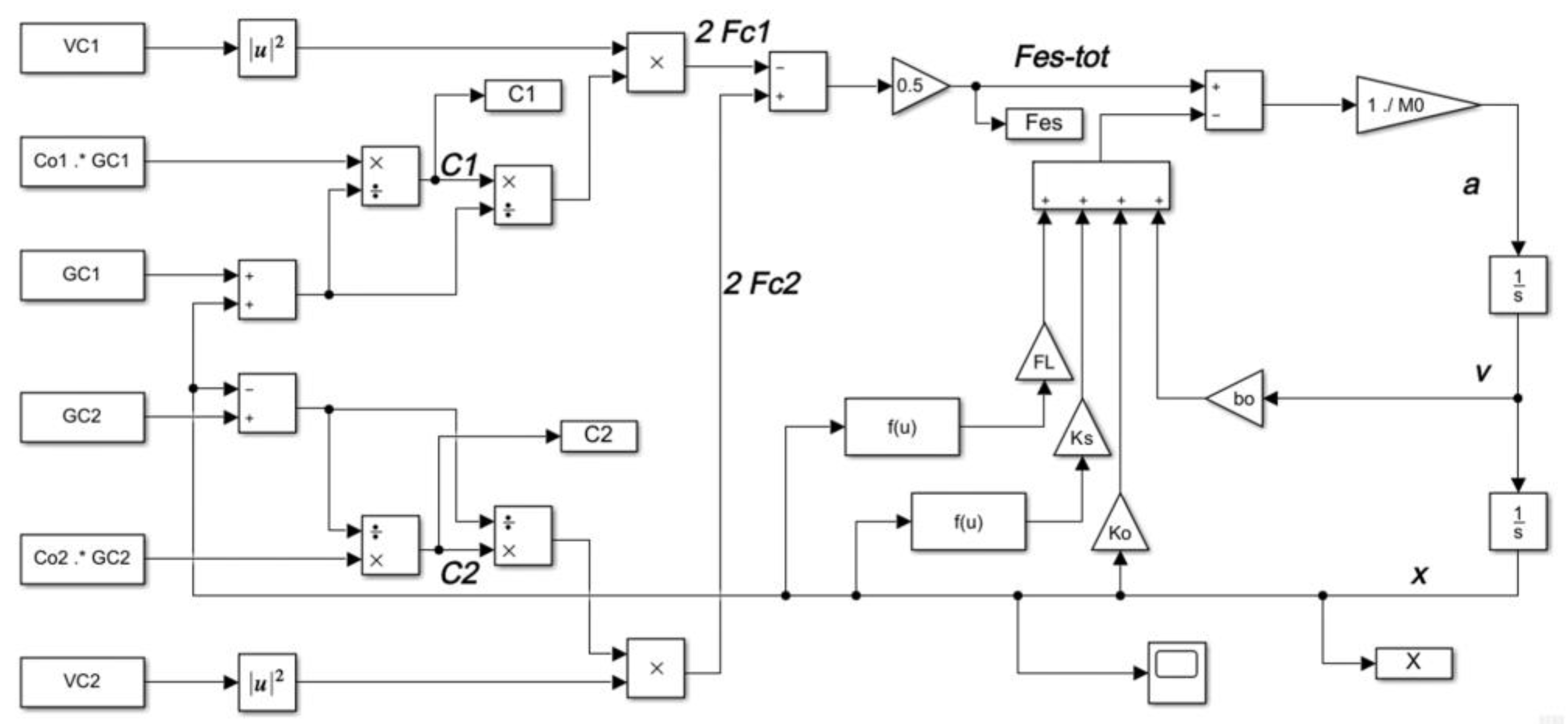

2.2. Mathematical Modelling and Simulink Model

3. Results and Discussion

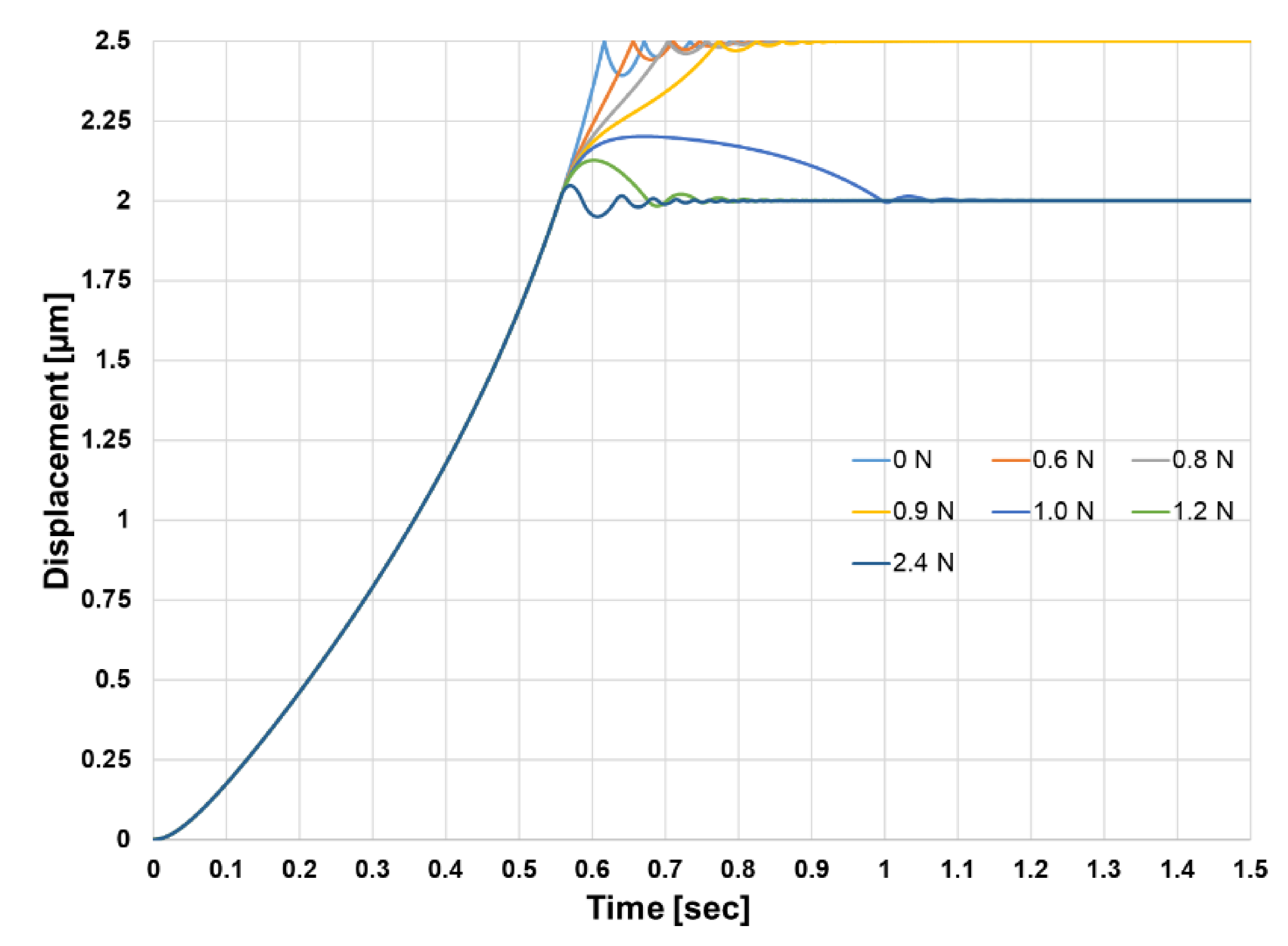

3.1. Effect of Mechanical Stoppers and External Mechanical Loading

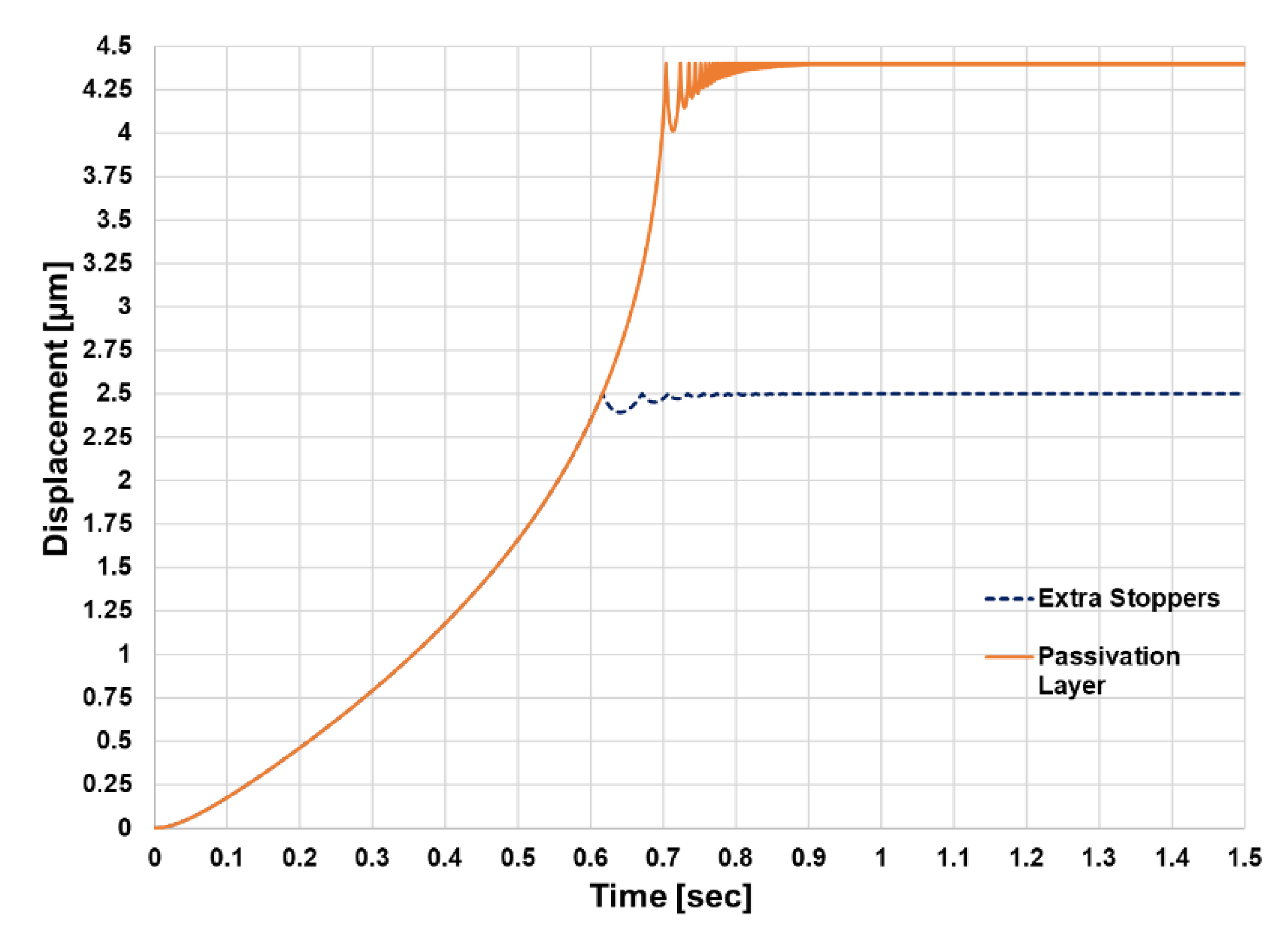

3.2. Dynamic Response Under Increased Gap Design

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Kim, S.-H.; Hwang, I.-H.; Jo, K.-W.; Yoon, E.-S.; Lee, J.-H. High resolution inchworm linear motor based on electrostatic twisting microactuators. J. Micromech. Microeng. 2005, 15, 1674–1682. [Google Scholar] [CrossRef]

- Erismis, M.A.; Neves, H.P.; Puers, R.; Hoof, C.V. A low voltage large displacement large force inchworm actuator. JMEMS 2008, 17, 1294–1301. [Google Scholar] [CrossRef]

- Penskiy, I.; Bergbreiter, S. Optimized electrostatic inchworm motors using a flexible driving arm. J. Micromech. Microeng. 2013, 23, 015018. [Google Scholar] [CrossRef]

- Saito, K.; Contreras, D.S.; Takeshiro, Y.; Okamoto, Y.; Hirao, S.; Nakata, Y.; Tanaka, T.; Kawamura, S.; Kaneko, M.; Uchikoba, F.; et al. Study on electrostatic inchworm motor device for a heterogeneous integrated microrobot system. Trans. Jpn. Inst. Electron. Packag. 2019, 12. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kloub, H. Effect of Mechanical Loading and Increased Gap on the Dynamic Response of Multiple Degree of Freedom Electrostatic Actuator. Proceedings 2020, 64, 18. https://doi.org/10.3390/IeCAT2020-08498

Kloub H. Effect of Mechanical Loading and Increased Gap on the Dynamic Response of Multiple Degree of Freedom Electrostatic Actuator. Proceedings. 2020; 64(1):18. https://doi.org/10.3390/IeCAT2020-08498

Chicago/Turabian StyleKloub, Hussam. 2020. "Effect of Mechanical Loading and Increased Gap on the Dynamic Response of Multiple Degree of Freedom Electrostatic Actuator" Proceedings 64, no. 1: 18. https://doi.org/10.3390/IeCAT2020-08498

APA StyleKloub, H. (2020). Effect of Mechanical Loading and Increased Gap on the Dynamic Response of Multiple Degree of Freedom Electrostatic Actuator. Proceedings, 64(1), 18. https://doi.org/10.3390/IeCAT2020-08498