Fracture Energy of Engineered Cementitious Composites †

Abstract

1. Introduction

2. Experimental Program

2.1. Raw Materials and Mix-Design Ratios

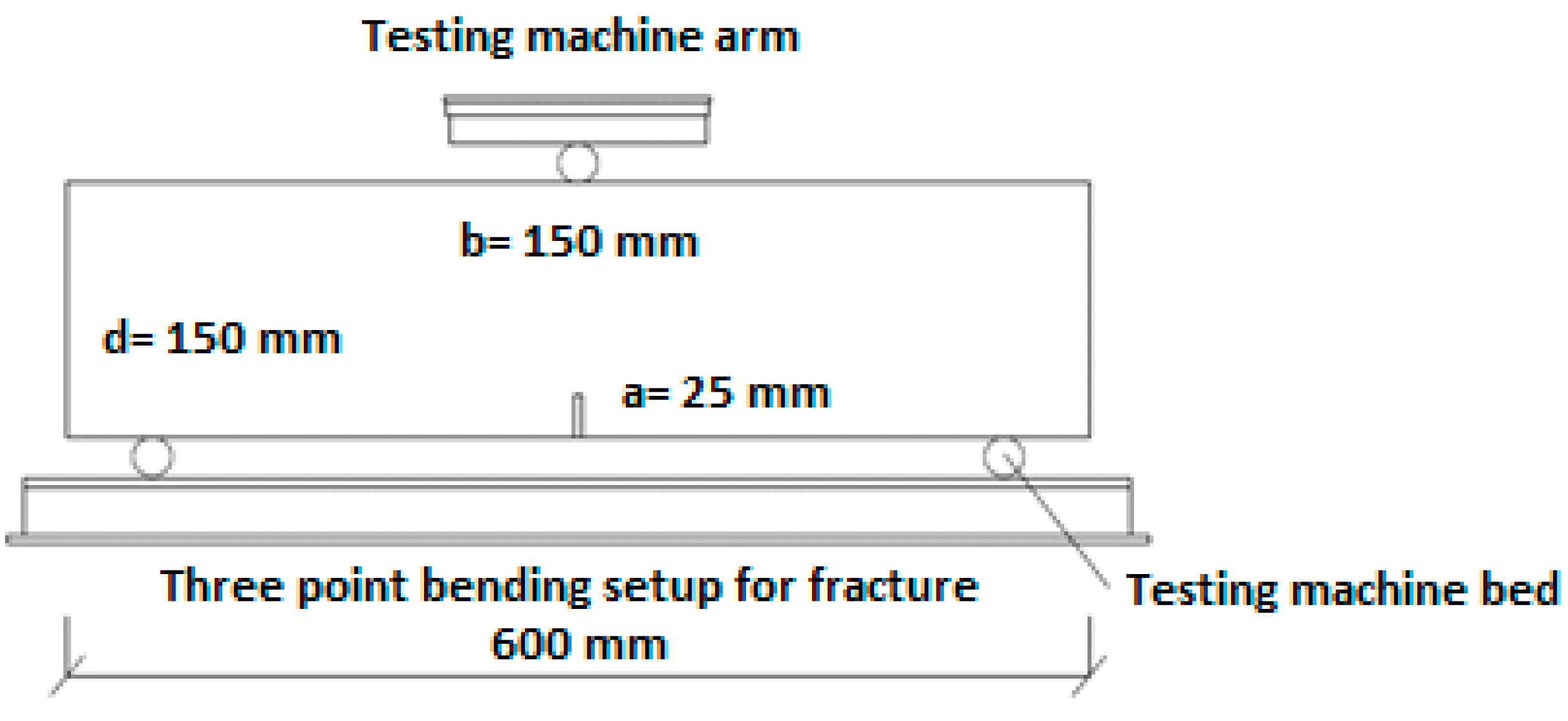

2.2. Testing Methods

3. Results and Discussions

3.1. Mechanical Properties

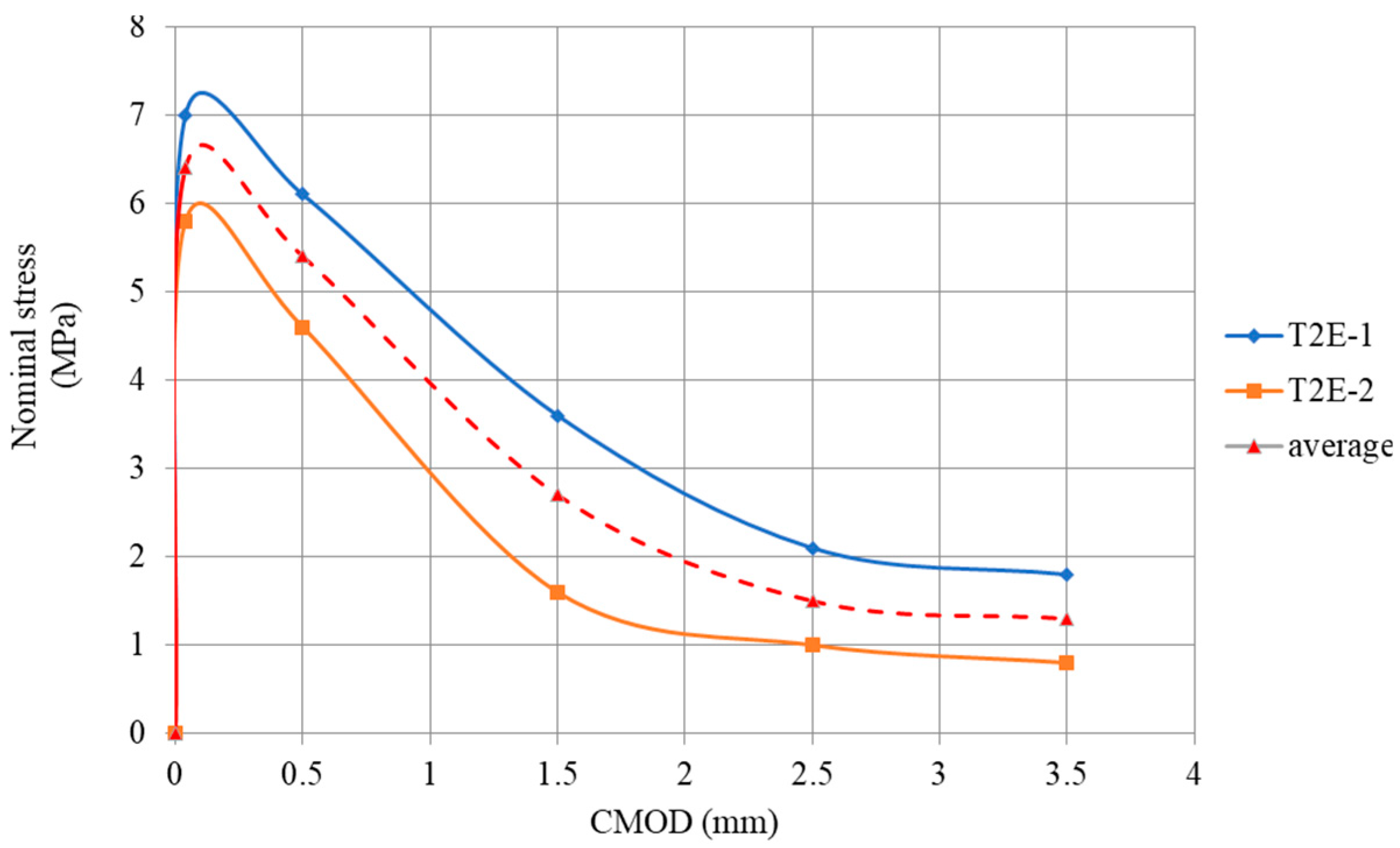

3.2. Flexural Tensile Strength (LOP and Residual Strength)

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, V.C. On Engineered Cementitious Composites (ECC) A Review of the Material and Its Applications. J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Li, V.C. Engineered Cementitious Composites (ECC)—Tailored Composites through Micromechanical Modeling Volume 2164. CSCE 1997, 1–38. [Google Scholar]

- Sherir, M.A.A.; Houssain, K.M.A. Fracture Energy Characteristics of Engineered Cementitious Composites Incorporating Different Aggregates. 2014, 2982, 293–302. [Google Scholar]

- Kanda, T.; Li, V.C. Multiple Cracking Sequence and Saturation in Fiber Reinforced Cementitious Composites. Concr. Res. Technol. 1998, 9, 19–33. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructural Properties and Materials, 3rd ed.; McGraw Hill: New York, NY, USA, 2006. [Google Scholar]

- Petersson, P.E. Fracture Energy of Concrete: Method of Determination. Cem. Concr. Res. 1980, 10, 78–89. [Google Scholar] [CrossRef]

- Sahmaran, M.; Lachemi, M.; Hossain, K.M.A.; Ranade, R.; Li, V. Influence of Aggregate Type and Size on Ductility and Mechanical Properties of Engineered Cementitious Composites. ACI Mater. J. 2009, 106, 308–316. [Google Scholar]

- Mehta, P.K. Influence of Fly Ash Characteristics on The Strength of Portland-Fly Ash Mixtures. Cem. Concr. Res. 1985, 15, 669–674. [Google Scholar] [CrossRef]

- Mindess, S.; Young, J.F.; Darwin, D. Concrete, 2nd ed.; Pearson Education, Inc.: Upper Saddler River, NJ, USA, 2003. [Google Scholar]

- Li, V.; Wu, C.; Wang, S.X.; Ogawa, A.; Saito, T. Interface Tailoring for Strain-Hardening PVA-ECC. ACI Mater. J. 2002, 99, 463–472. [Google Scholar]

- Rus, M.-I. The knowledge triangle in a knowledge-based society. Univ. Oradea. Şt. Ec Tom XXII 2013, 1, 942–947. [Google Scholar]

- Szilagyi, H.; Baeră, C.; Hegyi, A.; Lăzărescu, A. Romanian resources of waste and industrial by-products as additions for cementitious mixtures. Int. Multidiscip. Sci. Geoconf. SGEM 2018, 18, 325–332. [Google Scholar]

- Lăzărescu, A.; Mircea, C.; Szilagyi, H.; Baeră, C. Mechanical properties of alkali activated geopolymer paste using different Romanian fly ash sources—Experimental results. MATEC Web Conf. 2019, 289, 11001. [Google Scholar] [CrossRef]

- Mircea, A.C.; Mircea, C.; Szilágyi, H.; Baeră, C.; Hegyi, A. Experimental study regarding the influence of fibre to matrix compatibility on general performance of Fibre Engineered Cementitious Materials (FECM). MATEC Web Conf. 2019, 289, 04005. [Google Scholar] [CrossRef]

- Withers, P.J. Residual stress and its role in failure. Rep. Prog. Phys. 2007, 70, 2211–2264. [Google Scholar] [CrossRef]

- Coules, H.E.; Horne, G.C.M.; Abburi Venkata, K.; Pirling, T. The effects of residual stress on elastic-plastic fracture propagation and stability. Mat. Des. 2018, 143, 131–140. [Google Scholar] [CrossRef]

- ASRO. SR EN 196-1. Methods of Testing Cement. Determination of Strength; Romanian Standards Association: Bucharest, Romania, 2016. [Google Scholar]

- ASRO. SR EN 14651+ A1. Method of Testing a Concrete with Metal Fibers. Measurement of Bending Tensile Strength (Proportionality Limit (LOP), Residual Strength); Romanian Standards Association: Bucharest, Romania, 2008. [Google Scholar]

- Wang, S.; Li, V.C. Engineered Cementitious Composites with High-Volume Fly Ash. ACI Mater. J. 2007, 104, 233–241. [Google Scholar]

| Mixtures | CEM 2 | FA 3 | Sand | Water | PVA | LS 4 | Admixture |

|---|---|---|---|---|---|---|---|

| SS-L-PVA- FA/C | 1.00 | 1.20 | 0.76 | 0.65 | 0.05 | 0.18 | 0.02 |

| Mixture | Type of Sand | Ingredients (wt.%) | ||||||

|---|---|---|---|---|---|---|---|---|

| CEM 2 | FA 3 | Sand | Water | PVA | LS 4 | Admixture | ||

| T1E | Silica Sand | 1.00 | 1.20 | 0.76 | 0.58 | 0.05 | 0.22 | 0.02 |

| T2E | Normal Sand | 1.00 | 1.20 | 0.76 | 0.56 | 0.05 | 0.22 | 0.02 |

| Mix | FL | l | b | hps | ffct,L | ffct,Lmed | |

|---|---|---|---|---|---|---|---|

| T1E | T1E-1 | 16844 | 500 | 150 | 125 | 5.4 | 4.9 |

| T1E-2 | 14018 | 4.5 | |||||

| T2E | T2E-1 | 21832 | 7.0 | 6.4 | |||

| T2E-2 | 18073 | 5.8 | |||||

| Mixture ID | CMOD (mm) | fR,j (MPa) | |

|---|---|---|---|

| T1E | T1E-1 | 0.5 | 5.2 |

| 1.5 | 3.8 | ||

| 2.5 | 1.6 | ||

| 3.5 | 1.0 | ||

| T1E-2 | 0.5 | 3.6 | |

| 1.5 | 2.2 | ||

| 2.5 | 0.8 | ||

| 3.5 | 0.4 | ||

| T2E | T2E-1 | 0.5 | 6.1 |

| 1.5 | 3.6 | ||

| 2.5 | 2.1 | ||

| 3.5 | 1.8 | ||

| T2E-2 | 0.5 | 4.6 | |

| 1.5 | 1.7 | ||

| 2.5 | 1.0 | ||

| 3.5 | 0.8 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mircea, A.C.; Toader, T.P. Fracture Energy of Engineered Cementitious Composites. Proceedings 2020, 63, 8. https://doi.org/10.3390/proceedings2020063008

Mircea AC, Toader TP. Fracture Energy of Engineered Cementitious Composites. Proceedings. 2020; 63(1):8. https://doi.org/10.3390/proceedings2020063008

Chicago/Turabian StyleMircea, Anamaria Cătălina, and Tudor Panfil Toader. 2020. "Fracture Energy of Engineered Cementitious Composites" Proceedings 63, no. 1: 8. https://doi.org/10.3390/proceedings2020063008

APA StyleMircea, A. C., & Toader, T. P. (2020). Fracture Energy of Engineered Cementitious Composites. Proceedings, 63(1), 8. https://doi.org/10.3390/proceedings2020063008