Abstract

Highly textured Ba0.5Sr0.5TiO3 and Ba0.6Sr0.4TiO3 thin films have been successfully processed using chemical solution deposition (CSD) techniques and annealed at different temperatures to investigate the influence on crystal growth. Microstructure and texture have been evaluated using SEM and XRD techniques. The films showed a homogeneous thickness of ~120 nm and the grain growth seemed to be highly influenced by the annealing temperature. Moreover, by tuning the deposition and annealing conditions, an almost epitaxial growth of Ba0.6Sr0.4TiO3 on the platinized silicon substrate has been achieved. Nevertheless, the samples showed severe cracking due to the strain imposed by the substrate or due to the growing direction.

1. Introduction

Perovskites are high dielectric constant materials and therefore optimal candidates for energy storage devices [1]. Among lead-free perovskites, of great interest is doped BaTiO3 for its high polarization and permittivity values, and its low hysteretic losses which give high recoverable energy density. However, one of the biggest limitations for the application of these materials is the high porosity and the presence of defects that reduce the breakdown dielectric strength [2].

In the present study, the sol-gel method and spin-coating technique have been employed to prepare dense, textured Sr-doped barium titanate thin films. The microstructure has been evaluated using scanning electron microscopy (SEM) and X-ray diffraction (XRD) measurements.

2. Materials and Methods

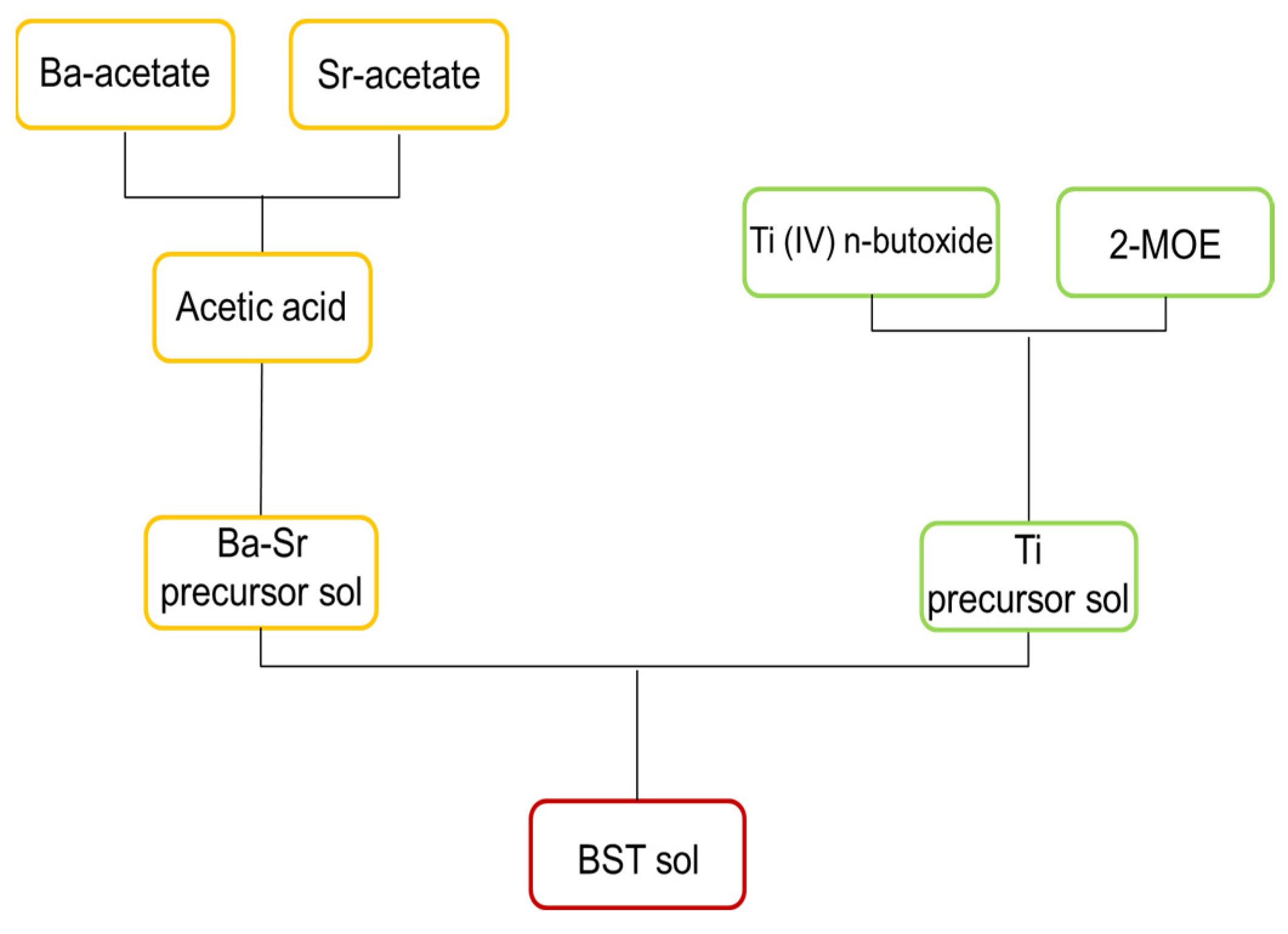

Sol-gel synthesis using organic solvents has been chosen for its reliability and the high homogeneity of the solution. The synthesis of BaxSr(1−x)TiO3 is schematically illustrated in Figure 1. Two precursor solutions have been prepared in a dry box by weighing the appropriate amount of Ba(OAc)2 and Sr(OAc)2 in acetic acid, and Ti(OBu)4 in 2-methoxyethanol. The two solutions have been mixed according to stoichiometry and diluted to a concentration of 0.125 M.

Figure 1.

Synthesis of BaxSr(1−x)TiO3 [3].

The sol has been deposited on platinized silicon (111) by spin-coating at 3000 rpm for 30 s. It was then immediately dried at 200 °C and then pyrolyzed at 350 °C. The amorphous films have been annealed at three different temperatures (700 °C, 750 °C, and 800 °C) to evaluate the grain growth. The deposition procedure was repeated until the desired thickness was achieved.

3. Results and Discussion

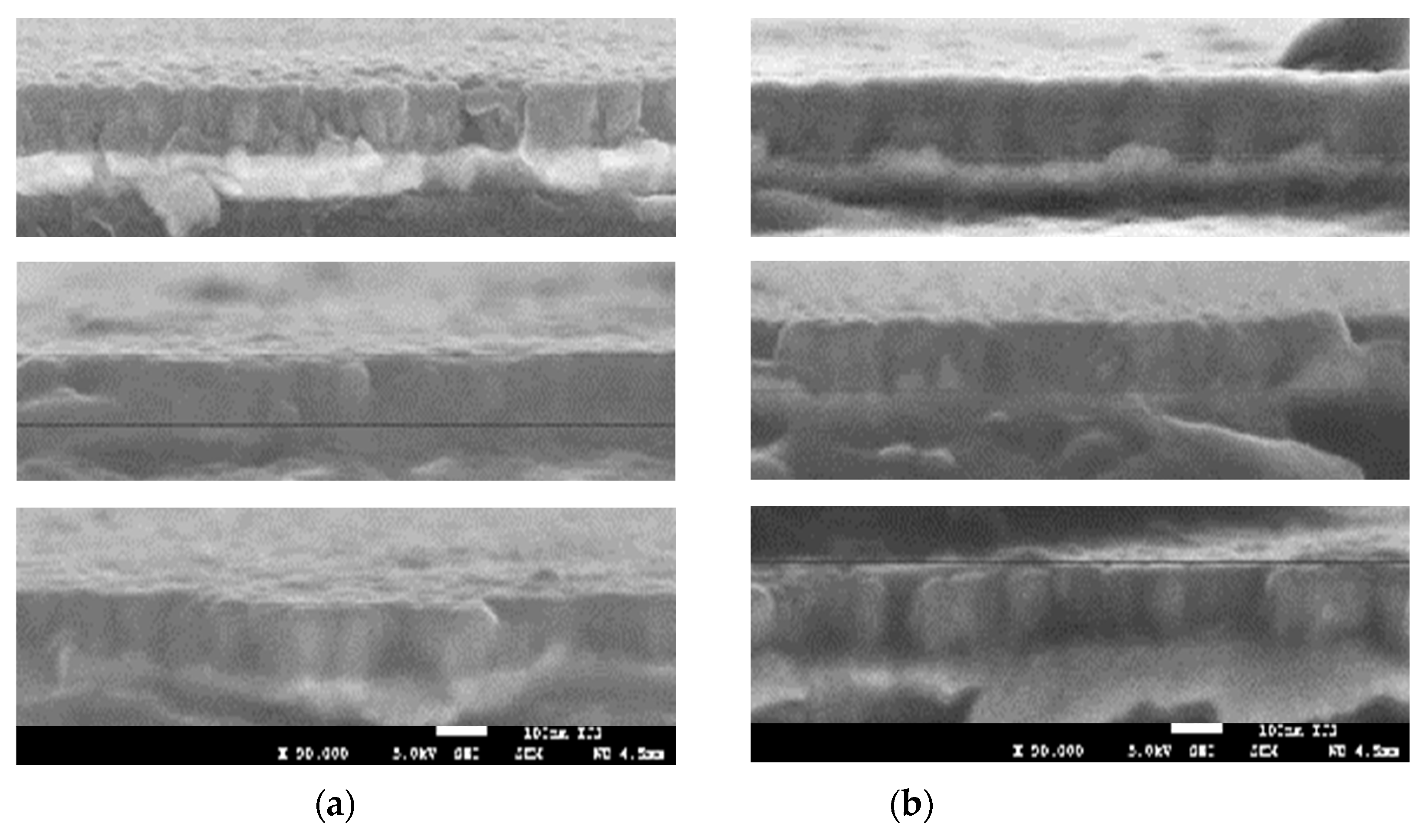

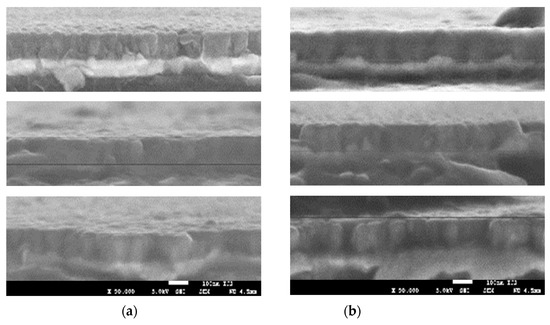

Thin films thickness, uniformity, and growth have been evaluated with the SEM technique. The average thickness was been found to be 118 nm overall, with 17 nm thickness found for each deposited layer. For both compositions, the annealing conditions showed a great influence on the growth. Lower temperatures led to a more granular and less dense microstructure, whether higher temperatures produced a columnar film (Figure 2). Nevertheless, the surface showed cracks which were probably due to the difference in the expansion coefficients between barium strontium titanate and the platinum, or due to the growing direction induced by the substrate.

Figure 2.

Cross-section of Ba0.5Sr0.5TiO3 (a) and of Ba0.6Sr0.4TiO3 (b) thin films annealed at 700 °C, 750 °C, and 800 °C (top to bottom).

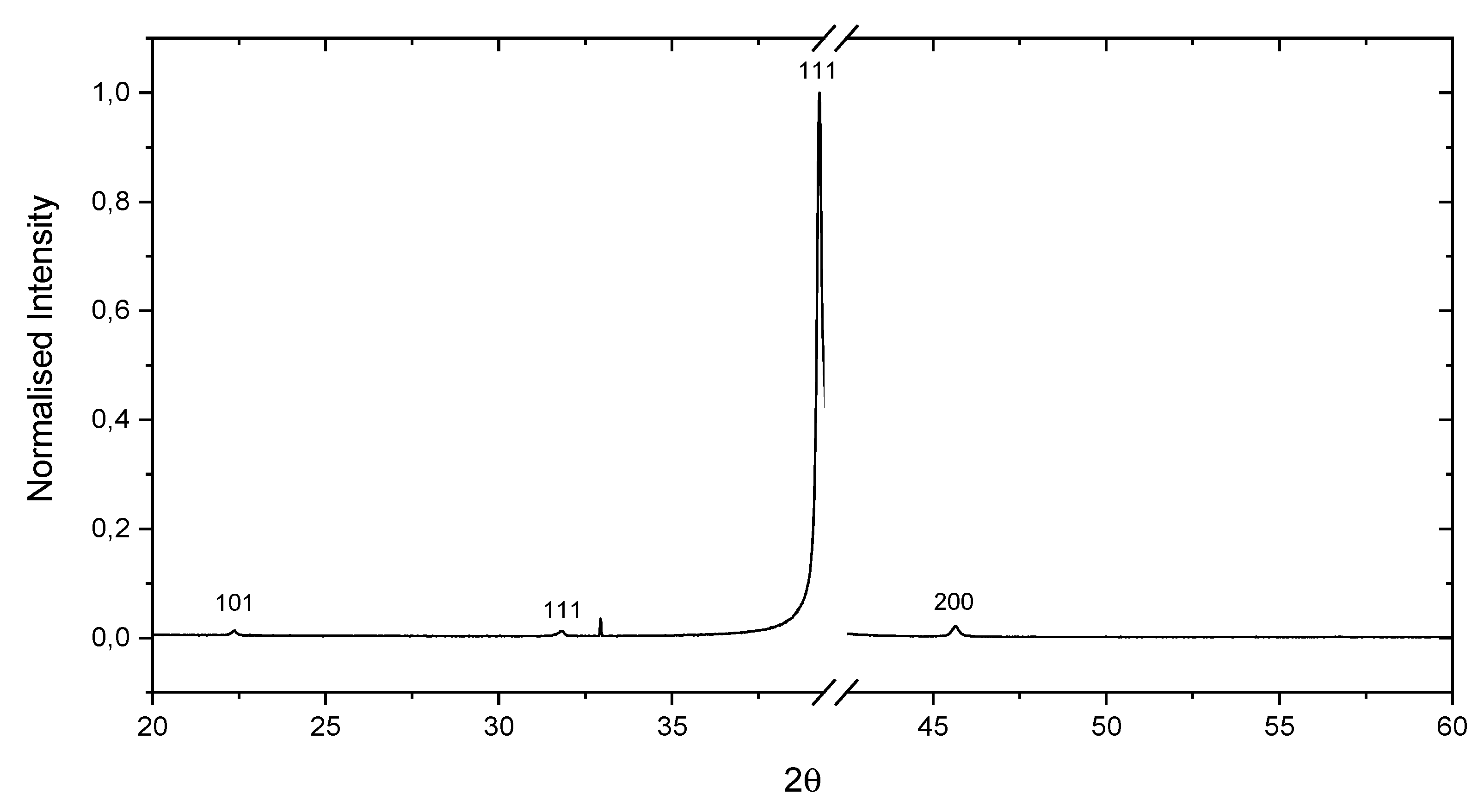

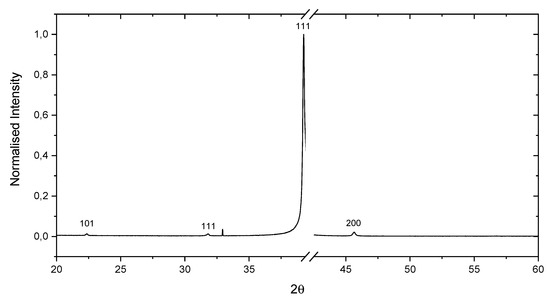

To have a better understanding of the growth direction and texture, XRD has been performed on the Ba0.6Sr0.4TiO3 thin film annealed at 800 °C. The peak at 39.26° is the most intense one and therefore indicates that the preferred orientation of the film is (111), which is likely induced by the platinum on the substrate which has a (111) orientation (Figure 3).

Figure 3.

XRD pattern of Ba0.6Sr0.4TiO3 thin film annealed at 800 °C. Substrate peaks have been removed.

4. Conclusions

Ba0.5Sr0.5TiO3 and Ba0.6Sr0.4TiO3 thin films have been successfully synthesized via sol-gel method and deposited on platinized silicon, achieving columnar growth and highly textured films. SEM micrographs of the cross-section showed a great influence of the annealing temperature on the growth in both of the two compositions. Moreover, the texture of the films was evaluated with XRD and found to be almost epitaxial with a preferred orientation of (111).

Acknowledgments

This project has received funding from the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation program (grant agreement No. 817190).

References

- Majdoub, M.S.; Maranganti, R.; Sharma, P. Understanding the origins of the intrinsic dead layer effect in nanocapacitors. Phys. Rev. B Condens. Matter Mater. Phys. 2009, 79, 1–8. [Google Scholar] [CrossRef]

- Huang, Y.H.; Wu, Y.J.; Li, J.; Liu, B.; Chen, X.M. Enhanced energy storage properties of barium strontium titanate ceramics prepared by sol-gel method and spark plasma sintering. J. Alloys Compd. 2017, 701, 439–446. [Google Scholar] [CrossRef]

- Pečnik, T.; Glinšek, S.; Kmet, B.; Malič, B. Combined effects of thickness, grain size and residual stress on the dielectric properties of Ba0.5Sr0.5TiO3 thin films. J. Alloys Compd. 2015, 646, 766–772. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).