Optimal Integration of Renewable Sources and Latent Heat Storages for Nearly Zero-Energy Buildings †

Abstract

:1. Introduction

2. Case Study and Methods

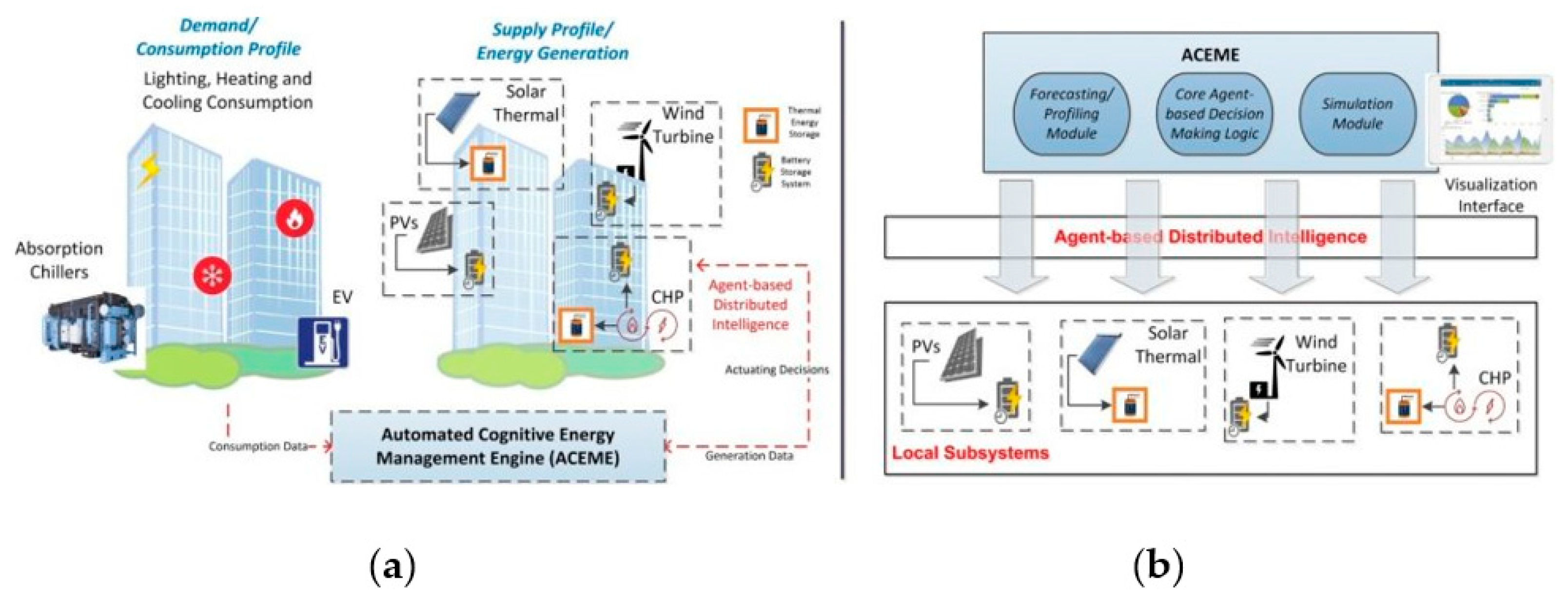

2.1. The Project

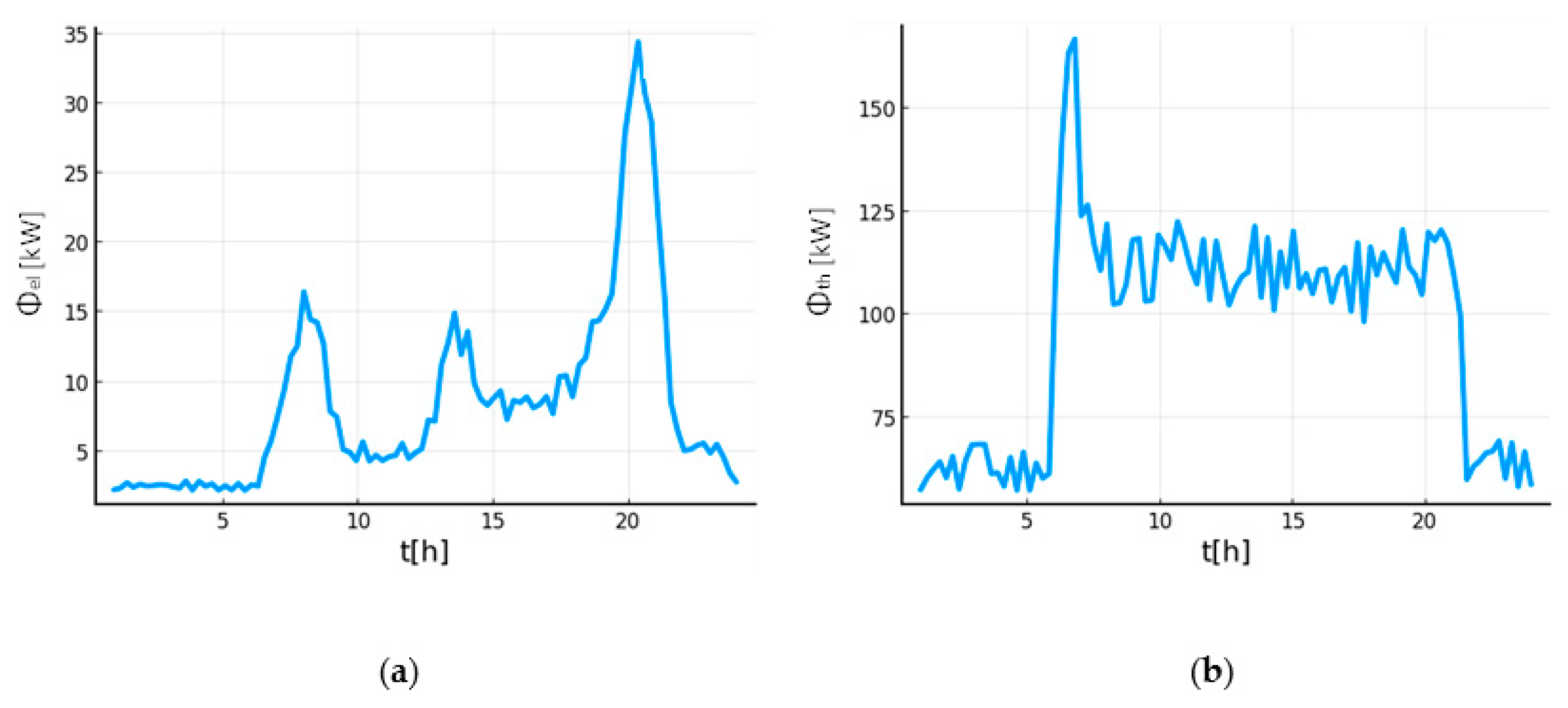

2.2. Case Study

2.3. Methodology

2.3.1. Optimal Operations

2.3.2. Combined Design and Operation Optimization

3. Results

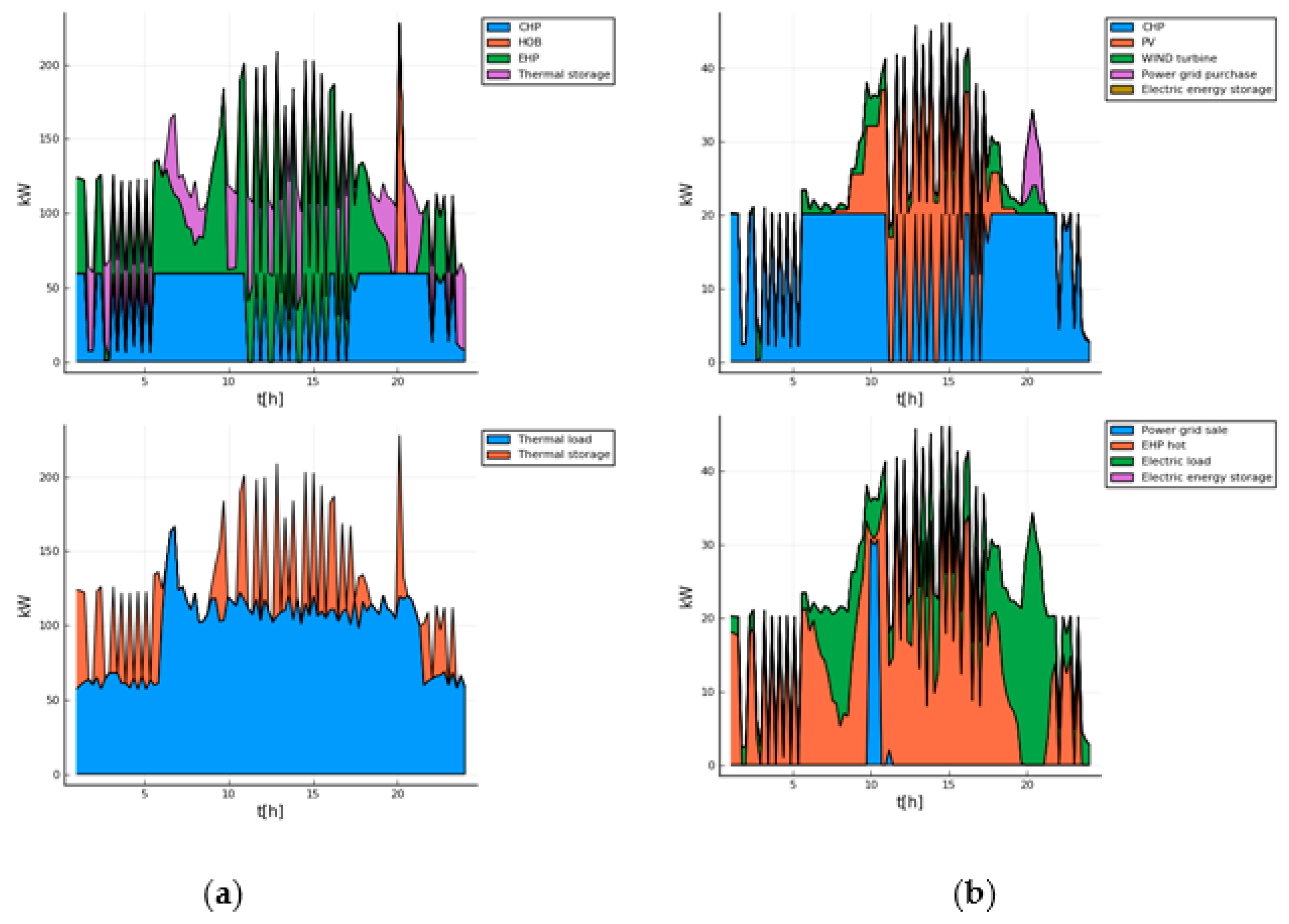

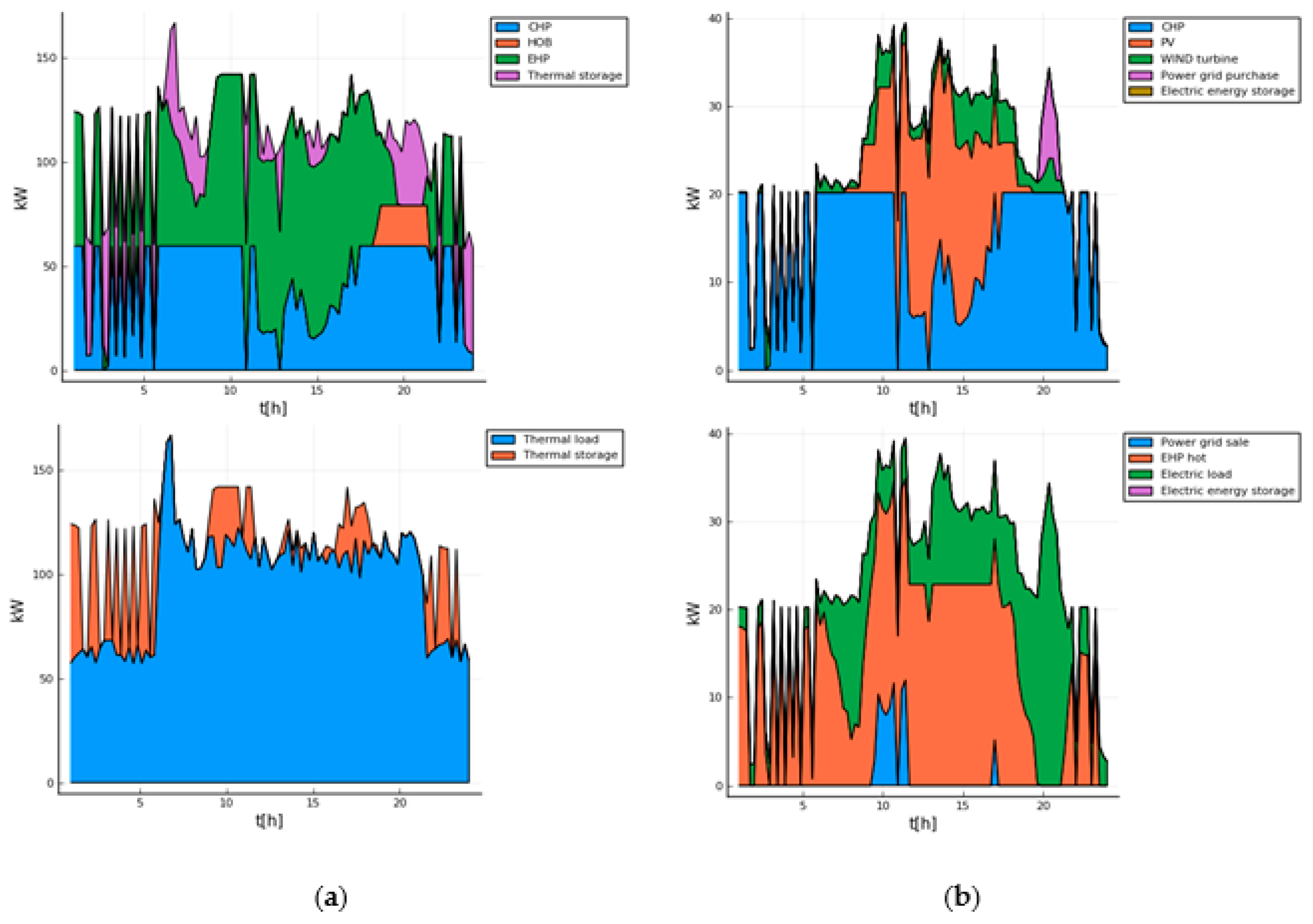

3.1. Operations Optimization

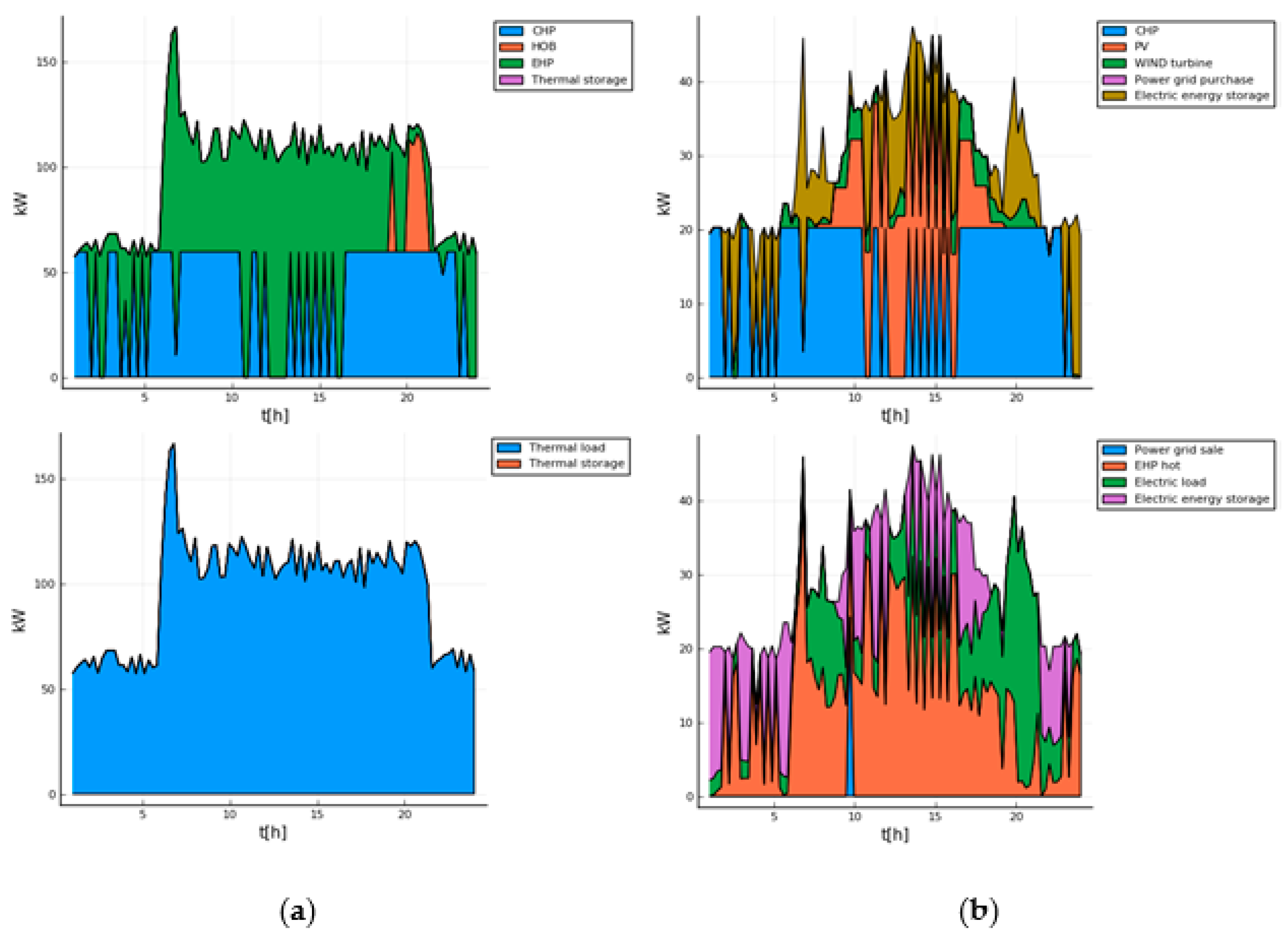

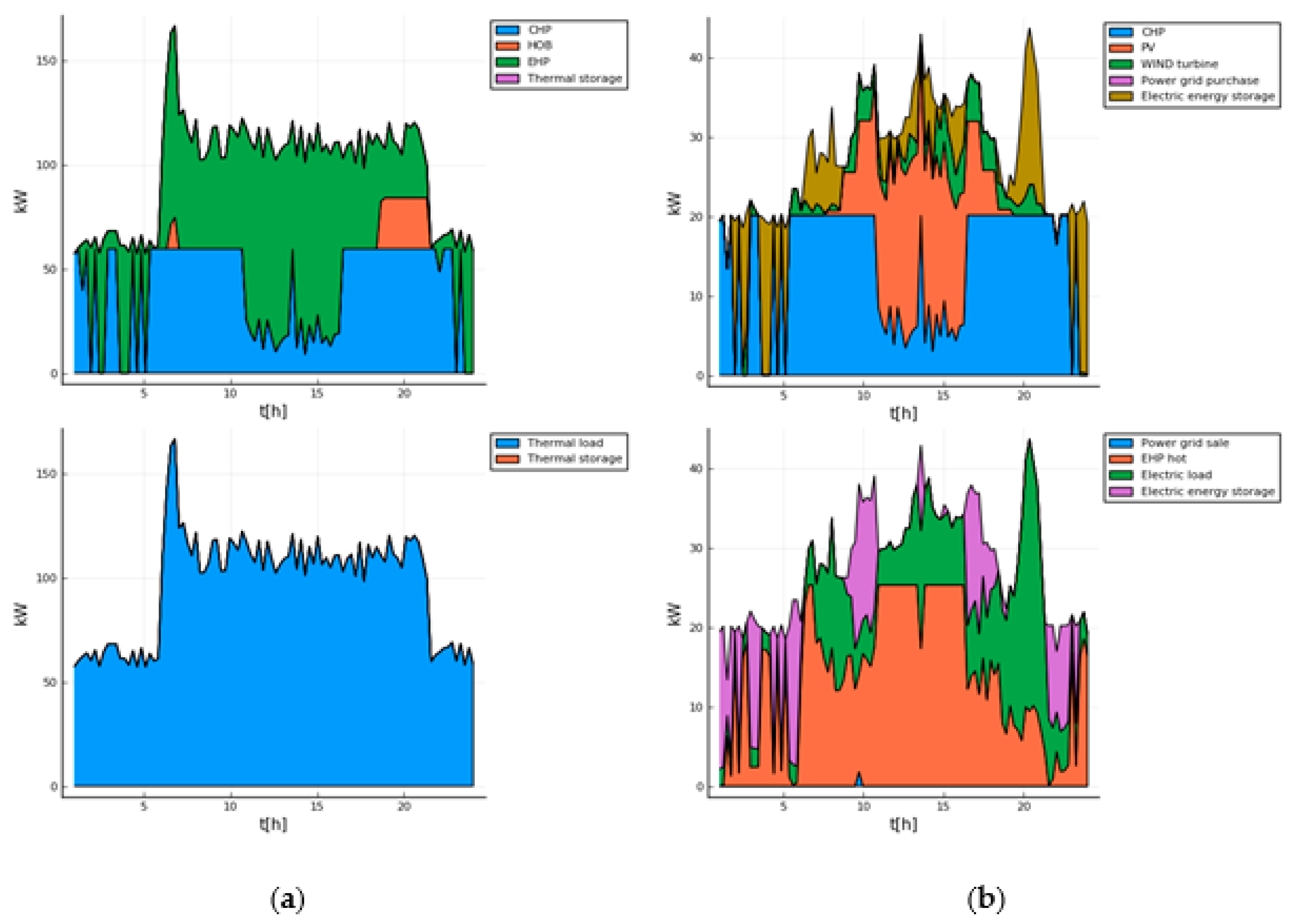

3.2. Combined Design and Operation Optimization

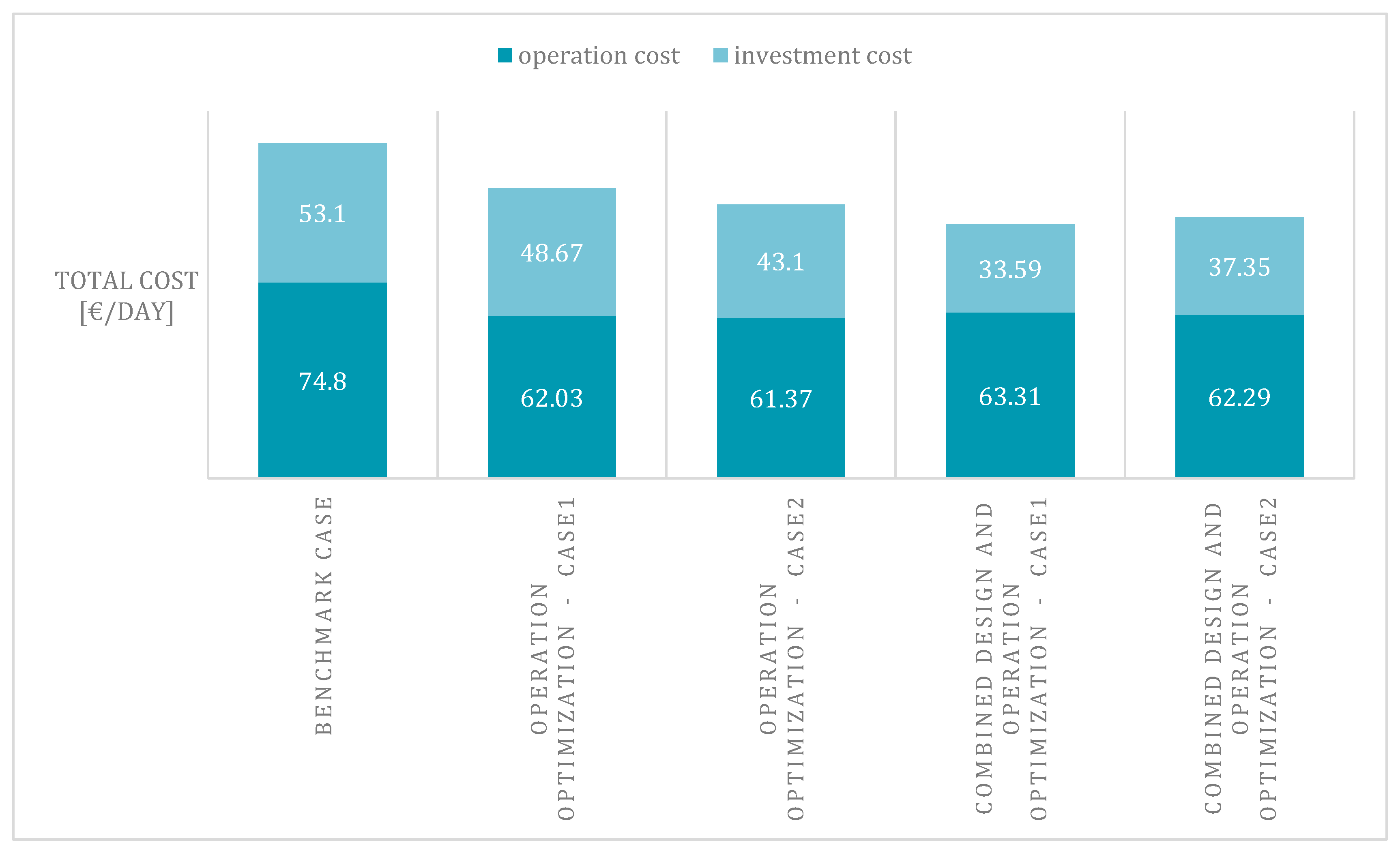

4. Comparison and Discussion

- Benchmark Case;

- Operation Optimization Case 1 (with thermal storage);

- Operation Optimization Case 2 (with electric storage);

- Combined Design and Operation Optimization Case 1 (with thermal storage);

- Combined Design and Operation Optimization Case 2 (with electric storage) and a detail of the fraction covered by investment and operations.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Marszal, A.J.; Heiselberg, P.; Bourrelle, J.S.; Musall, E.; Voss, K.; Sartori, I.; Napolitano, A. Zero Energy Building–A review of definitions and calculation methodologies. Energy Build. 2011, 43, 971–979. [Google Scholar] [CrossRef]

- Visa, I.; Moldovan, M.D.; Comsit, M.; Duta, A. Improving the renewable energy mix in a building toward the nearly zero energy status. Energy Build. 2014, 68, 72–78. [Google Scholar] [CrossRef]

- Task 40/Annex 52, Towards Net Zero Energy Solar Buildings, IEA SHC Task 40 and ECBCS Annex 52. 2008. Available online: http://www.iea-shc.org/task40/index.html (accessed on 10 February 2020).

- Rubio-Maya, C.; Uche-Marcuello, J.; Martínez-Gracia, A.; Bayod-Rújula, A.A. Design optimization of a polygeneration plant fuelled by natural gas and renewable energy sources. Appl. Energy 2011, 88, 449–457. [Google Scholar] [CrossRef]

- Ortiga, J.; Bruno, J.C.; Coronas, A.; Grossman, I.E. Review of optimization models for the design of polygeneration systems in district heating and cooling networks. Comput. Aided Chem. Eng. 2007, 24, 1121. [Google Scholar]

- Pikas, E.; Thalfeldt, M.; Kurnitski, J. Cost optimal and nearly zero energy building solutions for office buildings. Energy Build. 2014, 74, 30–42. [Google Scholar] [CrossRef]

- Testi, D.; Schito, E.; Conti, P. Cost-optimal sizing of solar thermal and photovoltaic systems for the heating and cooling needs of a nearly Zero-Energy Building: Design methodology and model description. In Proceedings of the 4th International Conference on Solar Heating and Cooling for Buildings and Industry, SHC 2015, Turkey, 2–4 December 2015; Volume 91, pp. 517–527. [Google Scholar]

- Attia, S.; Gratia, E.; De Herde, A.; Hensen, J.L. Simulation-based decision support tool for early stages of zero-energy building design. Energy Build. 2012, 49, 2–15. [Google Scholar] [CrossRef]

- Attia, S.; Hamdy, M.; O’Brien, W.; Carlucci, S. Assessing gaps and needs for integrating building performance optimization tools in net zero energy buildings design. Energy Build. 2013, 60, 110–124. [Google Scholar] [CrossRef]

- Hamdy, M.; Nguyen, A.T.; Hensen, J.L. A performance comparison of multi-objective optimization algorithms for solving nearly-zero-energy-building design problems. Energy Build. 2016, 121, 57–71. [Google Scholar] [CrossRef]

- Zheng, X.; Wu, G.; Qiu, Y.; Zhan, X.; Shah, N.; Li, N.; Zhao, Y. A MINLP multi-objective optimization model for operational planning of a case study CCHP system in urban China. Appl. Energy 2018, 210, 1126–1140. [Google Scholar] [CrossRef]

- Karavas, C.S.; Kyriakarakos, G.; Arvanitis, K.G.; Papadakis, G. A multi-agent decentralized energy management system based on distributed intelligence for the design and control of autonomous polygeneration microgrids. Energy Convers. Manag. 2015, 103, 166–179. [Google Scholar] [CrossRef]

- Kuang, J.; Zhang, C.; Sun, B. Stochastic dynamic solution for off-design operation optimization of combined cooling, heating, and power systems with energy storage. Appl. Therm. Eng. 2019, 163, 114356. [Google Scholar] [CrossRef]

- Yang, S.; Tan, Z.; Lin, H.; Li, P.; De, G.; Ju, L. A two-stage optimization model for Park Integrated Energy System operation and benefit allocation considering the effect of Time-Of-Use energy price. Energy 2020, 195, 117013. [Google Scholar] [CrossRef]

- Rakipour, D.; Barati, H. Probabilistic optimization in operation of energy hub with participation of renewable energy resources and demand response. Energy 2019, 173, 384–399. [Google Scholar] [CrossRef]

- European Project RECOGNITION. Available online: https://re-cognition-project.eu/ (accessed on 10 February 2020).

- Gustafsson, M.; Dipasquale, C.; Poppi, S.; Bellini, A.; Fedrizzi, R.; Bales, C.; Holmberg, S. Economic and environmental analysis of energy renovation packages for European office buildings. Energy Build. 2017, 148, 155–165. [Google Scholar] [CrossRef]

- SMALL WIND WORLD ANNUAL REPORT 2016; WWEA-World Wind Energy Association: Bonn, Germany, 2016.

- Coelho, S.T.; Velázquez, S.M.S.G.; Martins, O.S.; Castro de Abreu, F. Biogas from Sewage Treatment used to Electric Energy Generation, by a 30 kW (ISO) Microturbine; World Bioenergy Conference & Exhibition: Jönköping, Sweden, 2006. [Google Scholar]

- IEA-ETSAP and IRENA, Tecnology-Policy Brief E17. Available online: http://www.inship.eu/docs/TES%201%20IRENA-ETSAP%20Tech%20Brief%20E17%20Thermal%20Energy%20Storage.pdf (accessed on 10 February 2020).

- Zekeri, B.; Syri, S. Electrical energy storage systems: A comparative life cycle cost analysis. Renew. Sustain. Energy Rev. 2015, 42, 569–596. [Google Scholar] [CrossRef]

- Installation & Maintenance Manual-Eoltec Scirocco E5.6-6. Available online: https://s1.solacity.com/docs/Scirocco%20Manual.pdf (accessed on 10 February 2020).

- do Nascimento, M.A.R.; de Oliveira Rodrigues, L.; dos Santos, E.C.; Gomes, E.E.B.; Dias, F.L.G.; Velásques, E.I.G.; Carrillo, R.A.M. Micro Gas Turbine Engine: A Review; InTech: London, UK, 2013. [Google Scholar]

| Case N° | Technology 1 | Technology 2 | Technology 3 | Technology 4 | Technology 5 | Technology 6 |

|---|---|---|---|---|---|---|

| 1 | Small-scale wind turbine | Photovoltaics | mCHP | Gas heat-only boiler | Air heat pump | Latent heat storage |

| 2 | Small-scale wind turbine | Photovoltaics | mCHP | Gas heat-only boiler | Air heat pump | Electric storage |

| Technology | Details | Cost and Ref. | Lifetime and Ref. | ||

|---|---|---|---|---|---|

| Photovoltaics | - | 2280 (EUR/kW) | [17] | 20 | [17] |

| Wind Turbine | Small scale | 6424 (EUR/kW) | [18] | 25 | [22] |

| mCHP | Biogas microturbine | 1950 (EUR/kW) | [19] | 10 | [23] |

| Heat pump | Traditional air heat pump | 720 (EUR/kW) | [17] | 15 | [17] |

| Gas heat-only boiler | Condensing boiler | 180 (EUR/kW) | [17] | 12 | [17] |

| Latent heat storage | Paraffin wax PCM | 50 (EUR/kWh) | [20] | 30 | [20] |

| Electric storage | Li-ion | 546 (EUR/kWh) | [21] | 10 | [21] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guelpa, E.; Mancò, G.; Verda, V. Optimal Integration of Renewable Sources and Latent Heat Storages for Nearly Zero-Energy Buildings. Proceedings 2020, 58, 35. https://doi.org/10.3390/WEF-06914

Guelpa E, Mancò G, Verda V. Optimal Integration of Renewable Sources and Latent Heat Storages for Nearly Zero-Energy Buildings. Proceedings. 2020; 58(1):35. https://doi.org/10.3390/WEF-06914

Chicago/Turabian StyleGuelpa, Elisa, Giulia Mancò, and Vittorio Verda. 2020. "Optimal Integration of Renewable Sources and Latent Heat Storages for Nearly Zero-Energy Buildings" Proceedings 58, no. 1: 35. https://doi.org/10.3390/WEF-06914

APA StyleGuelpa, E., Mancò, G., & Verda, V. (2020). Optimal Integration of Renewable Sources and Latent Heat Storages for Nearly Zero-Energy Buildings. Proceedings, 58(1), 35. https://doi.org/10.3390/WEF-06914