Development of New Starch Formulations for Inclusion in the Dietotherapeutic Treatment of Glycogen Storage Disease †

Abstract

1. Introduction

2. Materials and Methods

2.1. Starches

2.2. Thermal Properties

2.3. Preparation of Samples for Digestion

2.4. In Vitro Starch Digestion and Glycaemic Index (GI) Estimation

2.5. Statistical Analysis

3. Results and Discussion

4. Conclusions

Funding

References

- Rosin, P.M.; Lajolo, F.M.; Menezes, E.W. Measurement and characterization of dietary starches. J. Food Compos. Anal. 2002, 15, 367–377. [Google Scholar] [CrossRef]

- Ahmadi-Abhari, S.; Woortman, A.J.J.; Oudhuis, A.A.C.M.; Hamer, R.J.; Loos, K. The influence of amylose-LPC complex formation on the susceptibility of wheat starch to amylase. Carbohydr. Polym. 2013, 97, 436–440. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Ratnayake, W.S.; Jackson, D.S. A new insight into the gelatinization process of native starches. Carbohydr. Polym. 2007, 67, 511–529. [Google Scholar] [CrossRef]

- Srichuwong, S.; Sunarti, T.C.; Mishima, T.; Isono, N.; Hisamatsu, M. Starches from different botanical sources I: Contribution of amylopectin fine structure to thermal properties and enzyme digestibility. Carbohydr. Polym. 2005, 60, 529–538. [Google Scholar] [CrossRef]

- Ballester-Sánchez, J.; Gil, J.V.; Fernández-Espinar, M.T.; Haros, C.M. Quinoa wet-milling: Effect of steeping conditions on starch recovery and quality. Food Hydrocoll. 2019, 89, 837–843. [Google Scholar] [CrossRef]

- Haros, M.; Blaszczak, W.; Perez, O.E.; Sadowska, J.; Rosell, C.M. Effect of ground corn steeping on starch properties. Eur. Food Res. Technol. 2006, 222, 194–200. [Google Scholar] [CrossRef]

- Goñi, I.; Garcia-Alonso, A.; Saura-Calixto, F. A starch hydrolysis procedure to estimate glycemic index. Nutr. Res. 1997, 17, 427–437. [Google Scholar] [CrossRef]

- Sanz-Penella, J.M.; Laparra, J.M.; Haros, M. Impact of α-amylase during breadmaking on in vitro kinetics of starch hydrolysis and glycaemic index of enriched bread with bran. Plant Foods Hum. Nutr. 2014, 69, 216–221. [Google Scholar] [CrossRef] [PubMed]

- Srichuwong, S.; Curti, D.; Austin, S.; King, R.; Lamothe, L.; Gloria-Hernandez, H. Physicochemical properties and starch digestibility of whole grain sorghums, millet, quinoa and amaranth flours, as affected by starch and non-starch constituents. Food Chem. 2017, 233, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Selma-Gracia, R.; Laparra, J.M.; Haros, C.M. Potential beneficial effect of the hydrothermal treatment of starches from different sources on the in vitro digestion. Food Hydrocol. 2020, 103, 105687. [Google Scholar] [CrossRef]

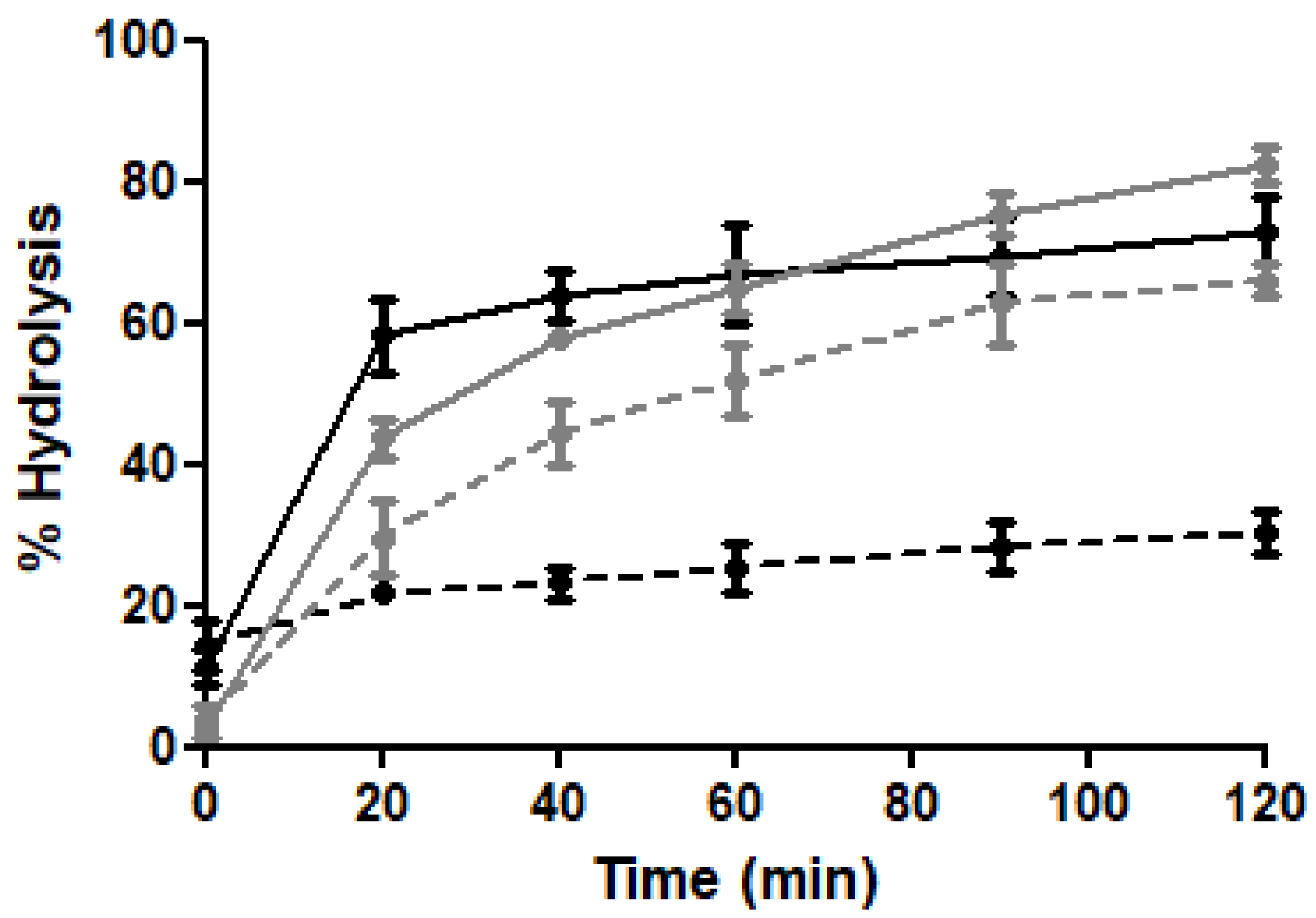

Maize 100 °C starch;

Maize 100 °C starch;  Raw maize starch;

Raw maize starch;  Quinoa 100 °C starch;

Quinoa 100 °C starch;  Raw quinoa starch. Selma-Gracia et al. [10].

Raw quinoa starch. Selma-Gracia et al. [10].

Maize 100 °C starch;

Maize 100 °C starch;  Raw maize starch;

Raw maize starch;  Quinoa 100 °C starch;

Quinoa 100 °C starch;  Raw quinoa starch. Selma-Gracia et al. [10].

Raw quinoa starch. Selma-Gracia et al. [10].

| Starch | Gelatinisation | Retrogradation | ||||||

|---|---|---|---|---|---|---|---|---|

| To (°C) | Tp (°C) | Tc (°C) | ΔH (J/g) | To (°C) | Tp (°C) | Tc (°C) | ΔH (J/g) | |

| Maize | 65 ± 1 b | 70 ± 1 b | 76 ± 1 b | 13 ± 1 b | 44 ± 1 b | 54 ± 1 b | 63 ± 1 b | 3.5 ± 1 a |

| Quinoa | 51 ± 2 a | 59 ± 1a | 69 ± 1 a | 10 ± 1 a | 37 ± 1a | 47 ± 1 a | 56 ± 1 a | 1.6 ± 1 a |

| Starch | Treatment | TSH120 (%) | AUC | HI (%) | GI | Slope (SH/min) |

|---|---|---|---|---|---|---|

| Maize | Raw | 30 ± 3 a | 2975 ± 323 a | 39 ± 4 a | 61 ± 2 a | 2.6 ± 0.2 a |

| Gelatinised | 73 ± 4 bc | 7408 ± 572 c | 97 ± 7 c | 93 ± 4 c | 11.7 ± 2.1 b | |

| Quinoa | Raw | 67 ± 4 b | 5741 ± 606 b | 75 ± 8 b | 81 ± 4 b | 2.2 ± 0.6 a |

| Gelatinised | 82 ± 2 c | 7153 ± 167 c | 94 ± 2 c | 91 ± 1 c | 3.9 ± 0.5 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Selma-Gracia, R.; Llopis, J.M.L.; Haros, C.M. Development of New Starch Formulations for Inclusion in the Dietotherapeutic Treatment of Glycogen Storage Disease. Proceedings 2020, 53, 3. https://doi.org/10.3390/proceedings2020053003

Selma-Gracia R, Llopis JML, Haros CM. Development of New Starch Formulations for Inclusion in the Dietotherapeutic Treatment of Glycogen Storage Disease. Proceedings. 2020; 53(1):3. https://doi.org/10.3390/proceedings2020053003

Chicago/Turabian StyleSelma-Gracia, Raquel, José Moisés Laparra Llopis, and Claudia Monika Haros. 2020. "Development of New Starch Formulations for Inclusion in the Dietotherapeutic Treatment of Glycogen Storage Disease" Proceedings 53, no. 1: 3. https://doi.org/10.3390/proceedings2020053003

APA StyleSelma-Gracia, R., Llopis, J. M. L., & Haros, C. M. (2020). Development of New Starch Formulations for Inclusion in the Dietotherapeutic Treatment of Glycogen Storage Disease. Proceedings, 53(1), 3. https://doi.org/10.3390/proceedings2020053003