Measurement and Visualization of Airflow through Sports Textiles †

Abstract

1. Introduction

2. Materials and Methods

2.1. Wind Tunnel

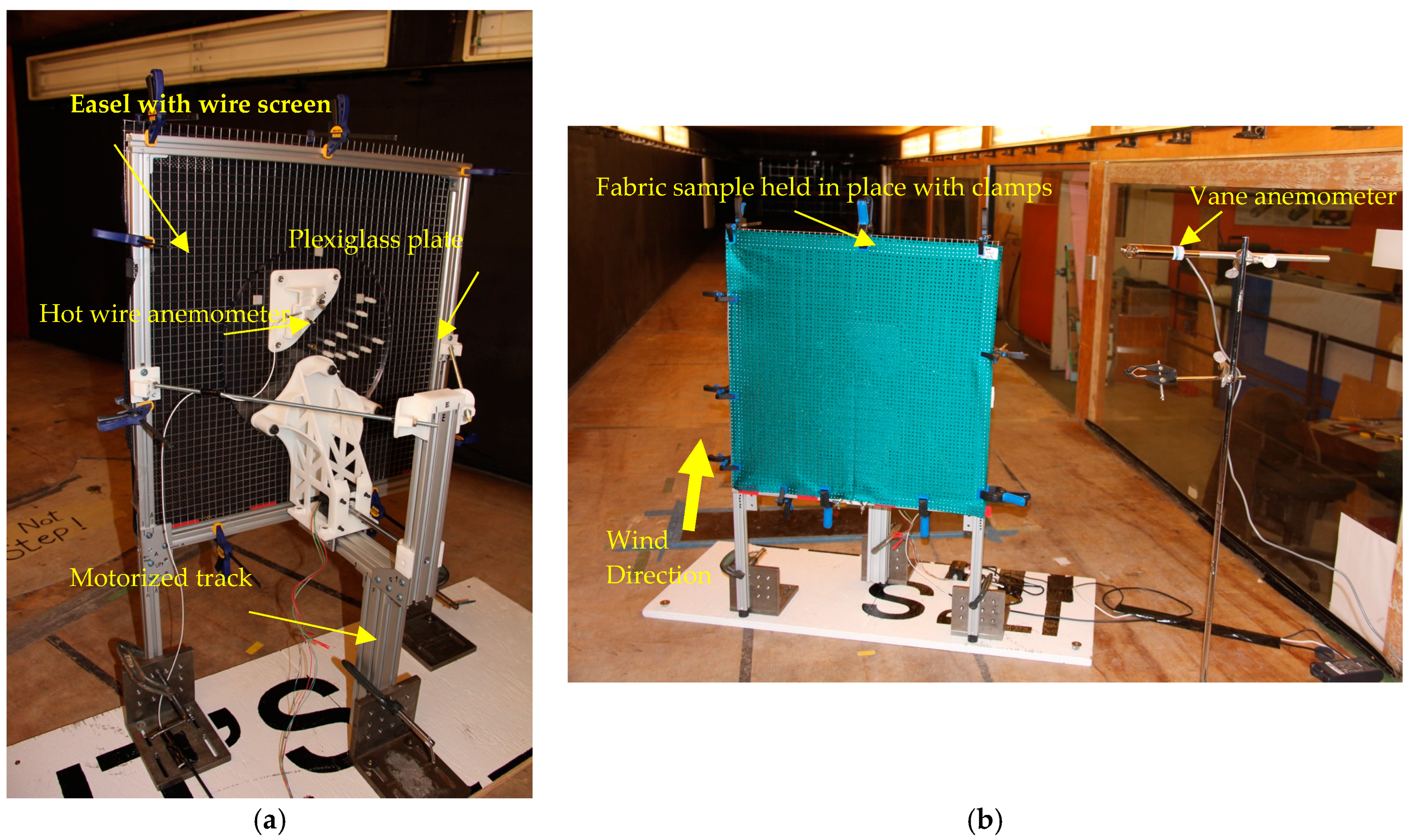

2.2. Airflow Measurement Device

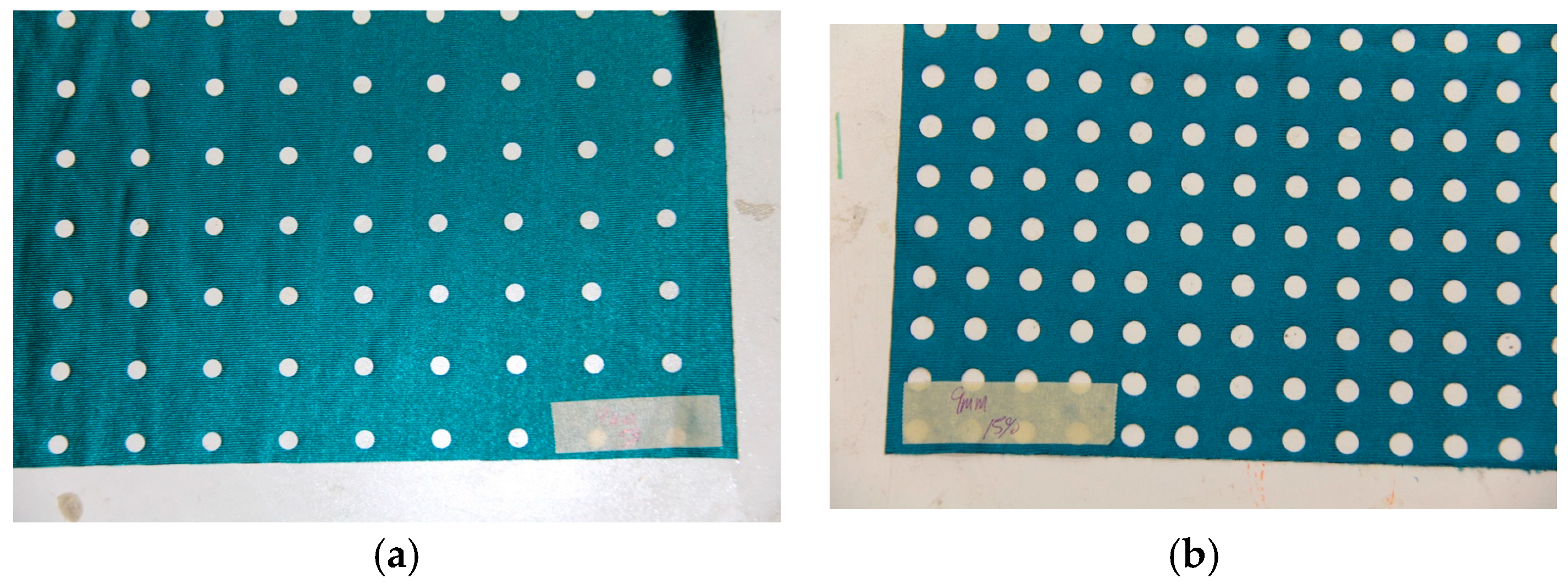

2.3. Test Samples

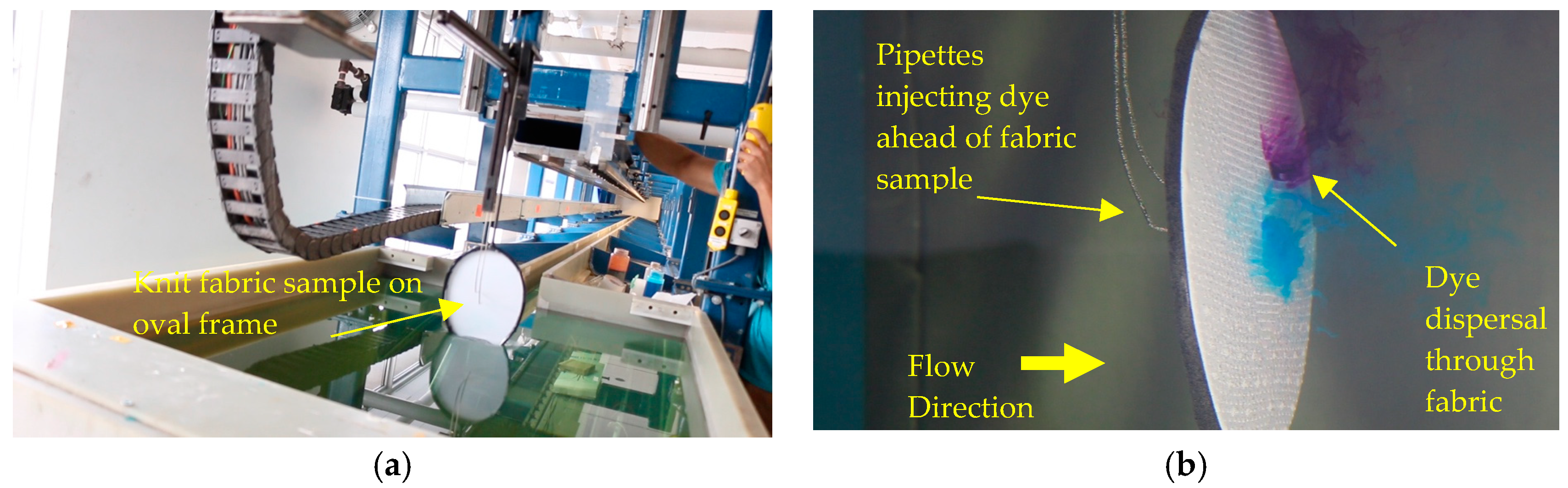

2.4. Flow Visualization

3. Results and Discussion

3.1. Calibration of Hot Wire Anemometer and Repeatability of Flow Measurements

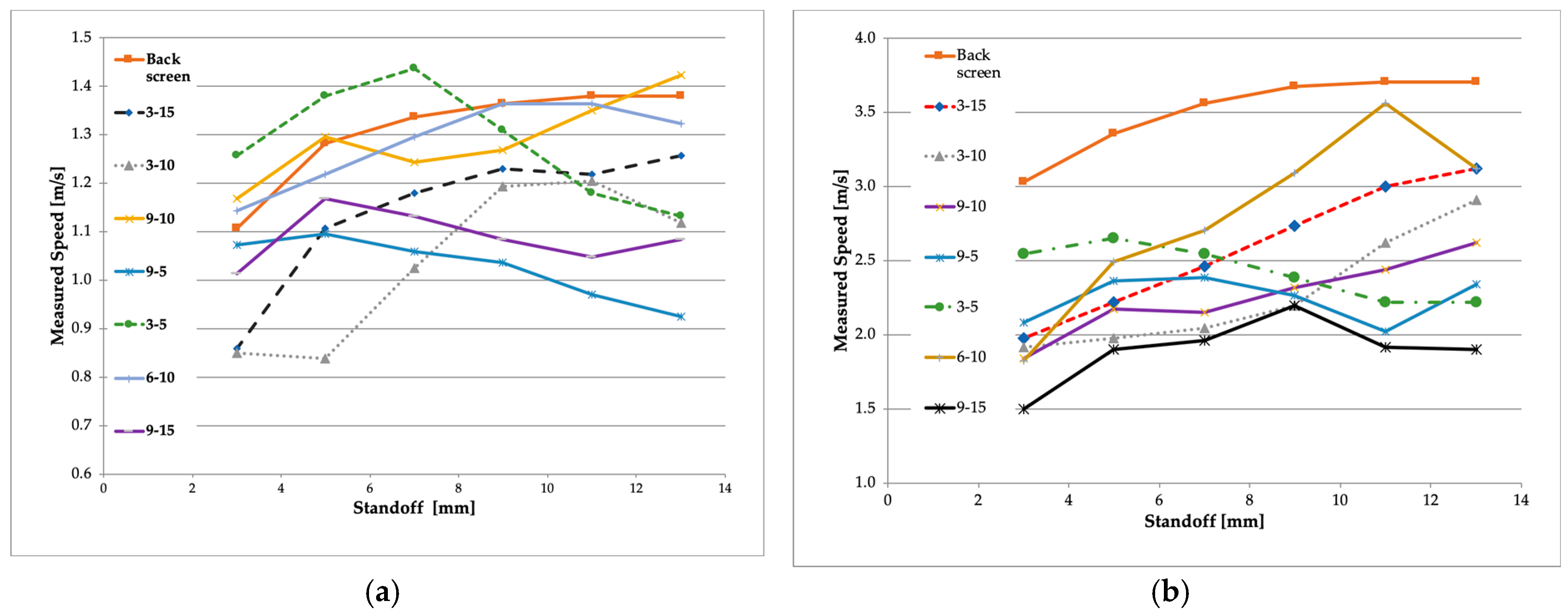

3.2. Effect of Ambient Wind Speed on Measured Flow Rate at Plate

3.3. Effects of Standoff, Hole Diameter and % Openness

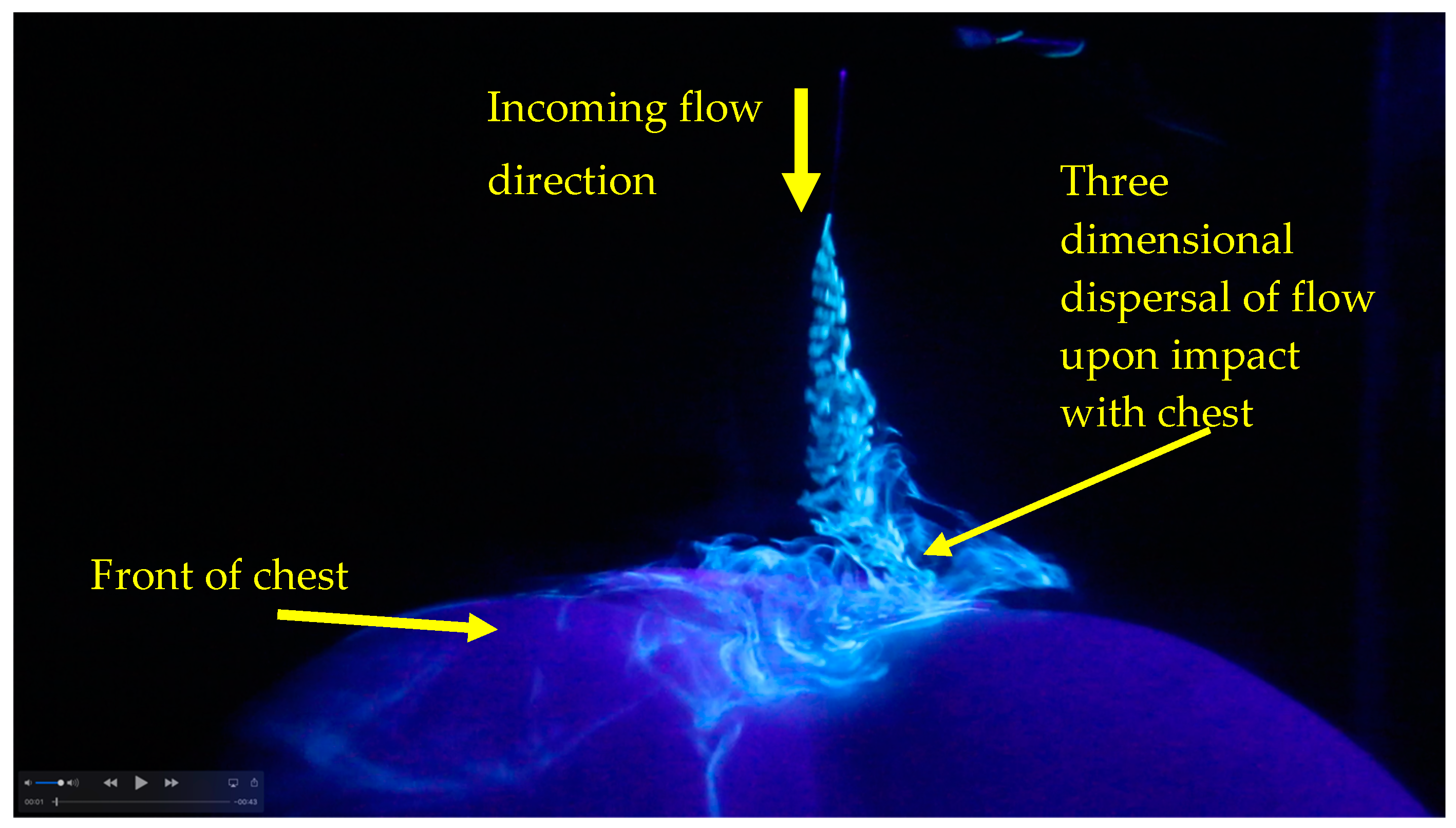

3.4. Interpretation of Flow Visualization

4. Conclusions

Funding

Conflicts of Interest

References

- Adams, W.C. Influence of exercise mode and selected ambient conditions on skin temperature. Ann. N. Y. Acad. Sci. 1977, 301, 110–127. [Google Scholar] [CrossRef] [PubMed]

- Adams, W.C.; Mack, G.W.; Langhans, G.W.; Nadal, E.R. Effects of varied air velocity on sweating and evaporative rates during exercise. J. Appl. Phys. 1992, 73, 2668–2674. [Google Scholar] [CrossRef] [PubMed]

- Shaffrath, J.D.; Adams, W.C. Effects of airflow and workload on cardiovascular drift and skin blood flow. J. Appl. Phys. 1984, 56, 1411–1417. [Google Scholar] [CrossRef]

- Saunders, A.G.; Dugas, J.P.; Tucker, R.; Lambert, M.I.; Noakes, T.D. The effects of different air velocities on heart storage and body temperature in humans cycling in a hot, humid environment. Acta Physiol. Scand. 2005, 183, 241–255. [Google Scholar] [CrossRef] [PubMed]

- Teunissen, L.P.J.; de Haan, A.; de Koning, J.J.; Daanen, H.A.M. Effects of wind application on thermal perception and self-paced performance. Eur. J. Appl. Physiol. 2013, 113, 1705–1717. [Google Scholar] [CrossRef] [PubMed]

- Brownlie, L.W.; Ostafichuk, P.; Carbo, J.; Demarest, N. Air permeability of sports fabrics at running speeds. Proc. Eng. 2014, 72, 697–702. [Google Scholar] [CrossRef][Green Version]

| Wind Speed | Hole Size | Permeability (% Openesss) | |||

|---|---|---|---|---|---|

| (m/s) | (mm) | 5 | 10 | 15 | Avg |

| 3.3 | 3 | 1.09 | 0.73 | 0.84 | 0.89 |

| 6 | 0.98 | 0.98 | |||

| 9 | 0.87 | 1.00 | 0.94 | ||

| Avg | 0.98 | 0.90 | 0.84 | 0.92 | |

| 10 | 3 | 0.78 | 0.60 | 0.67 | 0.68 |

| 6 | 0.70 | 0.70 | |||

| 9 | 0.69 | 0.62 | 0.65 | ||

| Avg | 0.73 | 0.64 | 0.67 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brownlie, L.; Bailey, C.; Carbo, J.; Judelson, D.; Ostafichuk, P.; Allison, J.; Rival, D. Measurement and Visualization of Airflow through Sports Textiles. Proceedings 2020, 49, 21. https://doi.org/10.3390/proceedings2020049021

Brownlie L, Bailey C, Carbo J, Judelson D, Ostafichuk P, Allison J, Rival D. Measurement and Visualization of Airflow through Sports Textiles. Proceedings. 2020; 49(1):21. https://doi.org/10.3390/proceedings2020049021

Chicago/Turabian StyleBrownlie, Len, Collin Bailey, Jorge Carbo, Dan Judelson, Peter Ostafichuk, Jeff Allison, and David Rival. 2020. "Measurement and Visualization of Airflow through Sports Textiles" Proceedings 49, no. 1: 21. https://doi.org/10.3390/proceedings2020049021

APA StyleBrownlie, L., Bailey, C., Carbo, J., Judelson, D., Ostafichuk, P., Allison, J., & Rival, D. (2020). Measurement and Visualization of Airflow through Sports Textiles. Proceedings, 49(1), 21. https://doi.org/10.3390/proceedings2020049021