Investigation of the Athlete’s Motion Using the Gymnastics Apparatus’s Motion †

Abstract

:1. Introduction

2. Experiment

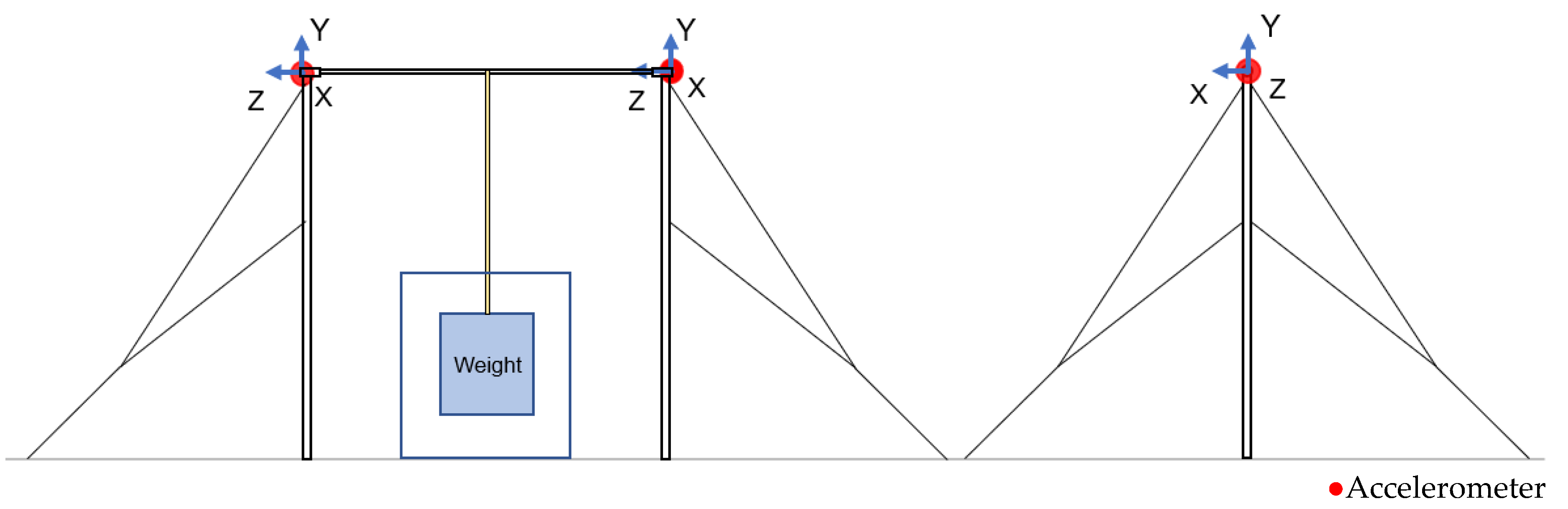

2.1. Experiment That Measures the Apparatus’s Motion

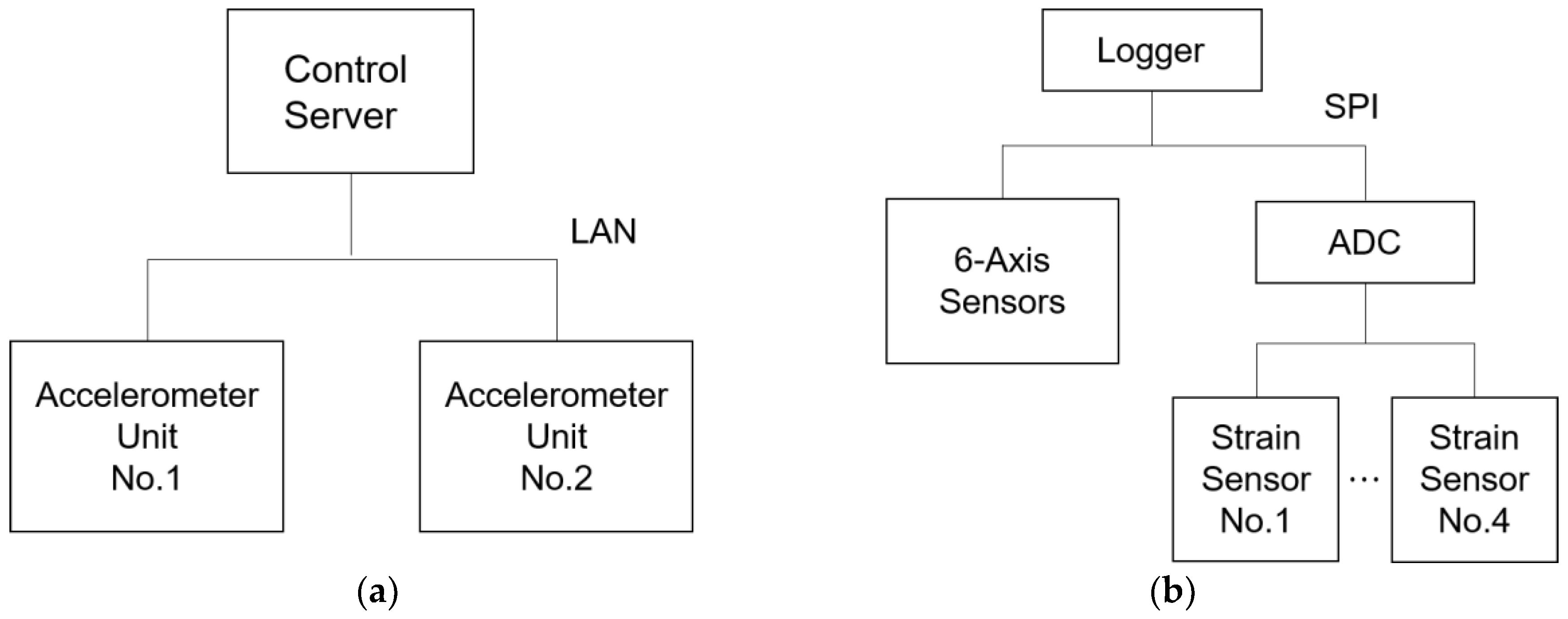

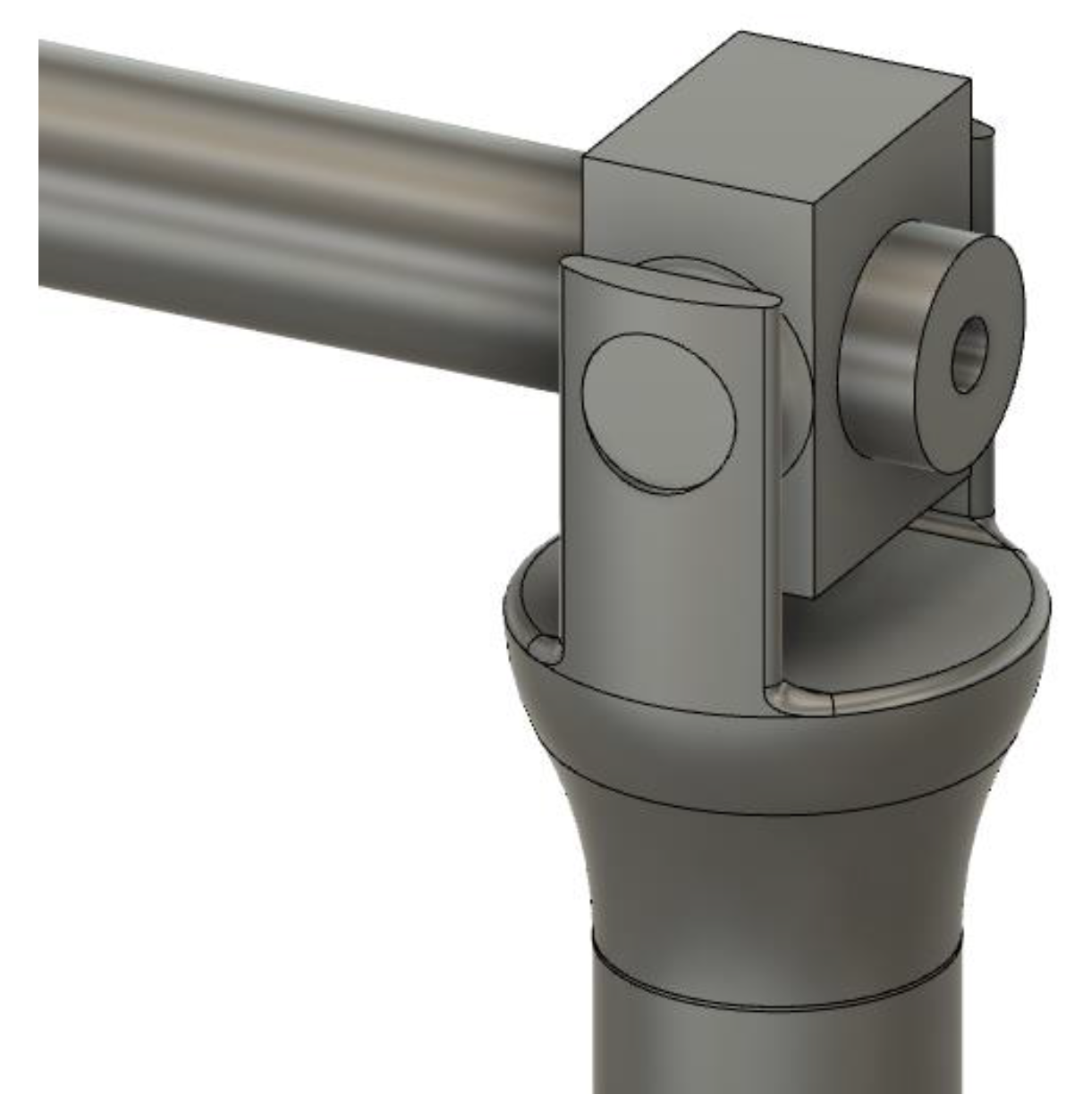

2.2. Equipment

2.3. Results

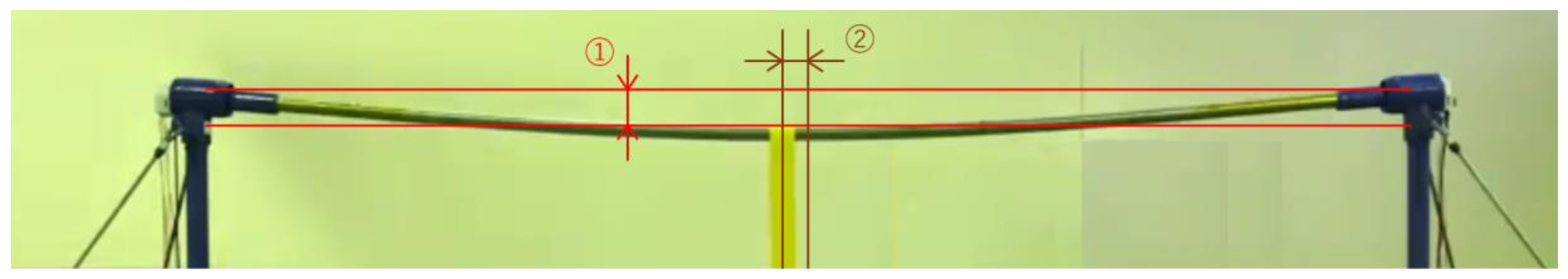

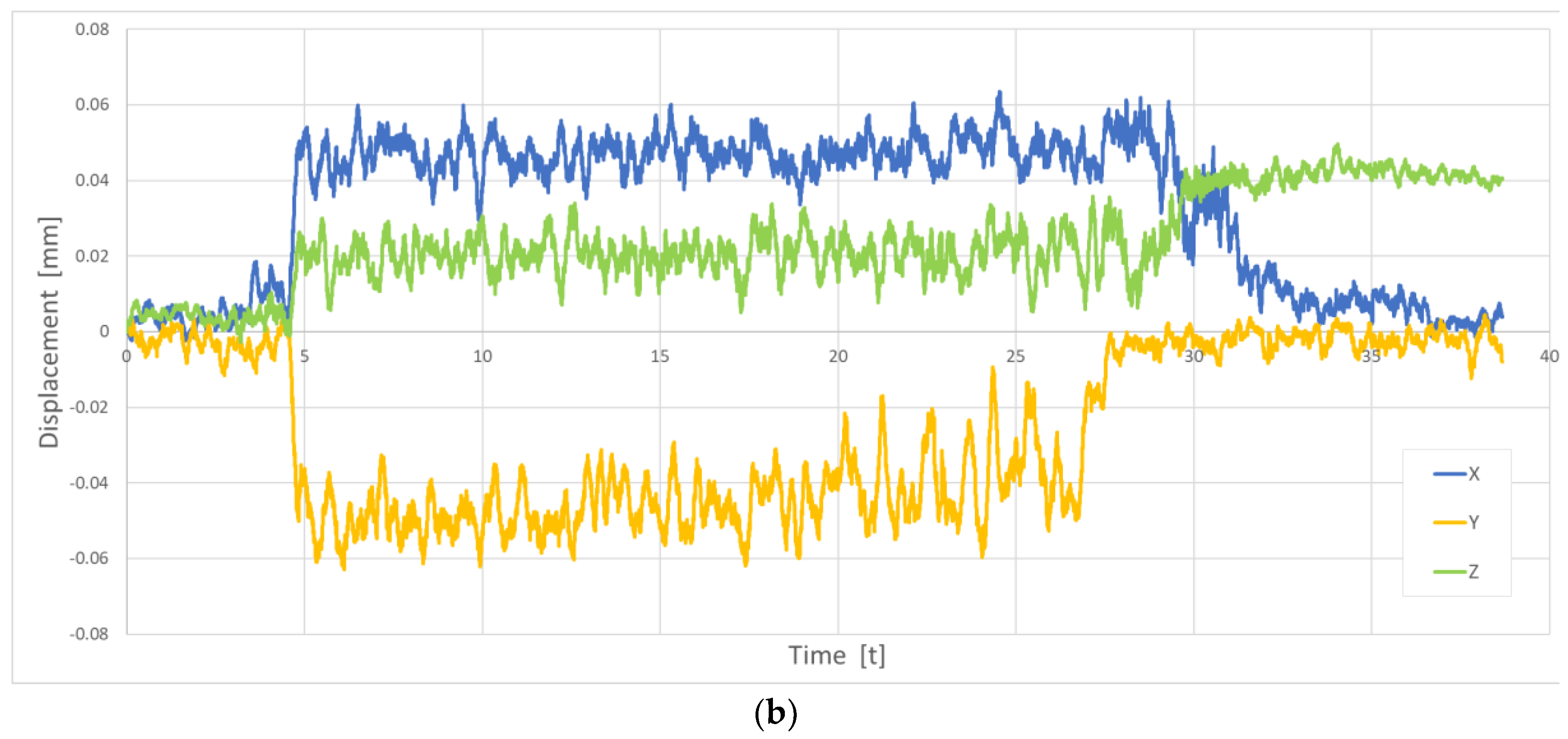

2.3.1. Static Load Experiment

2.3.2. Analysis

3. Conclusions

References

- Díaz-Pereira, M.P.; Gómez-Conde, I.; Escalona, M.; Olivieri, D.N. Automatic recognition and scoring of olympic rhythmic gymnastics movements. Hum. Mov. Sci. 2014, 34, 63–80. [Google Scholar] [CrossRef] [PubMed]

- Goichi, B.; Toru, F.; Hiroyki, K. New: Mechanics of Materials (Japanese); Baifukan: Tokyo, Japan, 2010; pp. 75–117. [Google Scholar]

- Susumu, T.; Masayasu, K. Introduction to Strain Measurement with Strain Gauge (Japanese); Taiseisha: Tokyo, Japan, 2011; pp. 41–46. [Google Scholar]

- Yoshio, A.; Taisei, Y.; Akihisa, T.; Goichi, B. Application of Localized Flexibility Method to Detection of Loosing Part for Jointed Frame Structure. Trans. Jpn. Soc. Mech. Eng. Ser. A 2006, 72, 111–117. [Google Scholar]

| Bar | Inner diameter [m] | 9 × 10−3 |

| Outside Diameter [m] | 28 × 10−3 | |

| Length [m] | 2.4 | |

| Post | Inner diameter [m] | 35.7 × 10−3 |

| Outside Diameter [m] | 42.7 × 10−3 | |

| Length [m] | 2.8 | |

| Tension of rope [N] | 2750 | |

| LSM6DS3 | |

|---|---|

| Frequency [Hz] | 500 |

| Resolution [bit] | 16 |

| Measuring range [g] | ±2 |

| Post | Displacement [mm] | ||

|---|---|---|---|

| X | Y | Z | |

| A (left) | 0.0003 | −0.0016 | −0.0288 |

| B (right) | 0.0002 | −0.0006 | 0.0374 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arakawa, N.; Ohtsuka, K.; Yoshio, A. Investigation of the Athlete’s Motion Using the Gymnastics Apparatus’s Motion. Proceedings 2020, 49, 120. https://doi.org/10.3390/proceedings2020049120

Arakawa N, Ohtsuka K, Yoshio A. Investigation of the Athlete’s Motion Using the Gymnastics Apparatus’s Motion. Proceedings. 2020; 49(1):120. https://doi.org/10.3390/proceedings2020049120

Chicago/Turabian StyleArakawa, Naoki, Kenya Ohtsuka, and Aoki Yoshio. 2020. "Investigation of the Athlete’s Motion Using the Gymnastics Apparatus’s Motion" Proceedings 49, no. 1: 120. https://doi.org/10.3390/proceedings2020049120

APA StyleArakawa, N., Ohtsuka, K., & Yoshio, A. (2020). Investigation of the Athlete’s Motion Using the Gymnastics Apparatus’s Motion. Proceedings, 49(1), 120. https://doi.org/10.3390/proceedings2020049120