A Preliminary Study on Non Contact Thermal Monitoring of Microwave Photonic Systems †

Abstract

:1. Introduction

2. Methods

3. Results

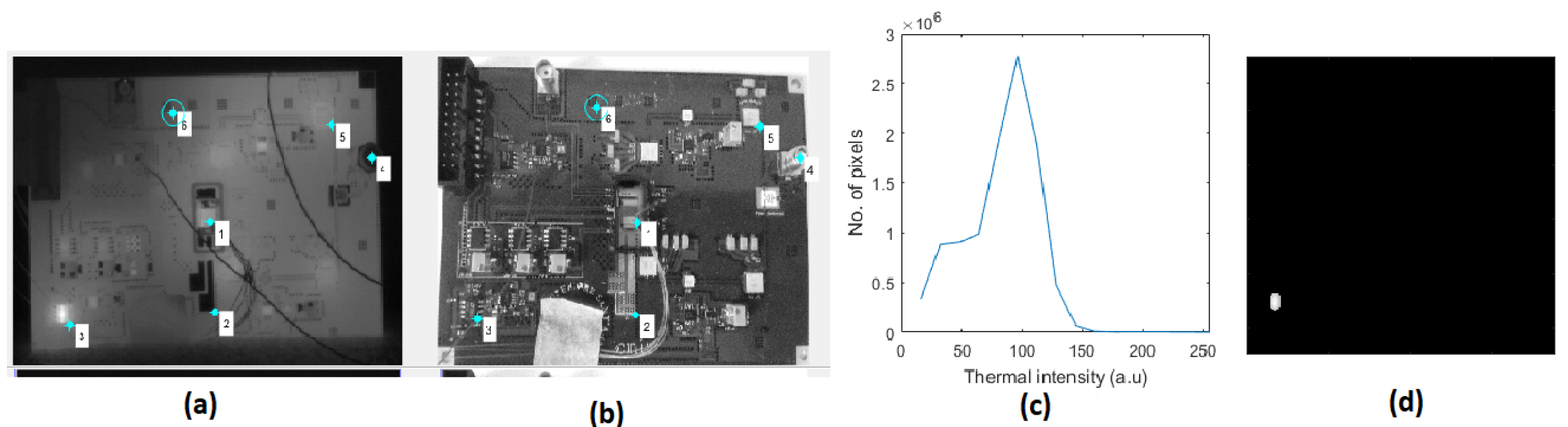

3.1. Data Acquisition

3.2. Experimental Results

4. Conclusions

Conflicts of Interest

References

- Wagh, C.R.; Baru, M.V.B. Detection of Faulty Region on Printed Circuit Board With IR Thermography. Int. J. Sci. Eng. Res. 2013, 4, 4. [Google Scholar]

- Petrosyants, K.; Kharitonov, I. Non-destructive testing of electronic components overheating using infrared thermography. Proceedings of The VIII-th International Workshop on NonDestructive Test (NDT) in Progress 2015, Prague, Czech Republic, 12–14 October 2015; Brno University of Technology: Brno, Czech Republic, 2015; Volume 3. [Google Scholar]

- Breitenstein, O. Lock-in IR Thermography for Functional Testing of Electronic Devices. In Proceedings of the Vortrag 7th Int. Conf. on Quantitative Infrared Thermography, Sint-Genesius-Rode, Belgium, 5–8 July 2004; pp. 1–6. [Google Scholar]

- Amato, F.; Serafino, G.; Hussain, B.; Toccafondo, V.; Chiesa, M.; Scotti, F.; Porzi, C.; Bogoni, A.; Ghelfi, P. Ultra-Fast Beam Steering of a Phased-Array Antenna Based on Packaged Photonic Integrated Circuits. In Proceedings of the 2018 European Conference on Optical Communication (ECOC), Rome, Italy, 23–27 September 2018. [Google Scholar]

- Kim, K. Survey on Registration Techniques of Visible and Infrared Images. IT Converg. Ractice (INPRA) 2015, 3, 25–35. [Google Scholar]

- Hines, G. Multi-Image Registration for an Enhanced Vision System; NASA Langley Research Center: Hampton, VA, USA, 2003.

- Otsu, N. A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

| SEQ | Board | Temperature | Switch |

|---|---|---|---|

| 1–3 | Front | decreasing | OFF |

| 4–5 | Front | stable | OFF |

| 6 | Back | stable | OFF |

| 7–10 | Back | increasing | ON |

| 11–12 | Front | stable | ON |

| 13–15 | Front | decreasing | OFF |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jalil, B.; Hussain, B.; Pascali, M.A.; Serafino, G.; Moroni, D.; Ghelfi, P. A Preliminary Study on Non Contact Thermal Monitoring of Microwave Photonic Systems. Proceedings 2019, 27, 19. https://doi.org/10.3390/proceedings2019027019

Jalil B, Hussain B, Pascali MA, Serafino G, Moroni D, Ghelfi P. A Preliminary Study on Non Contact Thermal Monitoring of Microwave Photonic Systems. Proceedings. 2019; 27(1):19. https://doi.org/10.3390/proceedings2019027019

Chicago/Turabian StyleJalil, Bushra, Bilal Hussain, Maria Antonietta Pascali, Giovanni Serafino, Davide Moroni, and Paolo Ghelfi. 2019. "A Preliminary Study on Non Contact Thermal Monitoring of Microwave Photonic Systems" Proceedings 27, no. 1: 19. https://doi.org/10.3390/proceedings2019027019

APA StyleJalil, B., Hussain, B., Pascali, M. A., Serafino, G., Moroni, D., & Ghelfi, P. (2019). A Preliminary Study on Non Contact Thermal Monitoring of Microwave Photonic Systems. Proceedings, 27(1), 19. https://doi.org/10.3390/proceedings2019027019