Fast Assessment of Post-Fire Residual Strength of Reinforced Concrete Frame Buildings Based on Non-Destructive Tests †

Abstract

:1. Introduction

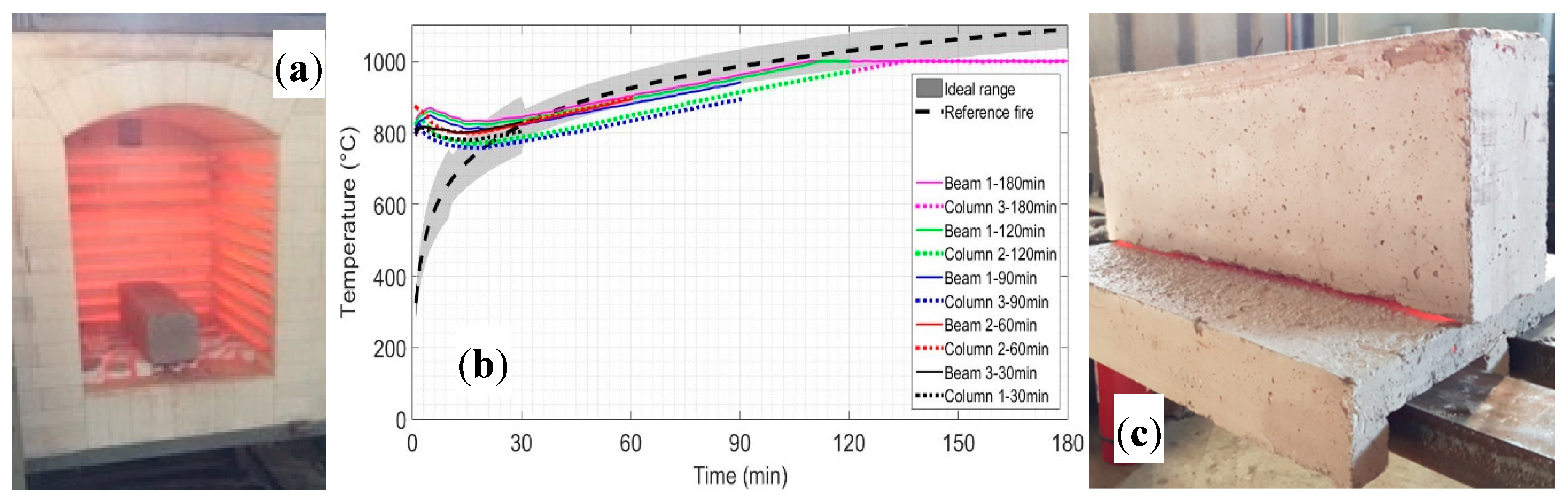

2. Materials and Methods

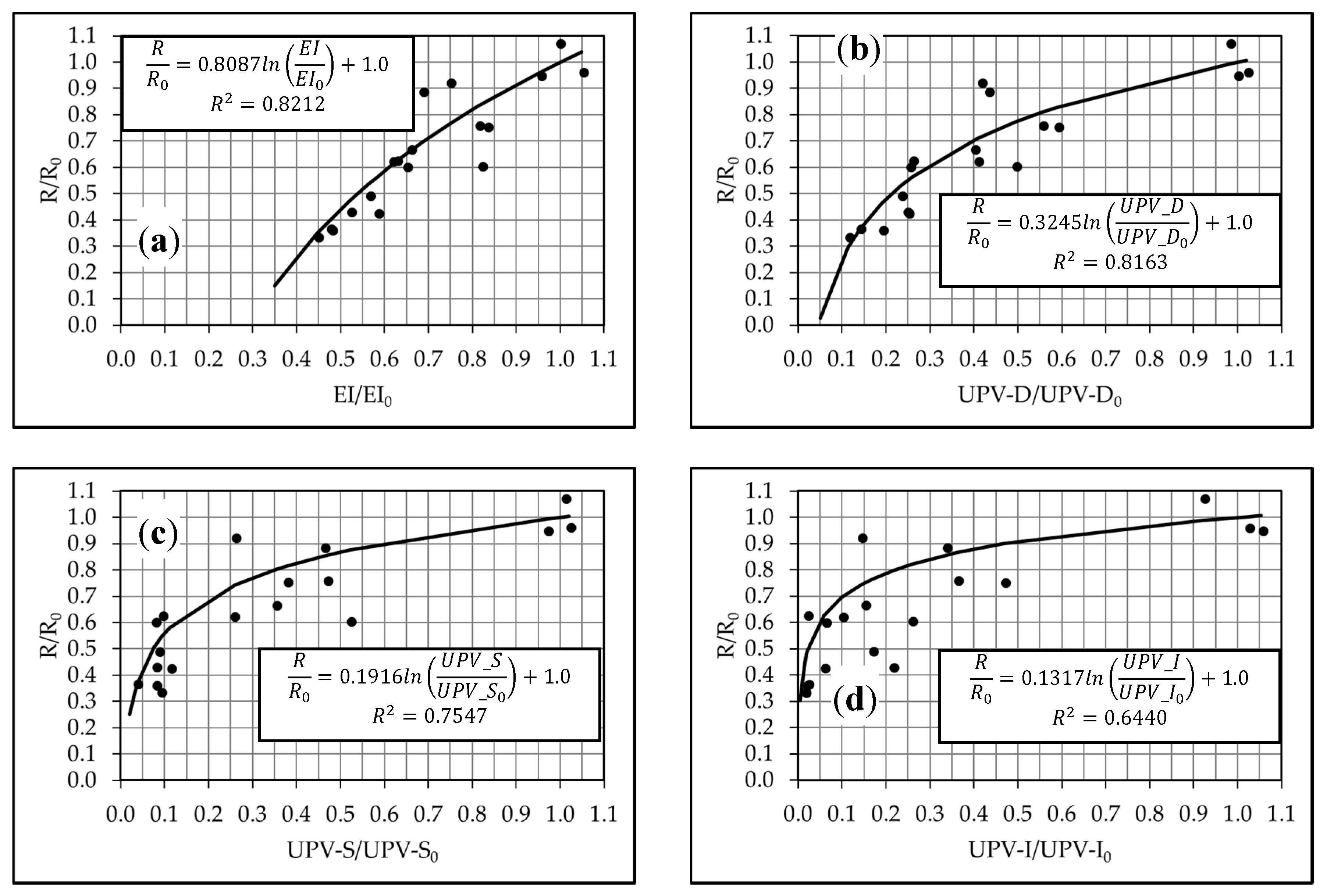

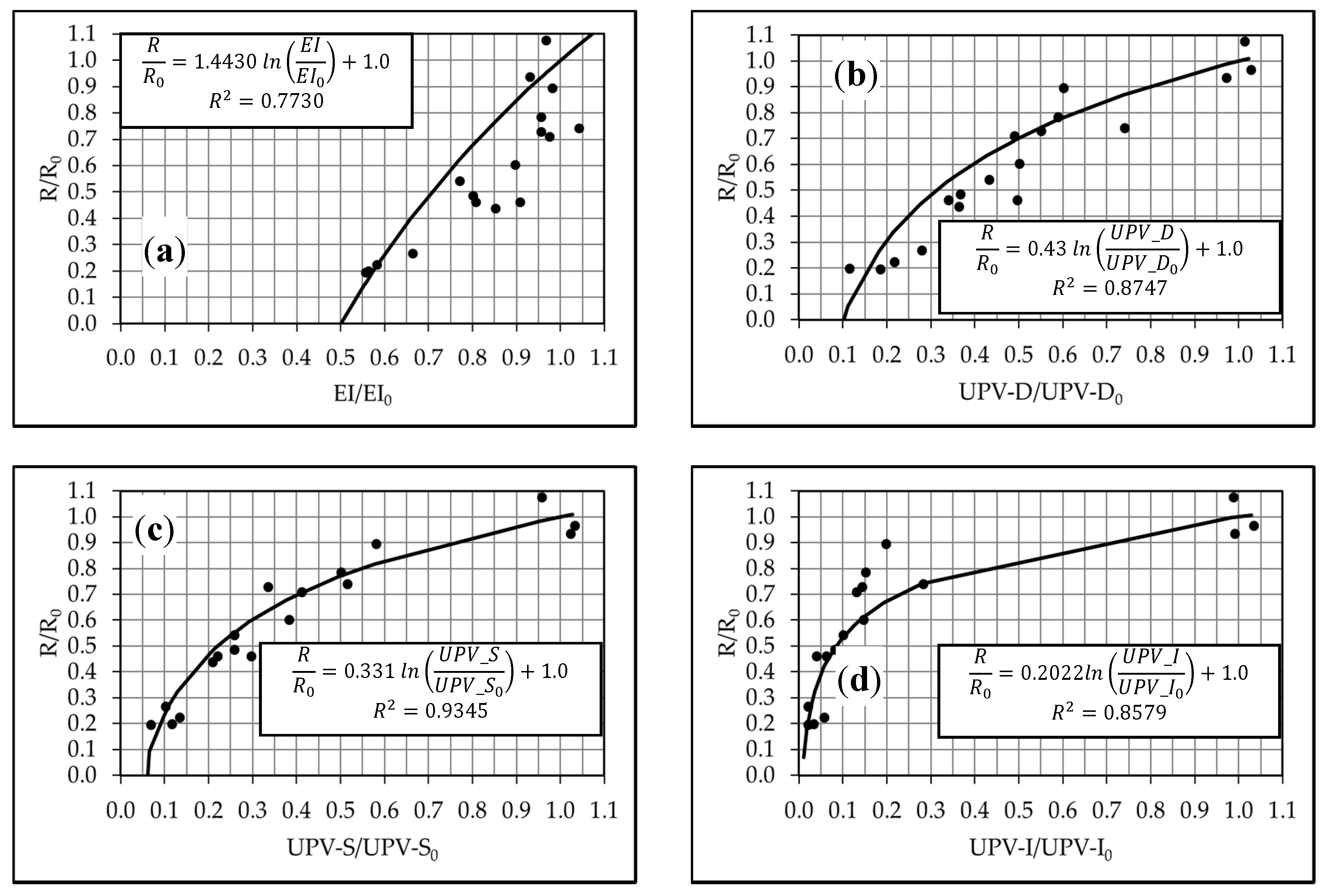

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Pérez, A. Metodología de Evaluación de Resistencia Post-Incendio de Elementos de Hormigón Armado Sometidos a Flexión. Master’s Thesis, Pontificia Universidad Católica de Valparaíso, Valparaíso, Chile, 2017. [Google Scholar]

- Maluk, C.; Bisby, L. 120 years of structural fire testing: Moving away from the status quo. In Proceedings of the 2nd Fire Engineering Conference, Valencia, Spain, 25–26 October 2012. [Google Scholar]

- Lea, F. The Effect of Temperature on Some of the Properties of Materials. Engineering 1920, 110, 293–298. [Google Scholar]

- Lea, F.; Stradling, R. The Resistance to Fire of Concrete and Reinforced Concrete. Engineering 1922, 114, 338–382. [Google Scholar] [CrossRef]

- Malhotra, H.L. The Effect of Temperature on the Compressive Strength of Concrete. Mag. Concr. Res. 1952, 8, 85–94. [Google Scholar] [CrossRef]

- Abrams, M.S. Compressive Strength of Concrete at Temperatures to 1600F. Spec. Publ. 1971, 25, 33–58. [Google Scholar]

- Schneider, U. Concrete at High Temperatures—A General Review. Fire Saf. J. 1988, 13, 55–68. [Google Scholar] [CrossRef]

- Savva, A.; Manita, P.; Sideris, K.K. Influence of elevated temperatures on the mechanical properties. Cem. Concr. Compos. 2005, 27, 239–248. [Google Scholar] [CrossRef]

- Señas, L.; Maiza, P.; Priano, C.; Marfil, S.; Valea, J. Evaluación de elementos estructurales de hormigón expuestos a un incendio. In Proceedings of the VI Congreso Internacional Sobre Patología y Recuperación de Estructuras, Córdoba, Argentina, 2–4 June 2010. [Google Scholar]

- Stawiki, B. Attempt to Estimate Fire Damage to Concrete Building Structure. Arch. Civil Mech. Eng. 2006, 6, 23–29. [Google Scholar] [CrossRef]

- Gernay, T.; Dimia, M. Structural Behavior of Concrete Columns under Natural Fires including Cooling down Phase. In Proceedings of the International Conference on Recent Advances in Nonlinear Models—Structural Concrete Applications, Coimbra, Portugal, 24–25 November 2011. [Google Scholar]

- American Concrete Institute. Building Code Requirements for Structural Concrete and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2008. [Google Scholar]

- Instituto Nacional de Normalización. Hormigón—Requisitos de Diseño y Cálculo; Instituto Nacional de Normalización: Santiago, Chile, 2007. [Google Scholar]

- Instituto Nacional de Normalización. Hormigón—Confección y Curado de Probetas para Ensayos de Compresión y Tracción; Instituto Nacional de Normalización: Santiago, Chile, 1975. [Google Scholar]

- Instituto Nacional de Normalización. Hormigón—Determinación del Índice Esclerométrico; Instituto Nacional de Normalización: Santiago, Chile, 1979. [Google Scholar]

- European Standard. CSN EN 12504-4—Testing Concrete—Part 4: Determination of Ultrasonic Pulse Velocity; European Standard: Brussels, Belgium, 2004. [Google Scholar]

- ASTM International. ASTM C597-02, Standard Test Method for Pulse Velocity through Concrete; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- Instituto Nacional de Normalización. Prevención de Incendio en Edificios—Ensayo de Resistencia al Fuego—Parte 1: Elementos de Construcción en General; Instituto Nacional de Normalización: Santiago, Chile, 1997. [Google Scholar]

- ASTM International. ASTM E119-05a, Standard Test Methods for Fire Tests of Building Construction and Materials; ASTM International: West Conshohocken, PA, USA, 2005. [Google Scholar]

- Instituto Nacional de Normalización. Hormigón—Ensayo de Compresión de Probetas Cúbicas y Cilíndricas; NCh1037.Of77.; Instituto Nacional de Normalización: Santiago, Chile, 1977. [Google Scholar]

- Instituto Nacional de Normalización. Hormigón—Ensayo de Tracción por Flexion; NCh1038.Of77.; Instituto Nacional de Normalización: Santiago, Chile, 1977. [Google Scholar]

- Li, Y.-H.; Franssen, J.-M. Test Results and Model for the Residual Compressive Strength of Concrete after a Fire. J. Struct. Fire Eng. 2011, 2, 29–44. [Google Scholar] [CrossRef]

- Hidalgo, P.; Ledezma, C.; Jordan, R. Seismic Behavior of Squat Reinforced Concrete Shear Walls. Earthq. Spectra 2002, 18, 287–308. [Google Scholar] [CrossRef]

| Material | Cement | Sand | Gravel | Water |

|---|---|---|---|---|

| % (kg/m3) | 18.2 (436) | 36.4 (873) | 36.4 (873) | 9.1 (218) |

| Specimen | Length (mm) | Width (mm) | Height (mm) | Upper Bars | Lower Bars | Stirrups |

|---|---|---|---|---|---|---|

| Columns | 600 | 200 | 250 | 2ϕ8 mm | 2ϕ8 mm | ϕ8@50 mm |

| Beams | 650 | 150 | 250 | 2ϕ6 mm | 2ϕ8 mm | ϕ8@100 mm |

| Columns | Beams | |||||||

|---|---|---|---|---|---|---|---|---|

| >0.80 | <0.80 | >0.60 | <0.60 | >0.80 | <0.80 | >0.60 | <0.60 | |

| Safety | Caution | Danger | Safety | Caution | Danger | |||

| >0.78 | <0.78 | >0.61 | <0.61 | >0.87 | <0.87 | >0.76 | <0.76 | |

| >0.54 | <0.54 | >0.29 | <0.29 | >0.63 | <0.63 | >0.39 | <0.39 | |

| >0.35 | <0.35 | >0.12 | <0.12 | >0.55 | <0.55 | >0.30 | <0.30 | |

| >0.22 | <0.22 | >0.05 | <0.05 | >0.30 | <0.37 | >0.14 | <0.14 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alcaíno, P.; María, H.S.; Cortés, M.; Alfaro, J. Fast Assessment of Post-Fire Residual Strength of Reinforced Concrete Frame Buildings Based on Non-Destructive Tests. Proceedings 2018, 2, 515. https://doi.org/10.3390/ICEM18-05394

Alcaíno P, María HS, Cortés M, Alfaro J. Fast Assessment of Post-Fire Residual Strength of Reinforced Concrete Frame Buildings Based on Non-Destructive Tests. Proceedings. 2018; 2(8):515. https://doi.org/10.3390/ICEM18-05394

Chicago/Turabian StyleAlcaíno, Pablo, Hernán Santa María, Michael Cortés, and Jennyfer Alfaro. 2018. "Fast Assessment of Post-Fire Residual Strength of Reinforced Concrete Frame Buildings Based on Non-Destructive Tests" Proceedings 2, no. 8: 515. https://doi.org/10.3390/ICEM18-05394