Abstract

The effect of the nitrogen diffusion layer formed by gas blow induction heating nitriding on the wear resistance and the fatigue properties of a titanium alloy was investigated. The nitrogen diffusion layer deteriorated the wear resistance of a titanium alloy. This is probably because hard abrasive particles worn from the diffusion layer accelerates the wear of the material. In contrast, the diffusion layer improved the fatigue properties of a titanium alloy. This is due to the high hardness of the diffusion layer, and because the layer and the substrate share the same elastic modulus, the surface stress concentration is inhibited.

Keywords:

nitriding; titanium alloy; induction heating; wear resistance; fatigue property; diffusion 1. Introduction

Nitriding, which forms a hard nitride layer composed of a nitrogen compound layer and a nitrogen diffusion layer beneath it, is generally performed to improve the wear resistance [1] and fatigue properties [2] of metals. When standard processes such as gas or plasma nitriding are carried out on titanium, the wear resistance is improved due to the formation of a hard nitrogen compound layer [3]. However, the fatigue strength of nitrided titanium is reduced due to brittleness of the nitrogen compound layer [4].

Standard nitriding processes generally require several hours to achieve surface modification of the treated material. Therefore, the authors recently developed a new nitriding technique, referred to as gas blow induction heating (IH) nitriding. In this process, N2 gas is blown over a material heated by high-frequency induction in a N2 atmosphere. A nitride layer is formed on a titanium alloy within a few minutes using this process [5,6]. It was found that gas blow IH nitrided titanium alloy exhibited the same properties as titanium nitrided using standard processes, in that although the wear resistance was improved, the fatigue strength was reduced due to the formation of a nitrogen compound layer on the top surface [5,6]. However, a nitrogen diffusion layer is also present beneath the surface nitrogen compound layer, and this is also expected to possess a high degree of hardness, which may lead to improved wear resistance and fatigue properties.

In this study, gas blow IH nitriding was performed on a titanium alloy, and the nitrogen compound layer was removed, leaving only a nitrogen diffusion layer. The effect on the wear resistance and fatigue properties was then investigated.

2. Experimental Procedures

2.1. Specimen Preparation

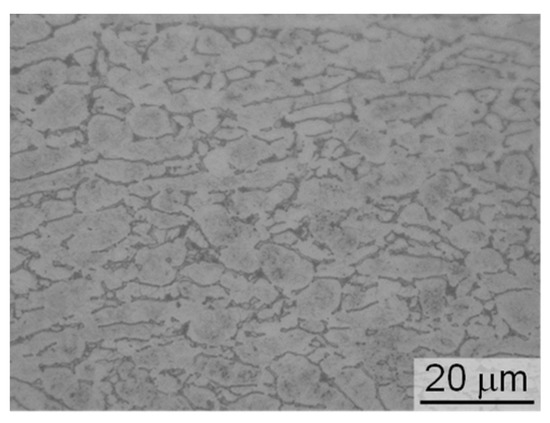

The material used in this study was Ti-6Al-4V alloy (ELI (Extra Low Interstitial) grade). The tensile strength and 0.2% proof stress were 961 MPa and 851 MPa, respectively. Figure 1 shows an optical micrograph of the alloy, which contains equiaxed α and β phase grains. Plates of this alloy with a thickness of 11 mm were machined into disk-shaped specimens with a diameter of 17 mm and a thickness of 5 mm, using wire electrical discharge and precision cutting machines. These specimens were polished to a mirror finish using emery paper (#240 to #1200) and a SiO2 suspension. The polished specimens are referred to as the P series.

Figure 1.

Optical micrograph of Ti-6Al-4V alloy.

The details of the gas blow IH nitriding system can be found in our previous paper [5]. Gas blow IH nitriding was carried out on the P series surfaces. The gas flow rate was 130 L/min, the treatment temperature was 1173 K, the heating time was 180 s, the internal diameter of the nozzle was 6 mm, and the nozzle distance was 100 mm. The temperature was controlled by adjusting the power applied to the IH unit, while measuring the temperature at the center of the treated specimen surface with a thermocouple. Some of the gas blow IH nitrided specimens were polished using emery paper (#2000 and #4000) and a SiO2 suspension until a mirror finish was achieved. The polishing step removed a layer with a thickness of 10–15 µm. The specimens treated by gas blow IH nitriding are referred to as the N series, and the N series specimens polished to a mirror finish are referred to as the N + P series.

2.2. Characterization of the Surface Modified Layer

The surface microstructure was observed using optical microscopy. The observations were performed after cutting the specimens, molding them in resin, and polishing them to a mirror finish using emery paper (#240 to #1200) and a SiO2 suspension, followed by etching with Kroll’s etchant. The hardness profiles in the specimen thickness direction was determined using a micro-Vickers hardness tester, with an indentation load of 0.245 N and a load holding time of 20 s. The surface properties were measured using a nano-indentation tester with a Berkovich indenter, with an indentation load of 100 mN and a load holding time of 5 s.

2.3. Reciprocating Ball-on-Disk Wear Tests

Reciprocating ball-on-disk wear tests were performed at room temperature in air to evaluate the wear resistance of the specimens. The ball was made from alumina and had a diameter of 3 mm, the load was 2.0 N, the sliding stroke was 8 mm, the sliding speed was 10 mm/s, the number of cycles was 14,000, and the total sliding distance was 224 m. The mass of the specimens was measured before and after the tests, and the wear loss during the tests was calculated. The wear tracks formed on the specimens were observed by scanning electron microscopy (SEM). The cross-sectional profiles of the wear tracks were examined by scanning white light interface microscopy.

2.4. Fatigue Tests under Four-Point Bending

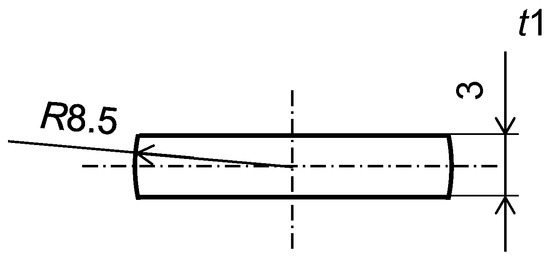

The disk-shaped specimens that had undergone each treatment were machined to the configuration shown in Figure 2, by precision cutting and polishing using emery paper (#120), to carry out four-point bending fatigue tests [7]. Fatigue tests were performed at room temperature in air, under a stress ratio of 0.1 and a stress cycling frequency of 10 Hz.

Figure 2.

Specimen configuration of four-point bending fatigue tests.

3. Results and Discussion

3.1. Characterization of Surface Modified Layer Formed on Ti-6Al-4V Alloy

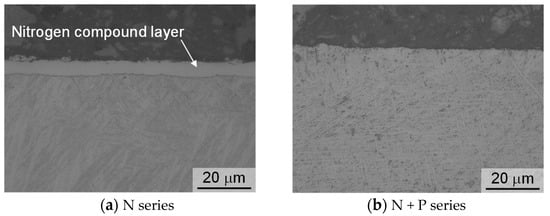

Figure 3 shows optical micrographs of the N and N + P series specimens. As seen in Figure 3a, a nitrogen compound layer with a thickness of approximately 5 µm was formed on the surface of the N series specimen. In contrast, no such layer is observed on the surface of the N + P series specimen in Figure 3b, indicating that it was completely removed by polishing. The figures also reveal that an acicular α phase was formed in the specimens, which was different to the microstructure before gas blow IH nitriding (Figure 1), and that grain coarsening occurred. This is because the temperature inside the specimen was higher than the β transus point (1268 K) due to the mismatch between the temperature measured by the thermocouple at the specimen surface and that inside the specimen [5].

Figure 3.

Cross-sectional optical micrographs of (a) gas blow IH nitrided (N series) and (b) polished after gas blow IH nitriding (N + P series) specimens.

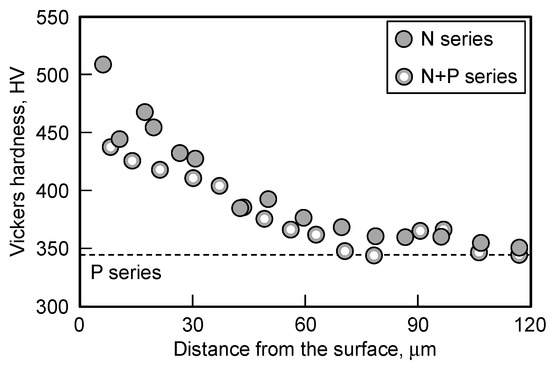

Figure 4 shows cross-sectional profiles of Vickers hardness for the N and N + P series specimens. Although the surface hardness for the N + P series specimen was reduced due to the removal of the compound layer, the surface of both specimens was harder than the interior. The increased hardness compared to the P series specimens indicates the presence of a nitrogen diffusion layer.

Figure 4.

Cross-sectional profiles of Vickers hardness for gas blow IH nitrided (N series) and polished after gas blow IH nitriding (N + P series) specimens.

These results show that a compound layer and a diffusion layer were formed at the surface of the N series specimens while only a diffusion layer was formed at the surface of the N + P series specimens.

3.2. Effect of Nitrogen Diffusion Layer on Wear Resistance of Ti-6Al-4V Alloy

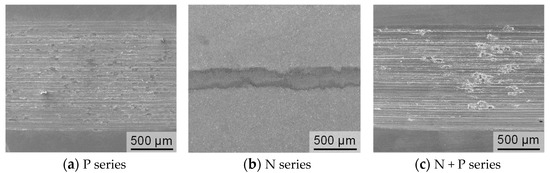

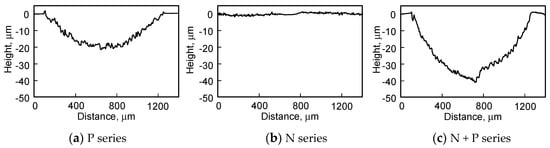

Reciprocating ball-on-disk wear tests were performed to investigate the wear resistance of the specimens. Figure 5 shows SEM micrographs of the wear tracks formed on the specimen surface. The N series (Figure 5b) showed a narrower wear track than the other specimens. The widths of the wear tracks formed on the P (Figure 5a) and N + P (Figure 5c) series specimens were almost the same. To examine the wear tracks in more detail, cross-sectional profiles were measured. Figure 6 illustrates the results. The N series specimen exhibited a relative small wear track (Figure 6b). In contrast, both P and N + P series specimens (Figure 6a,c) exhibited wide wear tracks, and that for the N + P series specimen was deeper. Table 1 summarizes the wear loss for the specimens during the tests. The wear loss for the N series specimen was less than that for the P series specimen, whereas the N + P series specimen showed the highest wear loss. These results indicate that the nitrogen compound layer on the N series specimens improved the wear resistance, whereas the nitrogen diffusion layer on the N + P series deteriorated the wear resistance.

Figure 5.

SEM micrographs of the wear tracks formed on the (a) polished (P series), (b) gas blow IH nitrided (N series) and (c) polished after gas blow IH nitriding (N + P series) specimens.

Figure 6.

Cross-sectional profiles of the wear tracks formed on the (a) polished (P series), (b) gas blow IH nitrided (N series) and (c) polished after gas blow IH nitriding (N + P series) specimens.

Table 1.

Wear losses of the polished (P series), gas blow IH nitrided (N series) and polished after gas blow IH nitriding (N + P series) specimens during the tests.

The wear resistance of a material is strongly affected by the surface hardness. Therefore, the surface hardness of the specimens was measured using a nano-indentation tester, and the results are shown in Table 2. The N series exhibited a significantly high hardness, due to the existence of the compound layer, which led to the improvement in the wear resistance of the Ti-6Al-4V alloy. The N + P series also exhibited a high hardness compared to the P series. However, the wear resistance of the N + P series was reduced, possibly because hard abrasive particles from the diffusion layer accelerated the wear of the material [8].

Table 2.

Surface hardness of the polished (P series), gas blow IH nitrided (N series) and polished after gas blow IH nitriding (N + P series) specimens measured by nano-indentation test.

3.3. Effect of Nitrogen Diffusion Layer on Fatigue Properties of Ti-6Al-4V Alloy

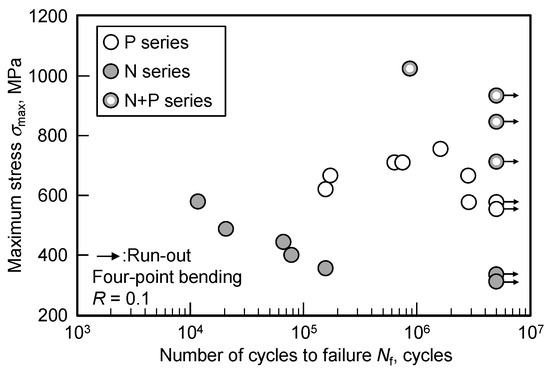

Four-point bending fatigue tests were carried out to investigate the fatigue properties of the specimens, and the results are shown in Figure 7. The N series specimen exhibited inferior fatigue properties than the P series specimen. The best results were obtained for the N + P series specimen.

Figure 7.

Results of four-point bending fatigue tests for the polished (P series), gas blow IH nitrided (N series) and polished after gas blow IH nitriding (N + P series) specimens.

To investigate the reason for the difference in fatigue properties, the elastic modulus at the outermost surface of the specimens was measured using a nano-indentation tester. Table 3 shows the results. The N series specimen exhibited a higher elastic modulus than the other specimens due to the presence of the nitrogen compound layer. A stress concentration occurred at the surface of the N series specimen due to the difference in elastic modulus between the substrate and compound layer [9], which resulted in a degradation of the fatigue properties. Table 3 also shows that the elastic modulus for the N + P and P series specimens was the same. Therefore, the surface stress concentration was not present in the N + P series specimen.

Table 3.

Elastic modulus at the surfaces of the polished (P series), gas blow IH nitrided (N series) and polished after gas blow IH nitriding (N + P series) specimens measured by nano-indentation tests.

Tokaji et al. [10] revealed that the crack initiation resistance was reduced by nitriding a Ti-6Al-4V alloy. Therefore, in this study, it is considered that premature crack initiation occurred, which deteriorated the fatigue properties of the N series specimen. In contrast, in the case of the N + P series specimen, the fatigue properties were improved because the nitrogen diffusion layer exhibited a high hardness and a similar elastic modulus to that of the substrate. It is noteworthy that the fatigue properties of the N + P series specimen were superior to those of the P series specimen, despite grain coarsening in the N + P series specimen during gas blow IH nitriding. Therefore, the nitrogen diffusion layer significantly improved the fatigue properties of Ti-6Al-4V alloy.

4. Conclusions

Gas blow IH nitriding was performed on a titanium alloy, and the nitrogen compound layer was then removed, leaving only a nitrogen diffusion layer. The effect of the nitrogen diffusion layer on the wear resistance and the fatigue properties of a titanium alloy was investigated. The main conclusions obtained in this study were as follows:

- The nitrogen diffusion layer deteriorated the wear resistance of a titanium alloy. This was probably caused by hard abrasive particles which were removed from the diffusion layer.

- By removing the nitrogen compound layer from the gas blow IH nitrided specimens, the fatigue properties of a titanium alloy were improved. This was due to the high hardness of the remaining nitrogen diffusion layer, and because this layer and the substrate shared the same elastic modulus, which prevented the occurrence of a stress concentration.

- The effects of the nitrogen diffusion layer were opposite to those of the nitrogen compound layer, in that the latter improved the wear resistance, but deteriorated the fatigue properties of a titanium alloy.

Author Contributions

S.T. performed the surface treatments and wear tests and wrote the paper. S.K. and H.A. performed the fatigue tests. J.K. conceived and designed the experiments.

Acknowledgments

This study was supported by JSPS KAKENHI (Grant Number 16K14121, 18J10220), The Light Metal Educational Foundation, Inc. and SEI Group Foundation. We are grateful for their financial support. The authors also thank Neturen Co., Ltd. for their support about IH equipment, and Kazutoshi Katahira (Materials Fabrication Laboratory, RIKEN) for the help with observations of the wear tracks.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Binder, C.; Bendo, T.; Hammes, G.; Klein, A.N.; de Mello, J.D.B. Effect of nature of nitride phases on sliding wear of plasma nitrided sintered iron. Wear 2015, 332–333, 995–1005. [Google Scholar] [CrossRef]

- Hiraoka, Y.; Ishida, A. Effect of compound layer thickness composed of γ’-Fe4N on rotated-bending fatigue strength in gas-nitrided JIS-SCM435 steel. Mater. Trans. 2017, 58, 993–999. [Google Scholar] [CrossRef]

- Rahman, M.; Reid, I.; Duggan, P.; Dowling, D.P.; Hughes, G.; Hashmi, M.S.J. Structural and tribological properties of the plasma nitrided Ti-alloy biomaterials: Influence of the treatment temperature. Surf. Coat. Technol. 2007, 201, 4865–4872. [Google Scholar] [CrossRef]

- Morita, T.; Takahashi, H.; Shimizu, M.; Kawasaki, K. Factors controlling the fatigue strength of nitrided titanium. Fatigue Fract. Eng. Mater. Struct. 1997, 20, 85–92. [Google Scholar] [CrossRef]

- Takesue, S.; Kikuchi, S.; Akebono, H.; Komotori, J.; Fukazawa, K.; Misaka, Y. Effects of gas blow velocity on the surface properties of Ti-6Al-4V alloy treated by gas blow IH nitriding. Mater. Trans. 2017, 58, 1155–1160. [Google Scholar] [CrossRef]

- Kikuchi, S.; Ota, S.; Akebono, H.; Omiya, M.; Komotori, J.; Sugeta, A.; Nakai, Y. Formation of nitrided layer using atmospheric-controlled IH-FPP and its effect on the fatigue properties of Ti-6Al-4V alloy under four-point bending. Procedia Struct. Integrity 2016, 2, 3432–3438. [Google Scholar] [CrossRef][Green Version]

- Kikuchi, S.; Takemura, K.; Hayami, Y.; Ueno, A.; Ameyama, K. Evaluation of the fatigue properties of Ti-6Al-4V alloy with harmonic structure in 4-points bending. J. Soc. Mater. Sci. Jpn. 2015, 64, 880–886. [Google Scholar] [CrossRef]

- Yetim, A.F.; Yildiz, F.; Vangolu, Y.; Alsaran, A.; Celik, A. Several plasma diffusion processes for improving wear properties of Ti6Al4V alloy. Wear 2009, 267, 2179–2185. [Google Scholar] [CrossRef]

- Morita, T.; Fuchikawa, S.; Komotori, J.; Shimizu, M.; Minakawa, K.; Kawasaki, K. Fatigue strength of nitrided high-strength titanium alloy. Trans. Jpn. Soc. Mech. Eng. A 2001, 67, 719–725. [Google Scholar] [CrossRef][Green Version]

- Tokaji, K.; Ogawa, T.; Shibata, H. The effects of gas nitriding on fatigue behavior in titanium and titanium alloys. J. Mater. Eng. Perform. 1999, 8, 159–167. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).