1. Introduction

PMMA is a glassy (amorphous) thermoplastic with excellent optical properties and long term-stability when compared with other tough transparent polymers such as polycarbonate (PC). On the other hand, PMMA has the disadvantage of poor impact (Charpy) toughness, which makes it unsuitable for many engineering applications. Hence, to broaden the range of applications of PMMA, various strategies have been applied. One approach is the addition of well-dispersed rubber particles inside the matrix of PMMA, leading to so called rubber toughened-PMMA or RT-PMMA [

1]. With the suitable choice of composition and rubber particles size, this can lead to significant improvements in impact resistance without significantly compromising the optical properties. The role of particle size in particle-filled PMMAs has been extensively discussed in the literature and it is also well recognized that increasing filler content will increase toughness [

2,

3,

4].

Polymer structural damage can be categorized into macro and microscopic levels. Micro cracking which results from impact and internal stresses is an example of microscopic scale damage. This micro-cracking is the main factor of material failure. Indeed, while being generally undetected, it is considered as inducing structural fragmentations which lead to several properties changes such as loss of strength, stiffness and dimensional stability, see e.g., [

5]. Rittel and Maigre [

6] also suggested that dynamic crack initiation in PMMA happens due to the nucleation of several micro-cracks along the notch tip. The presence of cracks causes stress/strain concentration and may lead to failure of structure with the cracks interfering in most cases.

The role of toughening mechanism that occurs in rubber-modified plastics, RT-PMMA in the present case, is to dissipate strain energy that are able to extend an existing flow or crack [

7]. This toughening mechanism consists of three stages. The stress applied to the materials leads to the development of micro-crazes around the nanoparticles with resulting elastic and plastic strains on their outer surface. These strains may lead to cavitation around the nanoparticle. The rubbery core which is more ductile deforms and detaches from the rigid shell. This cavitation activates plastic deformation within the area around and between the nanoparticles followed by shear yielding along the crack path. Shear yielding disperses energy which is assumed to favor macroscopic toughening of the material [

8].

The present work aims at investigating the crack arrest capability of RT-PMMA under impact loading. In the present work, crack arrest capability is defined by how an engineering structure which is initially weakened by a pre-crack behaves when dynamically reloaded. The Kalthoff and Winkler (KW) impact test consisting in impacting the edge of a double notched plate is accordingly used. An experimental investigation of the dynamic crack arrest capability of shock-resistant RT-PMMA under high strain rate loading is presented, evidencing the brittle feature of the material failure. High speed camera is used to record the chronology of the failure mechanisms.

2. Experimental Method

The material used in this study is highly transparent shock resistance RT-PMMA provided in the form of plate. It consists essentially of polymethyl methacrylate and a tough phase distributed therein which is usually present as a core/shell dispersion. In order to study the thermomechanical characteristics of the RT-PMMA under consideration, tensile tests were carried out using an Instron machine with a maximum capacity of 100 kN. The strain is measured using a mechanical extensometer mounted on the specimen.

The objective of this study is to investigate experimentally the crack arrest capability of notched structures made of RT-PMMA under dynamic conditions. Therefore, the edge of double-notched plates are impacted using a method similar to the one proposed by Kalthoff and Wrinkler [

9]. All Kalthoff and Wrinkler (KW)-type impact tests were conducted at Institut Clément Ader Lab using gas launchers STIMPACT platform. In order to study the effect of the impact velocity on the crack arrest capability of the PMMA, different impact velocities ranging between 50 and 100 m/s are considered. The plate dimensions are 40 × 82 × 6 mm

3 with notches of 300 μm-thickness and 20 mm-length. The two initial notches that act as a pre-crack in the structure are machined using a wire saw cutter. Specimens are then placed in a closed chamber (see

Figure 1). A 6 m-length gas launcher is used to launch a 20 mm-diameter cylindrical steel projectile. A Photron SA5 high-speed camera is used to observe the projectile/plate interaction at 10

5 fps (frame per second) and 320 × 192 pixel

2 spatial resolution.

3. Results and Discussion

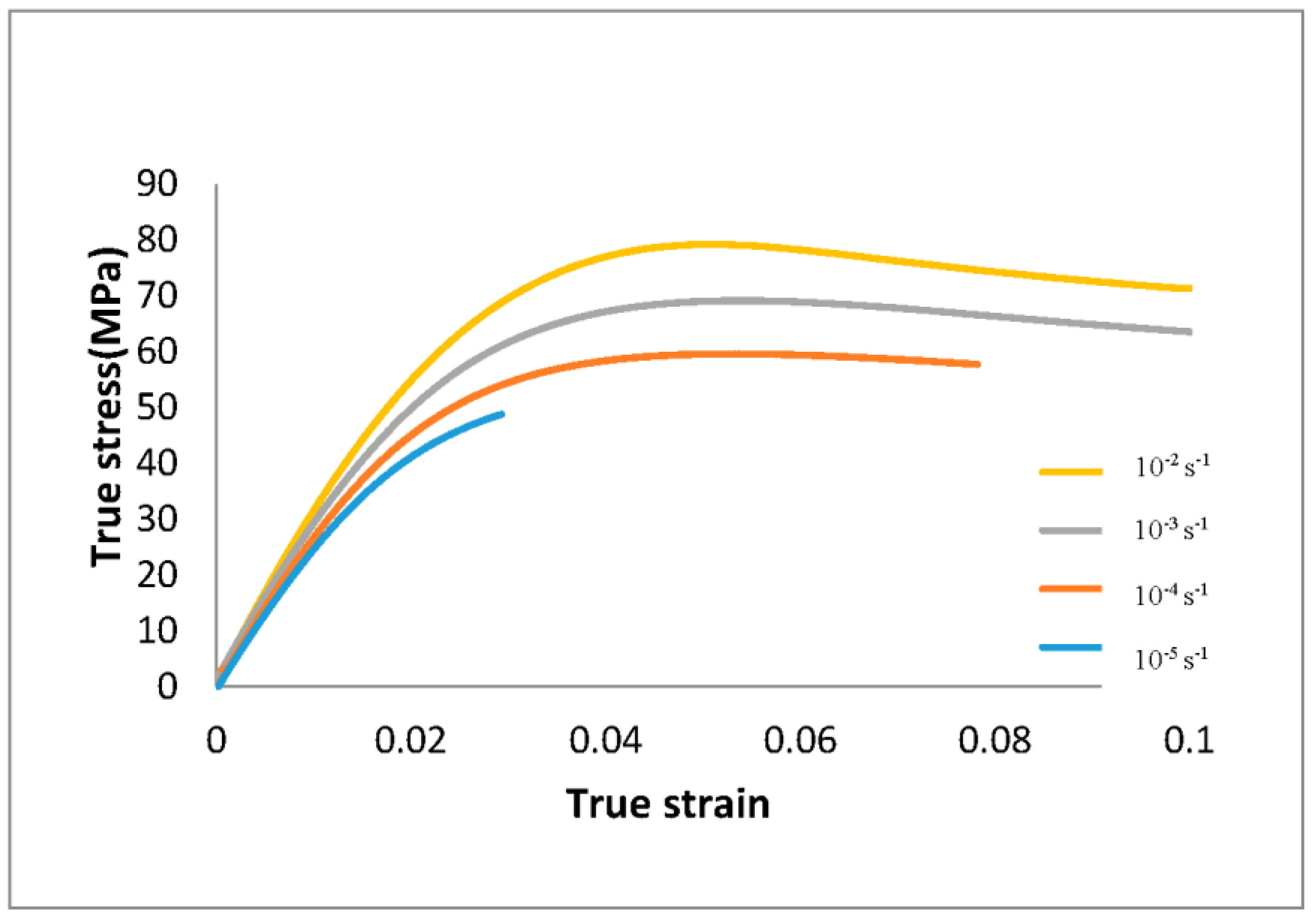

The tension true stress-true strain curves obtained at different strain rates and at room temperature are plotted in

Figure 2. As expected, both the Young’s modulus and the yield stress are seen to increase with increasing strain rate. The material fails in a ductile manner with a necking process while the strain at failure is increasing with increasing strain rate. This shows the strong dependence of mechanical properties of RT-PMMA on strain rate as in [

10]. On the other hand, under tension loading the initially transparent RT-PMMA specimens are subject to progressive stress-whitening, as in [

2,

11]. The stress whitening effect results from rubber particles-PMMA matrix debonding which leads to micro-voiding. The presence of micro-voids provokes light scattering and impairs the initial transparency of the RT-PMMA which progressively becomes opaque.

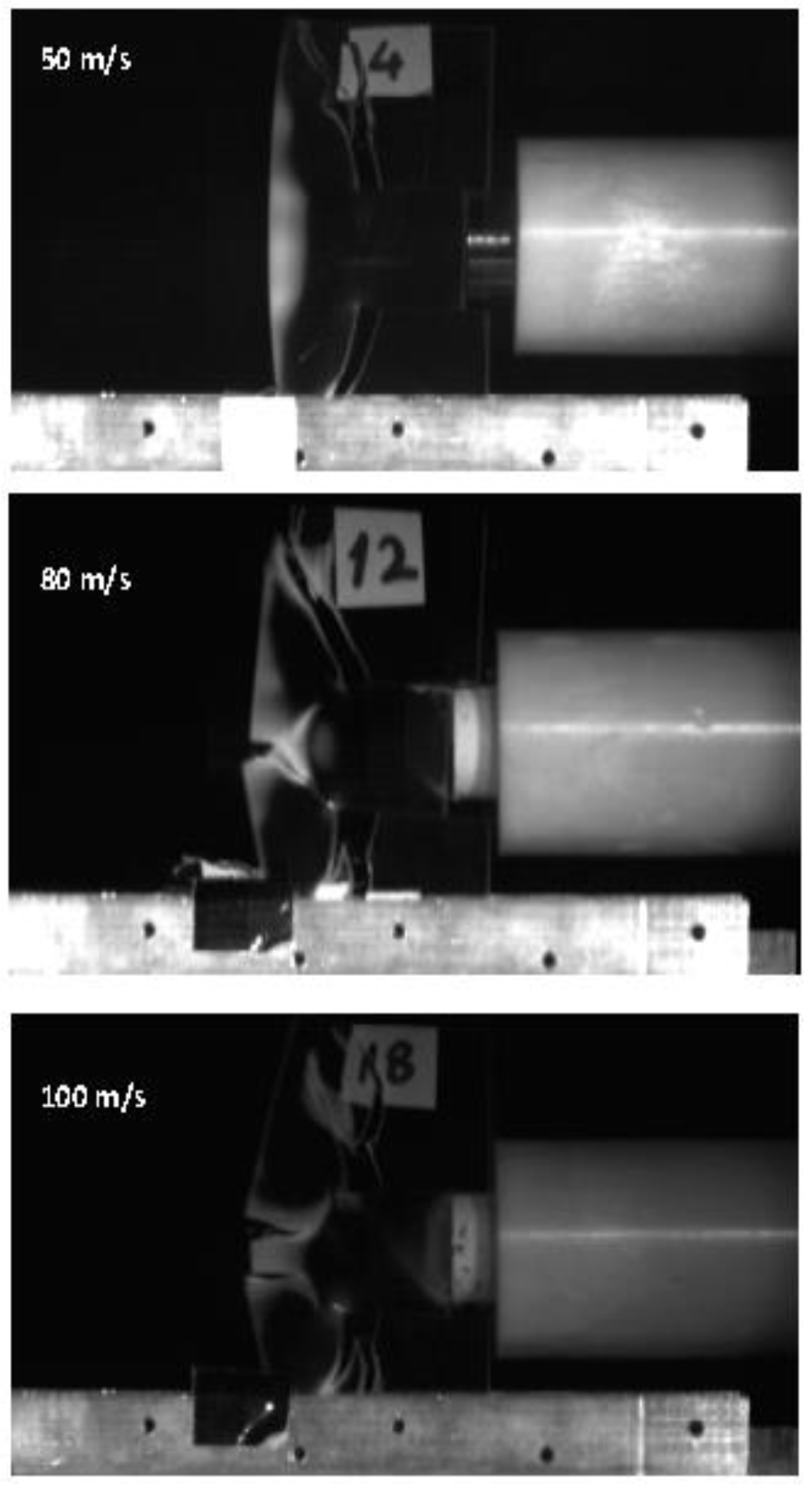

Some frames recorded using the high speed camera during the projectile/plate interaction are shown in

Figure 3. The frames correspond to different impact velocities and have been recorded at the same time after the impact.

According to

Figure 3, whatever the impact velocity, the first cracks initiate from both notches and propagate symmetrically throughout the specimen with an initial angle close to 70° with respect to the notch direction. This angle is typical of brittle failure controlled by normal stress—in the case of ductile failure the cracks propagate (at least initially) in the notch direction, see [

6]. Second cracks initiate from the rear edge of the plates followed by crack branching leading to multi-fragmentation at high velocities.

Stress whitening zones showing areas under tension loading are visible in

Figure 3, in particular near the rear side of the specimen (see the frame for 50 m/s) and also at the tip of the first cracks (not shown here). White localization bands are as well visible, initiating from the second cracks (coming from the rear side) and stopping or leading to crack formation in their wake depending on the impact velocity (see frames for 80 m/s and 100 m/s).

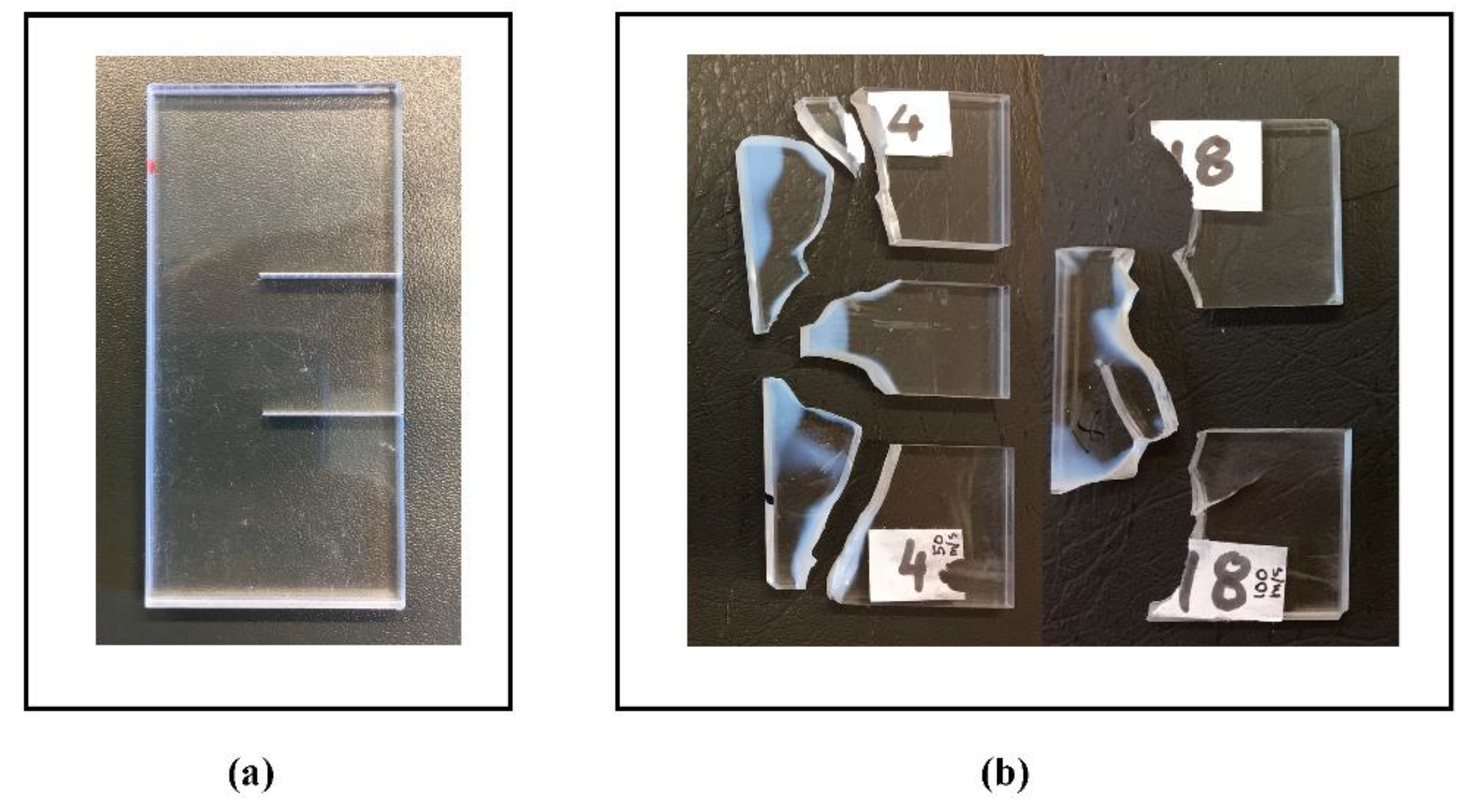

RT-PMMA plates impacted at 100 m/s are damaged giving rise to many fragments of varying sizes. In contrast, for 50 and 80 m/s, only a few large fragments were produced (see

Figure 4).

Figure. 4. KW-type impact tests for the RT-PMMA under consideration. Double notched plates (a) before and (b) after impact loading at 50 m/s (left) and 100 m/s (right).

The specimens under tension loading and the fragments of impacted plates, see

Figure 4, seem to evidence the irreversible feature of the process of micro-voiding induced stress-whitening. However, it can be seen from the frames recorded using the high-speed camera that some regions of the plates may become partially white (or grey) at the passage of the stress waves then recover their transparency after the passage of the stress waves. Thus, micro-voiding induced stress-whitening actually seems to be (at least partially) a reversible process. Micro-void opening indeed results from de-bonding which implies the failure of chemical bonds whereas the micro-void closure is merely a gap closure without chemical bonds recovery.

4. Conclusions

Crack arrest capability is an important characteristic for a structure especially when the latter undergoes dynamic loading as encountered during accidental events. Addition of rubber to PMMA matrix aids to enhance the toughness by dissipating a part of the impact (kinetic) energy. Low impact velocities result in less number of fragments. The cavitation and internal de-bonding of rubber particles during impact may contribute to dense stress-whitening of some regions of the structure.