Constructing a Transparent Air Chamber for an Innovative Ventilation System in an Operating Room †

Abstract

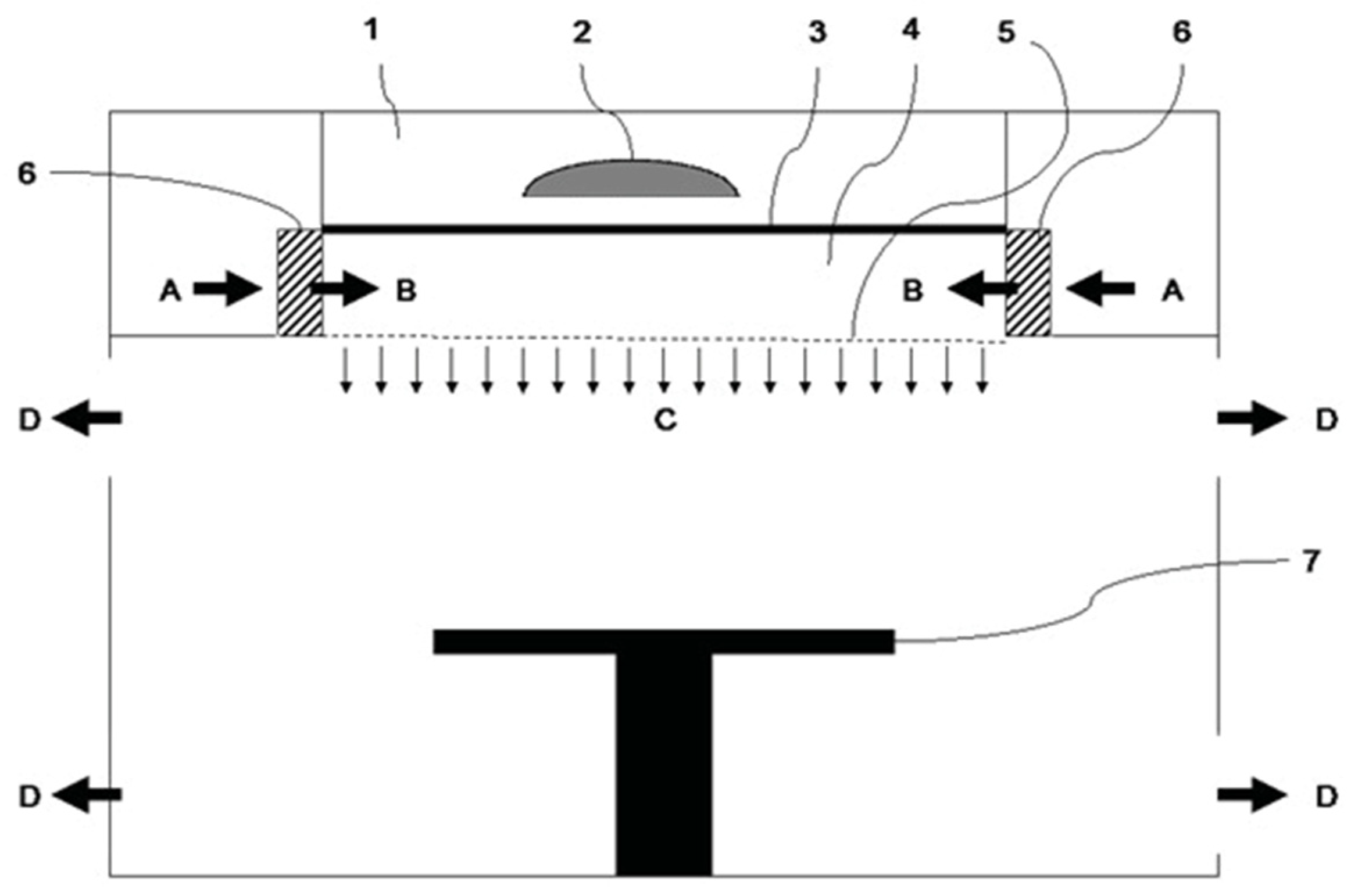

:1. Introduction

2. Structural Analysis of the Transparent Surfaces

2.1. Material

2.2. Partitioning

2.3. Polycarbonate Plates

2.4. Inner Supporting Beams

3. Optical Assessment

- a measurement plane of 60 × 60 cm located at ground level to plot the illuminance on a 128 × 128 pixels grid

- The mounting structure of the chamber, defined with a reflectance of 0.4 and an absorbance of 0.60 corresponding to stainless steel [14]. Its lower and upper sides are respectively located at 1.50 m and 2.20 m.

- A lighting system representing the configuration proposed by [7] for the surgical luminaire: 214 LEDs arranged in concentric regular polygons in a single plane around a center. The diameter of the system is 85 cm. Each LED has a luminous flux of 60 lumen equipped with focusing optics, resulting in an intensity distribution with a FWHM of 7° for each LED. Rays of monochromatic light with a wavelength λ = 546.1 nm are used. It is located at a distance of 2.70 m from the center point of the measurement plane. The incident angle varies among 0°, 12° and 24° for a center of the lighting system along the z axis and the diagonal of the chamber (Figure 2), totaling 5 studied positions.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ramachandran, S.; Research Associate Healthcare (EMEA). Surgical Site Infections in Europe—Paying too High a Price. Available online: http://www.frost.com/prod/servlet/market-insight-print.pag?docid=85996734 (accessed on 29 April 2018).

- Tartari, E.; Weterings, V.; Gastmeier, P.; Baño, J.R.; Widmer, A.; Kluytmans, J.; Voss, A. Patient engagement with surgical site infection prevention: An expert panel perspective. Antimicrob. Resist. Infect. Control 2017, 6, 45. [Google Scholar] [CrossRef] [PubMed]

- Nastase, I.; Croitoru, C.; Vartires, A.; Tataranu, L. Indoor Environmental Quality in Operating Rooms: An European Standards Review with Regard to Romanian Guidelines. Energy Procedia 2016, 85, 375–382. [Google Scholar] [CrossRef]

- Aganovic, A.; Cao, G.; Stenstad, L.-I.; Skogås, J.G. Impact of surgical lights on the velocity distribution and airborne contamination level in an operating room with laminar airflow system. Build. Environ. 2017. [Google Scholar] [CrossRef]

- Improved System and Method for Ventilation and Illumination of an Operating Room. Available online: https://patents.google.com/patent/EP3075368A1/sv (accessed on 29 April 2018).

- International Electrotechnical Commission. IEC 60601-2-41: Medical Electrical Equipment Part 2-41: Particular Requirements for Basic Safety and Essential Performance of Surgical Luminaires and Luminaires for Diagnosis; International Electrotechnical Commission: Geneva, Switzerland, 2009. [Google Scholar]

- Jacobs, V.A. Design Considerations for LED Based Surgical Luminaries. Ph.D. Thesis, Vrije Universiteit Brussel, Belgium, Brussels, 2015. [Google Scholar]

- Powel, D. Medical Applications of Polycarbonate. Available online: https://www.mddionline.com/medical-applications-polycarbonate (accessed on 29 April 2018).

- Nau, A.; Scholtes, B.; Rohleder, M.; Nobre, J. Application of the hole drilling method for residual stress analyses in components made of polycarbonate. J. Plast. Technol. 2011, 7, 66–85. [Google Scholar]

- Vereniging Contamination Control Nederland. Nieuwe Richtlijn: Nieuwe ziekenhuisrichtlijn in Zwitserland en Duitsland. VCCN Mag. 2004, 17, 3. [Google Scholar]

- Van Gaever, R. Design Considerations of the Operating Room Ventilation System: A Numerical and Experimental Study. Ph.D. Thesis, Vrije Universiteit Brussel, Belgium, Brussels, 2015. [Google Scholar]

- Equal Flange Tees, Tee Sections Specification, Dimensions, Properties. T Profile Accordance to standard EN 10055:1995. Available online: http://www.b2bmetal.eu/en/pages/index/index/id/64/ (accessed on 29 April 2018).

- European Committee for Standardisation. EN 1993-1-1: Eurocode 3: Design of Steel Structures—Part 1-1: General Rules and Rules for Buildings; European Committee for Standardisation: Brussels, Belgium, 2005. [Google Scholar]

- Lighting Materials for Simulation. Available online: http://lighting-materials.com/ (accessed on 29 April 2018).

| δmax [mm] | Non-Perforated Plates | Perforated Plates | |||

|---|---|---|---|---|---|

| t [mm] | δ [mm] | t [mm] | δ [mm] | ||

| 10 × 10 | 1.25 | 4 | 0.8 | 4 | 0.93 |

| 8 × 8 | 1.56 | 5 | 1.04 | 5 | 1.21 |

| 6 × 6 | 2.08 | 6 | 1.97 | 7 | 1.49 |

| 5 × 5 | 2.50 | 8 | 1.83 | 8 | 2.15 |

| 4 × 4 | 3.12 | 10 | 2.43 | 10 | 2.21 ± 0.017 |

| 3 × 3 | 4.17 | 13 | 3.79 | 14 | 3.62 ± 0.021 |

| Scenario | Profile | MEd [Nm] | Mc,Rd [Nm] | VEd [N] | Vpl,Rd [N] | δ [mm] | δmax [mm] |

|---|---|---|---|---|---|---|---|

| 10 × 10 | T60 | 215 | 1.28 × 103 | 316 | 50.3 × 103 | 2.9 | 3 |

| 8 × 8 | T70 | 281 | 2.07 × 103 | 407 | 67.3 × 103 | 2.0 | 3 |

| 6 × 6 | T70 | 333 | 2.07 × 103 | 473 | 67.3 × 103 | 2.4 | 3 |

| 5 × 5 | T70 | 358 | 2.07 × 103 | 503 | 67.3 × 103 | 2.6 | 3 |

| 4 × 4 | T80 | 480 | 82.5 × 103 | 657 | 82.5 × 103 | 2.1 | 3 |

| 3 × 3 | T80 | 548 | 82.5 × 103 | 720 | 82.5 × 103 | 2.3 | 3 |

| 3 × 3 | 4 × 4 | 5 × 5 | 6 × 6 | 8 × 8 | 10 × 10 | |

|---|---|---|---|---|---|---|

| emax | 22% | 37% | 32% | 26% | 43% | 34% |

| u | 0.60 | 0.50 | 0.56 | 0.47 | 0.55 | 0.48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Desmars, V.; Hemelrijck, D.V.; Jacobs, V.A. Constructing a Transparent Air Chamber for an Innovative Ventilation System in an Operating Room. Proceedings 2018, 2, 376. https://doi.org/10.3390/ICEM18-05199

Desmars V, Hemelrijck DV, Jacobs VA. Constructing a Transparent Air Chamber for an Innovative Ventilation System in an Operating Room. Proceedings. 2018; 2(8):376. https://doi.org/10.3390/ICEM18-05199

Chicago/Turabian StyleDesmars, Victorien, Danny Van Hemelrijck, and Valéry Ann Jacobs. 2018. "Constructing a Transparent Air Chamber for an Innovative Ventilation System in an Operating Room" Proceedings 2, no. 8: 376. https://doi.org/10.3390/ICEM18-05199

APA StyleDesmars, V., Hemelrijck, D. V., & Jacobs, V. A. (2018). Constructing a Transparent Air Chamber for an Innovative Ventilation System in an Operating Room. Proceedings, 2(8), 376. https://doi.org/10.3390/ICEM18-05199