Dynamics of the Golf Club-Grip Interaction †

Abstract

:1. Introduction

2. Materials and Methods

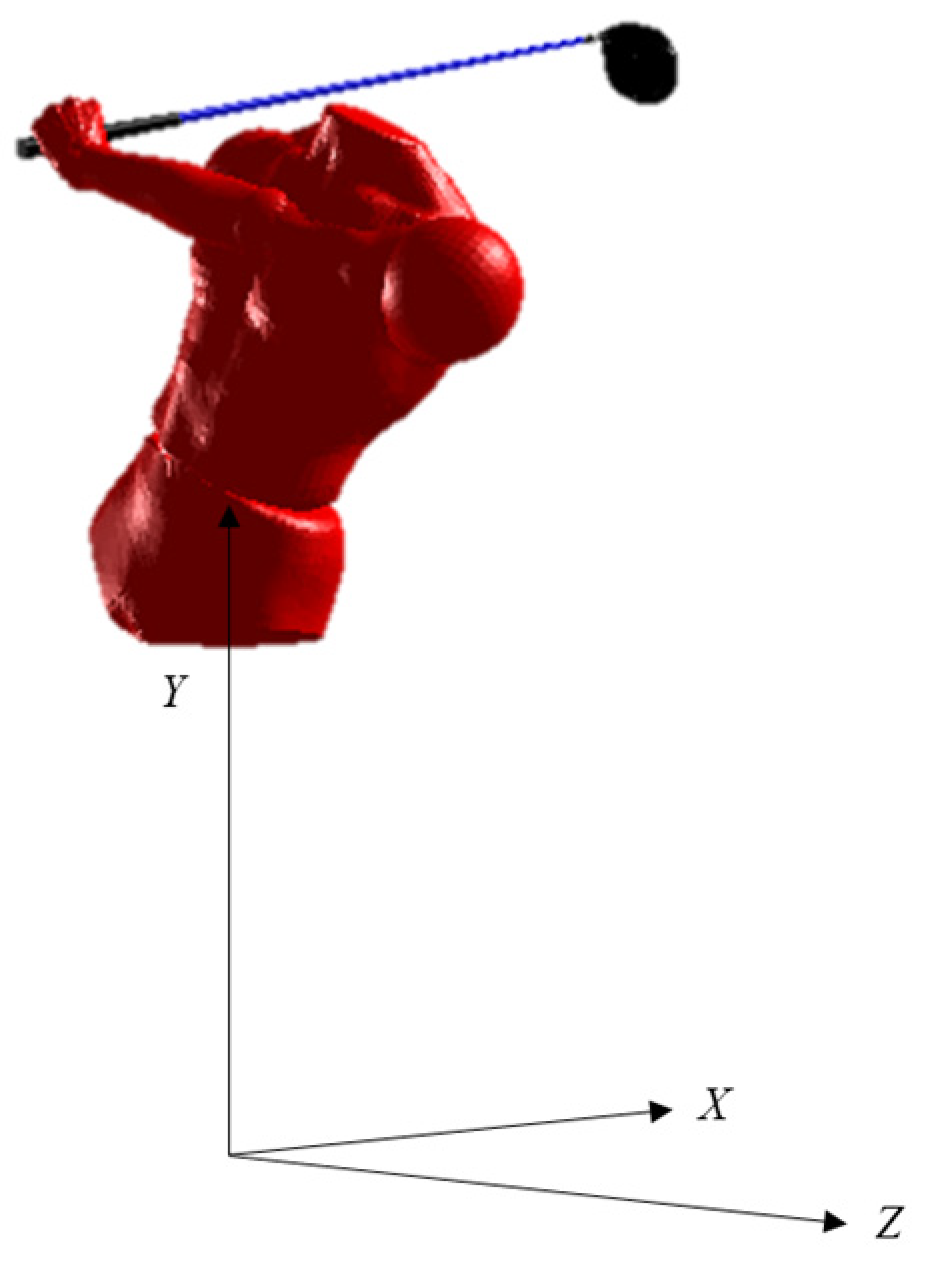

2.1. Golfer Model

2.2. Grip Model

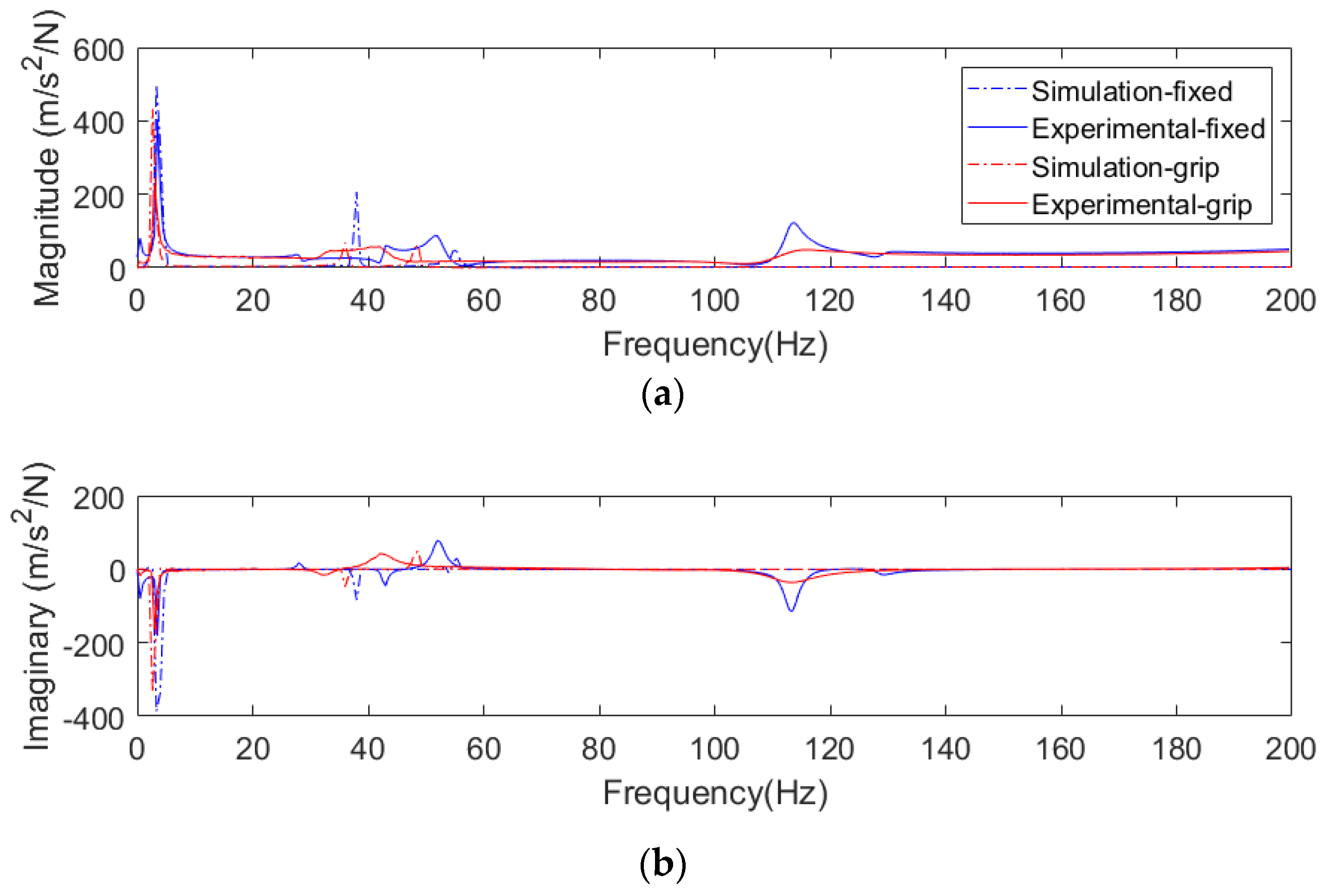

2.3. Modal Analysis

Comparison of Experiment to Simulation

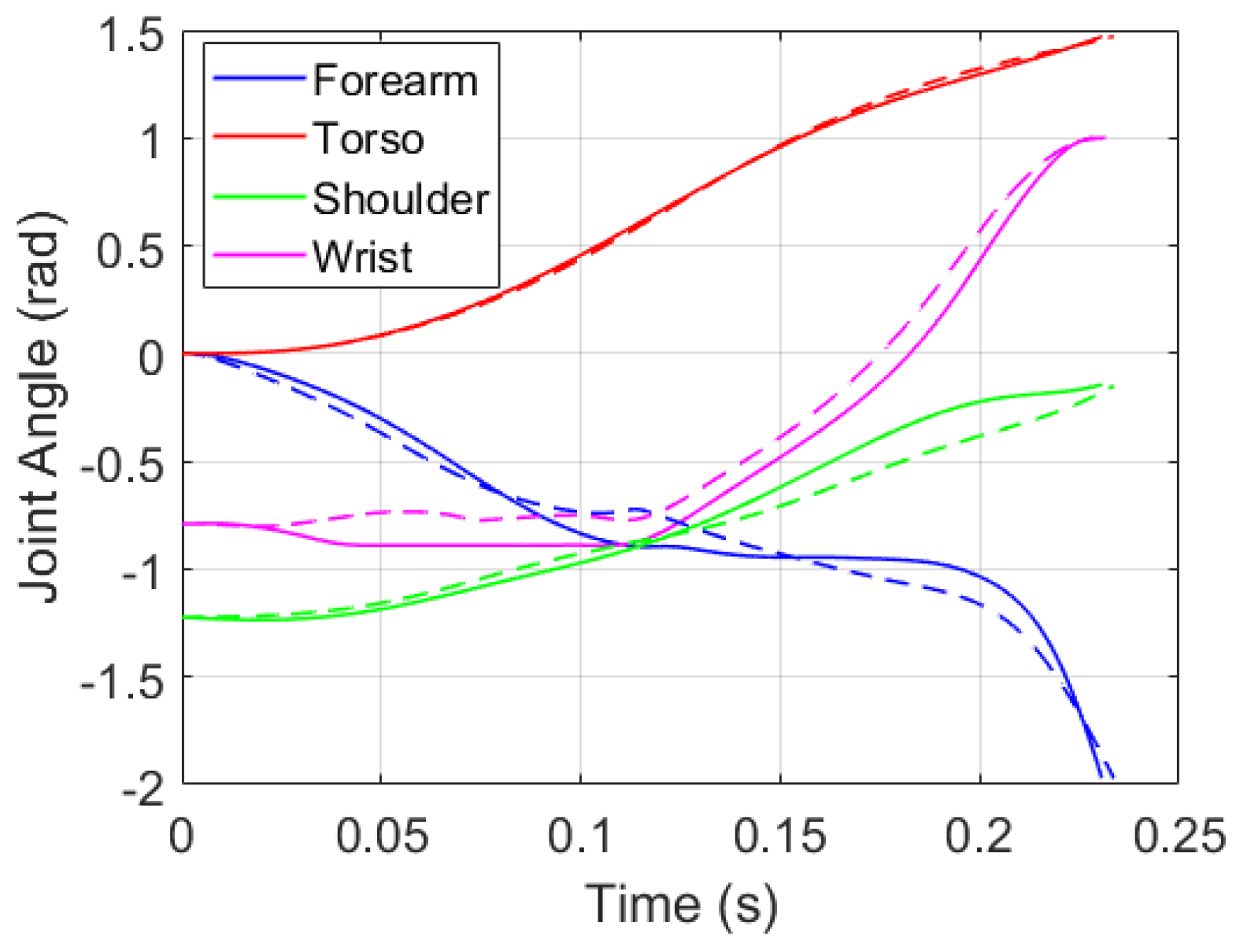

2.4. Optimization Method

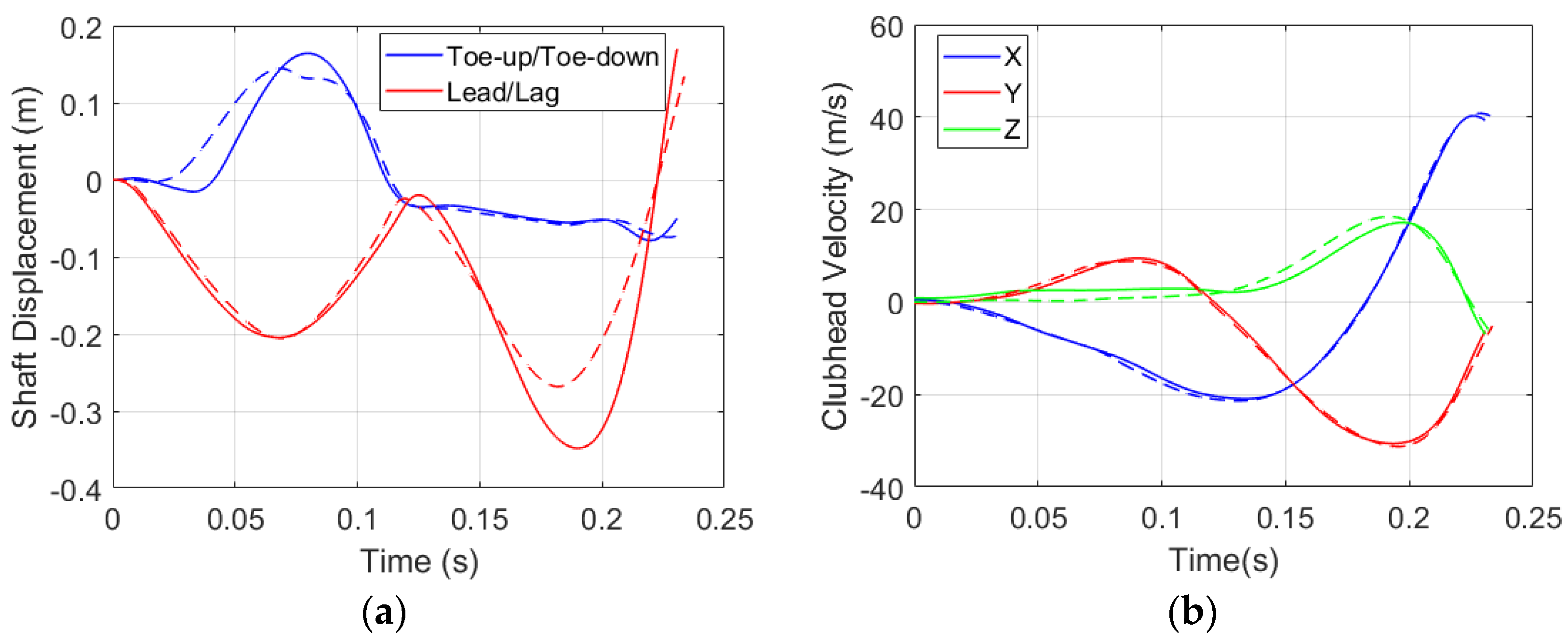

3. Results and Discussion

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Betzler, N.; Monk, S.; Wallace, E.; Otto, S.R.; Shan, G. From the double pendulum model to full-body simulation: Evolution of golf swing modeling. Sport. Technol. 2008, 1, 175–188. [Google Scholar] [CrossRef]

- MacKenzie, S.J.; Sprigings, E.J. A three-dimensional forward dynamics model of the golf swing. Sport. Eng. 2009, 11, 165–175. [Google Scholar] [CrossRef]

- Balzerson, D.; Banerjee, J.; McPhee, J. A three-dimensional forward dynamic model of the golf swing optimized for ball carry distance. Sport. Eng. 2016, 19, 237–250. [Google Scholar] [CrossRef]

- McNally, W.; McPhee, J. Dynamic optimization of the golf swing using a six degree-of-freedom biomechanical model. Proceedings 2018. [Google Scholar] [CrossRef]

- De Groote, F.; Kinney, A.L.; Rao, A.V.; Fregly, B.J. Evaluation of direct collocation optimal control problem formulations for solving the muscle redundancy problem. Ann. Biomed. Eng. 2016, 44, 2922–2936. [Google Scholar] [CrossRef] [PubMed]

- Sandhu, S.; Millard, M.; McPhee, J.; Brekke, D. 3D dynamic modelling and simulation of a golf drive. Procedia Eng. 2010, 2, 3243–3248. [Google Scholar] [CrossRef]

- Chadefaux, D.; Rao, G.; le Carrou, J.; Berton, E.; Vigouroux, L. The effects of player grip on the dynamic behaviour of a tennis racket. J. Sports Sci. 2016, 35, 1155–1164. [Google Scholar] [CrossRef] [PubMed]

- Englel, J. Tennis: Dynamics of racket-grip interaction. J. Hand Surg. Am. 1995, 20, 77–81. [Google Scholar] [CrossRef]

- Rossi, J.; Foissac, M.J.; Vigouroux, L.; Berton, E. The effect of tennis racket grip size on grip force during a simulated tennis match play. Comput. Methods Biomech. Biomed. Eng. 2009, 12, 219–220. [Google Scholar] [CrossRef]

- Savage, N.; Subic, A. Relating grip characteristics to the dynamic response of Tennis racquets. Eng. Sport 6 2006, 6, 155–160. [Google Scholar]

- Hocknell, A.; Mitchell, S.R.; Jones, R.; Rothberg, S.J. Hollow golf club head modal characteristics: Determination and impact applications. Exp. Mech. 1998, 38, 140–146. [Google Scholar] [CrossRef]

- Sprigings, E.J.; Neal, R.J. An insight into the importance of wrist torque in driving the golfball: A simulation study. J. Appl. Biomech. 2000, 16, 356–366. [Google Scholar] [CrossRef]

- Bastian, A.J.; Zackowski, K.M.; Thach, W.T. Cerebellar ataxia: Torque deficiency or torque mismatch between joints? . J. Neurophysiol. 2000, 83, 3019–3030. [Google Scholar] [CrossRef] [PubMed]

- Lampsa, M.A. Maximizing distance of the golf drive: An optimal control study. J. Dyn. Syst. Meas. Control 1975, 97, 362–367. [Google Scholar] [CrossRef]

- Jorgensen, T.P. The Physics of Golf, 2nd ed.; Springer-Verlsg: New York, NY, USA, 1999. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brown, C.; McPhee, J. Dynamics of the Golf Club-Grip Interaction. Proceedings 2018, 2, 239. https://doi.org/10.3390/proceedings2060239

Brown C, McPhee J. Dynamics of the Golf Club-Grip Interaction. Proceedings. 2018; 2(6):239. https://doi.org/10.3390/proceedings2060239

Chicago/Turabian StyleBrown, Colin, and John McPhee. 2018. "Dynamics of the Golf Club-Grip Interaction" Proceedings 2, no. 6: 239. https://doi.org/10.3390/proceedings2060239

APA StyleBrown, C., & McPhee, J. (2018). Dynamics of the Golf Club-Grip Interaction. Proceedings, 2(6), 239. https://doi.org/10.3390/proceedings2060239