Sustainability Enhancement of a Biomass Boiler through Exergy Analysis †

Abstract

:1. Introduction

2. Methods

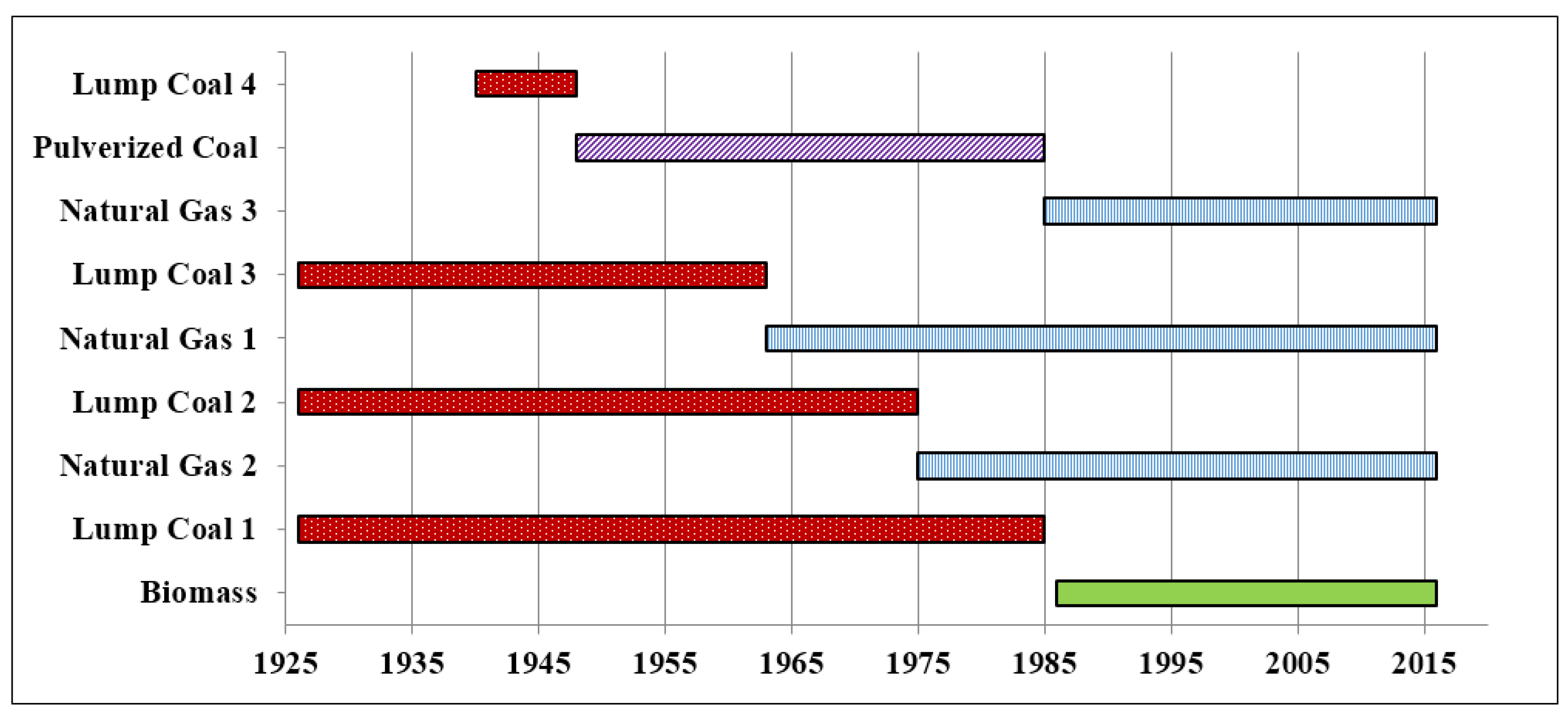

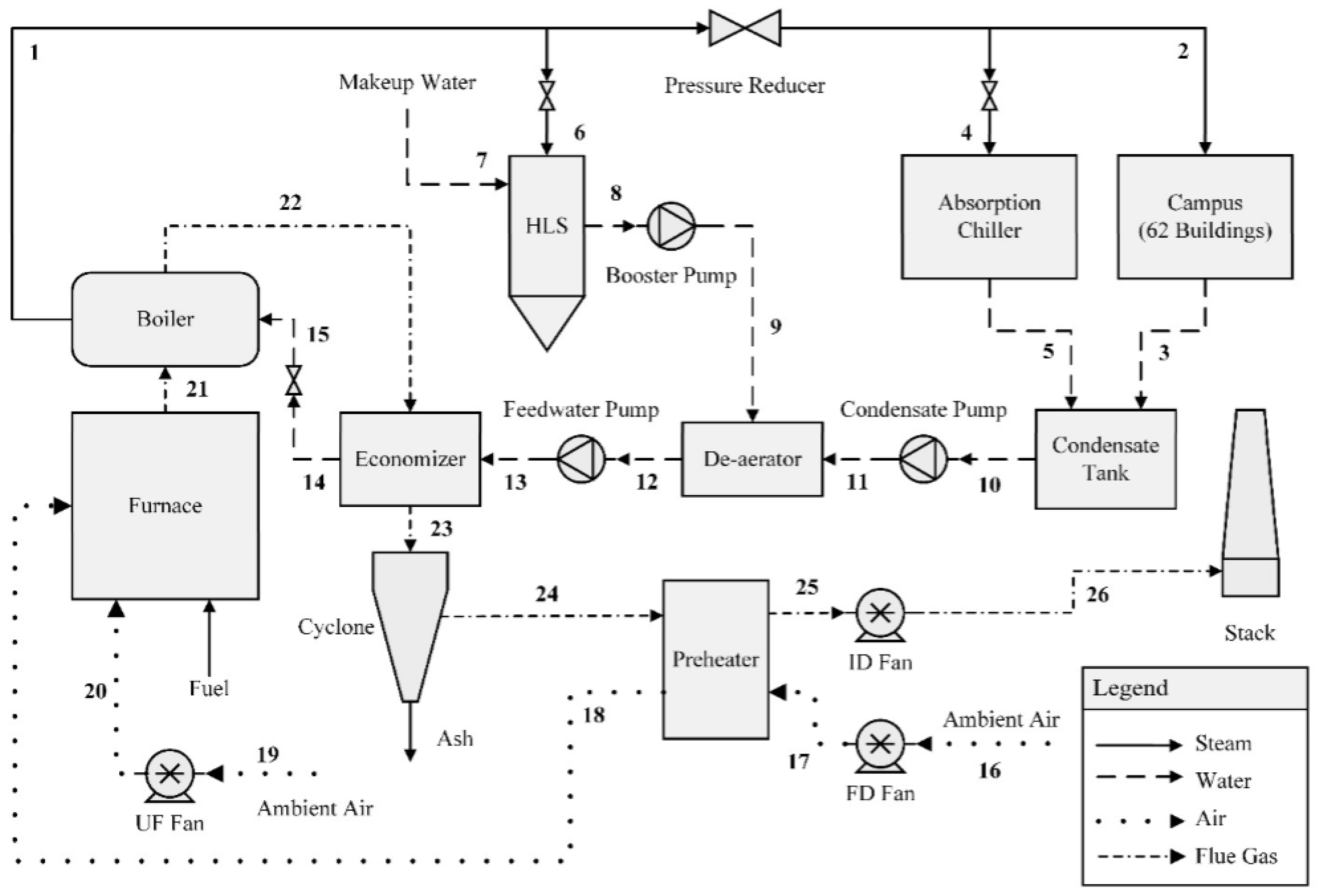

3. Case Study: University of Idaho

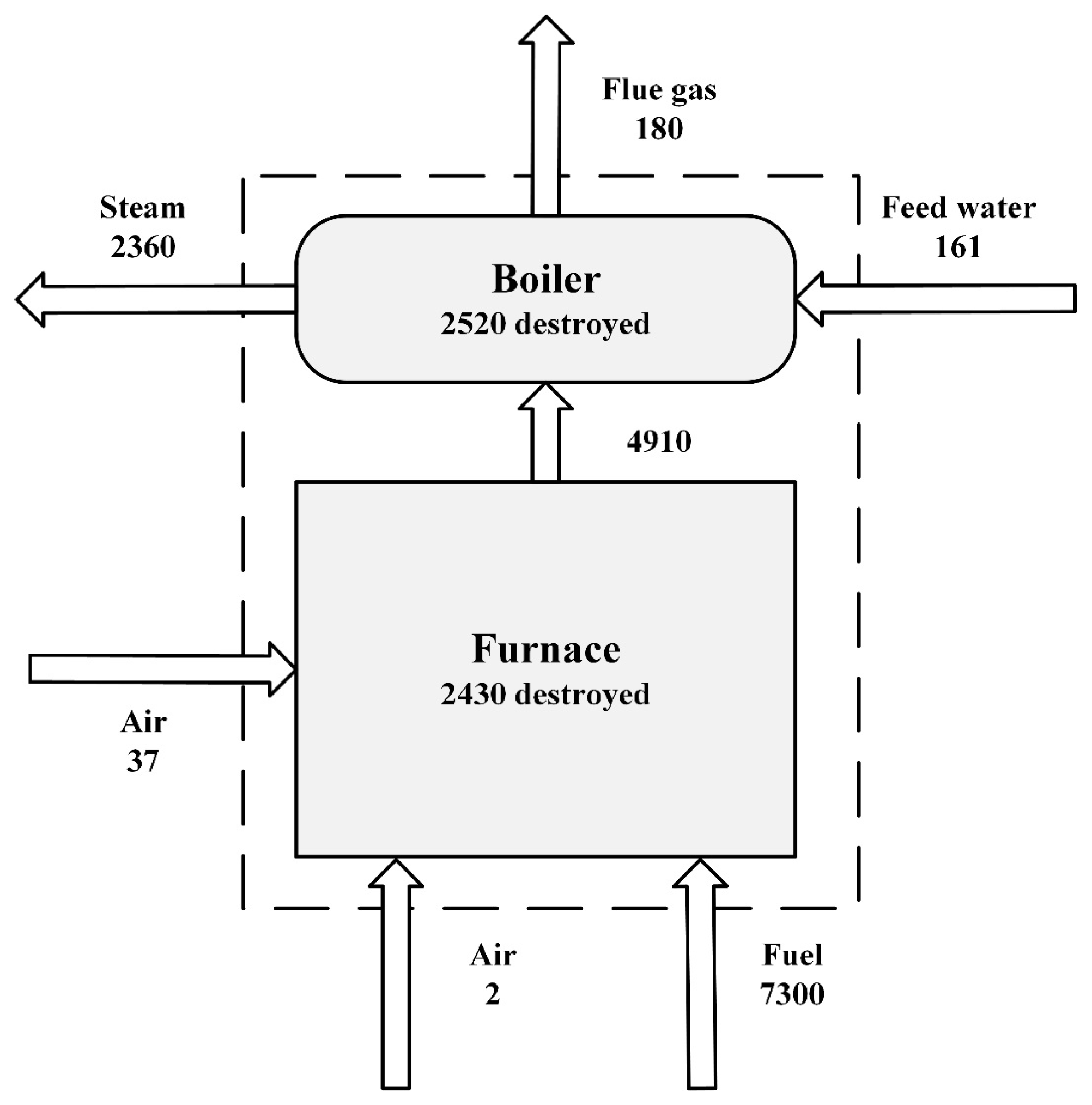

4. Analysis

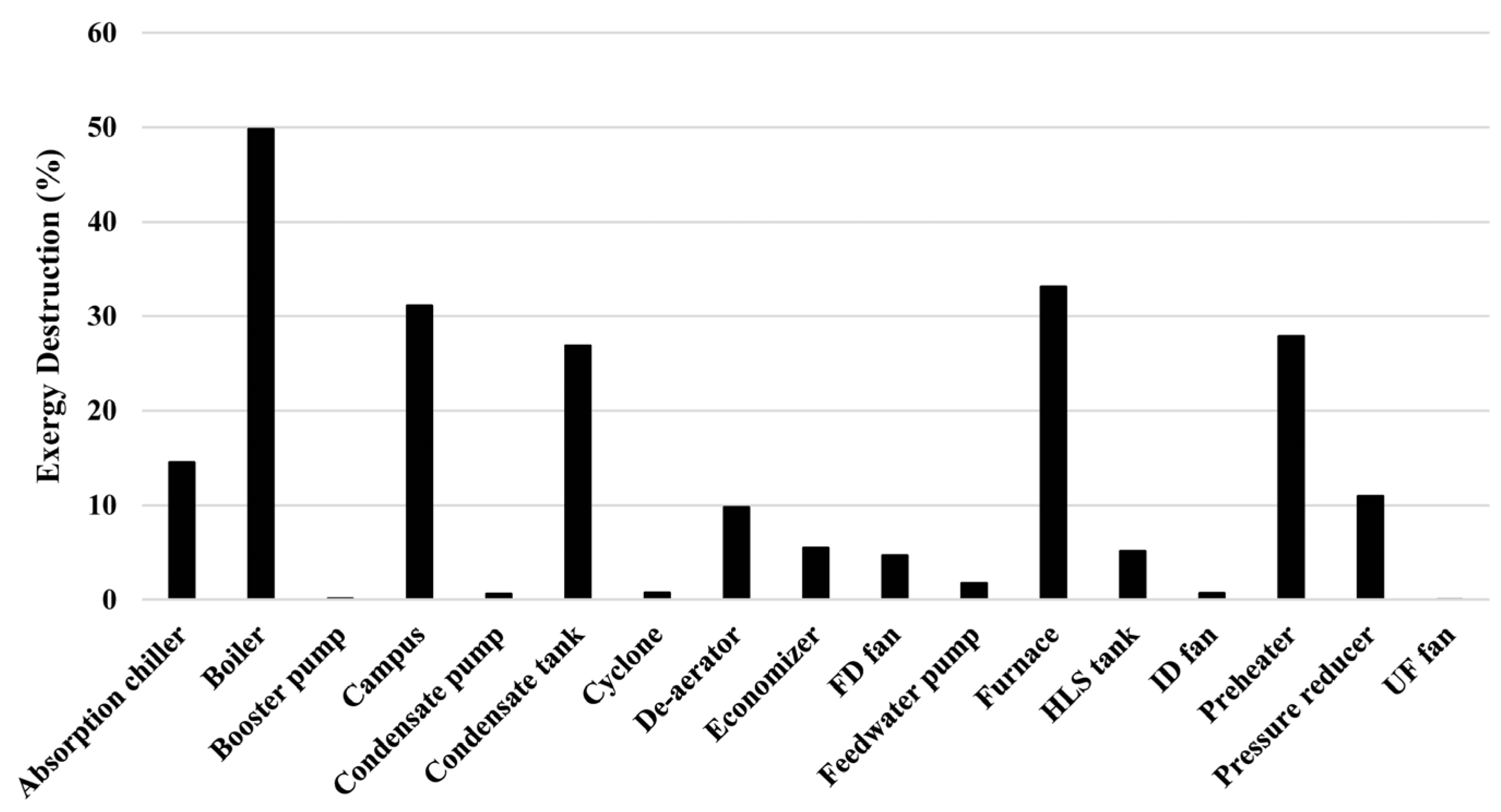

5. Results and Discussion

6. Conclusions

Acknowledgments

Nomenclature

| AF | Air Fuel Ratio |

| boost | booster |

| Cond | condensate |

| CT | condensate tank |

| DA | de-aerator |

| DE | district energy |

| η | efficiency |

| econ | economizer |

| FD | forced draft |

| feed | feed water |

| g | gravitational constant |

| GHG | greenhouse gas |

| h | specific enthalpy (kJ/kg) |

| HLS | hot lime softener |

| HV | heating value (kJ/kg) |

| ID | induced draft |

| mass flow rate (kg/s) | |

| P | pressure (kPa) |

| PH | air preheater |

| PR | Pressure Reducer |

| ψ | specific exergy (kJ/kg) |

| PTA | percent theoretical air |

| heat transfer rate (kW) | |

| s | specific entropy (kJ/kg-K) |

| T | temperature (K) |

| TES | thermal energy storage |

| UF | under-fire |

| V | velocity (m/s) |

| exergy rate (kW) | |

| z | height (m) |

| Subscripts | |

| 0 | reference property |

| act | Actual |

| des | destroyed |

| f | Flow |

| X | Exergy |

References

- U.S. Environmental Protection Agency. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2014; U.S. Environmental Protection Agency: Washington, DC, USA, 2016.

- Graedel, T.E.; Allenby, B.R. Industrial Ecology and Sustainable Engineering; Prentice Hall: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Rezaie, B.; Rosen, M.A. District heating and cooling: Review of technology and potential enhancements. Appl. Energy 2012, 93, 2–10. [Google Scholar] [CrossRef]

- Nijjar, J.S.; Fung, A.S.; Hughes, L.; Taherian, H. District heating system design for rural Nova Scotian communities using building simulation and energy usage databases. Trans. Can. Soc. Mech. Eng. 2009, 33, 51–63. [Google Scholar] [CrossRef]

- Lake, A.; Rezaie, B.; Beyerlein, S. Review of district heating and cooling systems for a sustainable future. Renew. Sustain. Energy Rev. 2017, 67, 417–425. [Google Scholar] [CrossRef]

- Dincer, I. The role of exergy in energy policy making. Energy Policy 2002, 30, 137–149. [Google Scholar] [CrossRef]

- Regulagadda, P.; Dincer, I.; Naterer, G.F. Exergy analysis of a thermal power plant with measured boiler and turbine losses. Appl. Therm. Eng. 2010, 30, 8–9. [Google Scholar] [CrossRef]

- Torío, H.; Angelotti, A.; Schmidt, D. Exergy analysis of renewable energy-based climatisation systems for buildings: A critical view. Energy Build. 2009, 41, 248–271. [Google Scholar] [CrossRef]

- Sengupta, S.; Datta, A.; Duttagupta, S. Exergy analysis of a coal-based 210 MW thermal power plant. Int. J. Energy Res. 2007, 31, 14–38. [Google Scholar] [CrossRef]

- Ayres, R.U.; Ayres, L.; Martinas, K. Eco-thermodynamics: Exergy and Life Cycle Analysis; INSEAD: Fontainebleau, France, 1996; pp. 1–22. [Google Scholar]

- Rosen, M.A.; Dincer, I. Exergy as the confluence of energy, environment and sustainable development. Exergy Int. J. 2001, 1, 3–13. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M.A. A worldwide perspective on energy, environment and sustainable development. Int. J. Energy Res. 1998, 22, 1305–1321. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M.A. Energy, environment and sustainable development. Appl. Energy 1999, 64, 427–440. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M.A. Thermodynamic aspects of renewables and sustainable development. Renew. Sustain. Energy Rev. 2005, 9, 169–189. [Google Scholar] [CrossRef]

- Kallert, A.; Schmidt, D.; Bläse, T. Exergy-based analysis of renewable multi-generation units for small scale low temperature district heating supply. Energy Procedia 2017, 116, 13–25. [Google Scholar] [CrossRef]

- Compton, M.; Rezaie, B. Enviro-exergy sustainability analysis of boiler evolution in district energy system. Energy 2017, 119, 257–265. [Google Scholar] [CrossRef]

- Energy and Environmtental Analysis Inc. Characterization of the U.S. Industrial/Commercial Boiler Population; Energy and Environmtental Analysis Inc.: Arlington, VA, USA, 2005. [Google Scholar]

- Behbahaninia, A.; Ramezani, S.; Hejrandoost, M.L. A loss method for exergy auditing of steam boilers. Energy 2017, 140, 253–260. [Google Scholar] [CrossRef]

- Terhan, M.; Comakli, K. Energy and exergy analyses of natural gas-fired boilers in a district heating system. Appl. Therm. Eng. 2017, 121, 380–387. [Google Scholar] [CrossRef]

- Da Silva, J.; Filho, S.Á.; Carvalho, M. Assessment of energy and exergy efficiencies in steam generators. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 3217–3226. [Google Scholar] [CrossRef]

- Gürtürk, M.; Oztop, H.F. Exergy analysis of a circulating fluidized bed boiler cogeneration power plant. Energy Convers. Manag. 2016, 120, 346–357. [Google Scholar] [CrossRef]

- Sciubba, E. Beyond thermoeconomics? The concept of extended exergy accounting and its application to the analysis and design of thermal systems. Exergy Int. J. 2001, 1, 68–84. [Google Scholar] [CrossRef]

- Dewulf, J.; Boesch, M.E.; de Meester, B.; van der Vorst, G.; van Langenhove, H.; Hellweg, S.; Huijbregts, M.A.J. Supporting information: Cumulative exergy extraction from the natural environment (CEENE): A comprehensive life cycle impact assessment method for resource accounting. Environ. Sci. Technol. 2007, 41, 8477–8483. [Google Scholar] [CrossRef]

- Gaggioli, R.A. The dead state. Int. J. Thermophys. 2012, 15, 191–199. [Google Scholar] [CrossRef]

- Kanoglu, M.; Dincer, I.; Rosen, M.A. Understanding energy and exergy efficiencies for improved energy management in power plants. Energy Policy 2007, 35, 3967–3978. [Google Scholar] [CrossRef]

- Wilson, P.L.; Funck, J.W.; Avery, R.B. Fuelwood Characteristics of Northwestern Conifers and Hardwoods (Updated); U.S. Department of Agriculture, Forest Service: Portland, OR, USA, 2010.

| Component | Biomass | NG 1 | NG 2 | NG 3 |

|---|---|---|---|---|

| Multi-cone cyclonic separator | X | |||

| Economizer | X | X | ||

| Air Pre-heater | X | X | ||

| New (<3 years) Burner Package | X |

| Point | (kg/s) | T (K) | P (kPa) | h (kJ/kg) | s (kJ/kg-K) | (kJ/kg) |

|---|---|---|---|---|---|---|

| Dead state | - | 294.2 | 91.7 | 88.18 | 0.3107 | - |

| Inlet (water) | 3.878 | 294.2 | 1034 | 88.1 | 0.3107 | 0 |

| Outlet (steam) | 3.878 | 454.5 | 1034 | 2778 | 6.573 | 848 |

| Point | (kg/s) | T (K) | P (kPa) | h (kJ/kg) | s (kJ/kg-K) | (kJ/kg) |

|---|---|---|---|---|---|---|

| 0 | - | 300.4 | 101.7 | 114.2 | 0.3982 | - |

| 1 | 2.949 | 452 | 977.3 | 2776 | 6.593 | 801.3 |

| 2 | 1.876 | 426.1 | 515.4 | 2749 | 6.811 | 709.2 |

| 3 | 1.819 | 373.2 | 101.7 | 419.5 | 1.308 | 31.99 |

| 4 | 0.9412 | 390.8 | 184.4 | 2703 | 7.154 | 559.1 |

| 5 | 0.9412 | 373.2 | 101.7 | 419.5 | 1.308 | 31.99 |

| 6 | 0.132 | 387.8 | 167.2 | 2698 | 7.187 | 544.8 |

| 7 | 0.05627 | 295.9 | 667.1 | 96.15 | 0.3358 | 0.7061 |

| 8 | 0.1882 | 385.4 | 223 | 470.8 | 1.443 | 42.71 |

| 9 | 0.1882 | 385.4 | 632.6 | 471.4 | 1.443 | 43.23 |

| 10 | 2.761 | 362.0 | 116.6 | 372.4 | 1.18 | 23.39 |

| 11 | 2.761 | 362.1 | 377.5 | 372.9 | 1.18 | 23.69 |

| 12 | 2.949 | 385.4 | 155.4 | 471.7 | 1.445 | 42.9 |

| 13 | 2.949 | 385.9 | 1625 | 474.2 | 1.448 | 44.67 |

| 14 | 2.949 | 396.5 | 1625 | 519 | 1.562 | 55.06 |

| 15 | 2.949 | 396.5 | 977.3 | 518.5 | 1.563 | 54.43 |

| 16 | 3.246 | 314.8 | 101.7 | 315.2 | 6.914 | 0.3389 |

| 17 | 3.246 | 315.3 | 102.1 | 315.7 | 6.914 | 0.7382 |

| 18 | 3.246 | 387 | 102.1 | 388.2 | 7.121 | 10.97 |

| 19 | 0.5127 | 300.4 | 101.7 | 300.7 | 6.867 | - |

| 20 | 0.5127 | 300.8 | 102.1 | 303.8 | 6.867 | 2.996 |

| 21 | 4.295 | 1829 | 101.7 | 2040 | 8.853 | 1143 |

| 22 | 4.295 | 486.5 | 101.7 | 489.5 | 7.356 | 41.98 |

| 23 | 4.295 | 456.5 | 101.7 | 458.8 | 7.291 | 30.84 |

| 24 | 4.292 | 456.5 | 101.4 | 458.8 | 7.291 | 30.63 |

| 25 | 4.292 | 402.7 | 101.4 | 404 | 7.164 | 14.19 |

| 26 | 4.292 | 403.2 | 101.7 | 404.5 | 7.164 | 14.54 |

| Boiler | Thermal | Exergy |

|---|---|---|

| Biomass | 76% | 24% |

| NG 1 | 85% | 27% |

| NG 2 | 78% | 25% |

| NG 3 | 85% | 27% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Compton, M.; Rezaie, B. Sustainability Enhancement of a Biomass Boiler through Exergy Analysis. Proceedings 2018, 2, 159. https://doi.org/10.3390/ecea-4-05012

Compton M, Rezaie B. Sustainability Enhancement of a Biomass Boiler through Exergy Analysis. Proceedings. 2018; 2(4):159. https://doi.org/10.3390/ecea-4-05012

Chicago/Turabian StyleCompton, Marc, and Behnaz Rezaie. 2018. "Sustainability Enhancement of a Biomass Boiler through Exergy Analysis" Proceedings 2, no. 4: 159. https://doi.org/10.3390/ecea-4-05012

APA StyleCompton, M., & Rezaie, B. (2018). Sustainability Enhancement of a Biomass Boiler through Exergy Analysis. Proceedings, 2(4), 159. https://doi.org/10.3390/ecea-4-05012