Abstract

Brewing industry generates a main residue, brewers’ spent grain (BSG), which has good properties both for use in animal consumption and for thermal use, but contains a very high content of moisture (20–25% dry matter content), so that its elimination or treatment should be immediate, since it can cause degeneration problems of the product. Currently, brewers often supply this material at low cost for use as livestock feed. This solution is not efficiently carried out without reporting too much benefit to the brewers more than to eliminate waste from their facilities. However, BSG is a raw material of interest for application in different areas due to its low price, availability throughout the year and a valuable chemical composition, so it seems necessary to look for an alternative use to give value to these characteristics. In this paper a drying study is carried out in order to establish the foundations for its energy use by thermal of BSG. BSG has been used from a craft brewery located at Badajoz, Spain. Drying analysis was carried out for various temperatures and inlet air flow by means a convective dryer. The properties studied show that BSG can be used for thermal utilization in large installations, being necessary heat drying processes as a pretreatment in order to obtain a biofuel with acceptable efficiency.

1. Introduction

Brewing industry appears as a very prominent sector in the Spanish economy. Internationally, Spain is the fourth largest producer of beer in the European Union, and eleventh in the world. In 2017, companies in the beer sector sold 35.7 million hectoliters, 3.8% more than the previous year [1].

During the manufacturing process, in mashing phase, its main residue is generated: brewers’ spent grain (BSG). The quantities of this by-product are increasingly important. If for every 10 L of beer produced, approximately 2 kg of BSG is obtained [2], 714,000 t per year would be obtained in Spain.

BSG is a wet product with a dry matter content of 20–25%. Due to this, the main and quickest alternative for its elimination is to use in animal feed [3,4,5,6]. However, BSG is a raw material of interest for application in different areas due to its low price, availability throughout the year and a valuable chemical composition, so it seems necessary to look for an alternative efficient use to give value to its characteristics.

In this paper, a drying study is carried out in order to establish the foundations for its energy use by thermal of BSG.

2. Materials and Methods

The BSG used in this study was collected from a craft brewery located in Badajoz (Spain). Initial moisture was previously analyzed, resulting in an average of 72.5%, approximately.

Drying Analysis

The drying tests for BSG were carried out through a convective dryer (CE130, Gunt Hamburg, Badajoz, Spain), composed of four removable stainless steel trays, a drying channel (in order to heat the product and remove moisture), flow control through a heatable fan and a digital balance to record weight loss.

The procedure was the following: around 250 g of waste was spread on each of the four trays (1 kg in total), so that the thickness of sample on each tray was less than 1 cm. Several tests were carried out, with different drying air velocities (v = 0.8, 1.2 and 1.6 m s−1) and temperatures (T = 30, 40 and 50 °C). Tests were carried out are shown in Table 1.

Table 1.

Tests carried out.

Through experimental tests, moisture ratio was obtained. Using the Fick’s diffusion equation for flat geometry, the characteristic dimension and properties of the product, effective diffusivity and activation energy parameters were calculated.

The effective diffusivity is a fundamental parameter in drying processes. Using experimental tests, it is possible to obtain the moisture ratio, MR, by direct taking. The variation of this ratio is closely associated with the Fick’s diffusion equation. The analytical solution of Fick’s second law for flat geometry and for long periods y MR values < 0.6 [7,8] can be simplified and obtain equation:

where Deff is the effective diffusivity (m2 s−1); L the characteristic dimension of the “thin layer” product (m); and t is the drying time.

A general form of equation can be written in logarithmic form (Equation (1)), from an equation of the type LN (MR) = A + Bt, where the constant B is the slope of the line of Equation (1).

In order to determine the characteristic dimension of the product, L, Equation (2) is used, considering the mass of the tests product, m, density, ρ, and sample area At.

In order to determine the effective diffusivity in the studied byproduct, drying analysis was carried out for various temperatures (30 °C, 40 °C and 50 °C) and for different inlet air flow(0.8 m s−1, 1.2 m s−1 and 1.6 m s−1) in the convective dryer previously mentioned.

The activation energy, Ea, is the minimum energy required to produce a chemical reaction. In this case, is the minimum energy required to start the drying process. Equation (3) is an Arrhenius equation [9,10], that relates the activation energy, the effective diffusivity and temperature.

where: D0: frequency or pre-exponential factor of the Arrhenius equation (m2 s−1); Ea: Activation energy of moisture diffusion (kJ kmol−1); T: Absolute temperature of the air (K); R: Universal gas constant (8.314 kJ (kmol K)−1).

Generally, activation energy and pre-exponential factor are been considered constant. If the values of LN (Deff) versus 1/T (K−1) are represented, it is possible to identify them by a linear relationship in the temperature range selected. The value of the slope of the line represented coincides with the value of Ea/R. So that it can obtain the values of the activation energy of the byproducts studied.

3. Results and Discussion

The parameters of effective diffusivity and activation energy obtained establish the first conclusions on the most appropriate drying technologies for energy use by thermal.

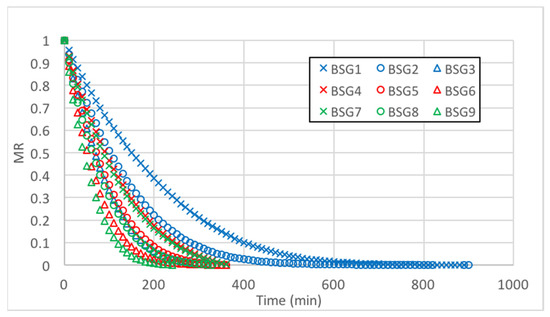

Figure 1 shows the moisture ratio with respect to drying time for each of the temperatures and air flows studied.

Figure 1.

Moisture ratio MR vs drying time.

As expected, drying of BSG is produced in a shorter period of time the higher the temperature of the experiment is.

For the same temperature, the drying process is slower the lower the air flow is.

In this way the highest speed in the decrease in moisture ratio is achieved in BSG9 test, obtaining the lowest value in BSG1 test.

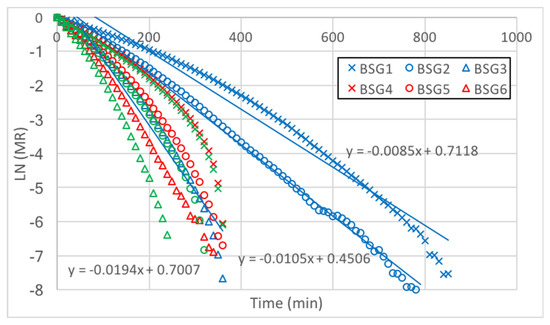

Figure 2 shows the LN (MR) versus drying time. For a sample, and for better understanding of the graph, lines (and equations) are only been represented for 0.8 m s−1 airflow.

Figure 2.

Moisture ratio MR vs. drying time.

From the values of the slope of the line in each case (B) and the characteristic dimension L, considering the mass of the product, m = 1 kg (approximately), ρ = 618 kg m−3 and At = 0.42 m2, effective diffusivity is obtained. Table 2 shows the values of the slope B of each line and the effective diffusivity.

Table 2.

Slope and effective diffusivity.

It can be verified that the effective diffusivity values are greater for higher temperatures and higher air flows.

Comparing Deff values obtained in this work with those suggested by other authors for other agricultural and food materials [11,12], it can be said that fall outside the usual range of 10−9 to 10−11, while approaching the values obtained for low temperatures and smaller airflow. As an example, the olive mill by-products present values, in natural convection at 40 °C, about 2.1 × 10−10 for olive pomace, about 1.1 × 10−10 for olive sludge and about 4.1 × 10−10 for olive mill waste water [11]. Therefore, on the basis of the results it can be expected that drying process for the studied byproduct is slightly more difficult than other agricultural waste such as by-products from olive mill industries, so it foreseeably will give rise to longer drying.

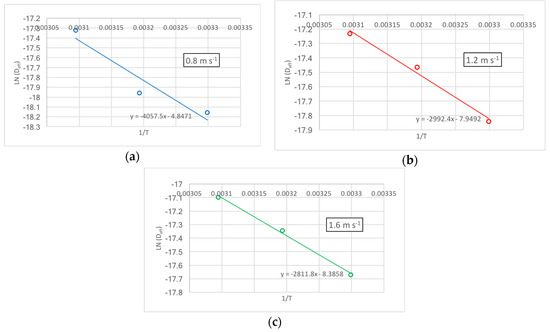

LN (Deff) values versus 1/T (K−1) values are represented in the Figure 3a–c, for each of the air flows studied, identified by a linear relationship in the range of temperatures selected.

Figure 3.

LN (Deff) vs 1/T (K−1) values. (a): for 0.8 m s−1. (b): for 1.2 m s−1. (c): for 1.6 m s−1.

The value of the slope of the line represented coincides with the value of Ea/R. Thus, it is possible to obtain the values of the activation energy of the byproduct studied. These values are shown in Table 3.

Table 3.

Activation energy.

Ea values obtained by other authors for various agricultural products are, in kJ mol−1: olive pomace 91.35 [11], olive sludge 14.04 [11], olive mill waste water 77.15 [11], vegetable waste 19.82 [8], beans 35.43 [9], mint 82.93 [13,14], carrots 28.36 [14,15].

It can be verified the values obtained for BSG studied in this work are of the same order of magnitude.

If the activation energy is higher, a delay in the start of the drying process will give rise in the product.

Finally, it is important to emphasize that the activation energy decreases when the air flow applied is increased. Therefore, it must been taken into account this aspect when designing the drying system, and in the calculation of the energy required to reduce moisture in a product.

4. Conclusions

The properties studied show that BSG can be used for thermal utilization in large installations, being necessary heat drying processes as a pretreatment in order to obtain a biofuel with acceptable efficiency.

Given the results obtained in tests of drying, from the point of view of heat utilization, the drying could be a solution for further use as a biofuel.

Acknowledgments

The authors would like to express their gratitude for the support granted by the Junta of Extremadura because of the funding by means of the support for research groups (Ref. GR18137) and by The European Regional Development Fund (FEDER—ERDF).

References

- Ministerio de Agricultura y Pesca, Alimentación y Medio Ambiente; Cerveceros de España. Memoria Anual de Cerveceros de España 2017; MAPAMA: Madrid, Spain, 2018. [Google Scholar]

- Mathias, T.R.S.; Moretzsohn, P.P.; Comporese, E.F. Solid wastes in brewing process: A review. J. Brew. Distill. 2014, 5, 1–9. [Google Scholar]

- Mussatto, S.I.; Dragone, G.; Roberto, I.C. Brewers’ spent grain: Generation, characteristics and potential applications. J. Cereal Sci. 2006, 43, 1–14. [Google Scholar] [CrossRef]

- Mussatto, S.I. Brewer’s spent grain: A valuable feedstock for industrial applications. J. Sci. Food Agric. 2014, 94, 1264–1275. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Jaiswal, A.K.; Abu-Ghannam, N. Optimization conditions for the utilization of brewing waste to develop a nutraceutical rich liquid product. Ind. Crops Prod. 2013, 44, 272–282. [Google Scholar] [CrossRef]

- Aliyu, S.; Bala, M. Brewer’s spent grain: A review of its potentials and applications. Afr. J. Biotechnol. 2011, 10, 324–331. [Google Scholar]

- Senadeera, W.; Bhandari, B.R.; Young, G.; Wijesinghe, B. Influence of shapes o selected vegetable materials on drying kinetics during fluidized bed drying. J. Food Eng. 2003, 58, 277–283. [Google Scholar] [CrossRef]

- López, A.; Iguaz, A.; Esnoz, A.; Virseda, P. Thin-Layer Drying Behaviour of Vegetable Wastes from Wholesale Market. Dry. Technol. 2000, 18, 995–1007. [Google Scholar] [CrossRef]

- Doymaz, I. Drying behaviour of green beans. J. Food Eng. 2005, 69, 161–165. [Google Scholar] [CrossRef]

- Akgun, N.A.; Doymaz, I. Modelling of olive cake thin-layer drying process. J. Food Eng. 2005, 68, 455–461. [Google Scholar] [CrossRef]

- Montero, I. Modelado y Construcción de un Secadero Solar Híbrido Para Residuos Biomásicos. Ph.D. Thesis, University of Extremadura, Badajoz, Spain, 2005. [Google Scholar]

- Mujumdar, A.S. Drying Technology in Agriculture and Food Sciences; Science Publishers, Inc.: Enfield, NH, USA, 2000. [Google Scholar]

- Doymaz, I. Thin-layer drying behaviour of mint leaves. J. Food Eng. 2006, 74, 370–375. [Google Scholar] [CrossRef]

- Doymaz, I. Drying characteristics and kinetics of okra. J. Food Eng. 2005, 69, 275–279. [Google Scholar] [CrossRef]

- Doymaz, I. Convective air drying characteristics of layer carrots. J. Food Eng. 2004, 61, 359–364. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).