Abstract

This paper presents a simplified procedure to analyse the Hydrogen Induced Cracking (HIC) of structural steels by means of the Small Punch Test (SPT). Two types of notched specimens were used: one with through-thickness lateral notch and another with surface longitudinal notch. The results for conventional specimens were compared with those for hydrogen pre-charged specimens. For this purpose, two different methods to introduce hydrogen in the specimens were used: cathodic/electrochemical pre-charging and pressurized gaseous hydrogen pre-charging. The results obtained with both methods are also discussed.

1. Introduction

Standardized tests such as the tensile test, the fracture toughness or the slow strain rate test (SSRT) require large specimens that cannot be obtained from in-service structures without compromising their structural integrity. Furthermore, the hydrogen induced cracking usually appears during the in-service life of structures. On this grounds, although the SSRT is commonly used for analysing mechanical properties in the presence of aggressive hydrogen environments [1], a different mechanical test is required when the volume of material available for testing is limited.

The small punch test (SPT) has been specifically developed to estimate the mechanical properties of materials by means of small samples [2]. In addition, the tensile tests parameters that are commonly used in the mechanical characterization of materials can be also estimated with the results of the SPT. For these two reasons, the SPT has been proposed to analyse the deterioration of mechanical properties due to HIC [3].

This work presents a general methodology to determine the influence of hydrogen in the mechanical properties of different steel types based on the SPT. Notched specimens are used to take into account the effects of hydrogen redistribution under stress gradients and two methods are applied to hydrogen pre-charge the specimens.

2. Materials and Methods

2.1. Materials

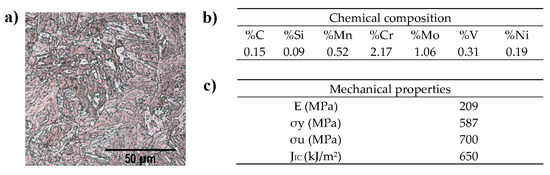

One 2.25Cr1Mo0.25V steel was used in this work. It is a quenched and tempered steel (720 °C) with a tempered martensitic microstructure (Figure 1a). The presence of vanadium (Figure 1b) makes this steel highly resistant to hydrogen embrittlement and for this reason it is frequently used in equipment exposed to hydrogen environments. Figure 1c shows the tensile properties of the steel.

Figure 1.

CrMoV: (a) Microstructure. (b) Chemical composition (c) Mechanical Properties.

2.2. Precharging Methods

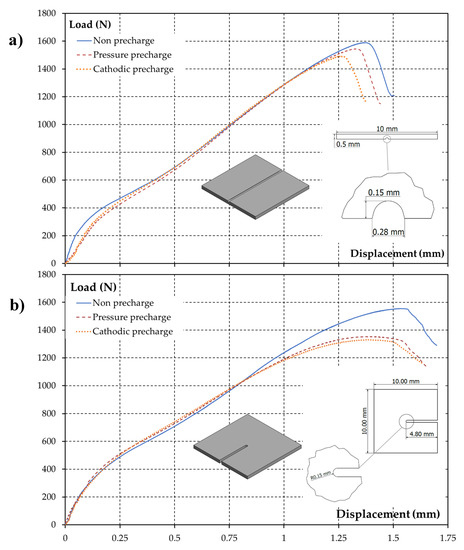

From the CrMoV steel, two different types of notched SPT specimens were machined: a surface longitudinal notch specimen (Figure 2a) and a through-thickness lateral notch specimen (Figure 2b).

Figure 2.

SPT load vs displacement curves: (a) surface longitudinal notch (b) through-thickness lateral notch.

Two techniques were used to hydrogen pre-charge both types of notched SPT specimens: the pressurized gas method and the electrochemical method. In the first one, an autoclave with gaseous hydrogen at 19.5 MPa and 450 °C for 21 h was used [4,5]. Once the hydrogen pre-charge was completed, the specimens were put into a Dewar vessel with liquid nitrogen to avoid the hydrogen desorption until the tests. In the second method, a 2-mole solution of H2SO4 in distilled water and 0.25 g of As2O3 per litre of solution was used as electrolyte, while platinum was used as counter electrode. The specimens were pre-charged at room temperature during 4 h with a current density of 2 mA/cm2 [3]. In both cases, the introduced hydrogen had a similar concentration of about 4 ppm.

2.3. Small Punch Test

Small punch tests were carried out using the standard device [1] mounted onto an Instron testing machine with a 5 kN load capacity. A COD extensometer was used to accurately measure the punch displacement. SPT test without hydrogen were carried out at the standard rate of 0.2 mm/min. Nevertheless, precharged specimens were tested at 10 times slower rate (0.02 mm/min) to ensure the migration of the hydrogen to the crack tip during the tests [5]. Once concluded each test, the embrittlement index was obtained as

where: Wm and WmH are the SPT fracture works (area under the load-displacement curve up to the maximum load point) of specimens tested without and with precharged hydrogen, respectively. Once concluded the tests, fracture surfaces were analyzed using a scanning electron microscope (SEM).

3. Results and Discussion

Figure 2 shows selected load-displacement curves as representatives of the SPT behaviour of the different tested specimens and conditions. As can be seen, regardless of the type of notch, the precharged hydrogen is only noticeable in the last part of the load-displacement curves, whose maximum takes place at lower values of load and displacement. In addition, interrupted tests carried out previously, showed that crack growth begins at the maximum of the curves. This is the reason to calculate the embrittlement index based on the variation of the area of the load-displacement curve up to the maximum (Equation (1)), named SPT’s fracture work or SPT toughness.

Table 1 shows the embrittlement index values for each type of notched specimen and hydrogen pre-charge method. As can be seen, regardless of the type of notch used, cathodic precharge provides a WEI due HIC around 20%.

Table 1.

Embrittlement results of SPT.

The high-pressure pre-charge, however, does not have the same effect on the different notches, resulting more effective, apparently, when the through-thickness lateral notch is used. Nevertheless, it should be mentioned that the pressure pre-charge was not effective in a large number of specimens, that did not show any embrittlement after removed from the autoclave, without regard the type of notch. Thus, the pressurized gas method does not appear to be very reliable as a hydrogen pre-charging method.

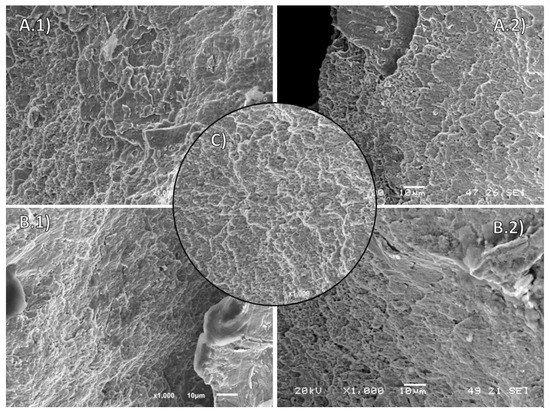

Fractography surface images of the different samples are shown in Figure 3. While in the initial conditions the specimens show ductile fracture with microvoids coalescence (Figure 3C), pre-charged samples show some typical HIC mechanisms. The facets show a much flatter surface that are stretching in the crack growth direction, behaviour linked to a greater localized plasticity induced by the environment.

Figure 3.

Fracture surfaces. (A.1) Cathodic-Surface longitudinal (A.2) Pressure-Surface longitudinal (B.1) Cathodic-Through-thickness lateral (B.2) Pressure-Through-thickness lateral (C) Non-pre-charged.

4. Conclusions

A methodology to identify HIC in steel specimens by means of SPT, hydrogen pre-charging methods and notched samples has been presented and discussed in this work. Some conclusions can be drawn:

- Pressure pre-charge has shown large variability of gaseous hydrogen introduced in the samples. In addition, this technique is more expensive than the cathodic pre-charging mode. Therefore, the cathodic method is recommended.

- The specimens with through-thickness lateral and surface longitudinal notches with cathodic charge showed similar embrittlement indexes after testing. Although both notched geometries can be used with this purpose, the through-thickness lateral notch is cheaper to be mechanized and allows higher embrittlement indexes to be reached.

Funding

The authors would like to thank the Spanish Ministry of Economy and Competitiveness for the support received to carry out research project MAT2014-58738-C3.

References

- Zhang, T.; Zhao, W.; Zhao, Y.; Ouyang, K.; Deng, Q.; Wang, Y.; Jiang, W. Effects of surface oxide films on hydrogen permeation and susceptibility to embrittlement of X80 steel under hydrogen atmosphere. Int. J. Hydrogen Energy 2018, 43, 3353–3365. [Google Scholar] [CrossRef]

- García, T.E.; Rodríguez, C.; Belzunce, F.J.; Suárez, C. Estimation of the mechanical properties of metallic materials by means of the small punch test. J. Alloys Compd. 2014, 582, 708–717. [Google Scholar] [CrossRef]

- García, T.E.; Rodríguez, C.; Belzunce, F.J.; Peñuelas, I.; Arroyo, B. Development of a methodology to study the hydrogen embrittlement of steels by means of the small punch test. Mater. Sci. Eng. A 2015, 626, 342–351. [Google Scholar] [CrossRef]

- Meng, B.; Gu, C.; Zhang, L.; Zhou, C.; Li, X.; Zhao, Y.; Han, Y. Hydrogen effects on X80 pipeline steel in high-pressure natural gas/hydrogen mixtures. Int. J. Hydrogen Energy 2017, 42, 7404–7412. [Google Scholar] [CrossRef]

- Zafra, A.; Peral, L.B.; Belzunce, J.; Rodríguez, C. Effect of hydrogen on the tensile properties of 42CrMo4 steel quenched and tempered at different temperatures. Int. J. Hydrogen Energy 2018, 43, 9068–9082. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).