1. Introduction

There are areas of usage such as processing tools of Al

2O

3-Y

3Al

5O

12 composite materials and jet engine parts in aviation industry [

1,

2,

3]. Two-phase microstructure of Al

2O

3-YAG (Y

3Al

5O

12, Yttrium aluminum garnet) which is formed as a result of sintering of powder mix of Al

2O

3 and Y

2O

3 is expected to exhibit a homogeneous granulation after sintering. Because this condition has a positive effect on the compressive stress of two phases with different coefficients of thermal expansion. This behavior improves the fracture toughness of the material by making difficult to transgranular crack to proceed. Oxide ceramics show better oxidation and corrosion resistance in ambient conditions with high temperature than non-oxide ceramics. YAG ceramics’ high friction resistance, which means it shows mechanical strength in high temperatures was proven with some studies. Generally, the eutectic ceramics produce from melt by the directional or non-directional solidification method. However, these methods increase the crack formation sensitivity in alumina based materials, furthermore it becomes difficult to obtain solidified crystals at large scale [

4,

5]. For this reason, the preparation of large sized fine eutectic ceramics based on alumina has become a problem today in terms of industrial applications. As a result, since there is not a method developed yet for manufacturing large size crystals to meet the requirements for applications of high temperature structural parts for engines and turbines, the production of composite materials by sintering is again in the foreground. Based on the effect of cost effectiveness, sintered ceramics are very advantageous when the ease of production methods is taken into account.

In this study, it was investigated that what percentage the yttrium oxide additive changes the microstructure of the aluminum oxide structure and how it gives the best result.

2. Experimental Procedure

The weight of the eutectic composition was planned to be 65–67–70%, as Al

2O

3-Y

2O

3 containing Al

2O

3. The properties of the powders were listed in

Table 1.

The powder of the desired composition was grinded in a vibrating micro mill. The powders were sintered for 1 h at 1273 K for granulation, then mixed dry in a ball jet mill and sieved in the sieve shaker and at 106 microns and below. The powders were pressed by cold isostatic pressing method under a pressure of 300 MPa for 5 min. Following the pressing process, the samples were subjected to sintering at 1923 K for 12 h. Sintered 3 samples were subjected to phase analysis after preparation. After XRD analysis, microstructure images of the samples were taken in rigid structure. In order to observe whether local gap or neck formation is occurred and for surface structure at large spectrum, images of SEM were examined. Binary homogeneous structure is an important factor in increasing the strength of the material. It is thought that this process is related to the formation of the conditions that can prevent the nucleation in the microstructure. For this reason, secondary electron views are important. In the microstructure appearance, the gap, fineness and degree of purity were evaluated. Thus, we have an idea about how the raw material composition affects the material properties. Microhardness test was applied to each sample. The measurement was carried out under 9.808 N for 15 s. It is known that hardness measurements give relative values about the strength of the material and it is formed in high hardness values of a better microstructure. Thus, information about the material was obtained at the determined caliber values and it was evaluated whether it is proper to production. Bending strength tests of samples were carried out with Instron 5581 model device. The bending strength test was carried out under a load of 2 kN at a loading speed of 0.5 mm/min. The samples were prepared in the form of a rectangular bar of 1.5 × 2 × 25 mm with precision cutting device before testing.

3. Results and Discussion

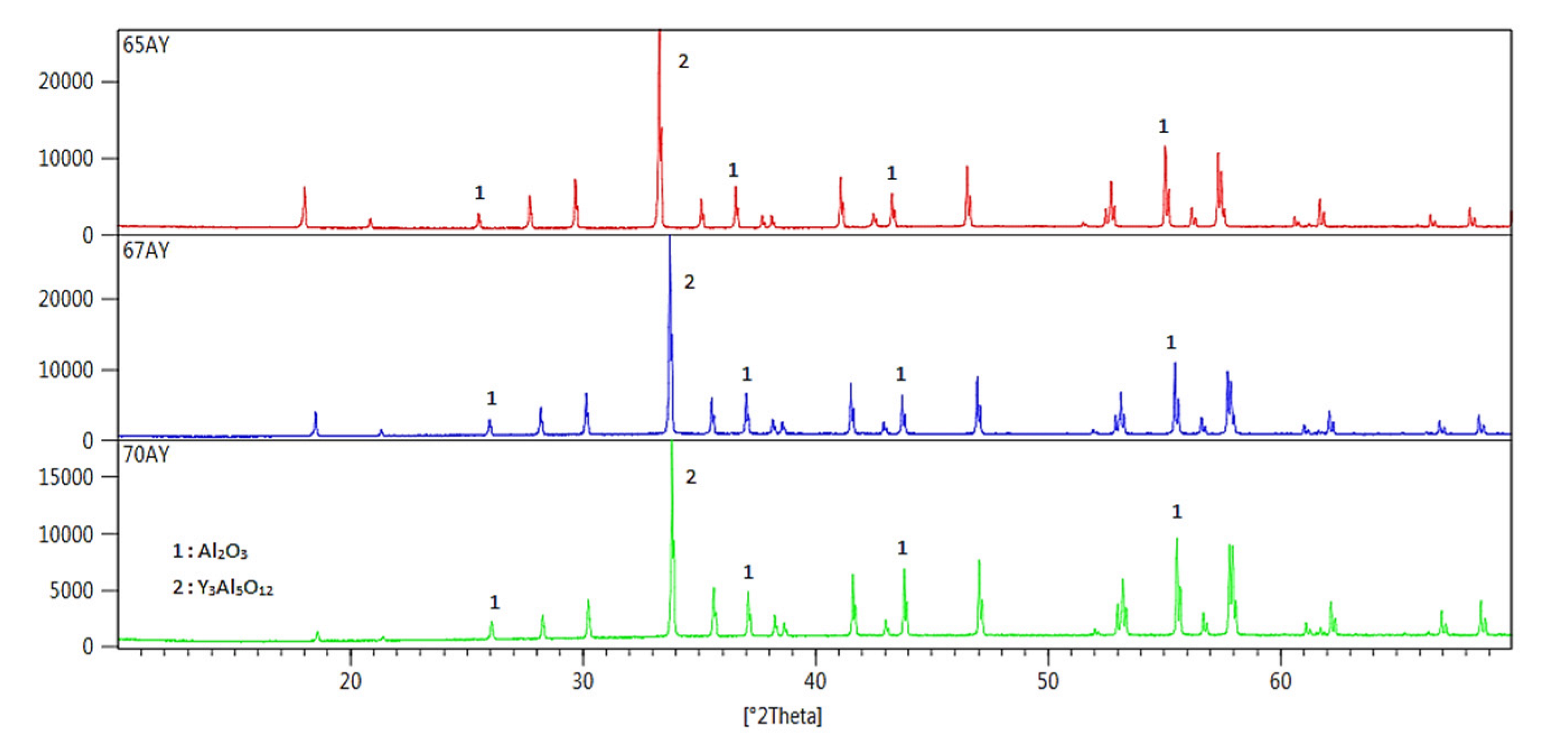

In the

Figure 1, it is shown phases analysis of sintered 3 samples. The sintered rigid samples obtained from the Al

2O

3-Y

2O

3 powder mixture containing 65% Al

2O

3, 67% Al

2O

3 and 70% Al

2O

3 by weight, were named as 65AY, 67AY and 70AY.

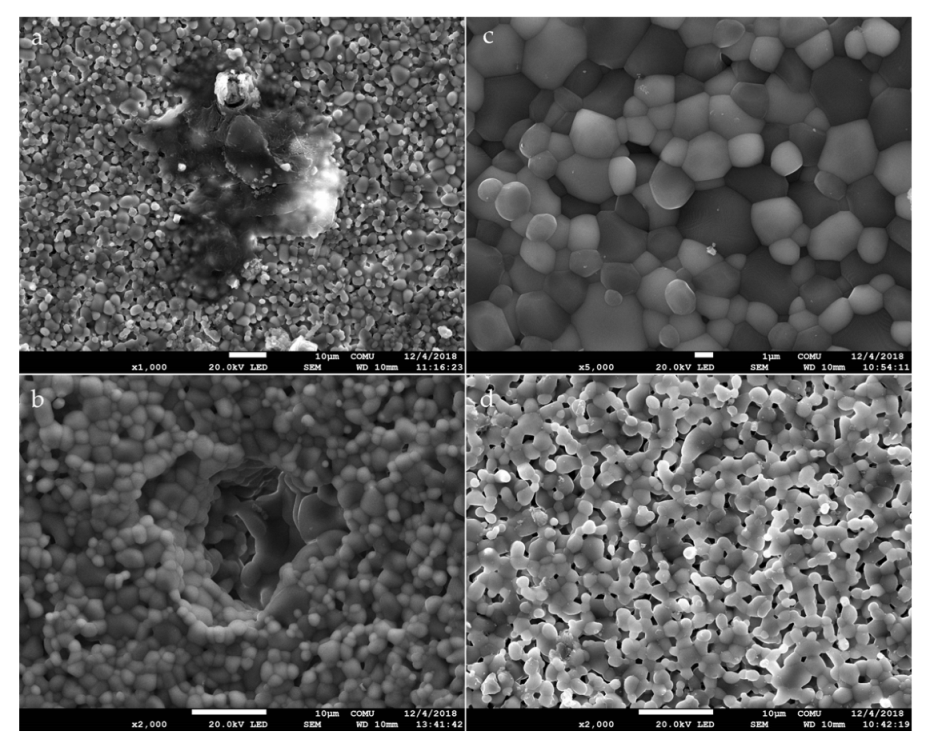

As seen in the figure, alumina and YAG phases were formed in 3 sintered samples. However, the intensity and peak sharpness of the YAG phase are higher in 67AY. For this reason, the YAG phase appeared more than the 65AY and 70AY samples. In the

Figure 2, SEM images of each sintered samples were seen. It shows Al

2O

3 phase in the black area and Y

3Al

5O

12 phase in grey area. In the 67AY sample, any structure containing amorphous phase or porosity was not found. Amorphous phase areas are observed in the 65AY sample, and porous structures are observed in the 70AY area. 67AY gives a very fine structure appearance. Cracks were not observed in any sample after the production phase.

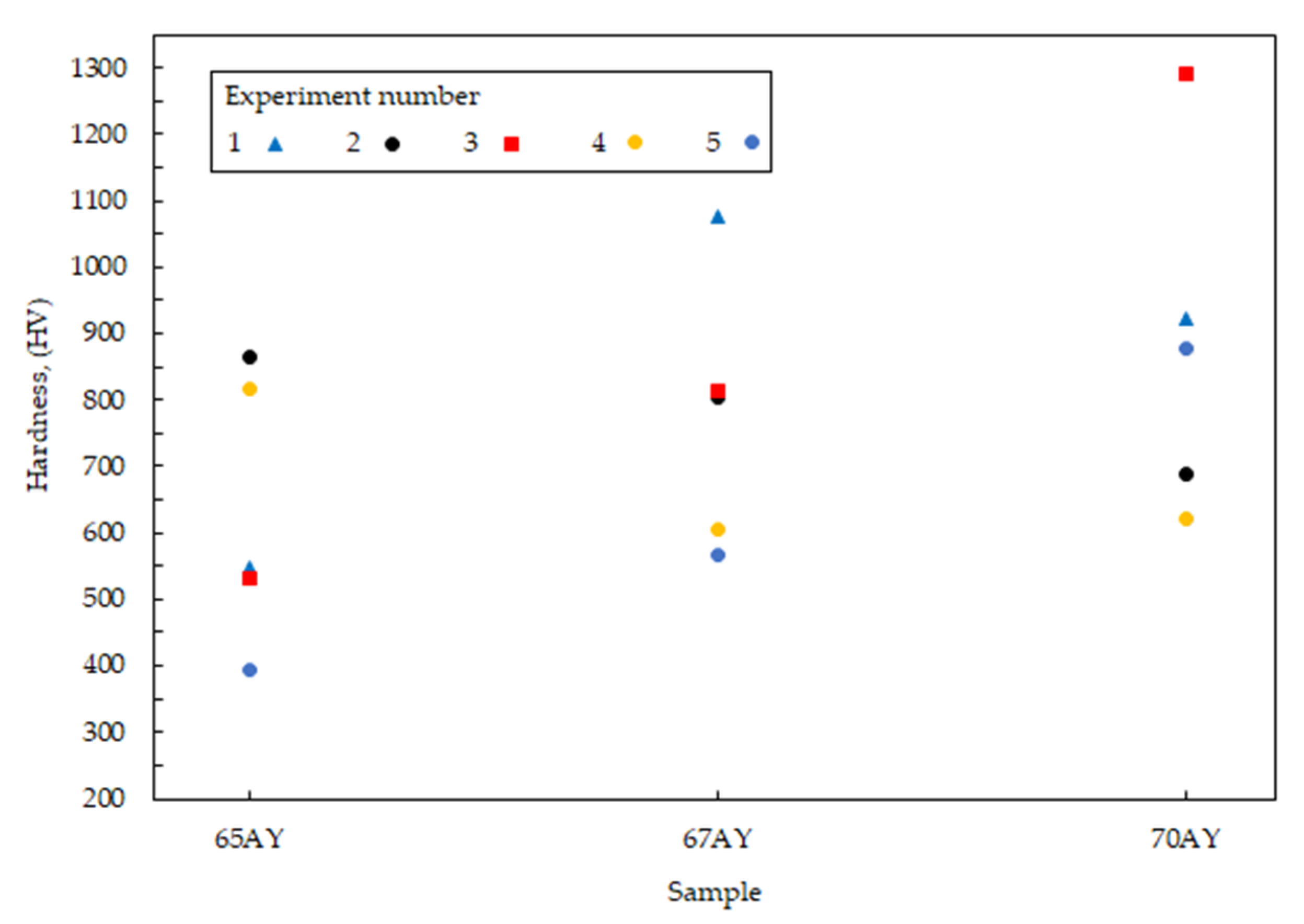

In the

Figure 3, 5 pieces’ hardness measurements results made to each three samples is seen. While the hardness measurements of the 67AY and 65AY samples show close homogeneity to each other, the homogeneity of the hardness distribution is lower in the 70AY sample. However, the hardness values of the 67AY sample are higher than the 65AY samples, which show homogeneity close to it.

For all three samples, three-point bending tests were performed at room temperature. The properties of the bending test result samples are given in

Table 2. The average and without fractions values of the test that made for 7 times for each sample were taken.

As seen in the table, the module and bending strength are inversely proportional. As the elasticity value of the material increases, the bending strength decreases. The sample with 67AY code has the lowest modulus of elasticity and the highest bending strength than other samples. The high module of elasticity of the 70AY material is also compatible with the hardness values. Although the 65AY material is close to the module value of the 67AY material, its microstructure defects cause a decrease in the bending strength.

4. Conclusions

The polycrystalline Al2O3-YAG (Y3Al5O12) eutectic oxide ceramic composite material obtained from Al2O3-Y2O3 powder mixture containing 67% Al2O3 by weight has the finest, homogeneously distributed microstructure. The same material, however, is also superior in terms of hardness distribution and bending strength. Continuous increase or continuous decrease of Y2O3 addition does not affect these properties. The emergence of superior properties in the 67AY material can be explained by examining the phase diagram results of the composition.