1. Introduction

Energy consumption of operating an air-conditioning (A/C) system accounts for a large proportion of total building energy consumption. Conventional A/C system relies on energy-intensive compressor and environmentally harmful chlorofluorocarbons (CFCs). In recent decade, desiccant enhanced evaporative cooling system becomes a research hot spot because of its low energy consumption and possible utilization of low-grade heat source [

1]. A LDD-RIEC system consists of a liquid desiccant dehumidifier (LDD) and a regenerative indirect evaporative cooler (RIEC) is one of the desiccant enhanced evaporative cooling systems. The hot and humid fresh air is firstly dehumidified by a LDD and then sensibly cooled by a RIEC. Without relying on a compressor, the energy consumption is greatly reduced by only operating pumps and fans.

The energy saving potential of desiccant enhanced evaporative cooling system is proved to be very promising by extensive theoretical and experimental studies [

2]. However, the main shortcoming of LDD-RIEC system is the high dependency on ambient air conditions. The supply air temperature varies according to changeable ambient temperature and humidity. To maintain stable indoor temperature and thermally-comfort environment, a control scheme is essential. However, very limited research work regarding control strategy of LDD, RIEC and LDD-RIEC system can be found in open literatures. Therefore, a novel controller named high-low (H-L) control is proposed for LDD-RIEC system. Multi-speed technology is utilized in RIEC for primary air fan and secondary air fan, which operates either at high speed or at low speed. The high speed is designed to meet the peak cooling load and the low speed meet the minimum fresh air demand of the occupants. The fan operates at high speed when the indoor air temperature is higher than the setting value and at low speed if the indoor air temperature is satisfied.

In this paper, the annual performance of LDD-RIEC system based on H-L control is investigated by numerical simulation. The LDD model, RIEC model and dynamic indoor heat and mass balance model are firstly established. Detailed control algorithm is introduced thereafter followed by a case study in Hong Kong, a typical hot and humid region. The year-round indoor temperature and humidity distribution are discussed. Fluctuations of fan speed and supply air temperature in a typical summer day are also analyzed. At last, the energy consumption of the system is evaluated.

2. Simulation Model

The LDD model, RIEC model and indoor heat and moisture balance model are established respectively. The heat and mass transfer process in the dehumidifier follows the energy and mass conservation. The model of RIEC is established based on energy and mass balance in the two channels.

H-L control is proposed as a novel control scheme for LDD-RIEC system. The controller is adopted for both of the LDD and RIEC with multi-speed technology. In LDD, the solution pump and fan operate either at high speed or at low speed. In RIEC, the primary air fan and secondary air fan operate either at high speed or at low speed. When the indoor air temperature is higher than the upper boundary of setting point, the fans and pump would operate at high speed. Otherwise, the fans and pump would operate at low speed instead of completely shutdown to meet the part load. To avoid overcooling in the early morning of transition seasons, the system would not be active until the indoor air temperature increases to the lower boundary of the setting point.

In this study, the system would be turned off if the t

N(T) is lower than 24 °C, operated at low speed if t

N(T) is between 24 °C to 25 °C, operated at high speed if t

N(T) is higher than 26 °C and maintain the current operation state if t

N(T) is between 25 °C to 26 °C. The structure and operational parameters of LDD and RIEC are listed in

Table 1.

A case study is conducted to evaluate the annual performance of LDD-RIEC under H-L control in Hong Kong. The studied room is a clinic with dimension of 4.0 m (L) × 8.0 m (W) × 2.6 m (H). There are two patients and two doctors equipped with two computers. The working hour is 8:00 to 20:00 every day. The cooling season is from 1 May to 30 September.

3. Results and Discussion

3.1. Annual Performance

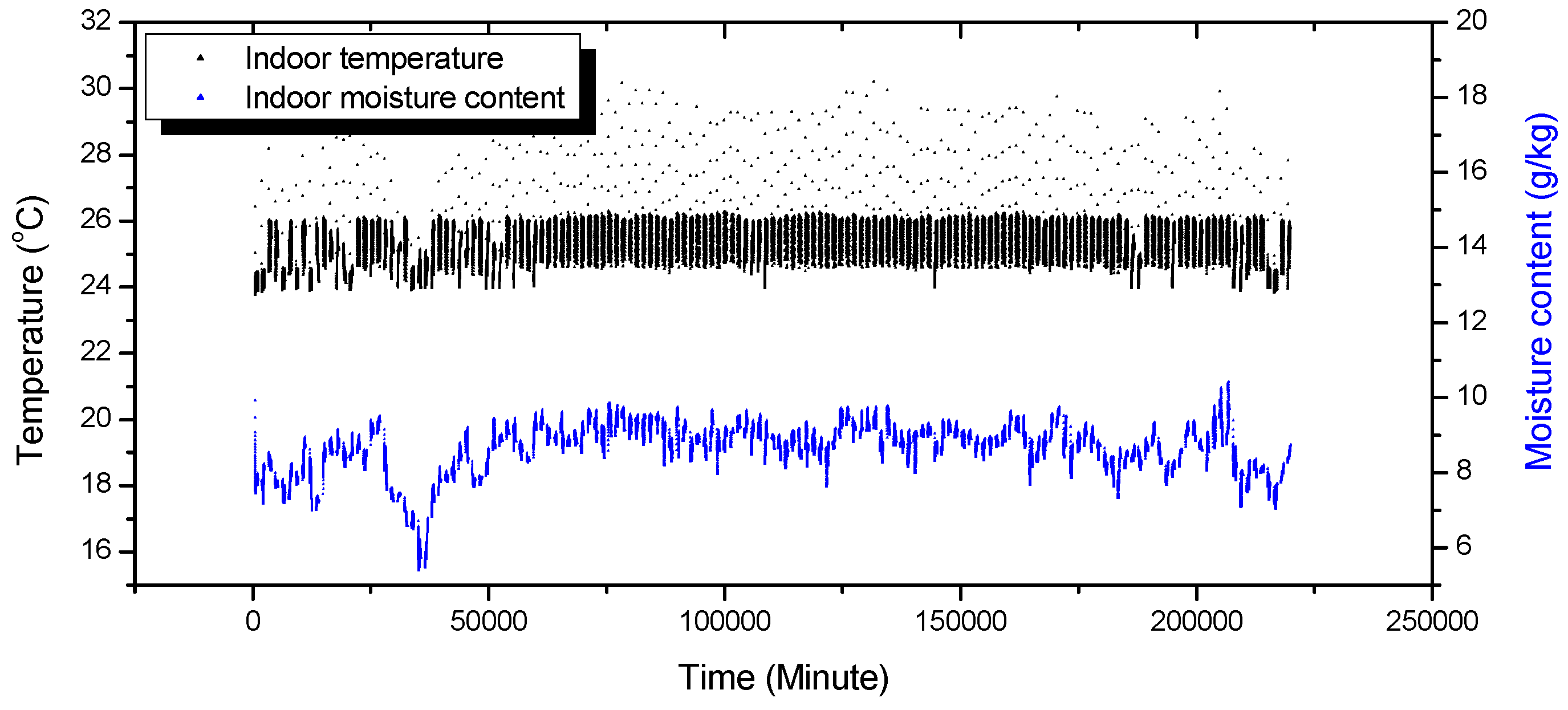

Figure 1 show the indoor temperature and humidity variation in cooling seasons (1 May to 30 September). It can be seen that the indoor air temperature mostly varies from 24 °C to 26 °C and indoor humidity varies from 5.5 g/kg to 10.7 g/kg. The highest temperature is about 30 °C Throughout the cooling seasons, the temperature varies from 26 °C to 27 °C accounts for 6.2% of operating time, from 25 °C to 26 °C accounts for 68.9% from 24 °C to 25 °C accounts for 24.0%. The temperature higher than 27 °C and below than 24 °C takes up for only 0.3% and 0.6% of operating time, respectively. Therefore, it indicates that H-L control adopted in LDD-RIEC system is effective in maintaining stable indoor thermal comfort with temperature fluctuation from 24 °C to 27 °C for 99% of time.

3.2. System Performance in a Typical Day

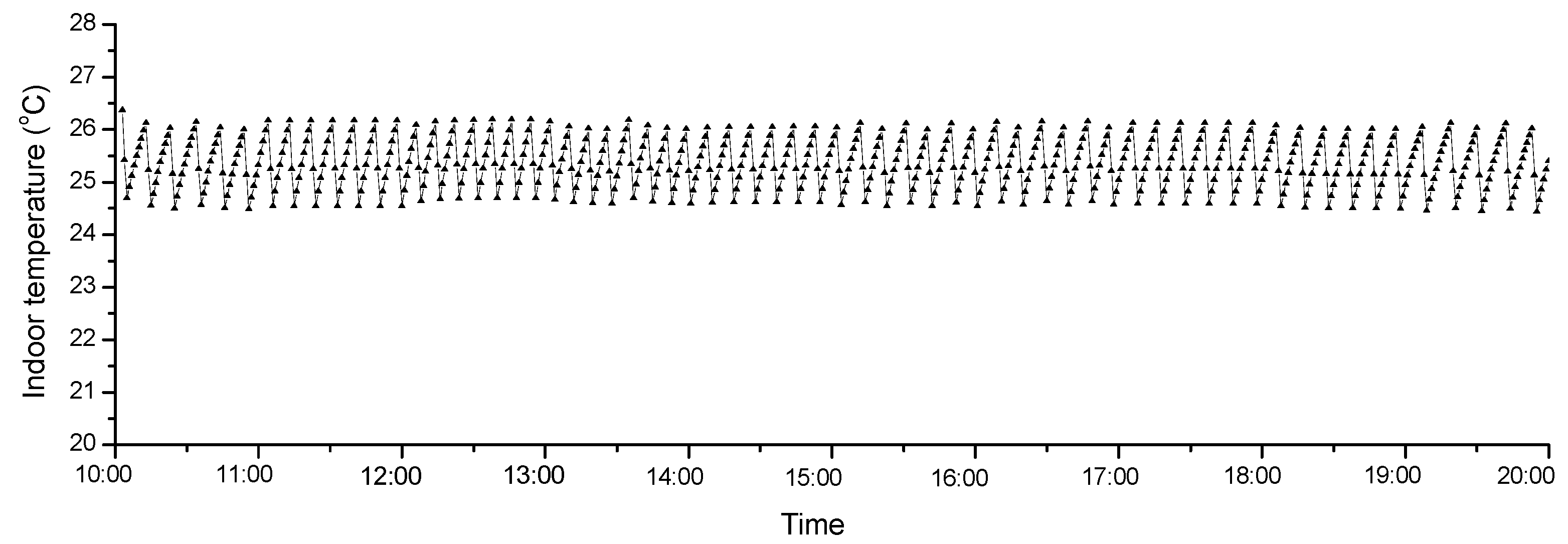

Figure 2 shows the indoor temperature fluctuation in a typical day during the working hours. It can be seen that the temperature varies between 24.5 °C to 26.5 °C, indicating good controllability of the system. As H-L control is adopted as the control scheme, the indoor temperature will increase to the upper setting boundary and then decrease as the fan switches to high speed. In sum, the indoor temperature fluctuates between upper setting boundary and lower setting boundary periodicity. The indoor temperature can be controlled within the thermal comfort zone.

Figure 3 shows the fan speed fluctuation in a typical day during the working hours. It can be seen that the fan speed switches between high speed (0.6 m/s) and low speed (0.15 m/s) periodicity. The fan operating at low speed lasts much longer than that of high speed. Throughout the cooling season, the fans’ shutdown period accounts for 58.5% of the cooling season, operating at low speed accounts for 34.7% and operating at high speed accounts for only 6.8%.

3.3. Energy Consumption

One of the most significant advantages of LDD-RIEC system is the low energy consumption. The high-low control provides huge energy saving potential based on the affinity laws in multi-speed technology. Based on the affinity laws, power is proportional to the cube of shaft speed, i.e, the power would reduce to 1/27 of rated power if the fan speed is reduced to 1/3 of rated speed. The breakdown of energy consumption in LDD-RIEC system is listed as

Table 2. In the calculation, the heat to power ratio is supposed to be 4. The energy consumption by the solution pump and cooling water pump are assumed to be 5% of the regeneration heat, respectively. The total energy consumption of LDD-RIEC system in cooling seasons is calculated to be only 1184 kWh.

4. Conclusions

LDD-RIEC system is a kind of desiccant enhanced evaporative cooling system, which is consisted of a liquid desiccant dehumidifier (LDD) and a regenerative evaporative cooler (RIEC). A novel controller named high-low (H-L) control is proposed for LDD-RIEC system. The studied case indicates that H-L control is effective in maintaining stable indoor thermal comfort with temperature fluctuation from 24 °C to 27 °C for 99% of time in Hong Kong. The fan speed switches between high speed and low speed periodicity, but operates under low speed for majority of time. The total energy consumption of LDD-RIEC system in cooling seasons is calculated to be only 1184 kWh.

Author Contributions

Y.C. and H.Y. established the simulation model; Y.L. proposed the idea, finalized the paper and provided valuable comments.

Acknowledgments

The work was supported by a grant from the Research Grants Council of the Hong Kong SAR, China (UGC/FDS25/E04/17). The publication fee in open access is covered by the received fund.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mohammad, A.T.; Mat, S.B.; Sulaiman, M.Y.; Sopian, K.; Al-Abidi, A.A. Survey of hybrid liquid desiccant air conditioning systems. Renew. Sustain. Energy Rev. 2013, 20, 186–200. [Google Scholar] [CrossRef]

- She, X.; Yin, Y.; Zhang, X. Investigation on air flow patterns of evaporative cooling and dehumidification process for a hybrid refrigeration system. Appl. Therm. Eng. 2016, 95, 79–94. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).