1. Introduction

Cigarette butts (CB) constitute one of the most common types of litter in urban areas with an estimated 4.5 trillion discarded annually that represents 22-46% of visible litter [

1]. In urban areas 76% of cigarettes smoked in public are littered rather than disposed in appropriate receptacles [

2]. Then butts are transported by rain or river water to coastal areas, where they are consistently the most numerous element of litter collected. The environmental impact of cigarette butts waste is related to their chemical composition [

3]. Approximately 130 chemicals have been reported to be present in cigarette butts. However many more chemicals (40,000–100,000) have been identified in cigarette smoke, some of which could potentially be retained in cigarette butts [

4]. This waste is made of nearly 95% microscopic-sized fibrous cellulose acetate. Plasticizers are applied to bond the fibers. Other toxic substances that compose cigarette butts are heavy metals (iron, manganese, strontium, aluminium, lead, copper, chromium, cadmium…), polycyclic aromatic compounds, ethyl phenol and nicotine [

5,

6]. These chemicals are released into the environment depending on the conditions and chemical properties.

Although cellulose acetate is a photodegradable polymer, it is not easily biodegradable. It may persist in the environment for more than ten years. The key mechanism for degradation is an initial deacetylation step by chemical hydrolysis and acetyl esterases, enzymes that are common in microrganisms. Then the cellulose backbone is degraded with cellulose. Regarding cigarette butts, the highly entangled network of the fibers mixed with plasticizers made the disintegration of butts very slow and difficult [

7]. Moreover, cigarette butts have been shown to leach out heavy metals [

8] and nicotine [

9]. One cigarette butt soaked in a liter of water for 96 hours is the Lethal Concentration 50 for test fish exposed to cigarette butts leachates. This waste when disposed of in the environment pose a major threat to living organisms and ecosystem health [

10]. In consequence, cigarette butts are a concern in terms of its environmental and public health.

Nowadays there is not a sustainable disposal method for this waste. A recycling technology for cigarette butts has not been stablished yet. The global production for cellulose acetate, the cigarette butts main component, was over 800000 metric tons per year in 2008 [

7] and this material is obtained by the reaction of cellulose with acetic anhydride and acetic acid in the presence of sulphuric acid. Therefore recycling cigarette butts might contribute to save natural resources and would be an environmentally friendly way to dispose of cigarette butts. In this context, our research group proposes in this communication, a methodology to value cigarette butt waste based on the recovery of the cellulose acetate by a methodology that includes several solid-liquid extractions and a chemical precipitation. Cellulose acetate fiber has an acetate group on approximately 2–2.5 of every three hydroxyls and it is used in a variety of consumer products, including textiles, plastics, films, membranes and in controlled release of active drugs, fertilizers, pesticides or fragances.

2. Materials and Methods

2.1. Materials

All solvents were of HPLC grade and other chemicals were of analytical-reagent grade. Acetone, ethyl acetate, diethyl ether, ethanol, hexanes, sodium acetate, sulfuric acid and sodium chloride were purchased from Scharlab S. L. (Spain). Ultrapure water was produced by an automatic water distillation apparatus (Barnstend Nanopure, Thermo Scientfic). Cigarette butts, from different brands, were collected from specific receptacles located in bars and buildings from the Campus of the University of Extremadura and surroundings. They formed a very heterogeneous mixture, each butt had its original tobacco and blend of additives, and different amounts of remaining unburnt tobacco, as well as other posible contaminats, such as lipstick and saliva residue. The wrapping paper and any remaining tobacco were manually removed from the cigarette tips.

2.2. Solid-Liquid Extraction and Precipitation of Cigarette Butts

Three aqueous solutions, 5% NaCl (w/v), 5% NaAc (w/v) and 0.02% H2SO4 (w/v) were prepared by adding the solid or de dilute solute to deionized water. Three samples of ten cigarette butts each were prepared. One of them was stirred in 100 mL of the NaCl aqueous solution, other in 100 mL of the NaAc aqueous solution and the third in 100 mL of the H2SO4 solution, for 30 min each at room temperature. The resulting solutions were decanted and the butts were stirred with fresh solutions twice. After that, each sample was extracted three times with absolute ethanol (50 mL) by stirring at room temperature for 30 min each Then, extractions with less polar organic solvents, such as diethyl ether (50 mL × 3) and hexane (50 mL × 3) were carried out. After that, the cleaned butts were suspended in acetone and distilled water was added until a white precipitate of cellulose acetate was formed.

2.3. Cellulose Acetate Characterization

Cellulose acetate was characterized by FTIR-ATR spectroscopy and its melting point determination. The FTIR spectrometer was an FTIR Nicolet 6700 from Thermo Scientific, equipped with a Smart Orbyt ATR accessory, with CsI lenses and a single-reflection diamond ATR element. Resolution was 4 cm−1 and an average of 32 (autoaccumulation mode) spectra were accumulated to improve the signal-to-noise ratio. Data were collected using the Jasco Spectra Analysis program. The FTIR-ATR spectrum was recorded in the 450–4000 cm−1 region. The melting point was determined using a MPS10 apparatus from Omega Engineering Limited.

2.4. ICP- and GC-MS analysis of extracts

The concentration of Al, Mn, Fe, Cu, Zn, Sr, Cd, Ba and Pb in the aqueous and the ethanolic solutions resulting from the cigarette butts extraction were measured by inductively coupled plasma spectrometry (PerkinElmer apparatus, model NexION 300 ICP-MS). We also investigated the presence of other organic components in cigarette butts by mass spectrometry using an Agilent GC/MS instrument.

3. Results

Cigarette butts composition include a variety of compounds, including aromatic and heterocyclic amines, carbonylated compounds, phenols, polycyclic aromatic hydrocarbons, carbon and nitrogen oxides and ammonia [

11]. That present different solubility according to their polarity. With this fact in mind, and considering that cellulose acetate is the main component and it is soluble in acetone or ethyl acetate, we propose a methodology to purify this polymer based on several solid-liquid extraction steps using solvents with different polarity. Thus, we carried out a first extraction using aqueous solutions. According to Potts and Moerman [

5] it might be a relationship between pH of solutions and the concentration of metals extracted from cigarette butts, although they did not found any appreciable effect in pH within the range typical of precipitation (4–6). For investigation of how more acidic or basic pH values affect to the extraction of metals we used three different solutions: (a) 5% NaCl (

w/

v); (b) 5% NaAc (

w/

v) and 0.02% H

2SO

4 (

w/

v). After that, cigarette butts resulting from the extraction with each one of the above solutions were extracted consecutively with absolute ethanol, diethyl ether and hexanes, in order to dissolve the organic components in cigarette butts according to their polarity. Finally, the resulting solid was further purified by a precipitation method. It was dissolved in acetone and water was added dropwise until a white solid was obtained and filtered.

FTIR-ATR spectrum of the cellulose acetate obtained by the proposed methodology shows intense bands due to the -OH, -CH and C=O stretching modes ( v

OH, v

CH and vc=o) at 3451, 2917 and 2847, and 1741 cm

−1 respectively, while the C-O single bond stretching modes are located at 1232 and 1043 cm

−1 [

12]. The calculated melting point for the solid was in the 240–243 °C range.

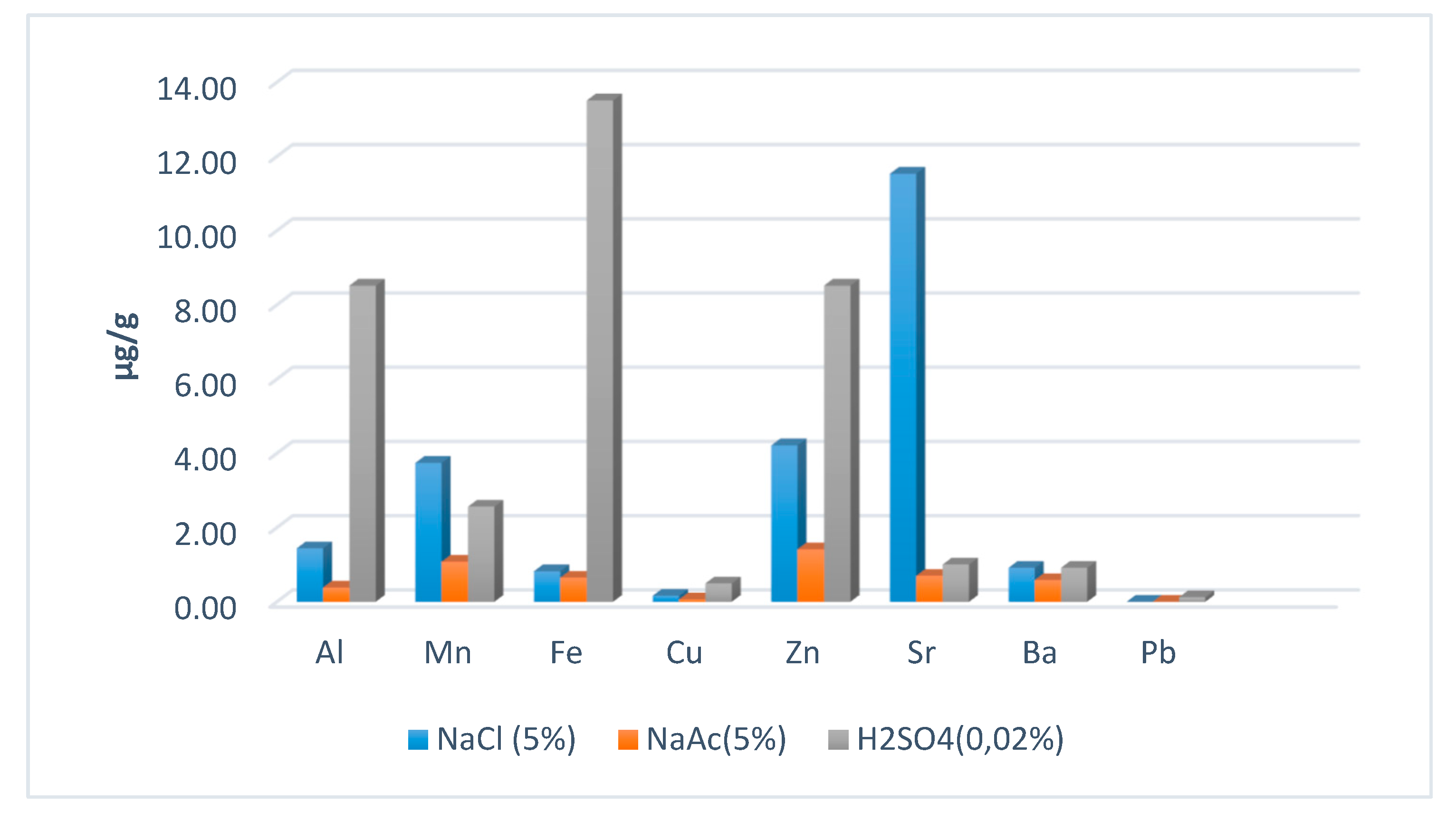

The concentration of metals in the three aqueous solutions resulting from the cigarette butts extractions are shown in

Figure 1. The values are converted to μg

analyte/g

sample added to account for variation in sample mass added. The average concentration of metal varies from values below limits of detection to over 13.5 μg/g (Fe in H

2SO

4 solution). According to the results, the acidic solution seems to be the most efficient to the extraction of Al, Fe, Cu, Zn, Ba and Pb and the NaCl solution is the most efficient to the extraction of Mn and Sr.

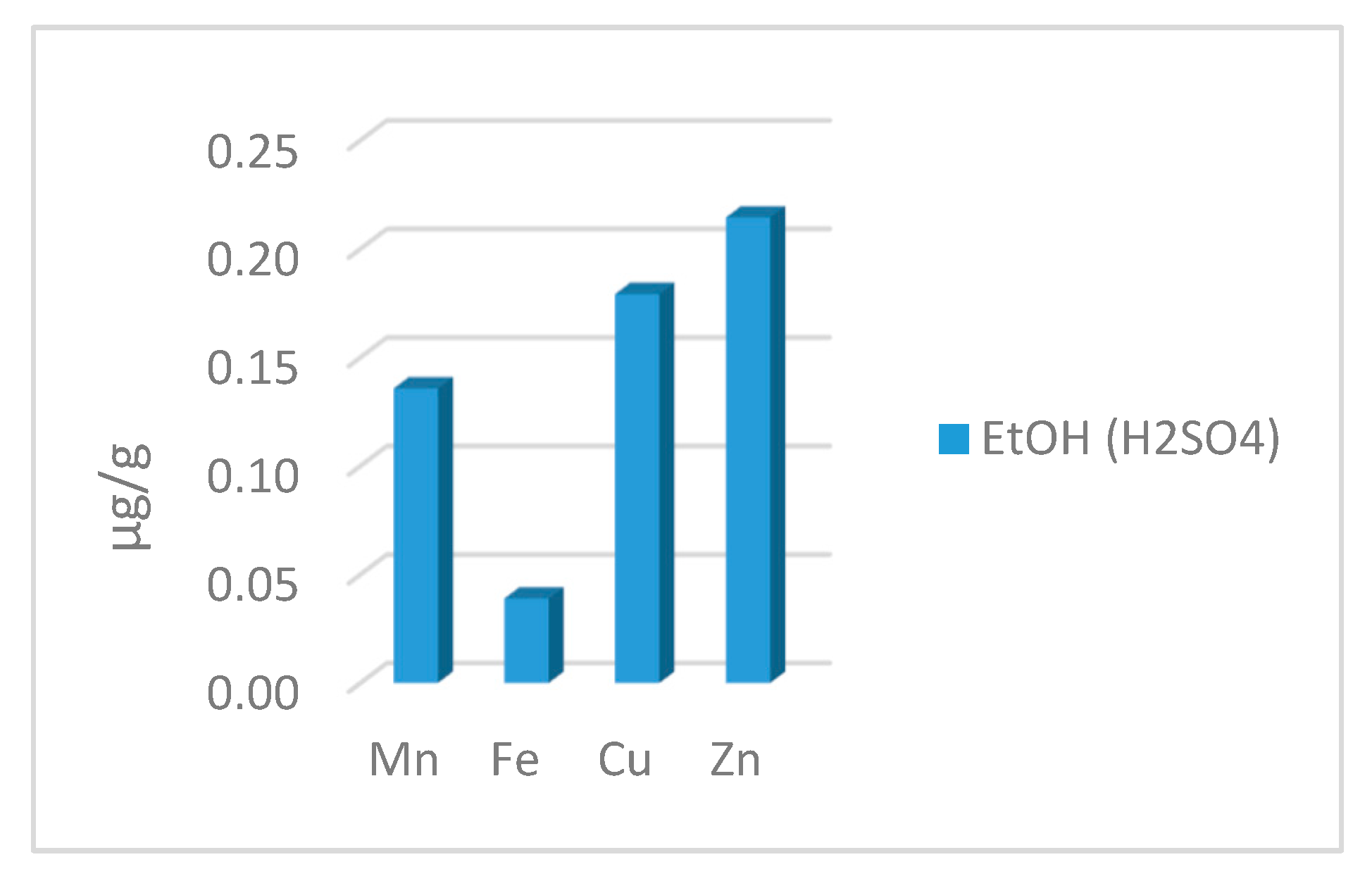

Once the cigarette butts were extracted with the above mentioned aqueous solutions, each resulting sample was extracted with absolute ethanol. Then ICP-MS spectrometry was used to analyze the concentration of metals in the liquid phase. Only the solution obtained from the sample previously extracted with sulfuric acid showed appreciable concentration of Mn, Fe, Cu and Zn (

Figure 2).

We also investigated the organic components that were extracted by ethanol and diethyl ether from each one of the three samples by GC-MS spectrometry. The compounds found in the ethanol extracts are shown in

Table 1. Extracts in ethanol from the samples previously extracted with NaCl and NaAc solutions are very similar. There are a number of flavouring agents such as m-cresol, indole or n-pentadecanol, adhesives such as 3-ethylphenol and nicotina. However extracts from the sample resulting from the H

2SO

4 aqueous solution are different. Different flavouring agents such as methyl dodecanoate or methyl octanoate are found.

The diethyl ether extracts showed less organic components (

Table 2). The plasticizer bis(2-ethylhexyl)phthalate is found in the extracts of samples resulting from the NaCl and H

2SO

4 solutions, as well as the waxes hexadecane and eicosane, and the antioxidant butylhydroxytoluene is found in the extract of samples resulting from the NaAc aqueous solution.

4. Conclusions

In summary, it is possible to recover cellulose acetate from cigarette butts in order to reuse it and to decrease the amount of a residue which is generated in large quantities all around the world. According to the results of this study, the most efficient methodology should include initial extraction steps with aqueous solutions, starting with an H2SO4 solution, followed by a NaCl solution. After that, an extraction process using an organic solvent should be also considered to eliminate the organic components of cigarette butts that are not soluble in water. Finally, a precipitation step using the acetone-water system would purify further the cellulose acetate. Additional research should be done to remove the metals and the organic compounds from the extraction media and to recover the water and the solvents used in the process.