1. Introduction

Fuels obtained from renewable sources can be divided into first, second and third generation biofuels. Biofuel production from raw materials also used for food production (first generation biofuels) has negative economic consequences, such as an increase in food prices and decreasing area of forests which are replaced by arable land. Alternatively, biofuels can be obtained from other raw materials, such as plant biomass and waste. In terms of quantity, materials containing lignocellulosic complex, such as straw, wood and plant waste from food production, account for the majority of raw materials in the production of second generation biofuels. Development of renewable energy sources is associated with the concept of the third generation fuels, which include algae and aquatic plants; according to numerous studies, aquatic biomass can yield biogas, bioethanol and biodiesel. Pretreatment is of key importance for ensuring a high output of monosaccharides from the polysaccharides present in the material under treatment. Without the pretreatment stage, hydrolysis efficiency of less than 20% can be achieved, while pretreatment can increase it to 90% and above [

1]. Physical, physico-chemical, chemical and biological pretreatment is conducted in order to increase the efficiency of energy production from biomass. It is important to establish the technological conditions which ensure that the conditioning process will be efficient, cost-effective and safe. If the treatment is not sufficiently effective, it can result in the formation of toxic compounds which inhibit the metabolism of methanogenic bacteria [

2]. To increase the productivity of ethanol fermentation, microwave pretreatment was tested in this study. Considering the effects of changes of lignocellulosic complex ultrastructure, microwave-based heating can be an alternative to conventional heating (Deng et al. 2015). Microwave radiation delignifies and partly removes hemicellulose and increases hydrolysis of sugars. Conventional heating is based on surface heat exchange; with microwaves, heat is generated by the electromagnetic field. Microwave radiation destroys cellulose by molecular collisions caused by dielectric polarization. The advantages of this method include: the short duration of the process, high selectivity and a smaller amount of the energy supplied compared to conventional heating [

1].

The aim of this study was to determine the effect of thermal hydrolysis on degradation of polysaccharides contained in biomass of cyanobacteria A. Platensis and to assess the effectiveness of ethanol production from pre-conditioned biomass. The effect of microwave-based and conventional heating on bioethanol production was compared.

2. Materials and Methods

Biomass of A. platensis obtained by the authors was used as the study material. The experiment was divided into two stage, I, hydrothermal treatment of the substrate was tested. Stage II involved an assessment of the effectiveness of the pretreatment methods to produce bioethanol in alcohol fermentation. The first stage of the study, with pretreatment, involved simultaneous testing of two variants of heating: microwave-based and conventional; each variant of the experiment was tested in three series at a different process temperature. The hydrothermal pretreatment was conducted for 20 min in both heating at 150 °C. Thermohydrolysis was conducted in two heating technologies. The hydrothermal microwave treatment was carried out with the Mars-Solvent Extraction system. Conventional heating of the plant material was done with a four-stand Laboplay O420E oil bath, in which silicon oil was used as the heating agent. The conditions during the thermohydrolysis—both with conventional and microwave-based heating—were the same. In stage two alcohol fermentation was conducted with an industrial yeast strain used in the industrial production of ethanol: Saccharomyces cerevisiae As4. Inoculum of yeast S. cerevisiae was done with liquid YPG medium: 10 g of yeast extract, 20 g of peptone, 20 g of glucose and 20 g agar dissolved in 1000 cm3 of distilled water. The pH was brought to 5.2 by adding 1 M HCl and controlled by a universal pH-meter. 5 cm3 of sterile distilled water was transferred into a tube with a yeast culture on YPG and washout was performed. The cell suspension obtained in the process was introduced to a conical flask with 100 cm3 of liquid YPG medium and incubated for 24 h in a shaker at a temperature of 30 °C.

Alcohol fermentation was conducted in an SHF (Separate Hydrolysis and Fermentation) system. After hydrolysis, the substrate was fermented. The inoculum of the appropriate yeast strain was added to the prepared medium (substrate after pretreatment). Fermentation was conducted for 72 h under anaerobic conditions, at an appropriate temperature for the yeast strain, i.e., at 38 °C. The content of ethanol in the medium was determined after the fermentation was completed. This was done by the method using Hach Lange’s LCK 300 reagents. Stage II involved testing three variants of the experiment tested at stage I. The variant was tested in which substrate pretreatment was conducted with microwave radiation at the most beneficial temperature; likewise, alcohol fermentation was conducted for substrates prepared in the same manner for pretreatment with conventional heating. The third variant under test was a control sample, i.e., a substrate without any pretreatment.

3. Results and Discussion

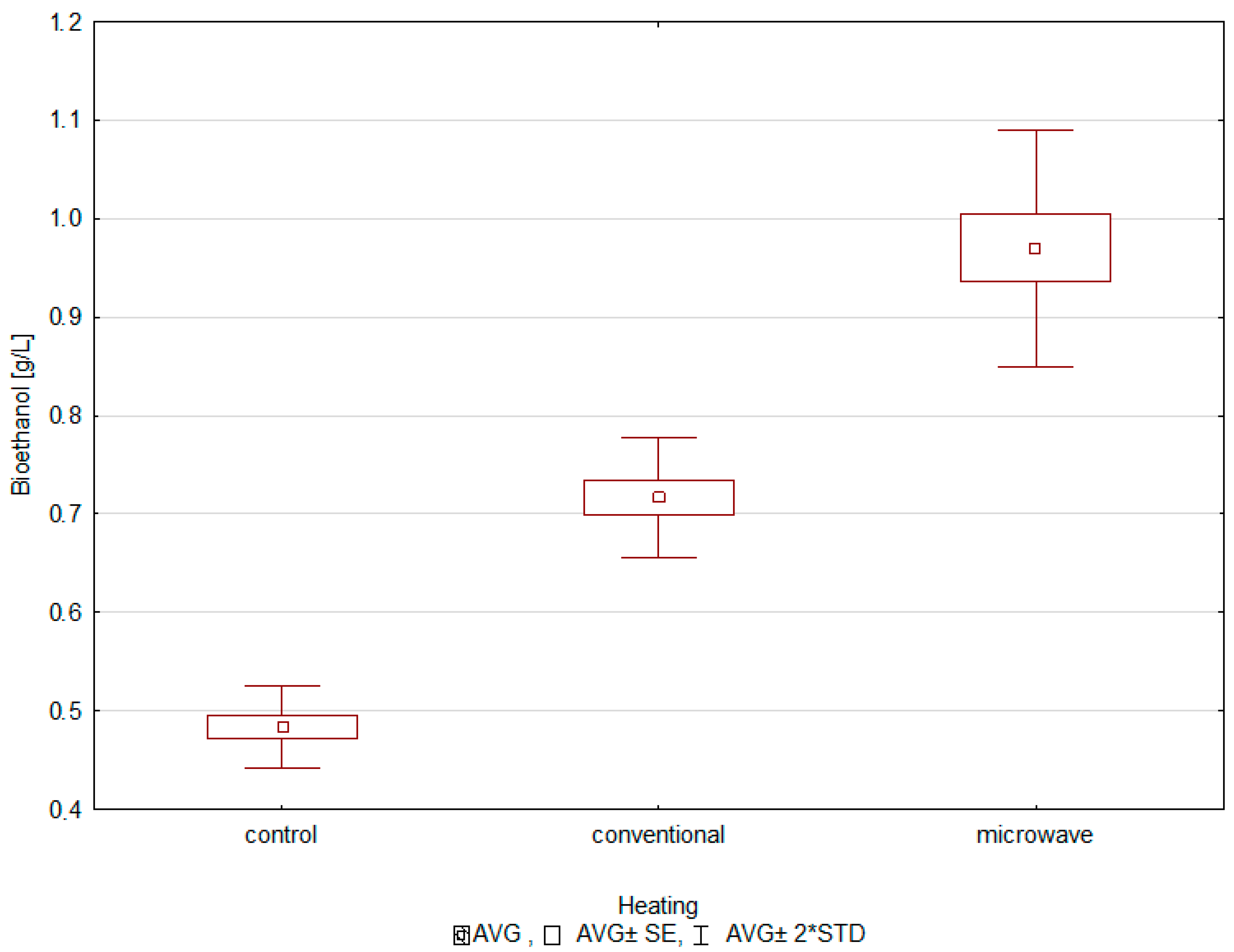

The content of ethanol in the medium—“mash”—was determined after fermentation was completed (72 h). Fermented samples were prepared at 150 °C. The control substrate yielded 0.49 g/L of bioethanol, the alcohol concentration in the conventionally pre-heated sample increased by 45%, i.e., to 0.71 g/L, the microwave-heated sample contained the highest concentration of alcohol: 0.97 g/L, which is more by 98% than in the control mash and more by 37% than in the conventionally heated sample (

Figure 1).

The literature provides examples of application of microwaves as a conditioning factor in alcohol fermentation. Substrate exposure to microwave radiation in various temperature ranges has shown that microwaves increase solubilisation of substrates and break the network of exopolysaccharides, thereby speeding up chemical processes [

1]. Klein et al. (2016) applied microwave radiation to increase the production of bioethanol from leaves of sacred fig. The authors applied simultaneous microwave-chemical treatment with hydrochloric acid as the reagent used in the experiment. They compared the results with conventionally heated samples. They tested saccharification of 1 g of the substrate with 20 mL of HCl as a function of acid concentration, time and temperature of exposure to microwave radiation. They observed the most satisfying results after adding 1 M HCl to the sacred fig leaves, followed by microwave heating for 8 min at temperatures increasing from 80 to 110 °C. The application of microwave radiation increased glucose production by up to 246% compared to conventionally heated samples. After the pretreatment, alcohol fermentation of the hydrolysate was conducted with Saccharomyces cerevisiae; the maximum ethanol recovery was 3% (

w/

w) of the dry weight of the substrate used [

3]. Microwave thermohydrolysis conducted by those authors increased the amount of bioethanol production by 98% compared to the control sample. Meinita et al. (2013) examined production of bioethanol from red algae: Gelidium amansii, Gracilaria tenuistipitata and Gracilariopsis chorda. The algae were hydrolysed at 130 °C for 15 min with 0.2 M H

2SO

4 and subsequently fermented at 30 °C; the distillate contained from 0.5 to 0.83 g/L of ethanol [

4]. Wu et al. (2014) conducted fermentation of algae of

Gracilaria sp. and produced ethanol with the yeast

Saccharomyces cerevisiae Wu-Y2; they obtained maximally 4.72 g/L of ethanol from 11.85 g/L of glucose [

5].

4. Conclusions

The application of microwave heating with a view to hydrothermal disintegration of cyanobacteria A.platensis helped to achieve higher efficiency of glucose release and production of ethanol compared to conventional heating. The application of microwave technology increased the amount of produced glucose by a maximum of 62% compared a sample with no pretreatment. The results have shown that 150 °C was the most beneficial for the thermohydrolysis process, both in the microwave and conventional heating. The results show that the increased concentration of phenolic compounds did not inhibit alcohol fermentation; the control mash yielded 0.49 g/L of bioethanol, the alcohol concentration in the conventionally pre-heated sample increased by 45% (to 0.71 g/L), the mash in the microwave-heated sample contained the highest concentration of alcohol: 0.97 g/L, which is 98% more than in the control mash and 37% more than in the conventionally heated sample.

Author Contributions

M.Z., M.D., M.H. and E.K. conceived and designed the experiments; P.R. and E.A. performed the experiments; M.Z., M.D. and P.R. analyzed the data; P.R. wrote the paper. All authors have read and agreed to the published version of the manuscript.

Acknowledgments

This paper was written as part of the research project Nr WSC/2016/1 carried out as part of the statutory scientific.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Balat, M. Production of bioethanol from lignocellulosic materials via the biochemical pathway: A review. Energy Convers. Manag. 2011, 52, 858–875. [Google Scholar] [CrossRef]

- Jönsson, J.L.; Martín, C. Pretreatment of lignocellulose: Formation of inhibitory by-products and strategies for minimizing their effects. Bioresour. Technol. 2016, 199, 103–112. [Google Scholar] [CrossRef] [PubMed]

- Ahn, J.H.; Shinb, S.G.; Hwangb, S. Effect of microwave irradiation on the disintegration and acidogenesis of municipal secondary sludge. Chem. Eng. J. 2009, 153, 145–150, Klein, M.; Griess, O.; Pulidindi, I.N.; Perkas, N.; Gedanken, A. Bioethanol production from Ficus religiosa leaves using microwave irradiation. J. Environ. Manag. 2016, 177, 20–25. [Google Scholar] [CrossRef]

- Meinita, M.D.N.; Marhaeni, B.; Winanto, T.; Jeong, G.T.; Khan, M.N.A.; Hong, Y.K. Hong Comparison of agarophytes (Gelidium, Gracilaria, and Gracilariopsis) as potential resources for bioethanol production. J. Appil. Phycol. 2013, 25, 1957–1961. [Google Scholar] [CrossRef]

- Wu, F.C.; Wu, J.Y.; Liao, Y.J.; Wang, M.Y.; Shih, I.L. Sequential acid and enzymatic hydrolysis in situ and bioethanol production from Gracilaria biomass. Bioresour. Technol. 2014, 156, 123–131. [Google Scholar] [CrossRef] [PubMed]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).