Abstract

This paper aims to assess the environmental impact of family houses designed as a building with green technologies and green materials. These family houses are located in villages of Velky Folkmar and Jedlinka, which are situated in eastern Slovakia. The analysis investigates the role of application of these technologies on impact categories such as: global warming potential (GWP), acidification potential (AP), eutrophication potential (EP), photochemical ozone creation potential (POCP), abiotic depletion potential fossil fuels (ADPF) expressed as CO2eq, SO2eq, PO43−eq, kg ethylene and MJ, respectively within “Cradle to Grave” boundary by using the LCA assessment method. The main contribution of the study is to highlight the significance of green technologies in reduction of environmental impacts. The presented results show that house with built-in green materials and technologies causes significantly lower environmental impacts compared to house where both green technologies and conventional materials are built. The operation phase (B6) is characterized by greater environmental impacts compared to the product and construction phases, as well as deconstruction phase due to the use of green materials and technologies.

1. Introduction

The three known streams of methods such as Life Cycle Assessment (LCA), Life Cycle Energy Assessment (LCEA) and Life Cycle Carbon Emissions Assessment (LCCO2A) were reviewed in study [1]. Results show that they all share some similarities in the overall objective in evaluating the impacts over the life cycle of building construction. Review points to differences. The major focus of evaluation of LCEA is on energy input, LCCO2A is on carbon-equivalent inputs and LCA is on both environmental inputs and outputs. All of these methods pointed to the same conclusion that the use-phase of a building contributes the largest life cycle environmental impacts with their structural materials dominating the share. However, major discrepancies in findings are observed among the three streams when different compositions of fuel mixes are used in power generation, or when the overall impacts are not contributed mostly by greenhouse gases emissions. According to this study they can be applied for comparing different building designs with respect to their environmental impacts, there are still some drawbacks in boundary scoping, methodology framework, data inventory and practices, which impairs their usefulness as a decision making support tool. The usefulness of LCA can be further enhanced in building construction by standardizing the requirements for individual studies on the boundary scoping, methodology choices and data inventories so as to establish benchmarks for different types of buildings. Study [2] investigates the potential environmental impacts related to the end-of-life phase of a residential building, identified in a multifamily dwelling of three levels, constructed in the South of Italy by utilizing conventional materials and up-to-date procedures. An attributional life cycle assessment has been utilized to quantify the contributions of each stage of the end-of-life phase, with a particular attention to the management of the demolition waste. Presented results quantify the advantage of an appropriate technique of selective demolition, which could increase the quality and quantity of residues sent to the treatment of resource recovery and safe disposal. They also highlight the contributions to the positive or negative environmental impact of each stage of the investigated waste management system. The recycling of reinforcing steel appears to play a paramount role, accounting for 65% of the total avoided impacts related to respiratory inorganics, 89% of those for global warming and 73% of those for mineral extraction. Another study [3] presents results of LCA conducted on a low-energy industrial building under construction in Thailand. As a result, the manufacturing phase yields largest impacts in primary energy demand (71%), global warming potential (60%), and four other environmental impact categories. This is largely attributable to steel and concrete production and a higher embodied energy quantity per material. Additionally, four scenarios—a base case, recycling case, photovoltaic system scenario, and combined recycling/photovoltaic scenario—are simulated to evaluate strategies for further energy reduction. Analysis indicates that significant life cycle energy savings can be achieved through recycling (29%) and a rooftop PV system (64%). The combination of both enhancements compensates for all manufactured material embodied energies and results in a building with zero or sub-zero total life cycle energy demand. Buildings that are already low-energy can further reduce environmental impacts through inclusion of the aforementioned approaches in design and implementation.

This paper deal with life cycle assessment of two detached family houses to be applied natural building materials and green technologies.

2. Design of Assessed Family House

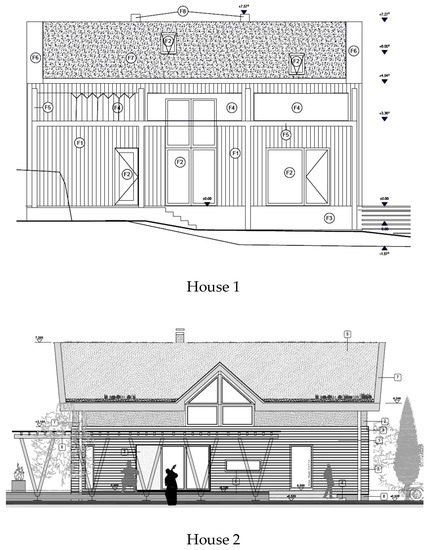

Family house 1 is located on a slightly sloping terrain in the village Velky Folkmar with a built-up area of 120 m2. It is designed as a separate two-storey building for four-person household. In terms of an existing area, it is oriented to the south-east side. The family house has a compact solution with minimized communication spaces, which provide a comfortable living space and create an ideal ratio between living and communication space. On the ground floor there is living room, kitchen, workroom, staircase, technical room and lobby. The second floor consists of two children’s rooms, corridor and bathroom. The vertical load-bearing structures are designed from the shrouded unblended clay into the shell. The building is equipped with its own heat source—a gas condensing boiler with a water tank. Boiler power is 3.8–13.0 kW.

The second house with a built-up area of 68 m2 is located on a flat terrain in the village of Jedlinka. It is also designed as a separate two-storey building for four-person household. In terms of the existing area, it is oriented to the south-east and south-west. The family house has a similar layout solution as the first one. On the ground floor there is living room with kitchen, children’s room, bedroom, bathroom, staircase, technical room, storage room and lobby. The second floor consists of room, workroom and bathroom. The vertical load-bearing structures of the perimeter walls are designed from straw panels covered fiberboards. The building is equipped with its own heat source—An electric boiler with a water tank (14.0 kW). The architecture of both buildings is given by the design itself, consisting of a vegetation roof and a façade wood finish (Figure 1).

Figure 1.

Views of family houses.

3. Materials and Methods

Environmental performance of designed family houses is calculated by using the LCA assessment method within “cradle to grave” boundaries according to the recommendations of EN 15804:2012. The life-cycle phases included within the system boundaries include production of components (building materials), the installation process, operation and end-of-life. The analysis investigates the role of building material solutions as well as the usage of different building technologies in terms of equivalent emissions of CO2, SO2, PO43−, kg ethylene and MJ for reference study period of 60 years. The functional unit is considered to be one square meter of gross floor area for a period of the life cycle (1 m2). For the LCA analysis was used software eToolLCD which uses third party background processes aggregated as midpoint indicators and stored in a number of libraries within the software which are coupled with algorithms and user inputs to output the environmental impact assessment [4].

4. Results and Discussion

Comparisons between two family houses are presented in Table 1, in which five impact categories are determined.

Table 1.

Characteristic impacts on m2 of the total floor area of a family houses.

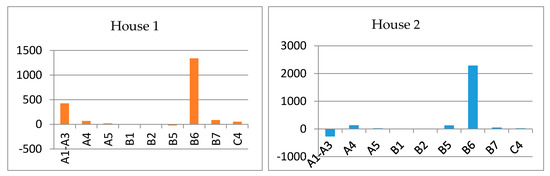

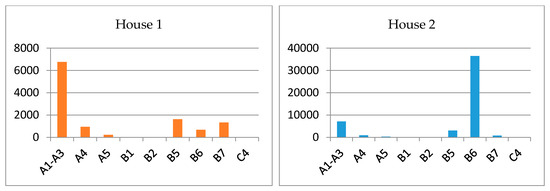

Figure 2 and Figure 3 depict impacts of GWP and ADPF for all phases of the family houses life cycle.

Figure 2.

LCA module impacts of GWP (kg CO2eq), A1–A3 Product Stage; A4 Transport of Equipment and Materials; A5 Construction; B1 Use of Products; B2 Maintenance; B5 Refurbishment; B6 Integrated Operational Energy Use; B7 Operational Water Use; C4 Disposal.

Figure 3.

LCA module impacts of ADPF (MJ), A1–A3 Product Stage; A4 Transport of Equipment and Materials; A5 Construction; B1 Use of Products; B2 Maintenance; B5 Refurbishment; B6 Integrated Operational Energy Use; B7 Operational Water Use; C4 Disposal.

The major contributors for GWP expressed as equivalent emissions of CO2 is energy use (B6) with percentage weight of 70% and 96% for family houses 1 and 2. For the family house 1 the product phase (A1–A3) contributes to the CO2eq emissions by 22%. With regard to the family house 2, the product phase reduces CO2eq emissions by 11% due to using natural building materials, such as wood and straw.

Family house 1 significantly contributes to ADPF in product phase (A1–A3) with value of 59%, phase of recurring (B5) with percentage weight of 14% and in phase of water use with value of 11%. With regard to the family house 2, the phase of energy use significantly contributes to ADPF with percentage weight of 75% due to electrical energy used for operation of the house. Product phase contributes to ADPF only by 14% due to using natural building materials.

5. Conclusions

The LCA provides the best currently available framework for assessing potential environmental impacts of products. LCA as a tool for evaluating environmental impacts associated with all life cycle phases of the building can be applied to buildings on different levels, including at the level of the building materials and products, building parts and whole buildings. This study indicates that combining green technologies such as green roof and natural building materials, such as wood and straw are lower negative impacts on the environment in production phase as well as during their usage. Future research work will be aimed at the evaluation of large number of residential buildings using various green elements and technologies to find a point where more green technologies are no longer environmentally or economically effective.

Acknowledgments

This paper was financially supported by the Slovak Grants No. 1/0307/16 and 1/0648/17. Authors would like to thank to Ing. arch. Pavol Mészáros and Ing. arch. Viliam Holeva for providing family house’s project documentations that has been used during the elaboration of this paper.

References

- Chau, C.K.; Leung, T.M.; Ng, W.Y. A review on Life Cycle Assessment, Life Cycle Energy Assessment and Life Cycle Carbon Emissions Assessment on buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- Vitale, P.; Arena, N.; Di Gregorio, F.; Arena, U. Life cycle assessment of the end-of-life phase of a residential building. Waste Manag. 2017, 60, 311–321. [Google Scholar] [CrossRef] [PubMed]

- Tulevech, S.M.; Hage, D.J.; Jorgensen, S.K.; Guensler, C.L.; Himmler, R.; Gheewala, S.H. Life cycle assessment: A multi-scenario case study of a low-energy industrial building in Thailand. Energy Build. 2018, 68, 191–200. [Google Scholar] [CrossRef]

- eTool. eToolLCD Software. Available online: https://etoolglobal.com/ (accessed on 1 January 2018).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).