1. Introduction

Producing about 50% of total GHG emissions (electricity consumed, transport, production of building materials, etc.), using more than 40% of raw materials and producing over 35% of solid waste, cities and building sector are one of the main causes of GHG emissions and contribute to aggravating the Climate Change (CC) [

1,

2]. Among the sectors that mostly contribute to GHG emissions, we find, in particular, the cement production sector, which alone accounts for about 8% of total CO

2 emissions [

3].

To reduce the climate change, since the 1990s, the main world countries have signed numerous agreements (Kyoto Protocol, United Nations Framework Convention on Climate Change—UNFCCC, Energy Roadmap 2050 (COM (2011) 885/2, etc.). Among the main measures indicated by these agreements to be adopted at global level to achieve the minimum targets set, we find the reduction of GHGs (Paris 2015 Accord). Re-naturalization and reforestation processes, implementing energy efficiency and reducing consumption, increasing the production of renewable energy, favoring processes based on the circular economy, reuse and recovery, favoring the production of low carbon materials are some of the possible Green Strategies (GS) that have to be adopted [

4]. In this framework building material industry can play a fundamental role in the reduction of GHG, by means of GS.

Several research has been conducted to evaluate, specifically, the environmental impact of building materials, applying the methodology of the Life Cycle Assessment (LCA), defined by international standards [

5,

6], which allows to identify the GHG emissions of each production phase for the entire life cycle of a specific product. Applying this methodology, some authors have compared the environmental impact of different building materials [

7,

8,

9]; others have defined improvement scenarios [

10,

11]; others have also analyzed the impact of recycled materials [

12,

13] [

14]. Alongside these specific works, some authors have provided interesting and comprehensive reviews of the use of LCA compared to building materials [

15].

Thanks to this works, the better understanding of the impact of building material on the natural environment and the identification of possible strategies of improved environmental performance can drive, in fact, the construction sector toward sustainability.

2. Materials and Methods

2.1. Goal and Scope

The research aims to evaluate the impact of the GS applied to the industrial process in terms of GHG emission reduction. In particular, based on the LCA methodology applied to a case study related to the production of a concrete self-locking blocks for outdoor pavement (COP), the research aims to define possible scenarios of intervention on the industrial process, capable of favoring technological innovation and reduction of GHG emissions.

2.2. Contest, Materials and Scenarios

The research is limited to the sector of Lazio Region outdoor pavement industry, characterized mainly by a low level of innovation, within which a concrete self-locking blocks pavement is usually produced in a “traditional way”, mixing clinker and raw materials (sand and natural aggregate). To investigate the possibility of reduce the GHG emission during the production process, several scenarios will be analyzed and compared:

HP0: “traditional” production process

HP1: production process improved by the use of recycled aggregates

HP2: production process improved by the use of green transportation camion

HP3: production process improved by the use of renewable energy

2.3. General Approach and LCA Methodology

The work will be carried out using the LCA methodology to a typical production process. In particular, the following phases will be defined: identification of the production cycle; identification of the limits of the analysis; data collection; LCA application limited to the production phase; evaluation of the results. The base scenario will then be compared with improvement scenarios (GS). Based on the comparison of these results, the consequences in terms of GHG reduction of the adopted strategies will be defined and discussed.

2.4. Approach and Limitation

The LCA was carried out following the international ISO standards [

5,

6], limiting the analysis to the phase of production, without considering product application, use and dismissing phases. This limitation is due to the main goal of the research that is to analyze the impact in terms of GMG reduction of green strategies applied to the material production. A life cycle inventory was compiled for each of the scenarios examined, but since the study is a comparative LCA and the research is in progress, some common processes were omitted.

According to the IPCC GWP impact method, the corresponding Global Warming Potential (GWP) was calculated for the emitted GHG in kilograms of CO

2 equivalent (CO

2-eq) [

16]. The data were collected form the literature review. The functional units (FU) is one square meter of COP. The time horizon of the assessment is limited to 100 years. The LCA has been developed using Ecoinvent dabase.

2.5. Product System and System Boundaries

The following unit process were considered (

Figure 1): raw material profiles from extraction; energy required for processing raw materials; energy for the transportation of the materials to the manufacturing company; COP production process.

3. Results and Discussion

Several scenarios have been compared using LCA methodology to evaluate the impact of GS in terms of GHG reduction.

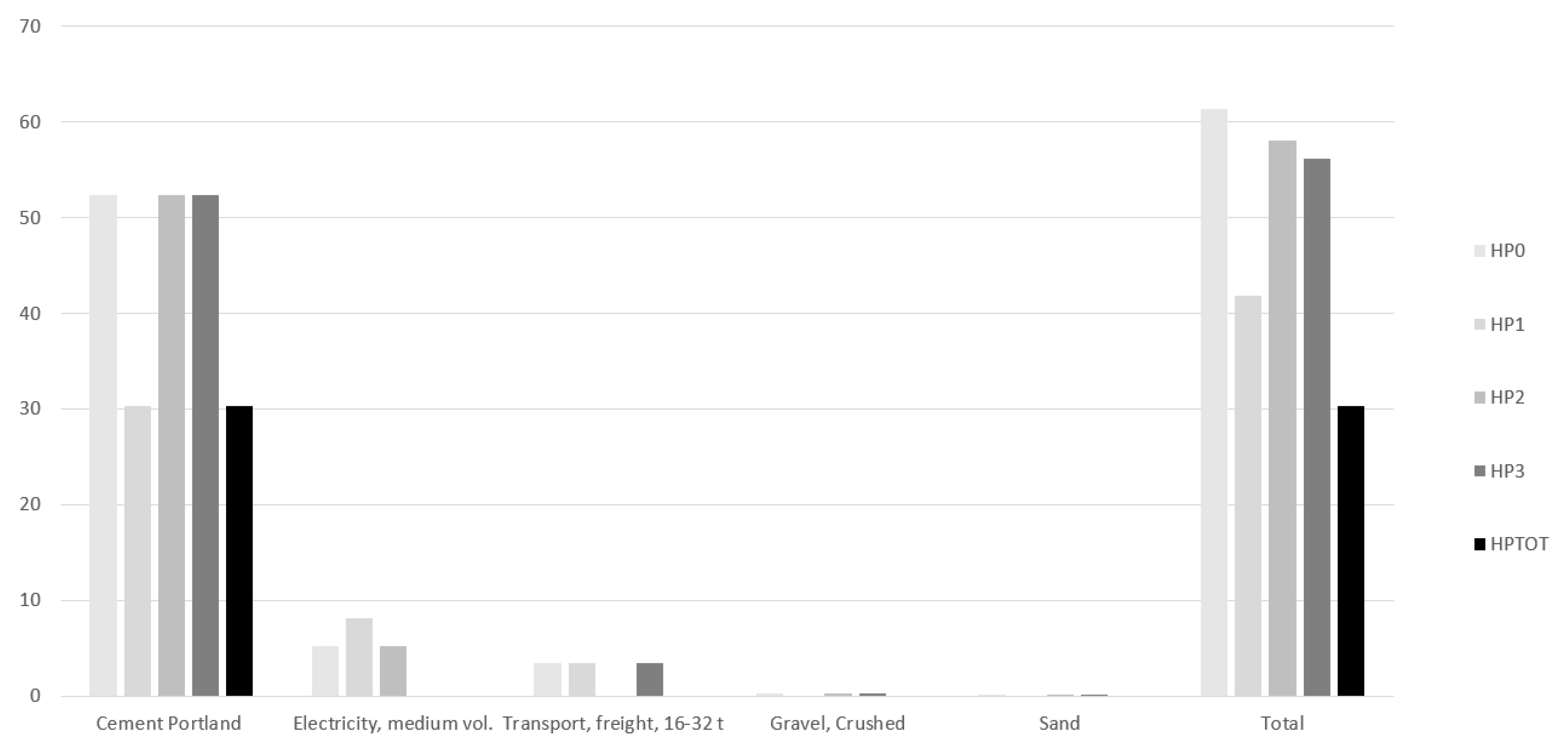

Table 1. Shows the data used as input for the LCA, defined as a percentage with respect to the definition of a functional unit of 1 square meter, while

Figure 1 shows the various scenarios compared in terms of reduction of GHG emissions, expressed in Kg of C02-Equivalent.

In HP0, the LCA shows the main impact of Cement Portland production respect to the other factors (gravel, transportation, energy, etc.), that contribute for more than the 80% of the global emission, confirming data of literature review. In HP1, the substitution of cement with other aggregates (i.e., Ash fly, recycled aggregates, etc.) reduce the global emission up to 30%; in HP2, the adoption of electric transportation increases the emission due to energy of 20% but guarantees a global reduction up to 10%; in the HP3, the introduction of PV allows to reduce GHG up to 10%. The combination of HP1+HP2+HP3 allows to reduce GHG up to 50%.

4. Conclusions

A comparative LCA for the production of a typical concrete self-locking blocks for outdoor pavement (COP) has been presented, comparing the “traditional” production process (HP0) with greener ones (HP1-3) defined by the use of alternative GS able to reduce GHG emission (i.e., use of removable energy, use of alternative aggregates, use of green transport system).

The LCA highlighted the role of cement production as the main source of GHG production into the actual scenario (HP0), confirming literature data. Comparing the HP0 with HP1-3, the LCA has showed the general capability in reducing the GHG emission of the GS applied, confirming literature data. In particular, the comparison of improved scenarios (HP1-3) respect the base scenario (HP0), underlines a GHG emission reduction a reduction up to respectively of 30%, 10% and 10%, while the implementation of the all green strategies can improve the GHG reduction until the 50%.

The next research developments are to applied the methodology defined in this first part of the research to a real case study of a Lazio industry; to increase the level of detail of the LCA channels; to implement items and data that have not been considered to date to facilitate the initial analysis process; to analyze other environmental impacts, such as the effects of air pollution (e.g., acidification and health effects caused by particulates), toxicity, etc.

Author Contributions

Conceptualization, P.M. and F.O.; Methodology, P.M. and F.O; Software, F.O.; Formal Analysis, F.O.; Investigation, F.O.; Writing-Original Draft Preparation, F.O.; Writing-Review & Editing, P.M.; Visualization, F.O.; Supervision, P.M.

Funding

This research received no external funding

Conflicts of Interest

The authors declare no conflict of interest.

References

- Construction Materials Recycling Association. Construction Materials Recycling Association; Construction Materials Recycling Association: Chicago, IL, USA, 2005. [Google Scholar]

- Marzouk, M.; Azab, S. Resources, Conservation and Recycling Environmental and economic impact assessment of construction and demolition waste disposal using system dynamics. Resour. Conserv. Recycl. 2014, 82, 41–49. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). Business Plan. In ISO/TC 71 Concrete, Reinforced Concrete and Prestressed Concrete; International Organization for Standardization (ISO): Geneva, Switzerland, 2005. [Google Scholar]

- European Commission. Energy Roadmap 2050; European Commission: Brussels, Belguim, 2012. [Google Scholar]

- International Organization for Standardization (ISO). Environmental Management—Life Cycle Assessment—Principles and Framework; 14,040:2006(E); International Organization for Standardization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization (ISO). Environmental Management—Life Cycle Assessment—Requirements and Guidelines; 14,044:2006(E); International Organization for Standardization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- Santero, N.J.; Masanet, E.; Horvath, A. Life-cycle assessment of pavements. Part I: Critical review. Resour. Conserv. Recycl. 2011, 55, 801–809. [Google Scholar] [CrossRef]

- Anastasiou, E.K.; Liapis, A.; Papayianni, I. Comparative life cycle assessment of concrete road pavements using industrial by-products as alternative materials. Resour. Conserv. Recycl. 2015, 101, 1–8. [Google Scholar] [CrossRef]

- Arrigoni, A.; Pelosato, R.; Melià, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Life cycle assessment of natural building materials: The role of carbonation, mixture components and transport in the environmental impacts of hempcrete blocks. J. Clean. Prod. 2017, 149, 1051–1061. [Google Scholar] [CrossRef]

- Gartner, E. Industrially interesting approaches to low-CO2 cements. Cem. Concr. Res. 2004, 34, 1489–1498. [Google Scholar] [CrossRef]

- Josa, A.; Aguado, A.; Cardim, A.; Byars, E. Comparative analysis of the life cycle impact assessment of available cement inventories in the EU. Cem. Concr. Res. 2007, 37, 781–788. [Google Scholar] [CrossRef]

- Talukdar, S.; Islam, S.; Banthia, N. Development of a lightweight low-carbon footprint concrete containing recycled waste materials. Adv. Civ. Eng. 2011, 2011, 594270. [Google Scholar] [CrossRef]

- Knoeri, C.; Sanyé-mengual, E.; Althaus, H. Comparative LCA of recycled and conventional concrete for structural applications. 2013, 18, 909–918. [Google Scholar] [CrossRef]

- De Schepper, M.; van den Heede, P.; van Driessche, I.; de Belie, N. Life Cycle Assessment of Completely Recyclable Concrete. Materials (Basel) 2014, 7, 6010–6027. [Google Scholar] [CrossRef] [PubMed]

- Cabeza, L.F.; Barreneche, C.; Miró, L.; Morera, J.M.; Bartolí, E.; Fernández, A.I. Low carbon and low embodied energy materials in buildings: A review. Renew. Sustain. Energy Rev. 2013, 23, 536–542. [Google Scholar] [CrossRef]

- IPCC. IPCC Fourth Assessment Report Cambridge; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).