Epitaxial Graphene Sensors Combined with 3D Printed Microfluidic Chip for Heavy Metals Detection †

Abstract

:1. Introduction

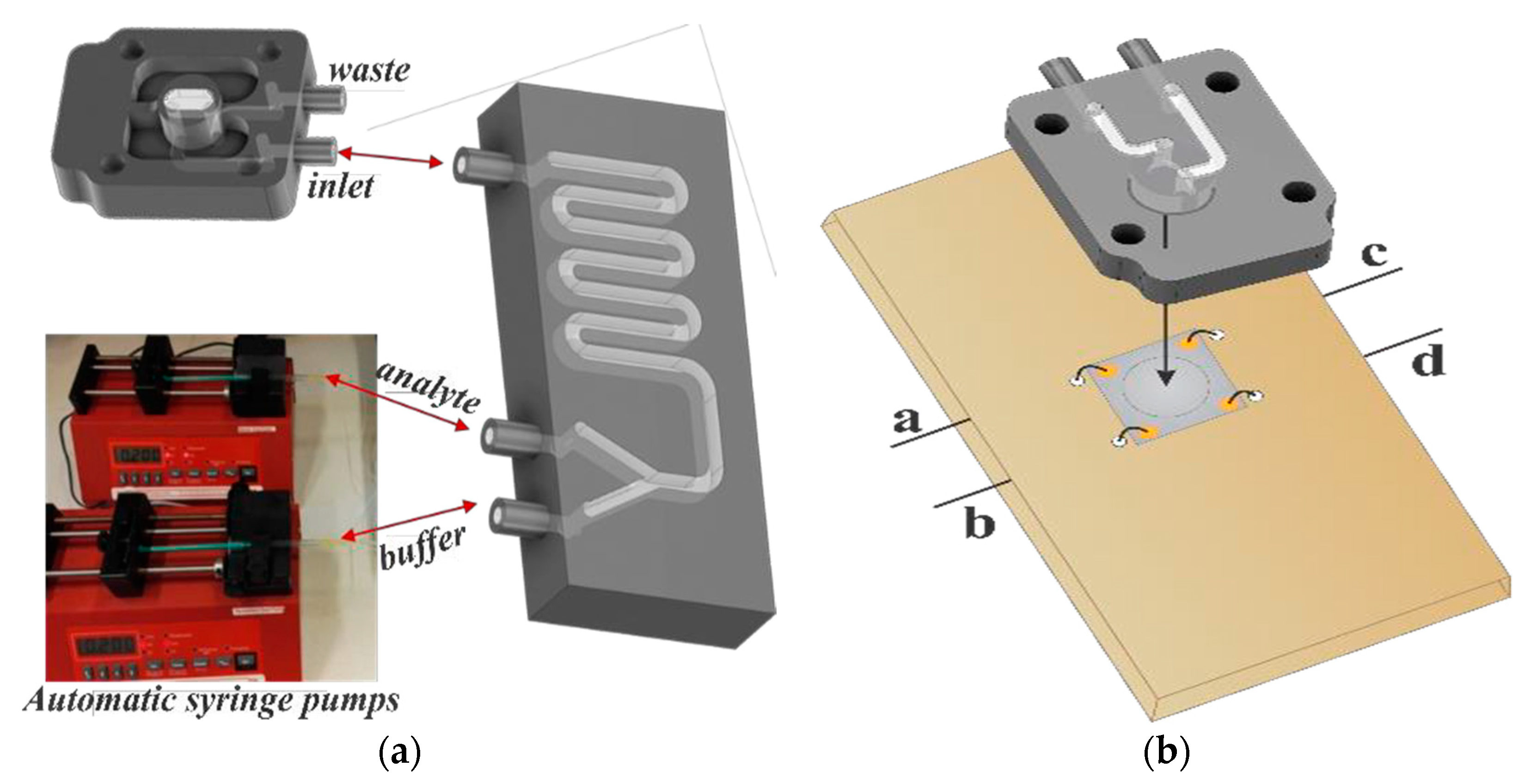

2. Materials and Methods

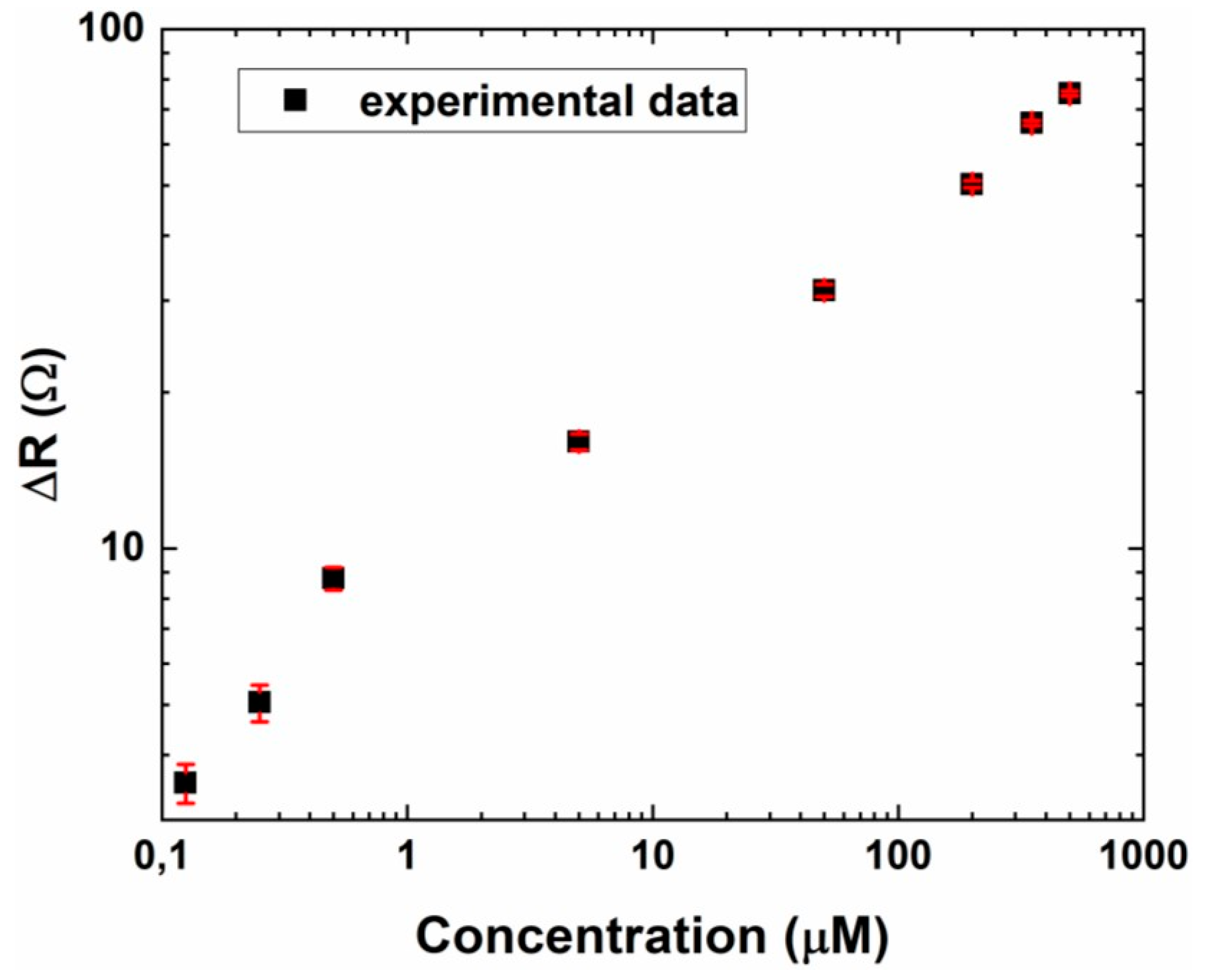

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Cui, L.; Wu, J.; Ju, H. Electrochemical sensing of heavy metal ions with inorganic, organic and bio-materials. Biosens. Bioelectron. 2015, 63, 276–286. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://www.hydroviv.com/blogs/water-smarts/heavy-metal-toxicity (accessed on 29 November 2018).

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Yazdi, G.R.; Vasiliauskas, R.; Iakimov, T.; Zakharov, A.; Syväjärvi, M.; Yakimova, R. Growth of large area monolayer graphene on 3C-SiC and a comparison with other SiC polytypes. Carbon 2013, 57, 477–484. [Google Scholar] [CrossRef]

- Rodner, M.; Bahonjic, J.; Mathisen, M.; Gunnarsson, R.; Ekeroth, S.; Helmersson, U.; Ivanov, I.G.; Yakimova, R.; Eriksson, J. Performance tuning of gas sensors based on epitaxial graphene on silicon carbide. Mater. Des. 2018, 153, 153–158. [Google Scholar] [CrossRef]

- Comina, G.; Suska, A.; Filippini, D. Towards autonomous lab-on-a-chip devices for cell phone biosensing. Biosens. Bioelectron. 2016, 77, 1153–1167. [Google Scholar] [CrossRef] [PubMed]

- Comina, G.; Suska, A.; Filippini, D. Low cost lab-on-a-chip prototyping with a consumer grade 3D printer. Lab Chip 2014, 14, 2978–2982. [Google Scholar] [CrossRef] [PubMed]

- Santangelo, M.F.; Libertino, S.; Turner, A.P.F.; Filippini, D.; Mak, W.C. Integrating printed microfluidics with silicon photomultipliers for miniaturised and highly sensitive ATP bioluminescence detection. Biosens. Bioelectron. 2018, 99, 464–470. [Google Scholar] [CrossRef] [PubMed]

- Leenaerts, O.; Partoens, B.; Peeters, F.M. Adsorption of H2O, NH3, CO, NO2, and NO on graphene: A first-principles study. Phys. Rev. B 2018, 77, 125416. [Google Scholar] [CrossRef]

- Available online: http://www.who.int/water_sanitation_health/dwq/chemicals/lead.pdf (accessed on 29 November 2018).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santangelo, M.F.; Shtepliuk, I.; Puglisi, D.; Filippini, D.; Yakimova, R.; Eriksson, J. Epitaxial Graphene Sensors Combined with 3D Printed Microfluidic Chip for Heavy Metals Detection. Proceedings 2018, 2, 982. https://doi.org/10.3390/proceedings2130982

Santangelo MF, Shtepliuk I, Puglisi D, Filippini D, Yakimova R, Eriksson J. Epitaxial Graphene Sensors Combined with 3D Printed Microfluidic Chip for Heavy Metals Detection. Proceedings. 2018; 2(13):982. https://doi.org/10.3390/proceedings2130982

Chicago/Turabian StyleSantangelo, Maria Francesca, Ivan Shtepliuk, Donatella Puglisi, Daniel Filippini, Rositsa Yakimova, and Jens Eriksson. 2018. "Epitaxial Graphene Sensors Combined with 3D Printed Microfluidic Chip for Heavy Metals Detection" Proceedings 2, no. 13: 982. https://doi.org/10.3390/proceedings2130982

APA StyleSantangelo, M. F., Shtepliuk, I., Puglisi, D., Filippini, D., Yakimova, R., & Eriksson, J. (2018). Epitaxial Graphene Sensors Combined with 3D Printed Microfluidic Chip for Heavy Metals Detection. Proceedings, 2(13), 982. https://doi.org/10.3390/proceedings2130982