An LED Platform for Micropower Gas Sensors †

Abstract

:1. Introduction

2. Materials and Methods

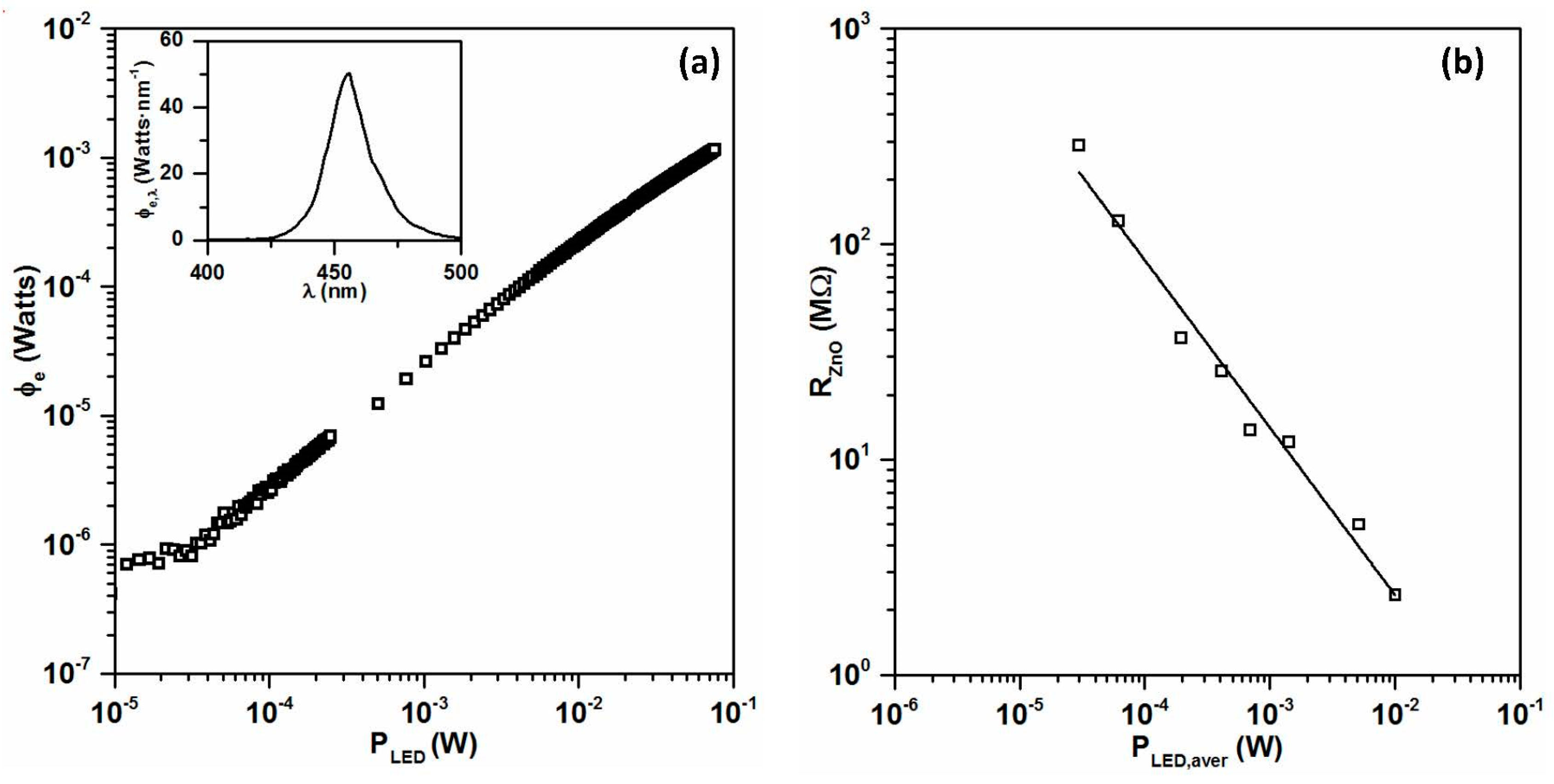

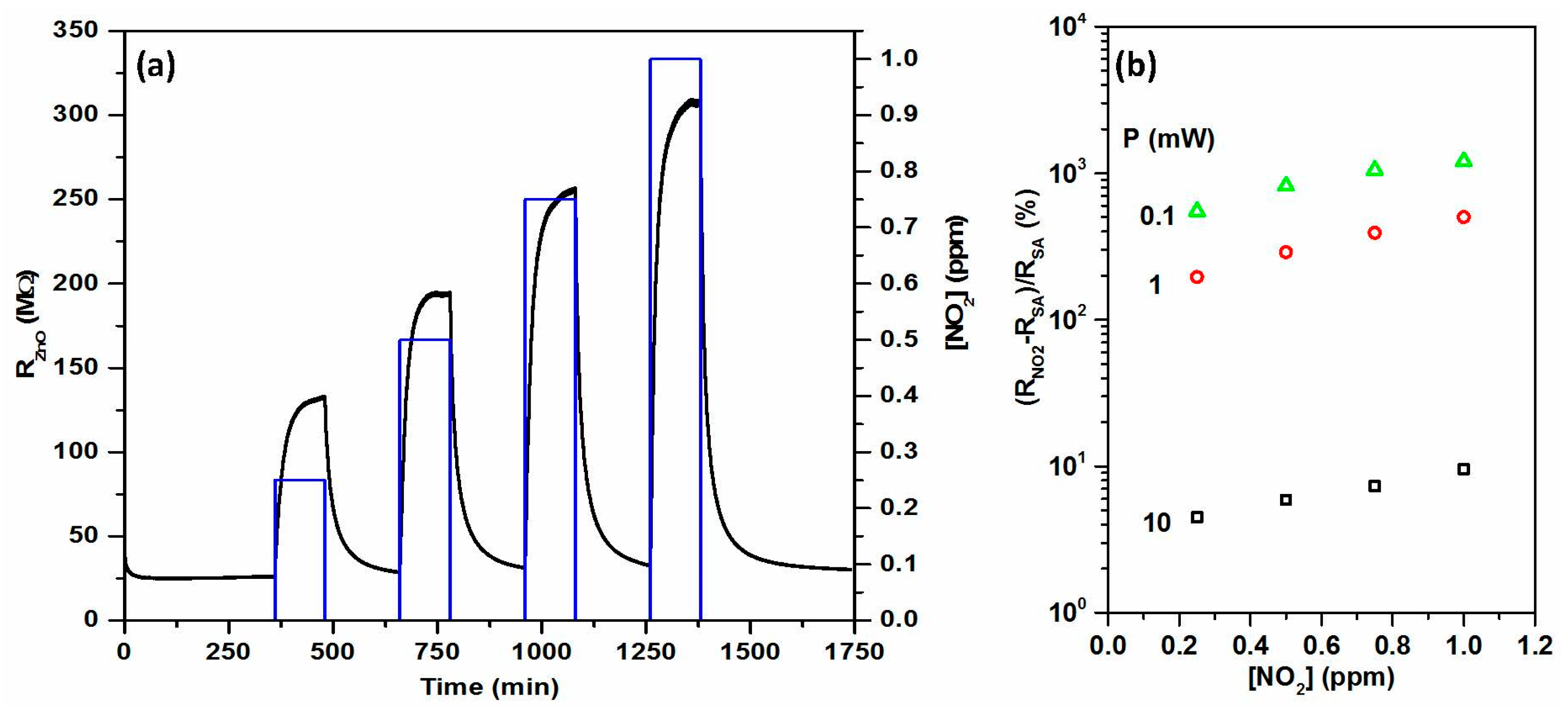

3. Results and Discussion

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Fabrega, C.; Casals, O.; Hernandez-Ramirez, F.; Prades, J.D. A review on efficient self-heating in nanowire sensors: Prospects for very-low power devices. Sens. Actuators B Chem. 2018, 256, 797–811. [Google Scholar] [CrossRef]

- Prades, J.D.; Jimenez-Diaz, R.; Manzanares, M.; Hernandez-Ramirez, F.; Cirera, A.; Romano-Rodriguez, A.; Mathur, S.; Morante, J.R. A model for the response towards oxidizing gases of photoactivated sensors based on individual SnO2 nanowires. Phys. Chem. Chem. Phys. 2009, 11, 10881. [Google Scholar] [CrossRef] [PubMed]

- Espid, E.; Taghipour, F. UV-LED Photo-activated Chemical Gas Sensors: A Review. Crit. Rev. Solid State Mater. Sci. 2017, 42, 416–432. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markiewicz, N.; Casals, O.; Fabrega, C.; Wasisto, H.S.; Waag, A.; Prades, J.D. An LED Platform for Micropower Gas Sensors. Proceedings 2018, 2, 971. https://doi.org/10.3390/proceedings2130971

Markiewicz N, Casals O, Fabrega C, Wasisto HS, Waag A, Prades JD. An LED Platform for Micropower Gas Sensors. Proceedings. 2018; 2(13):971. https://doi.org/10.3390/proceedings2130971

Chicago/Turabian StyleMarkiewicz, Nicolai, Olga Casals, Cristian Fabrega, Hutomo Suryo Wasisto, Andreas Waag, and Joan Daniel Prades. 2018. "An LED Platform for Micropower Gas Sensors" Proceedings 2, no. 13: 971. https://doi.org/10.3390/proceedings2130971

APA StyleMarkiewicz, N., Casals, O., Fabrega, C., Wasisto, H. S., Waag, A., & Prades, J. D. (2018). An LED Platform for Micropower Gas Sensors. Proceedings, 2(13), 971. https://doi.org/10.3390/proceedings2130971