Systematic Electro-Optical Study of Photodiodes in Intrinsic Material (Lowly Doped) with Backend Stack Optimization †

Abstract

:1. Introduction

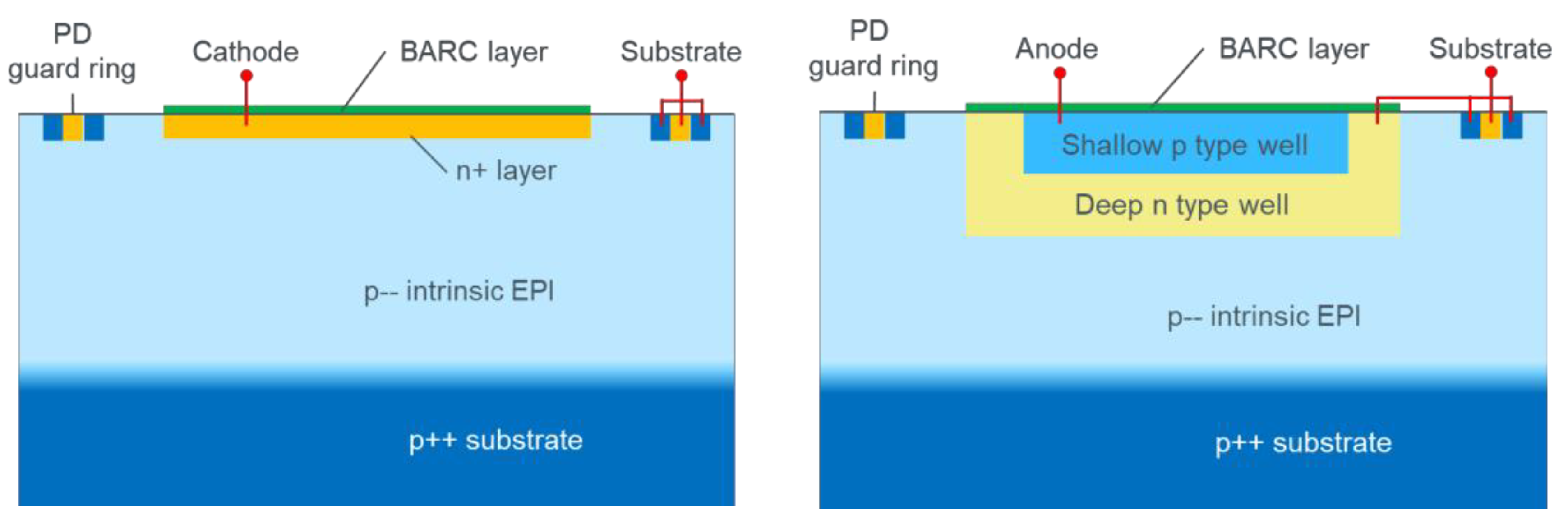

2. Materials and Methods

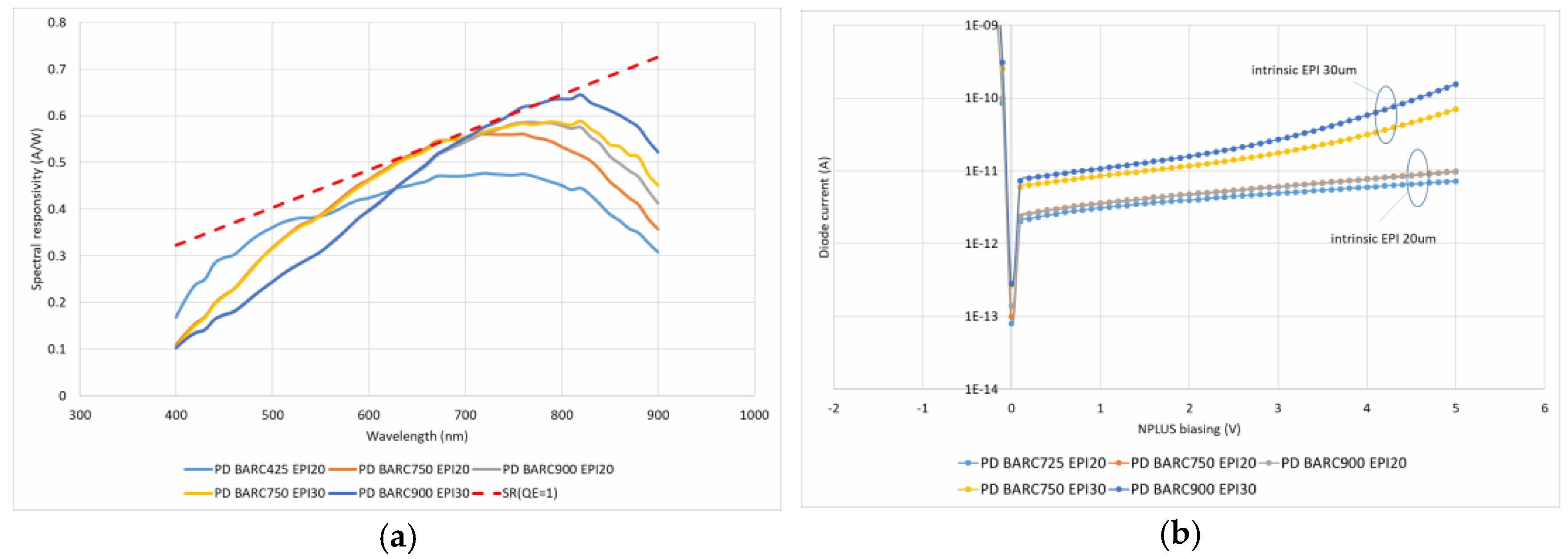

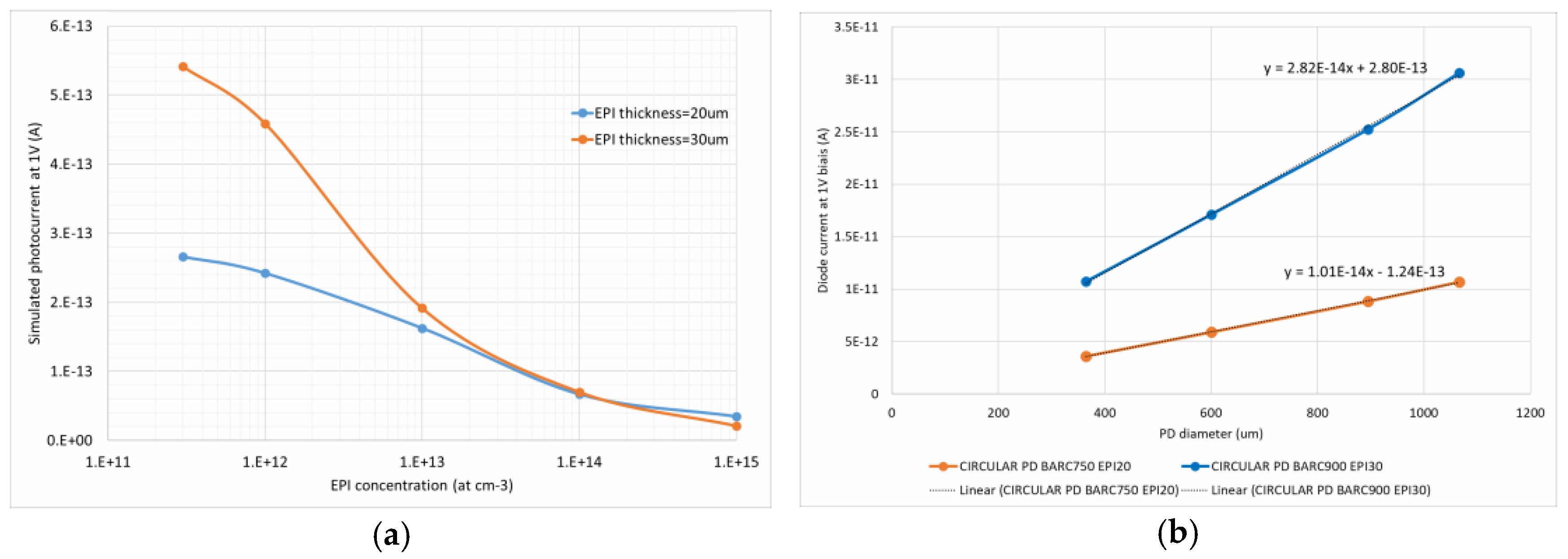

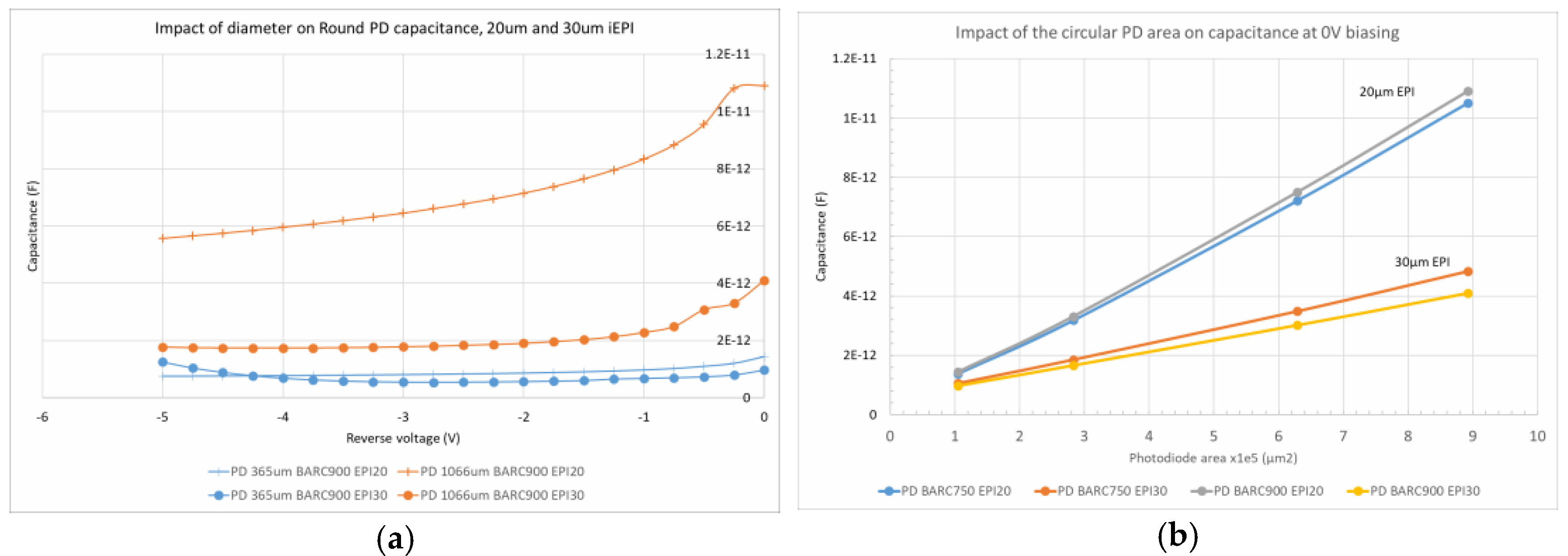

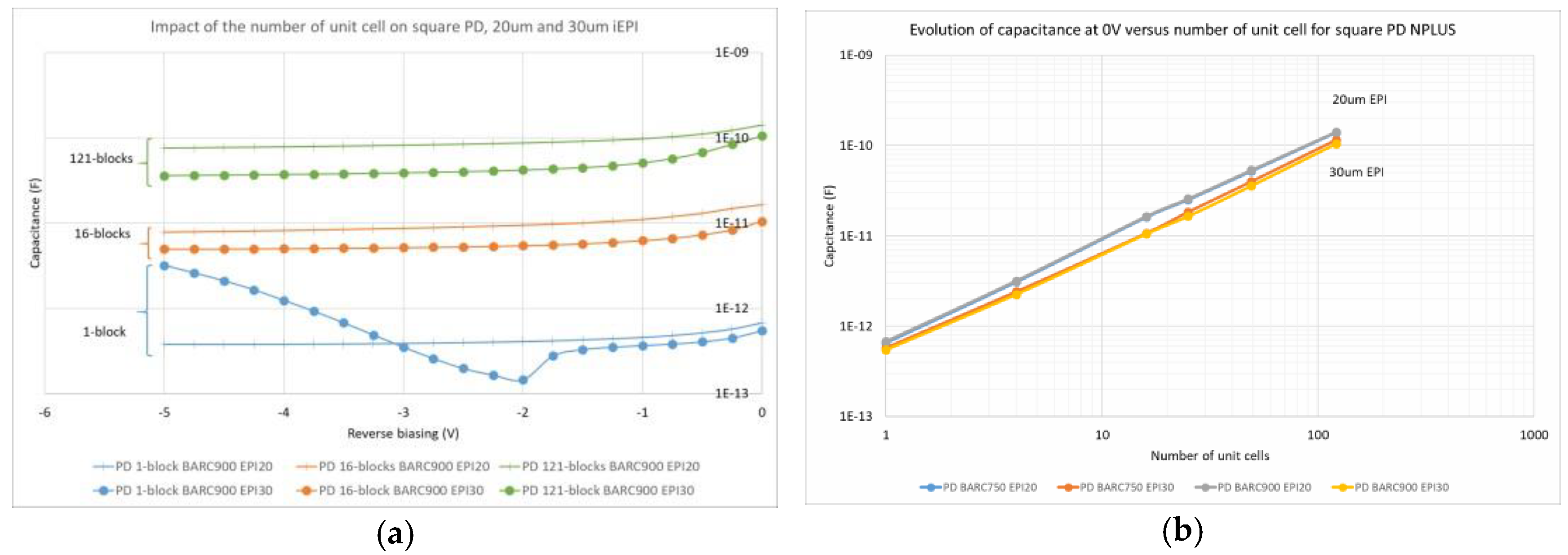

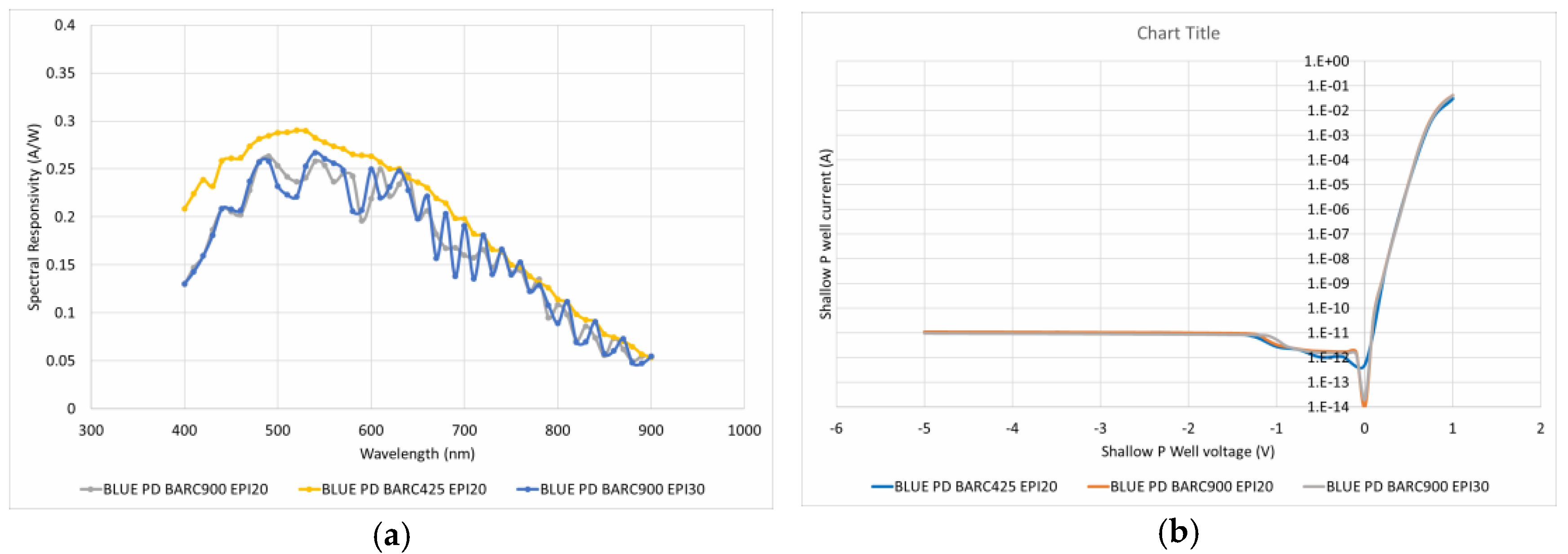

3. Results

4. Summary

References

- Sze, S.M.; Ng, K.K. Physics of Semiconductor Devices, 3rd ed.; Wiley: Hoboken, NJ, USA, 2007; pp. 671–682. [Google Scholar]

- Jonak-Auer, I.; Teva, J.; Park, J.M.; Jessenig, S.; Kailbauer, P.; Wachmann, E. New integration concept of PIN photodiodes in 0.35 µm CMOS technologies. Proc. SPIE 2012, 8431. [Google Scholar] [CrossRef]

- Teva, J.; Jessenig, S.; Jonak-Auer, I.; Schrank, F.; Wachmann, E. Dark current study for CMOS fully integrated-PIN-photodiodes. Proc. SPIE 2011, 8073. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roger, F.; Jonak-Auer, I.; Synooka, O.; Segmanovic, F.; Mellin, J.; Hofstaetter, H. Systematic Electro-Optical Study of Photodiodes in Intrinsic Material (Lowly Doped) with Backend Stack Optimization. Proceedings 2018, 2, 909. https://doi.org/10.3390/proceedings2130909

Roger F, Jonak-Auer I, Synooka O, Segmanovic F, Mellin J, Hofstaetter H. Systematic Electro-Optical Study of Photodiodes in Intrinsic Material (Lowly Doped) with Backend Stack Optimization. Proceedings. 2018; 2(13):909. https://doi.org/10.3390/proceedings2130909

Chicago/Turabian StyleRoger, Frederic, Ingrid Jonak-Auer, Olesia Synooka, Filip Segmanovic, Joni Mellin, and Helmut Hofstaetter. 2018. "Systematic Electro-Optical Study of Photodiodes in Intrinsic Material (Lowly Doped) with Backend Stack Optimization" Proceedings 2, no. 13: 909. https://doi.org/10.3390/proceedings2130909

APA StyleRoger, F., Jonak-Auer, I., Synooka, O., Segmanovic, F., Mellin, J., & Hofstaetter, H. (2018). Systematic Electro-Optical Study of Photodiodes in Intrinsic Material (Lowly Doped) with Backend Stack Optimization. Proceedings, 2(13), 909. https://doi.org/10.3390/proceedings2130909