InGaN/GaN nanoLED Arrays as a Novel Illumination Source for Biomedical Imaging and Sensing Applications †

Abstract

:1. Introduction

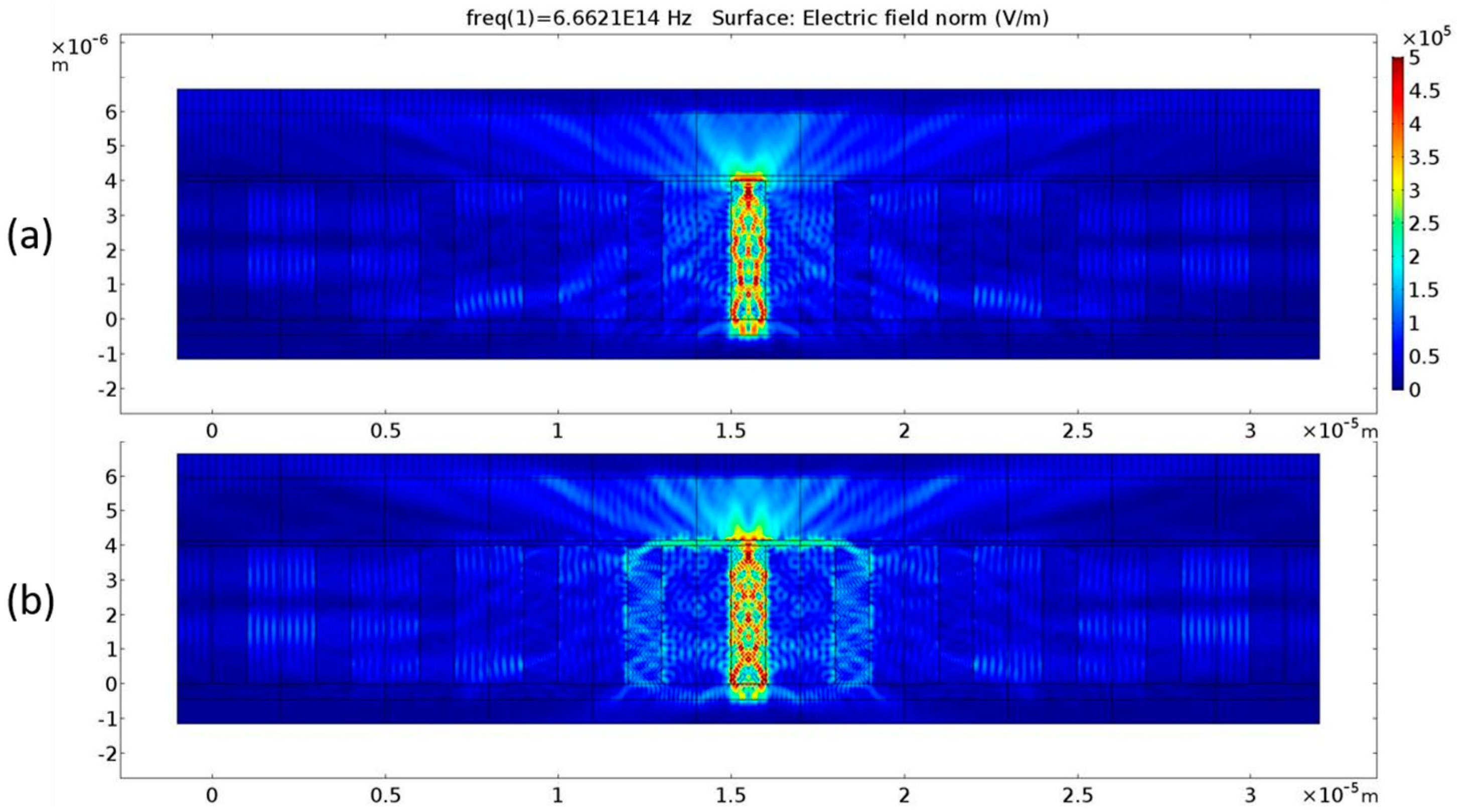

2. Device Concept and Simulation

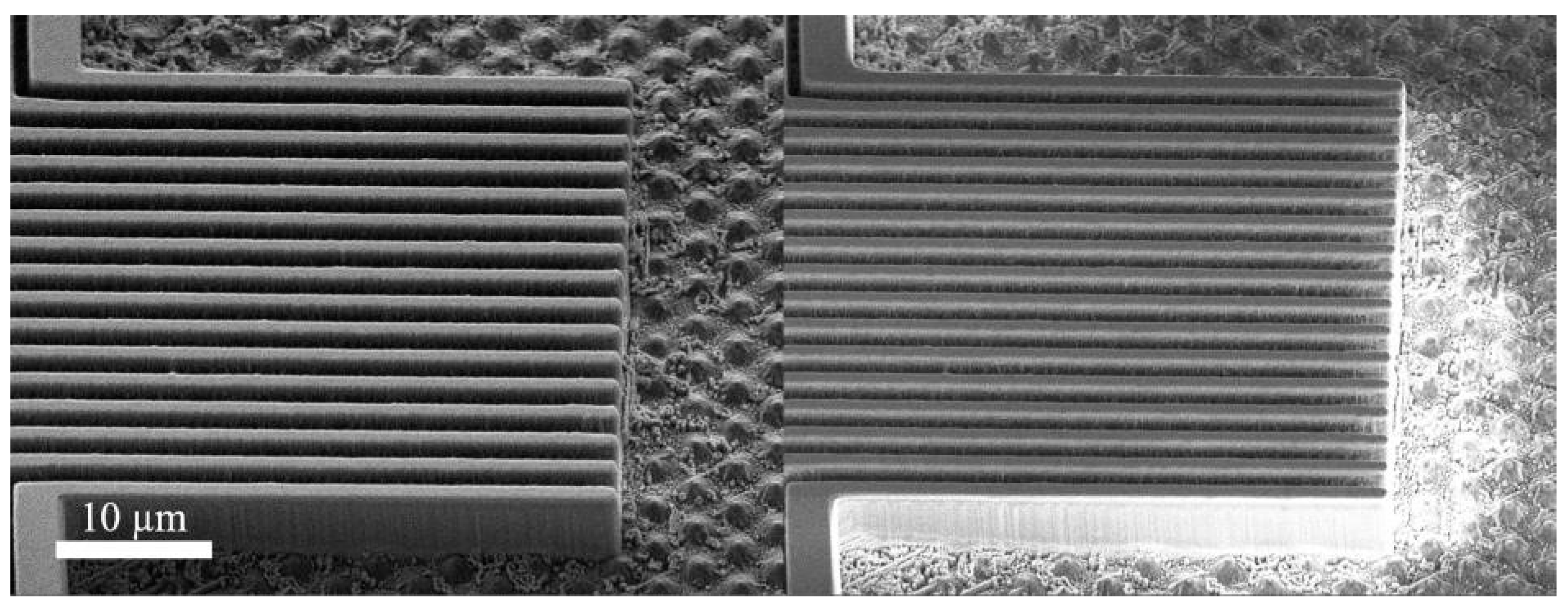

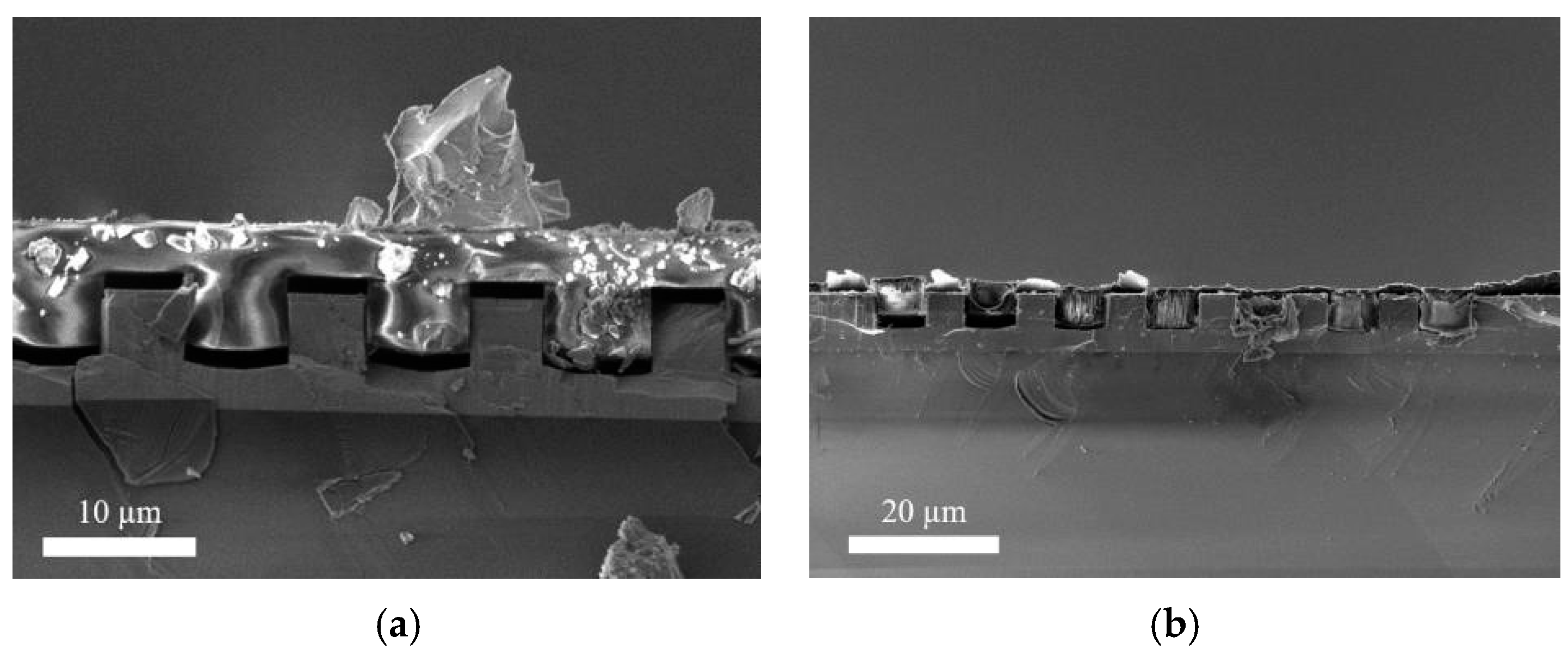

3. Device Fabrication

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Nakamura, S.; Senoh, M.; Iwasa, N.; Nagahama, S.I. High-brightness InGaN blue, green and yellow light-emitting diodes with quantum well structures. Jpn. J. Appl. Phys 1995, 34, L797–L799. [Google Scholar] [CrossRef]

- Herrnsdorf, J.; McKendry, J.J.; Zhang, S.; Xie, E.; Ferreira, R.; Massoubre, D.; Zuhdi, A.M.; Henderson, R.K.; Underwood, I.; Watson, S.; et al. Active-matrix GaN micro light-emitting diode display with unprecedented brightness. IEEE Trans. Electron Devices 2015, 62, 1918–1925. [Google Scholar] [CrossRef]

- Wasisto, H.S.; Merzsch, S.; Steib, F.; Waag, A.; Peiner, E. Vertical silicon nanowire array-patterned microcantilever resonators for enhanced detection of cigarette smoke aerosols. Micro Nano Lett. 2014, 9, 676–679. [Google Scholar] [CrossRef]

- Yu, F.; Yao, S.; Römer, F.; Witzigmann, B.; Schimpke, T.; Strassburg, M.; Bakin, A.; Schumacher, H.W.; Peiner, E.; Wasisto, H.S.; et al. GaN nanowire arrays with nonpolar sidewalls for vertically integrated fieldeffect transistors. Nanotechnology 2017, 28, 95206. [Google Scholar] [CrossRef] [PubMed]

- Yu, F.; Strempel, K.; Fatahilah, M.F.; Zhou, H.; Römer, F.; Bakin, A.; Witzigmann, B.; Schumacher, H.W.; Wasisto, H.S.; Waag, A. Normally Off Vertical 3-D GaN Nanowire MOSFETs With Inverted -GaN Channel. IEEE Trans. Electron Devices 2018, 65, 2439–2445. [Google Scholar] [CrossRef]

- Woehrmann, M.; Toepper, M. Polymerization of Thin Film Polymers. In New Polymers for Special Applications, 1st ed.; Ailton De Souza Gomes, IntechOpen: Rijeka, Croatia, 2012. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gülink, J.; Bornemann, S.; Spende, H.; Maur, M.A.d.; Carlo, A.D.; Prades, J.D.; Wasisto, H.S.; Waag, A. InGaN/GaN nanoLED Arrays as a Novel Illumination Source for Biomedical Imaging and Sensing Applications. Proceedings 2018, 2, 892. https://doi.org/10.3390/proceedings2130892

Gülink J, Bornemann S, Spende H, Maur MAd, Carlo AD, Prades JD, Wasisto HS, Waag A. InGaN/GaN nanoLED Arrays as a Novel Illumination Source for Biomedical Imaging and Sensing Applications. Proceedings. 2018; 2(13):892. https://doi.org/10.3390/proceedings2130892

Chicago/Turabian StyleGülink, Jan, Steffen Bornemann, Hendrik Spende, Matthias Auf der Maur, Aldo Di Carlo, Joan Daniel Prades, Hutomo Suryo Wasisto, and Andreas Waag. 2018. "InGaN/GaN nanoLED Arrays as a Novel Illumination Source for Biomedical Imaging and Sensing Applications" Proceedings 2, no. 13: 892. https://doi.org/10.3390/proceedings2130892

APA StyleGülink, J., Bornemann, S., Spende, H., Maur, M. A. d., Carlo, A. D., Prades, J. D., Wasisto, H. S., & Waag, A. (2018). InGaN/GaN nanoLED Arrays as a Novel Illumination Source for Biomedical Imaging and Sensing Applications. Proceedings, 2(13), 892. https://doi.org/10.3390/proceedings2130892