Polydimethylsiloxane (PDMS) Waveguide Sensor Detecting Fluid Flow Velocity by Mimicking the Fish Lateral Line Organ †

Abstract

:1. Introduction

2. Materials and Methods

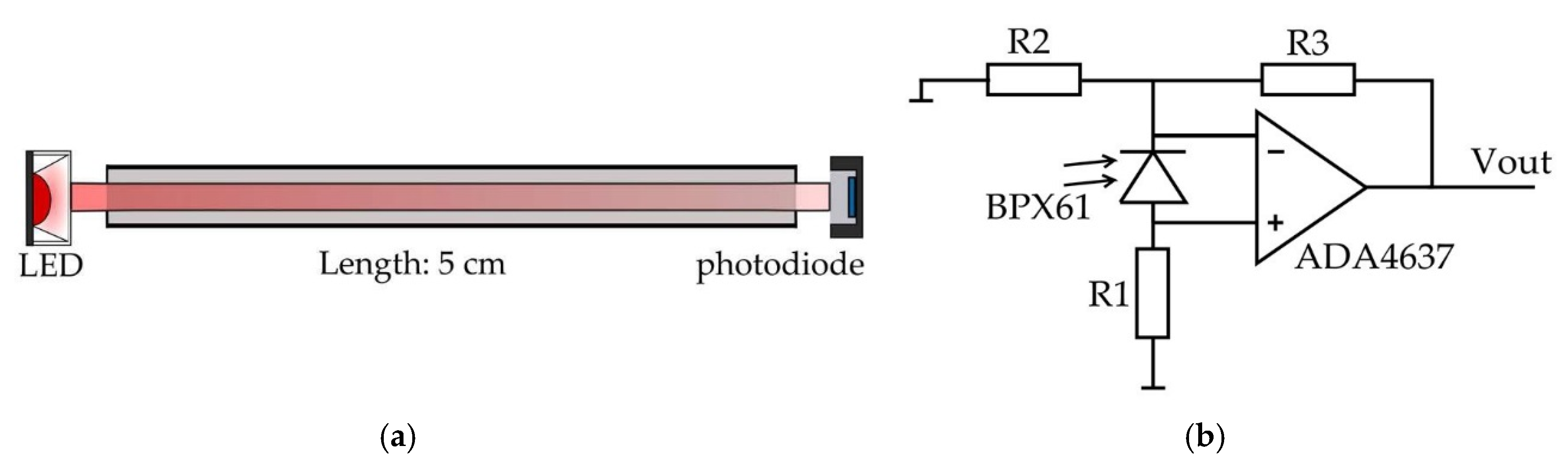

2.1. PDMS Waveguide

2.2. Photodiode and Photodiode Amplifier

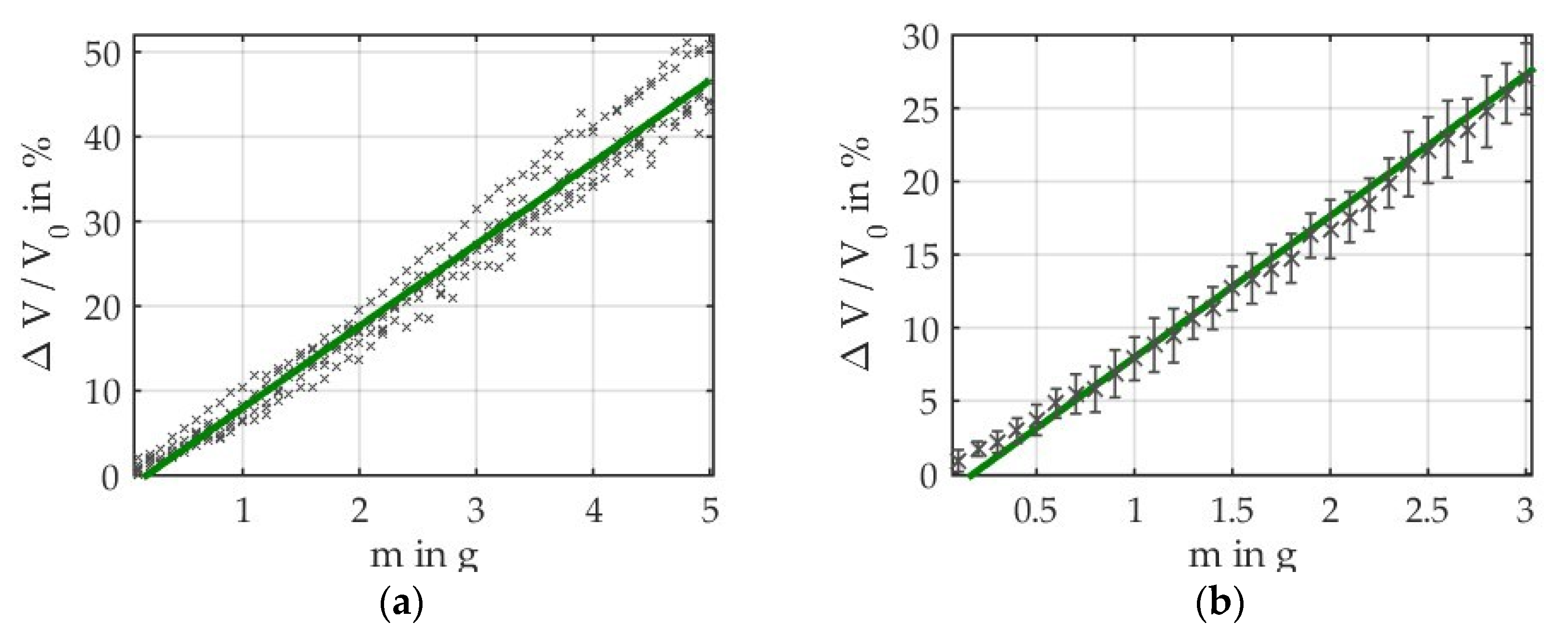

2.3. Measurements

3. Results

4. Discussion

5. Conclusions

Acknowledgments

Conflicts of Interest

References

- Bleckmann, H.; Zelick, R. Lateral line system of fish. Integr. Zool. 2009, 4, 13–25. [Google Scholar] [CrossRef] [PubMed]

- Coombs, S.; Montgomery, J.C. The Enigmatic Lateral Line System. In Comparative Hearing: Fish and Amphibians; Fay, R.R., Popper, A.N., Eds.; Springer: New York, NY, USA, 1999; pp. 319–362. [Google Scholar]

- Yang, Y.; Chen, J.; Engel, J.; Pandya, S.; Chen, N.; Tucker, C.; Coombs, S.; Jones, D.L.; Liu, C. Distant touch hydrodynamic imaging with an artificial lateral line. Proc. Natl. Acad. Sci. USA 2006, 103, 18891–18895. [Google Scholar] [CrossRef]

- Izadi, N.; de Boer, M.J.; Berenschot, J.W.; Krijnen, G.J.M. Fabrication of superficial neuromast inspired capacitive flow sensors. J. Micromech. Microeng. 2010, 20, 085041. [Google Scholar] [CrossRef]

- Asadnia, M.; Kottapalli, A.G.P.; Miao, J.; Warkiani, M.E.; Triantafyllou, M.S. Artificial fish skin of self- powered micro-electromechanical systems hair cells for sensing hydrodynamic flow phenomena. J. R. Soc. Interface 2015, 12, 20150322. [Google Scholar] [CrossRef] [PubMed]

- Abdulsadda, A.T.; Tan, X. An artificial lateral line system using IPMC sensor arrays. Int. J. Smart Nano Mater. 2012, 3, 226–242. [Google Scholar] [CrossRef]

- Herzog, H.; Klein, A.; Bleckmann, H.; Holik, P.; Schmitz, S.; Siebke, G.; Tätzner, S.; Lacher, M.; Steltenkamp, S. Micro-biomimetic flow sensors: Introducing light-guiding PDMS structures into MEMS. Bioinspir. Biomim. 2015, 10, 36001. [Google Scholar] [CrossRef] [PubMed]

- Herzog, H.; Steltenkamp, S.; Klein, A.; Tätzner, S.; Schulze, E.; Bleckmann, H. Micro-Machined Flow Sensors Mimicking Lateral Line Canal Neuromasts. Micromachines 2015, 6, 1189–1212. [Google Scholar] [CrossRef]

- Yang, Y.; Klein, A.; Bleckmann, H.; Liu, C. Artificial lateral line canal for hydrodynamic detection. Appl. Phys. Lett. 2011, 99, 23701. [Google Scholar] [CrossRef]

- Klein, A.T.; Kaldenbach, F.; Rüter, A.; Bleckmann, H. What We Can Learn from Artificial Lateral Line Sensor Arrays. Adv. Exp. Med. Biol. 2016, 875, 539–545. [Google Scholar] [PubMed]

- Chen, J.; Engel, J.; Chen, N.; Pandya, S.; Cocombs, S.; Liu, C. Artificial Lateral Line and Hydrodynamic Object Tracing. In Micro Electro Mechanical Systems; IEEE: Istanbul, Turkey, 2006. [Google Scholar]

- Nguyen, N.; Jones, D.L.; Yang, Y.; Liu, C. Flow Vision for Autonomous Underwater Vehicles via an Artificial Lateral Line. EURASIP J. Adv. Signal Process. 2011, 2011, 51. [Google Scholar] [CrossRef]

- Stadler, A.T.; Wiesmayr, B.; Krieger, M.; Baumgartner, W. An optical sensory principle for spirometry. In Sensors and Measuring Systems; VDE: Nuremberg, Germany, 2018. [Google Scholar]

- Snyder, A.W.; Love, J.D. Optical Waveguide Theory; Springer: Boston, MA, USA, 1983. [Google Scholar]

- Schneider, F.; Draheim, J.; Kamberger, R.; Wallrabe, U. Process and material properties of polydimethylsiloxane (PDMS) for Optical MEMS. Sens. Actuators A Phys. 2009, 151, 95–99. [Google Scholar] [CrossRef]

- Osram Opto Semiconductors. Silicon PIN Photodiode BPX61, 1st ed.; Osram Opto Semiconductors GmbH: Regensburg, Germany, 2015. [Google Scholar]

- Horowitz, P.; Hill, W. The Art of Electronics, 11th ed.; Cambridge University Press: Cambridge, UK, 2017. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wiesmayr, B.; Krieger, M.; Baumgartner, W.; Stadler, A.T. Polydimethylsiloxane (PDMS) Waveguide Sensor Detecting Fluid Flow Velocity by Mimicking the Fish Lateral Line Organ. Proceedings 2018, 2, 885. https://doi.org/10.3390/proceedings2130885

Wiesmayr B, Krieger M, Baumgartner W, Stadler AT. Polydimethylsiloxane (PDMS) Waveguide Sensor Detecting Fluid Flow Velocity by Mimicking the Fish Lateral Line Organ. Proceedings. 2018; 2(13):885. https://doi.org/10.3390/proceedings2130885

Chicago/Turabian StyleWiesmayr, Bianca, Michael Krieger, Werner Baumgartner, and Anna T. Stadler. 2018. "Polydimethylsiloxane (PDMS) Waveguide Sensor Detecting Fluid Flow Velocity by Mimicking the Fish Lateral Line Organ" Proceedings 2, no. 13: 885. https://doi.org/10.3390/proceedings2130885

APA StyleWiesmayr, B., Krieger, M., Baumgartner, W., & Stadler, A. T. (2018). Polydimethylsiloxane (PDMS) Waveguide Sensor Detecting Fluid Flow Velocity by Mimicking the Fish Lateral Line Organ. Proceedings, 2(13), 885. https://doi.org/10.3390/proceedings2130885