Design of Miniaturized, Self-Out-Readable Cantilever Resonator for Highly Sensitive Airborne Nanoparticle Detection †

Abstract

:1. Introduction

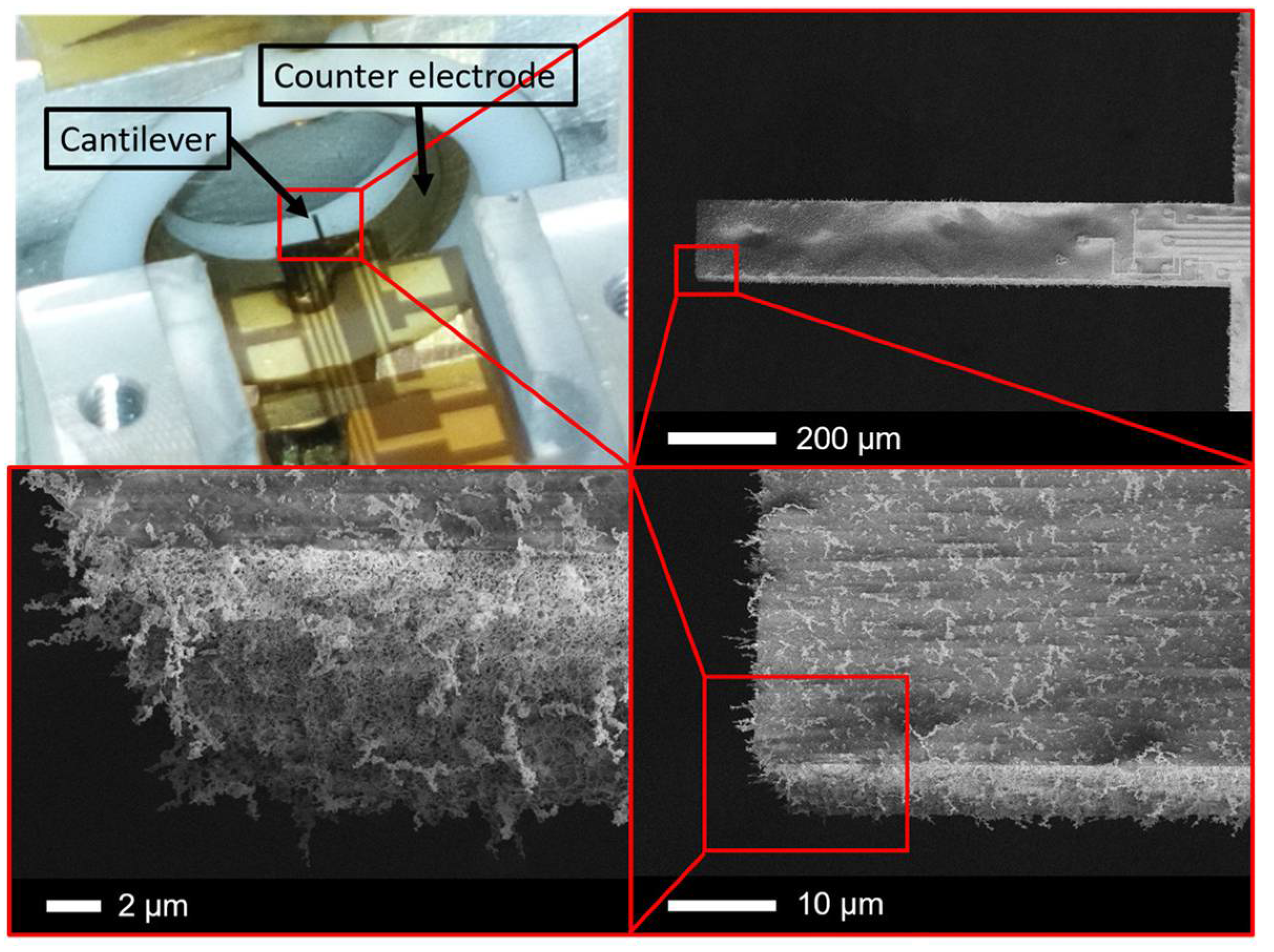

2. Sensor Concept and Design Optimization

3. Particle Collection

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Zalk, D.M.; Paik, S.Y. Assessing Nanoparticle Risks to Human Health; Ramachandran, G., Ed.; William Andrew: Oxford, UK, 2016; Volume 2, Chapter 6; pp. 121–152. [Google Scholar]

- Soysal, U.; Géhin, E.; Algré, E.; Berthelot, B.; Da, G.; Robine, E. Aerosol mass concentration measurements: Recent advancements of real-time nano/micro systems. J. Aerosol Sci. 2017, 114, 42–54. [Google Scholar] [CrossRef]

- Schmid, S.; Kurek, M.; Adolphsen, J.Q.; Boisen, A. Real-time single airborne nanoparticle detection with nanomechanical resonant filter-fiber. Sci. Rep. 2013, 3, 1288. [Google Scholar] [CrossRef] [PubMed]

- Chu, C.; Dey, S.; Liu, T.-Y.; Chen, C.-C.; Li, S.-S. Thermal-Piezoresistive SOI-MEMS Oscillators Based on a Fully Differential Mechanically Coupled Resonator Array for Mass Sensing Applications. J. Microelectromech. Syst. 2018, 27, 59–72. [Google Scholar] [CrossRef]

- Bao, Y.; Cai, S.; Yu, H.; Xu, T.; Xu, P.; Li, X. A resonant cantilever based particle sensor with particle-size selection function. J. Micromech. Microeng. 2018, 28, 11. [Google Scholar] [CrossRef]

- Bertke, M.; Hamdana, G.; Wu, W.; Wasisto, H.S.; Uhde, E.; Peiner, E. Analysis of asymmetric resonance response of thermally excited silicon micro-cantilevers for mass-sensitive nanoparticle detection. J. Micromech. Microeng. 2017, 27. [Google Scholar] [CrossRef]

- Wasisto, H.S.; Merzsch, S.; Uhde, E.; Waag, A.; Peiner, E. Handheld personal airborne nanoparticle detector based on microelectromechanical silicon resonant cantilever. Microelectron. Eng. 2015, 145, 96–103. [Google Scholar] [CrossRef]

- Wasisto, H.S.; Merzsche, S.; Stranz, A.; Waag, A.; Uhde, E.; Salthammer, T.; Peiner, E. Silicon resonant nanopillar sensors for airborne titanium dioxide engineered nanoparticle mass detection. Sens. Actuators B Chem. 2013, 189, 146–156. [Google Scholar] [CrossRef]

| Parameter | Value (µm) |

|---|---|

| Strut/cantilever width wS and wC | 2–4 |

| Cantilever length lC | 100 × √(wC/2) |

| Strut length lS | 25 |

| Strut/cantilever thickness t | 2 |

| Strut position pS (from clamped end) | 0.2 lC |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bertke, M.; Xu, J.; Fahrbach, M.; Setiono, A.; Hamdana, G.; Wasisto, H.S.; Peiner, E. Design of Miniaturized, Self-Out-Readable Cantilever Resonator for Highly Sensitive Airborne Nanoparticle Detection. Proceedings 2018, 2, 879. https://doi.org/10.3390/proceedings2130879

Bertke M, Xu J, Fahrbach M, Setiono A, Hamdana G, Wasisto HS, Peiner E. Design of Miniaturized, Self-Out-Readable Cantilever Resonator for Highly Sensitive Airborne Nanoparticle Detection. Proceedings. 2018; 2(13):879. https://doi.org/10.3390/proceedings2130879

Chicago/Turabian StyleBertke, Maik, Jiushuai Xu, Michael Fahrbach, Andi Setiono, Gerry Hamdana, Hutomo Suryo Wasisto, and Erwin Peiner. 2018. "Design of Miniaturized, Self-Out-Readable Cantilever Resonator for Highly Sensitive Airborne Nanoparticle Detection" Proceedings 2, no. 13: 879. https://doi.org/10.3390/proceedings2130879

APA StyleBertke, M., Xu, J., Fahrbach, M., Setiono, A., Hamdana, G., Wasisto, H. S., & Peiner, E. (2018). Design of Miniaturized, Self-Out-Readable Cantilever Resonator for Highly Sensitive Airborne Nanoparticle Detection. Proceedings, 2(13), 879. https://doi.org/10.3390/proceedings2130879