Development of a Heat-Driven-Type MEMS Olfactory Display †

Abstract

:1. Introduction

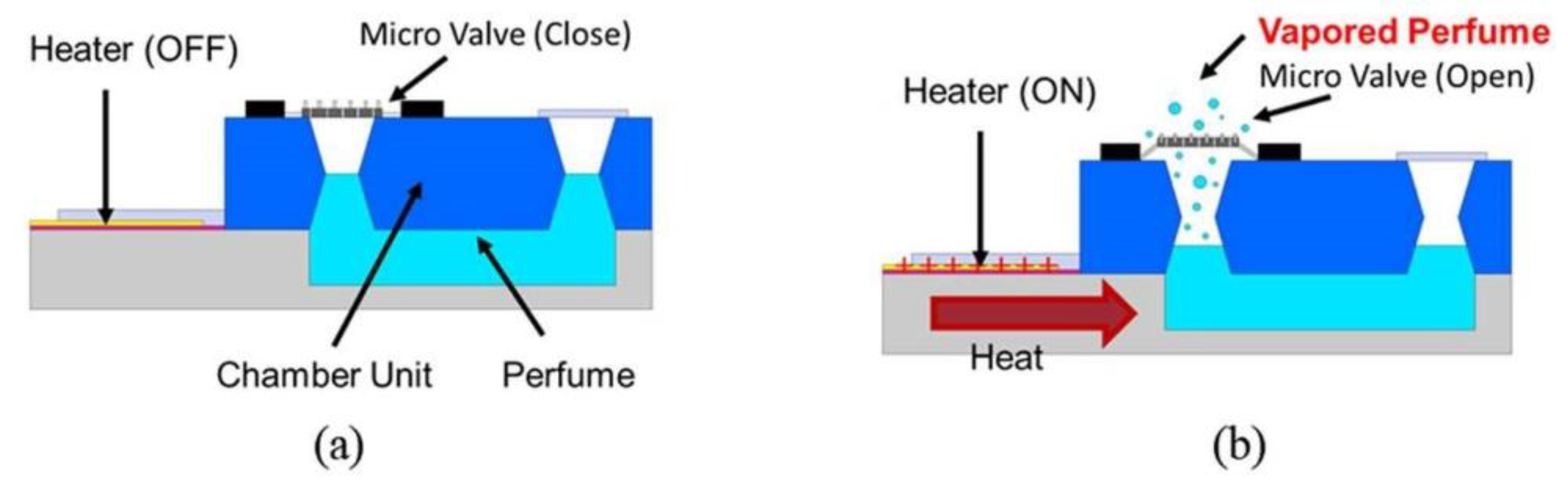

2. Principle

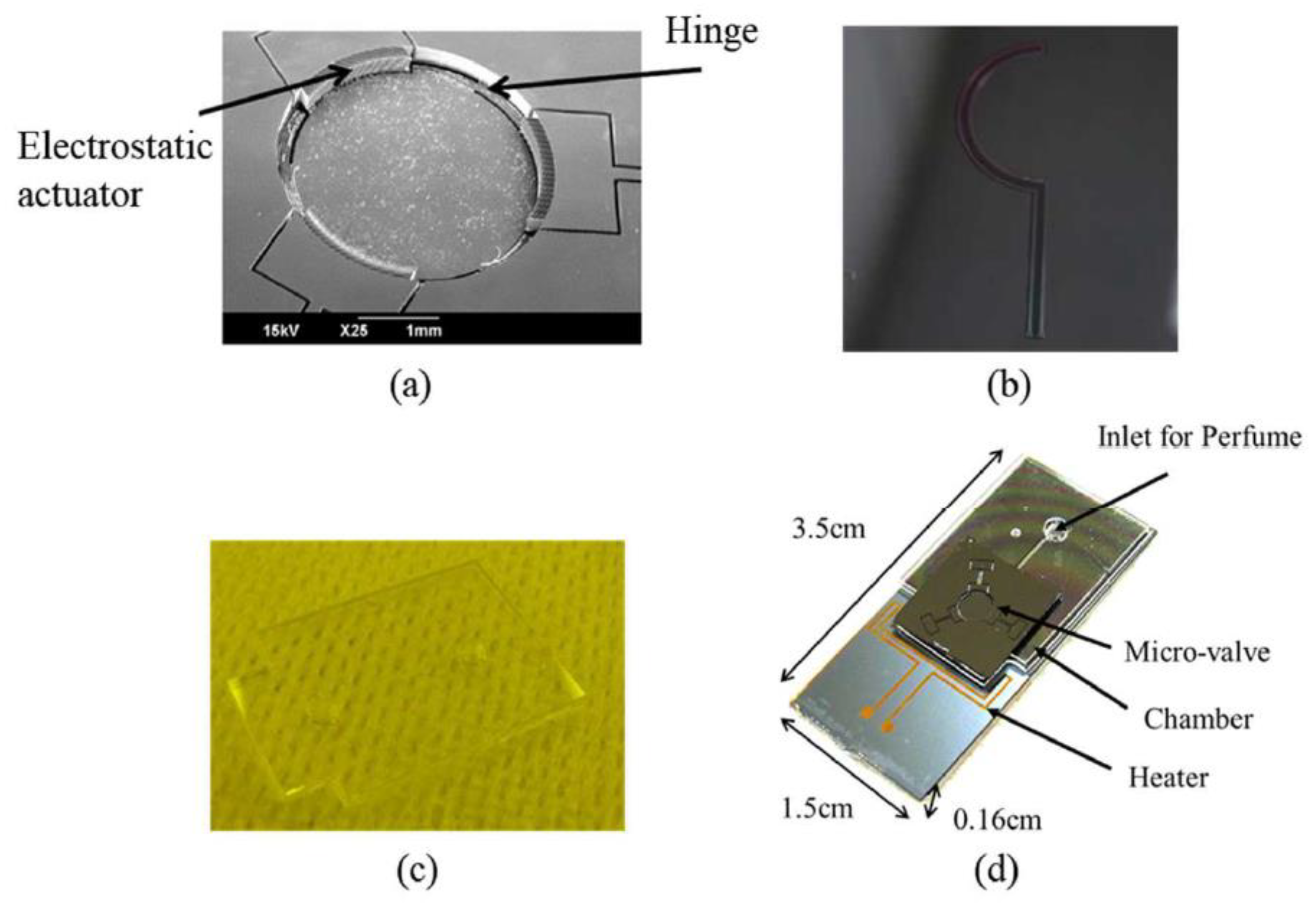

3. Design

4. Experimental Procedure

5. Experimental Results

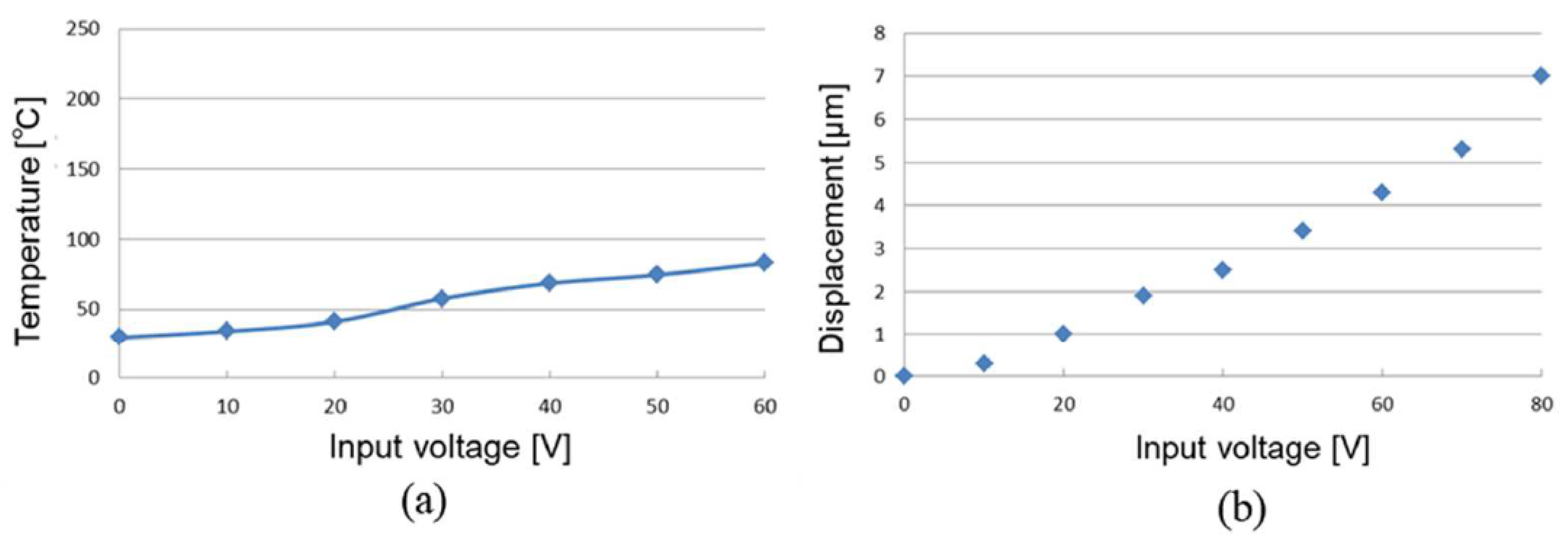

5.1. Characterization of Heater and Valve

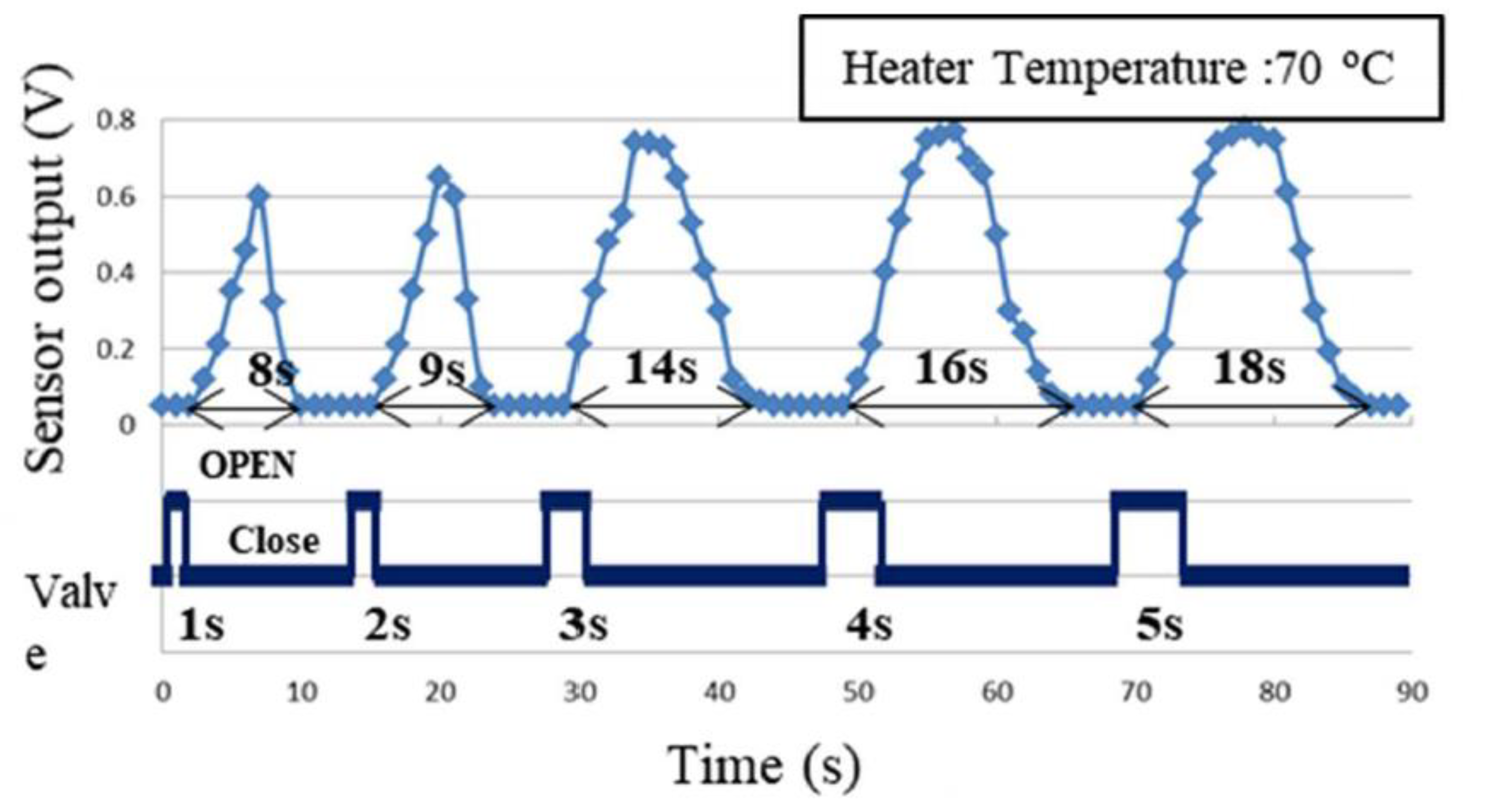

5.2. Characterization of Heater and Valve

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hasegawa, K.; Qiu, L.; Shinoda, H. Midair Ultrasound Fragrance Rendering. IEEE Trans. Vis. Comput. Gr. 2018, 24, 1477–1485. [Google Scholar] [CrossRef] [PubMed]

- Dobbelstein, D.; Herrdum, S.; Rukzio, E. inScent. In Proceedings of the 2017 ACM International Symposium on Wearable Computers, Maui, HI, USA, 11–15 September 2017; pp. 130–137. [Google Scholar] [CrossRef]

- Narumi, T.; Nishizaka, S.; Kajinami, T.; Tanikawa, T.; Hirose, M. Meta Cookie+: An Illusion-Based Gustatory Display. In Virtual and Mixed Reality–New Trends; In Proceedings of the Virtual and Mixed Reality 2011, Orlando, FL, USA, 9-14 July 2011; pp. 260–269. [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ishizuka, H.; Kashiwagi, K.; Terao, K.; Takao, H.; Shimokawa, F. Development of a Heat-Driven-Type MEMS Olfactory Display. Proceedings 2018, 2, 839. https://doi.org/10.3390/proceedings2130839

Ishizuka H, Kashiwagi K, Terao K, Takao H, Shimokawa F. Development of a Heat-Driven-Type MEMS Olfactory Display. Proceedings. 2018; 2(13):839. https://doi.org/10.3390/proceedings2130839

Chicago/Turabian StyleIshizuka, Hiroki, Kenta Kashiwagi, Kyohei Terao, Hidekuni Takao, and Fusao Shimokawa. 2018. "Development of a Heat-Driven-Type MEMS Olfactory Display" Proceedings 2, no. 13: 839. https://doi.org/10.3390/proceedings2130839

APA StyleIshizuka, H., Kashiwagi, K., Terao, K., Takao, H., & Shimokawa, F. (2018). Development of a Heat-Driven-Type MEMS Olfactory Display. Proceedings, 2(13), 839. https://doi.org/10.3390/proceedings2130839