Finite Element Method Simulation and Characterization of a Thermal Flow Sensor Based on Printed Circuit Board Technology for Various Fluids †

Abstract

:1. Introduction and Motivation

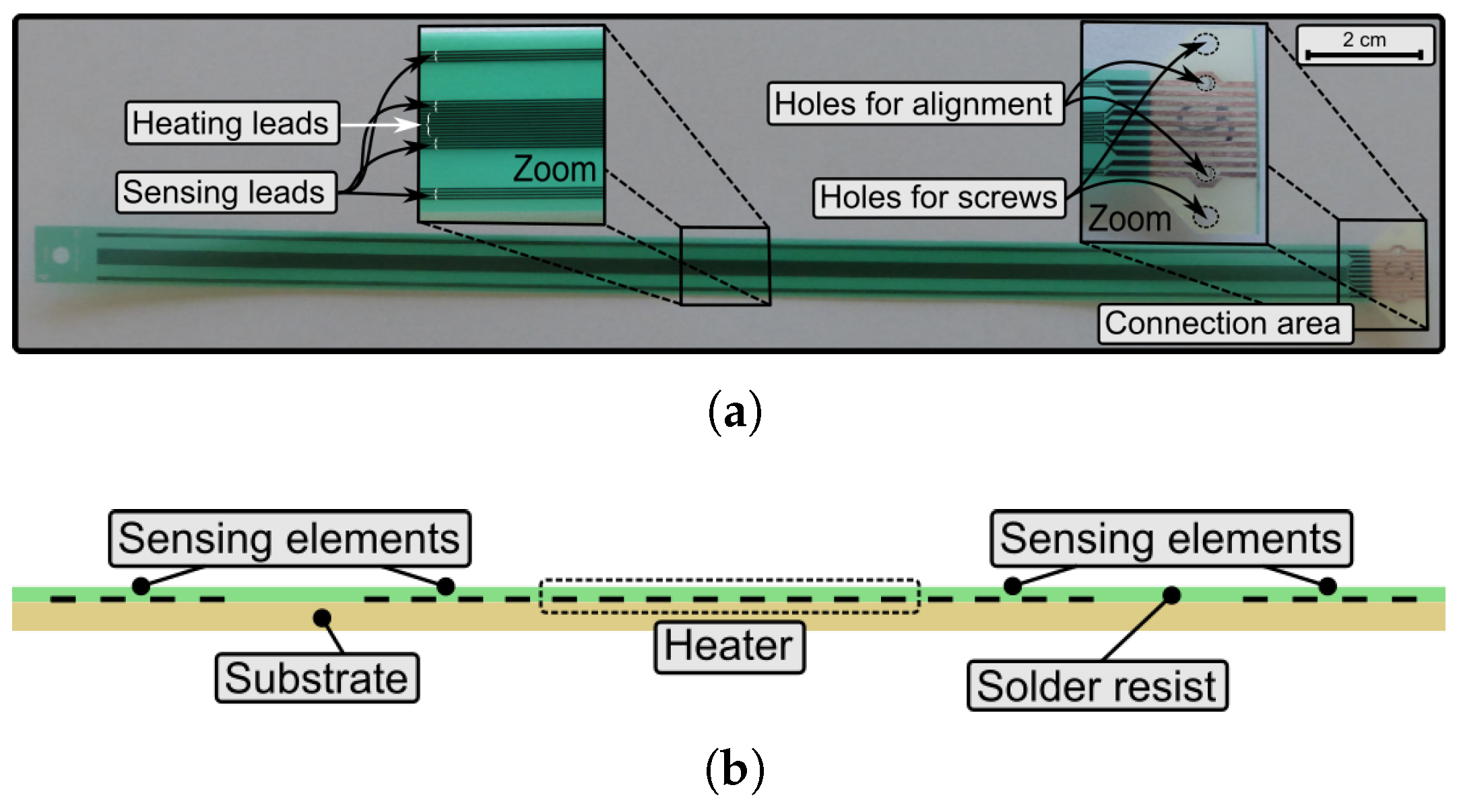

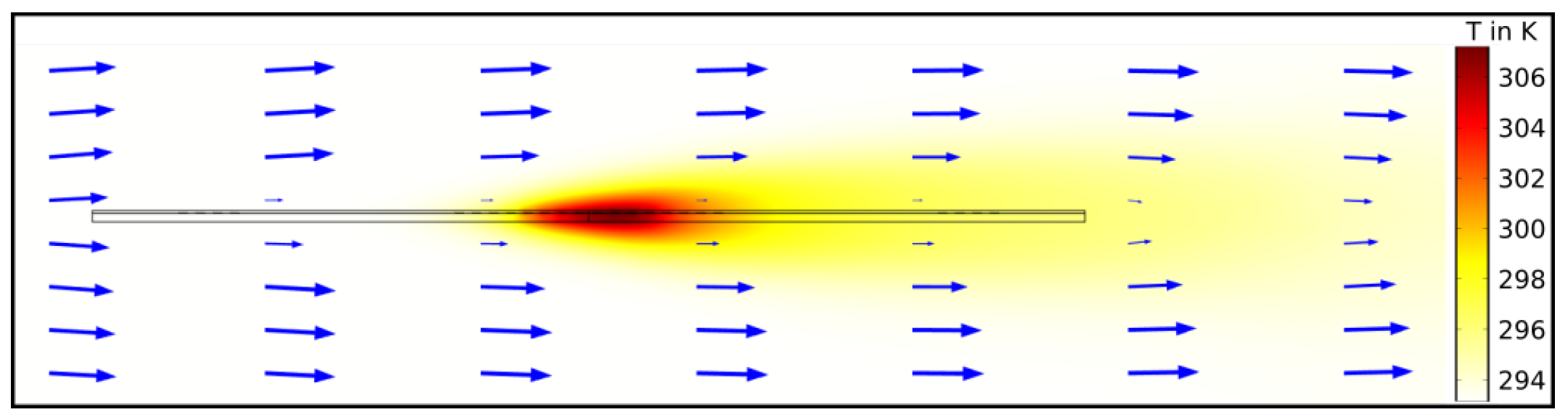

2. Experimental Procedure (Design, Simulation, and Experiments)

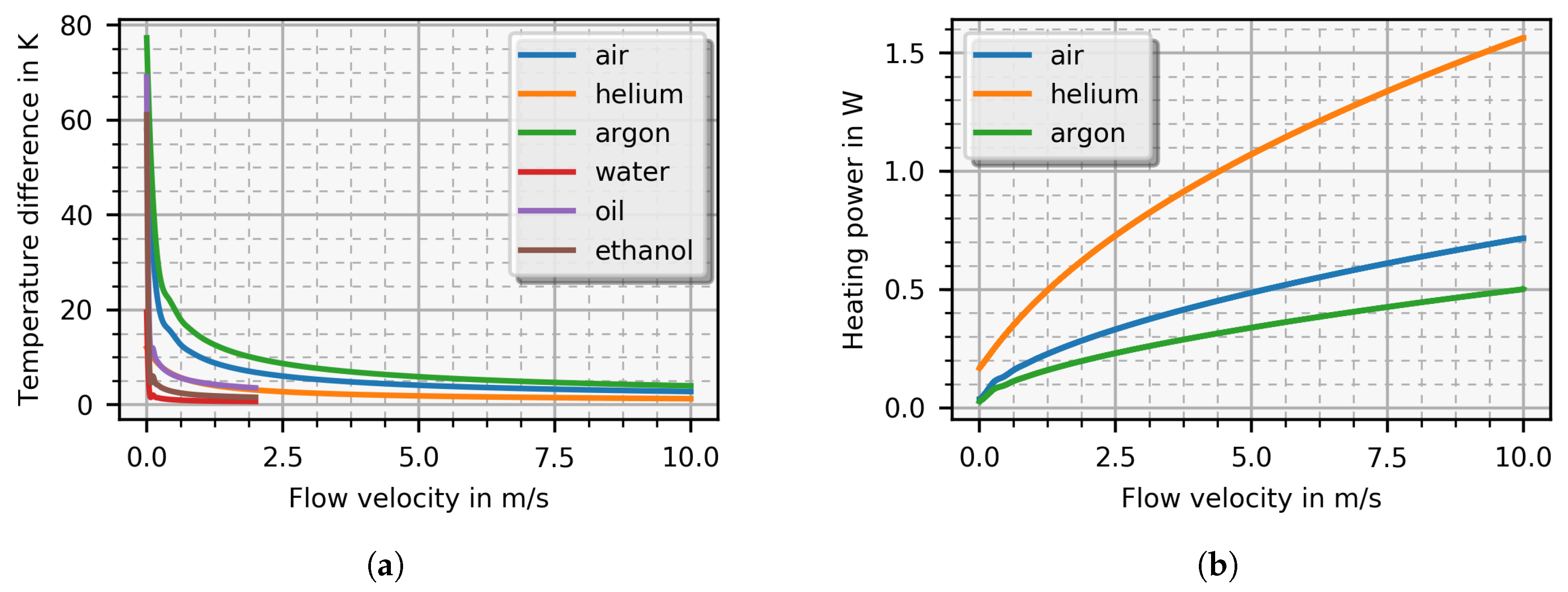

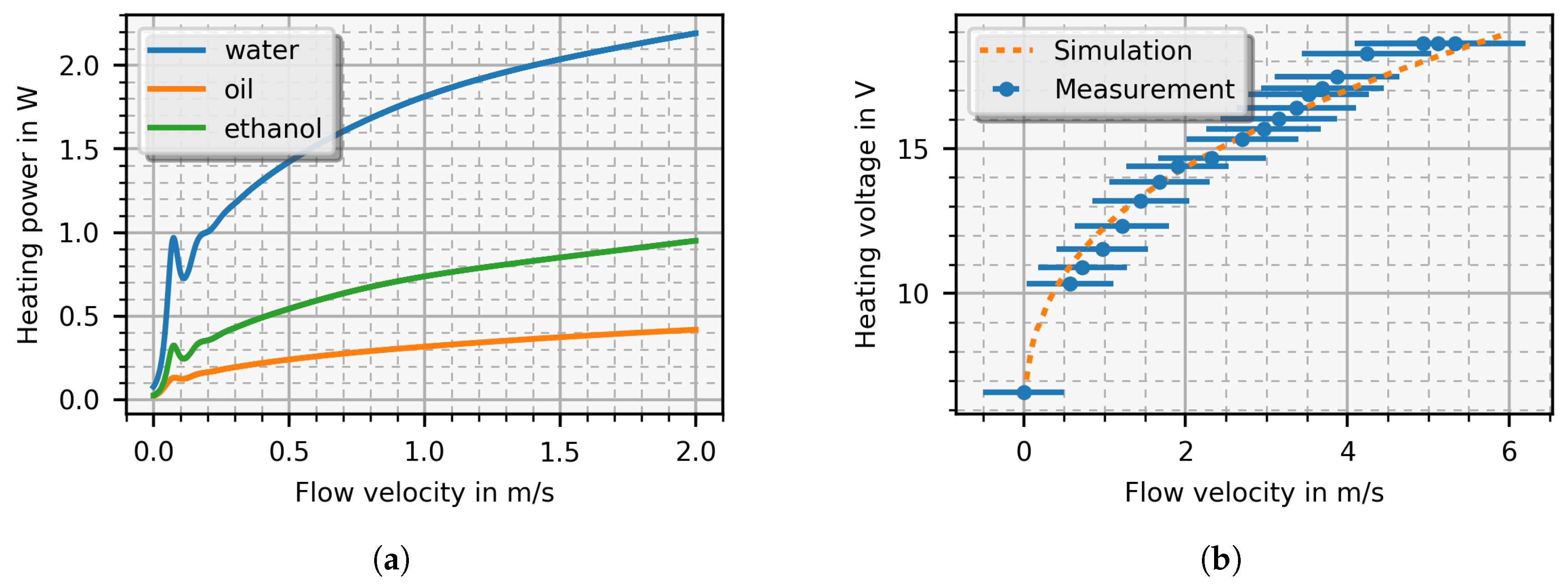

3. Results

4. Discussion

Acknowledgments

Conflicts of Interest

References

- Cao, X.; Dai, X.; Liu, J. Building energy-consumption status worldwide and the state-of-the-art technologies for zero-energy buildings during the past decade. Energy Build. 2016, 128, 198–213. [Google Scholar] [CrossRef]

- Sauter, T.; Steiner, H.; Glatzl, T.; Hortschitz, W.; Wenig, F.; Heschl, C. Towards distributed enthalpy measurement in large-scale air conditioning systems. In Proceedings of the 2015 9th Annual IEEE International Systems Conference (SysCon), Vancouver, BC, Canada, 13–16 April 2015; pp. 460–465. [Google Scholar]

- Glatzl, T.; Steiner, H.; Kohl, F.; Sauter, T.; Keplinger, F. Development of an air flow sensor for heating, ventilating, and air conditioning systems based on printed circuit board technology. Sens. Actuators A Phys. 2016, 237, 1–8. [Google Scholar] [CrossRef]

- Wenig, F.; Heschl, C.; Glatzl, T.; Sauter, T. Numerical and experimental characterization of a novel low-cost thermal air flow sensor. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017; pp. 3633–3637. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glatzl, T.; Beigelbeck, R.; Cerimovic, S.; Steiner, H.; Treytl, A. Finite Element Method Simulation and Characterization of a Thermal Flow Sensor Based on Printed Circuit Board Technology for Various Fluids. Proceedings 2018, 2, 833. https://doi.org/10.3390/proceedings2130833

Glatzl T, Beigelbeck R, Cerimovic S, Steiner H, Treytl A. Finite Element Method Simulation and Characterization of a Thermal Flow Sensor Based on Printed Circuit Board Technology for Various Fluids. Proceedings. 2018; 2(13):833. https://doi.org/10.3390/proceedings2130833

Chicago/Turabian StyleGlatzl, Thomas, Roman Beigelbeck, Samir Cerimovic, Harald Steiner, and Albert Treytl. 2018. "Finite Element Method Simulation and Characterization of a Thermal Flow Sensor Based on Printed Circuit Board Technology for Various Fluids" Proceedings 2, no. 13: 833. https://doi.org/10.3390/proceedings2130833

APA StyleGlatzl, T., Beigelbeck, R., Cerimovic, S., Steiner, H., & Treytl, A. (2018). Finite Element Method Simulation and Characterization of a Thermal Flow Sensor Based on Printed Circuit Board Technology for Various Fluids. Proceedings, 2(13), 833. https://doi.org/10.3390/proceedings2130833