1. Introduction

In plant factories and the farming industry, the realization of a next-generation agriculture sensor platform using IoT technology is expected. However, it is mostly limited to monitoring environmental information such as temperature, humidity, solar radiation, and CO2 concentration. Since plants absorb most of the water they need from soil, we generally manage the moisture conditions of the soil. However, the original purpose of moisture control is to maintain suitable sap dynamics (flow velocity and direction). The realization of moisture control and fertilizer management based on the biological information of plants makes it possible to maintain suitable sap dynamics for crop and fruit production. As a result, it will contribute to increased crop productivity and reliable high-quality fruit.

The measurement range of the Granier method, which is a conventional sap flow sensing method, is the plant stem diameter of 10 cm or more [

1]. In addition, other sap flow sensors that utilize the stem heat balance method have a measurement range of the plant stem’s diameter of 8 mm or more [

2]. Therefore, the flow velocity at the end of the plant stem (plant shoot) could not be directly measured. To solve this problem, we previously focused on the Granier method and fabricated the microscale xylem sap flow sensor by using MEMS technology. We also demonstrated the feasibility (velocity measurement) of the micro-sensor.

In this study, we proposed the microscale xylem sap flow sensor, facilitating the simultaneous measurement of flow velocity and direction to clarify the internal biological information of plants, and verified the feasibility of the sensor.

2. Sensor Device Design

2.1. Configuration of Proposed Sensor

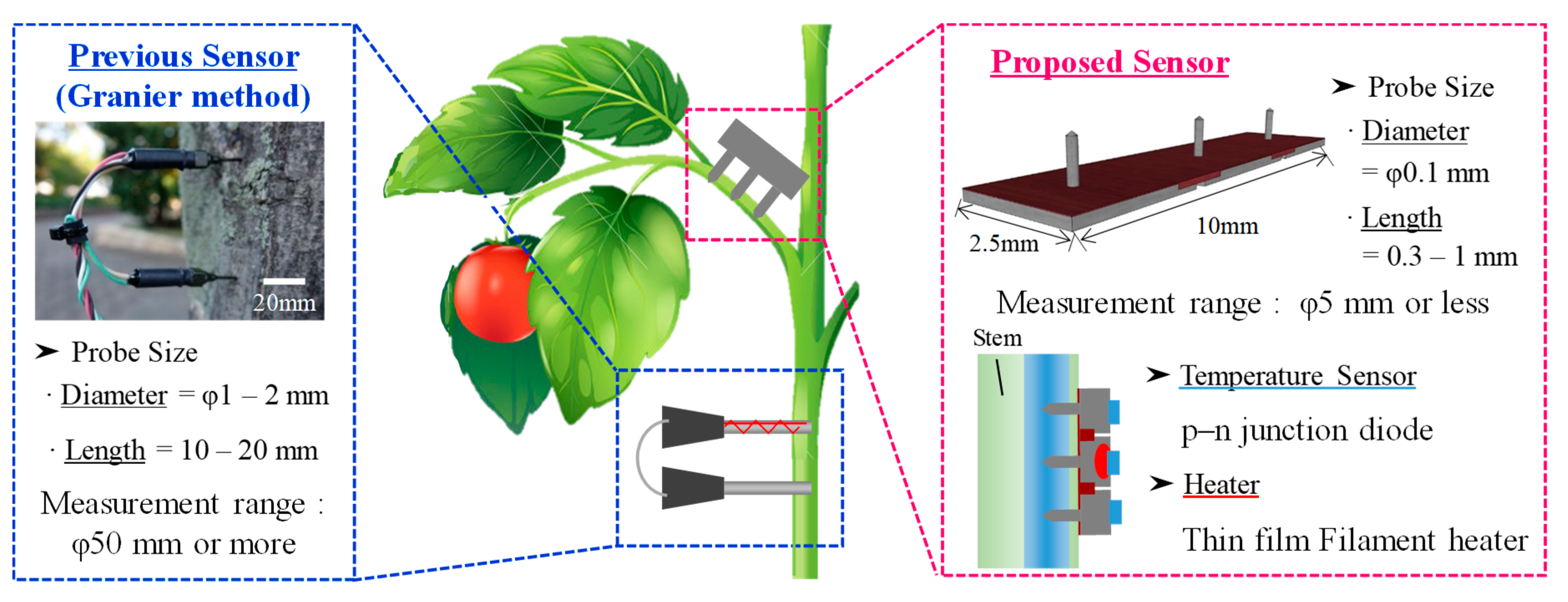

Figure 1 shows the comparison of proposed sensor and the previous sensor. The proposed micro-sensor consists of a temperature sensor with a heater, and two temperature sensors for reference. A micro-probe is formed on each sensor. By inserting these probes into the plant stem, we directly measure the sap dynamics. We fabricate the temperature sensor by using the temperature-dependence of the p-n junction diode and the heater by utilizing the thin film heater made of Au. In addition, we form the thermal isolation structure made of polyimide resin to prevent heat transfer between each sensor. The proposed sensor is downsized to about one tenth of the size of the conventional sensor, and the measurement range of the sensor aims at a plant stem diameter of 5 mm or less.

2.2. Measurement Principle of Proposed Sensor

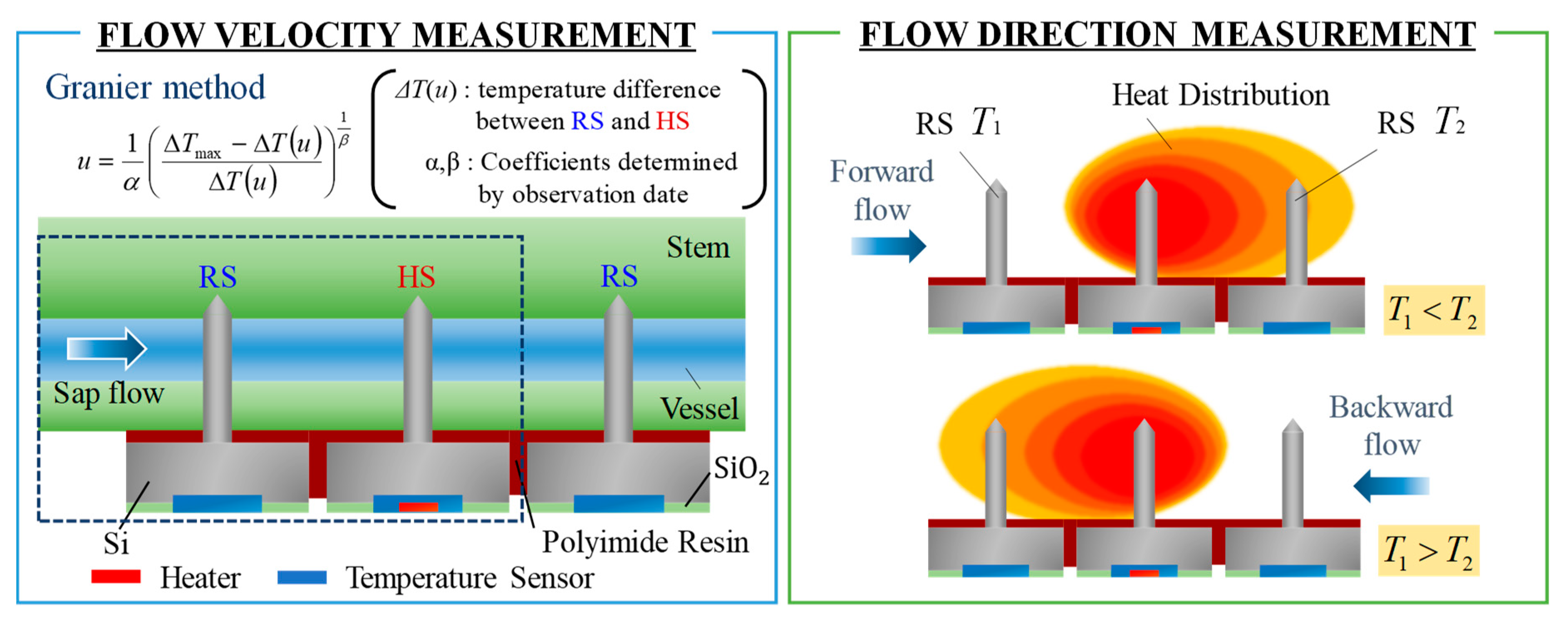

Figure 2 shows the measurement principle of the proposed sensor. We measure the flow velocity using the principle of the Granier method. The Granier sensor comprises a temperature sensor with a heater (HS) and a temperature sensor for reference (RS). The RS measures the original temperature of the flowing sap, which is defined as the reference temperature. We insert the sensor into the plants and drive the heater. Next, we measure the temperature reduction in the HS due to the sap flow. Then, the temperature difference

ΔT(u) between the HS and RS is calculated, and the xylem sap flow velocity

u is derived by the expression shown in the figure.

Next, we measure the flow direction by the principle of the thermal flow sensor. This method is based on the heat transfer that occurs from a heater through an internal fluid flow. The flow direction is determined by comparing the upstream and downstream temperatures measured by the temperature sensors at each side of the heater.

In this study, we combine the principles of these two conventional methods and integrate their functions in a microscale sensor using MEMS technology.

3. Fabrication

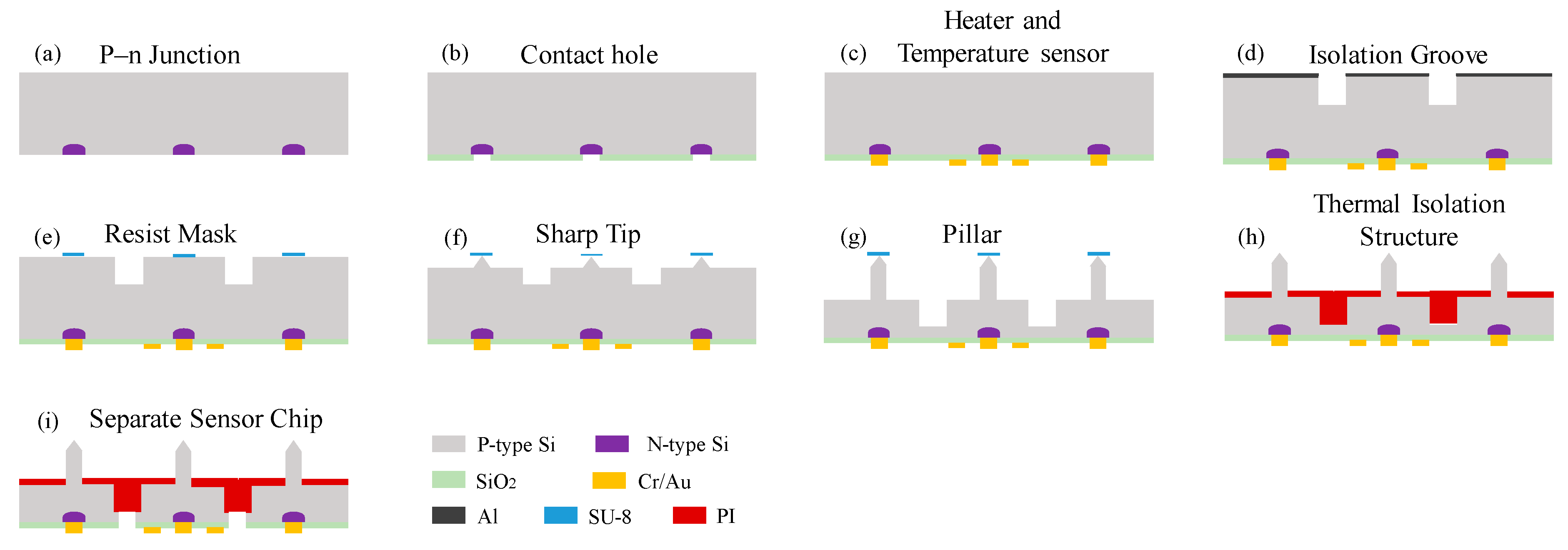

Figure 3 shows the fabrication process of the proposed sensor. First, the p–n junction is fabricated on a p-type silicon-on-insulator wafer via n-type diffusion (

Figure 3a). Next, it is thermally oxidized to form an insulation layer, and then a contact hole is opened (

Figure 3b). Subsequently, by sputtering Cr/Au on the surface, electrodes and wirings are fabricated for the micro-heater and temperature sensors (

Figure 3c). Furthermore, micro-probe and isolation grooves are formed by Si dry etching

Figure 3d–g. Finally, the resin (PI) is poured into the grooves and thermally cured (

Figure 3h–i). This completes the fabrication of the sensor.

4. Results and Discussion

4.1. Fundamental Performance of the Proposed Sensor

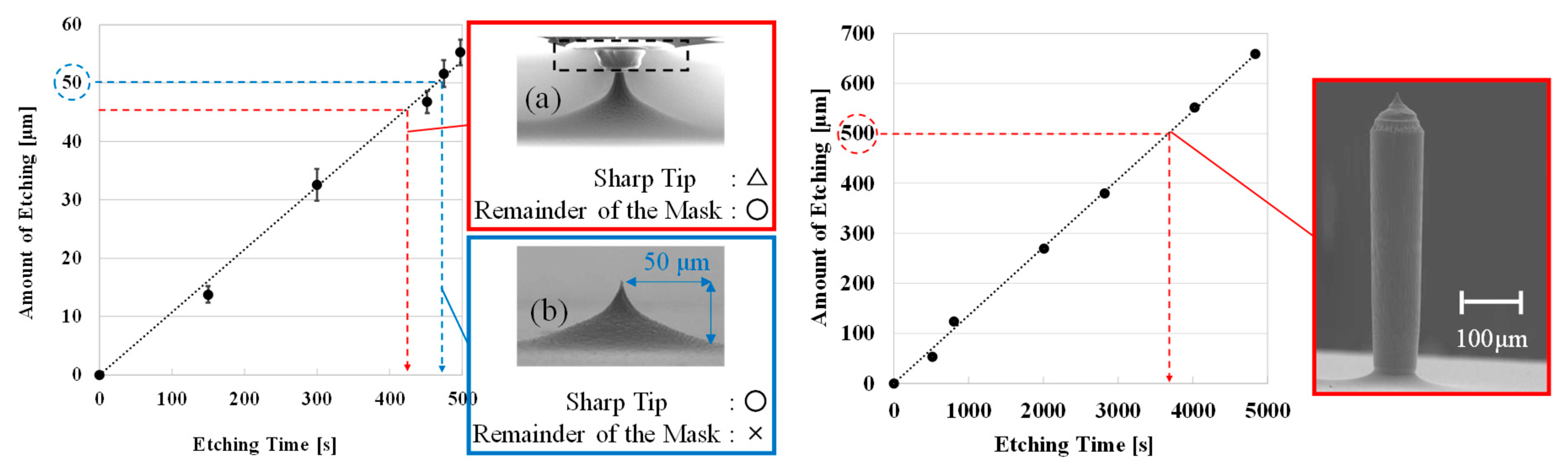

We fabricated a micro-probe consisting of a tip and pillar by using an inductively coupled plasma reactive ion etching (ICP-RIE) system.

Figure 4 shows the relationship between the amount of etching and etching time of the isotropic etching process with SF6 gas. Although the tip in

Figure 4b was remarkably sharp, the SU-8 masks disappeared, and this made the sequential fabrication of pillars difficult. Thus, by optimizing the fabrication conditions, we successfully fabricated the sharp tip with an SU-8 mask, as shown in

Figure 4a. Then, by using the remaining SU-8 masks, the pillars of the micro-probe were fabricated via the Bosch process with SF6/C4F8 gases.

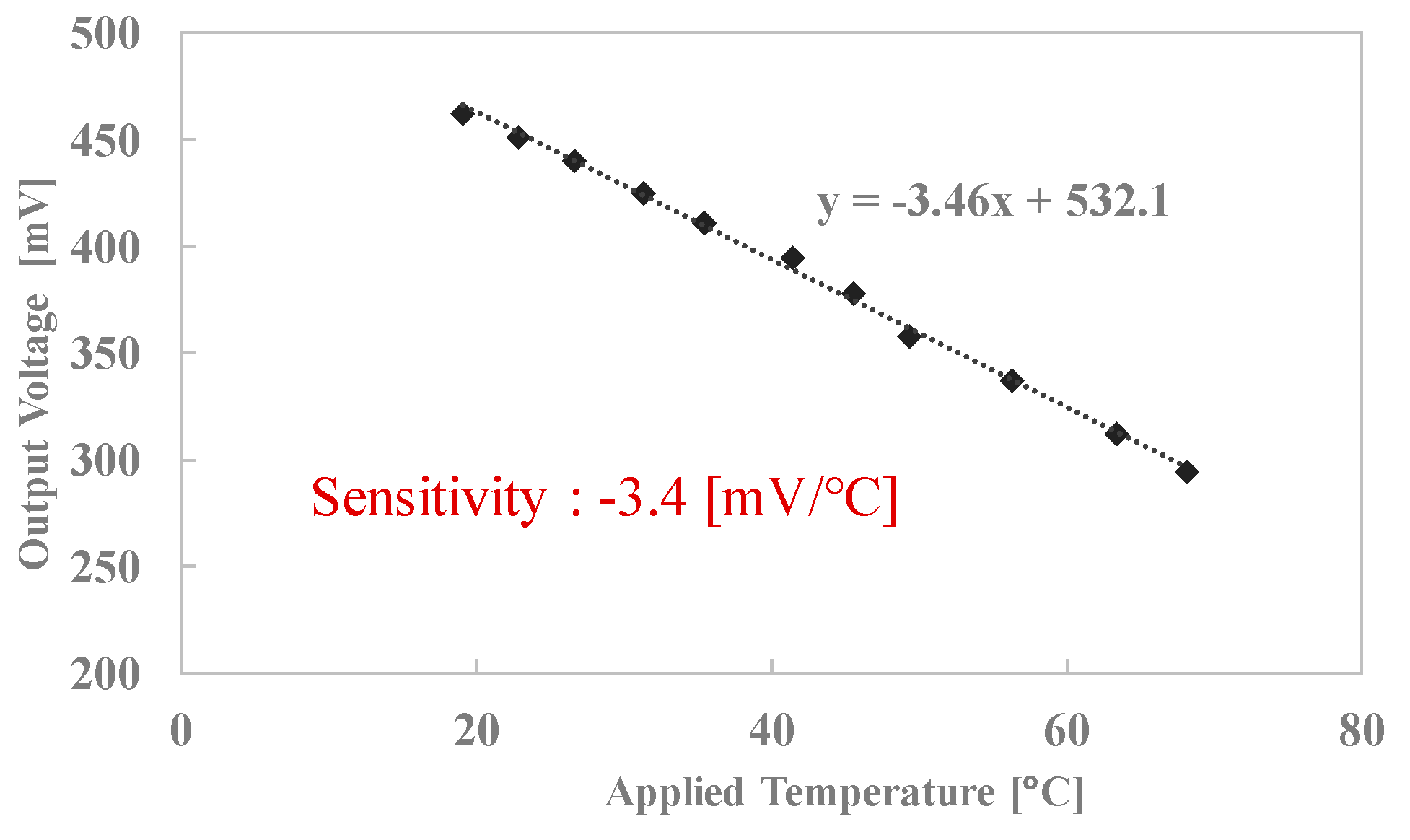

Figure 5 shows the relationship between the output voltage and applied temperature in the fabricated p-n junction-based temperature sensors. The sensitivity of the fabricated temperature sensors was −3.4 [mV/°C], which is same as the sensitivity a generic sensor.

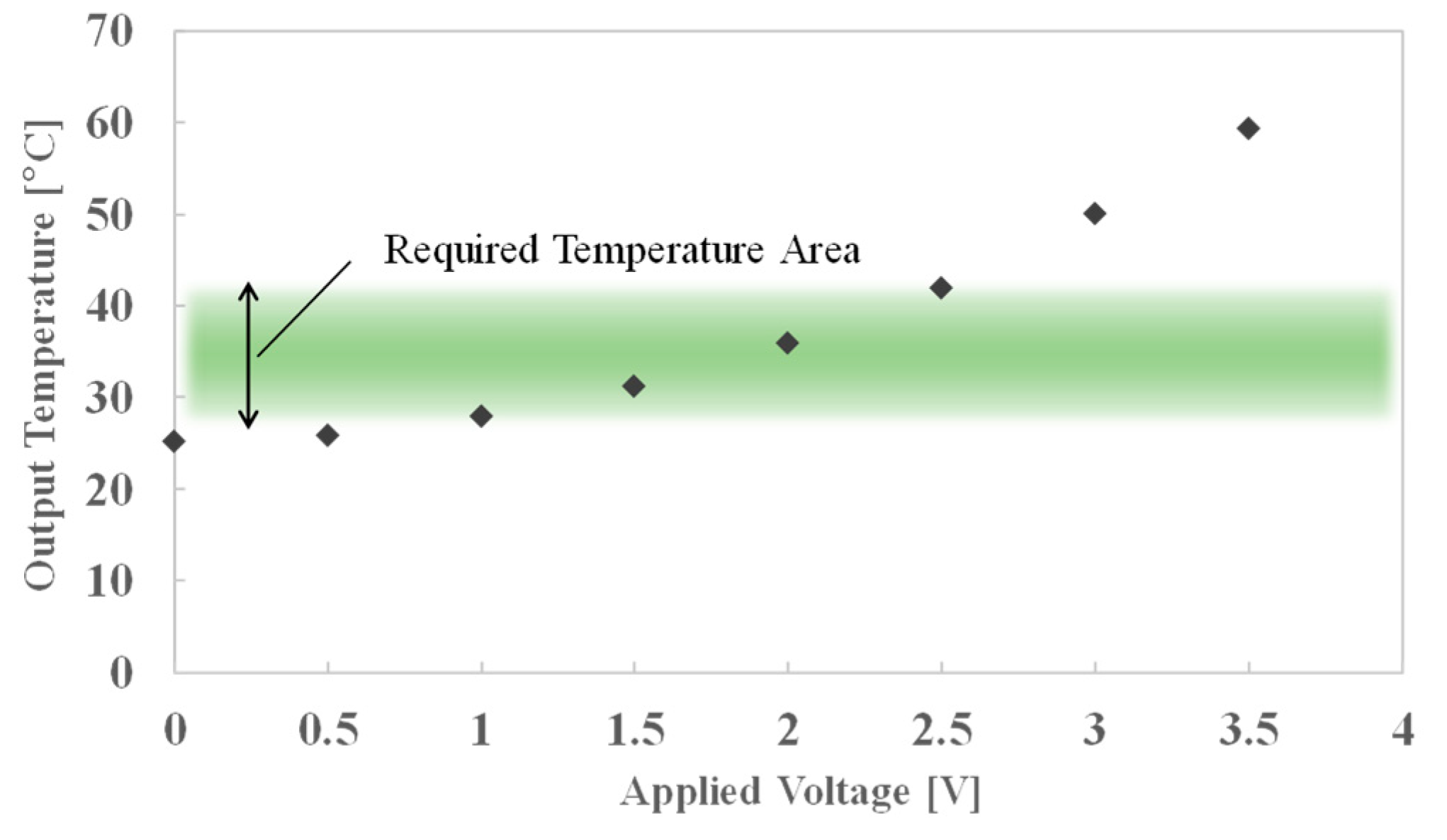

Figure 6 shows that the output temperature could be controlled by changing the applied voltage. The required maximum temperature of 40°C could be obtained by applying a voltage of approximately 2.5 V.

4.2. Sap Dynamics Measurements in Mimicked Plants

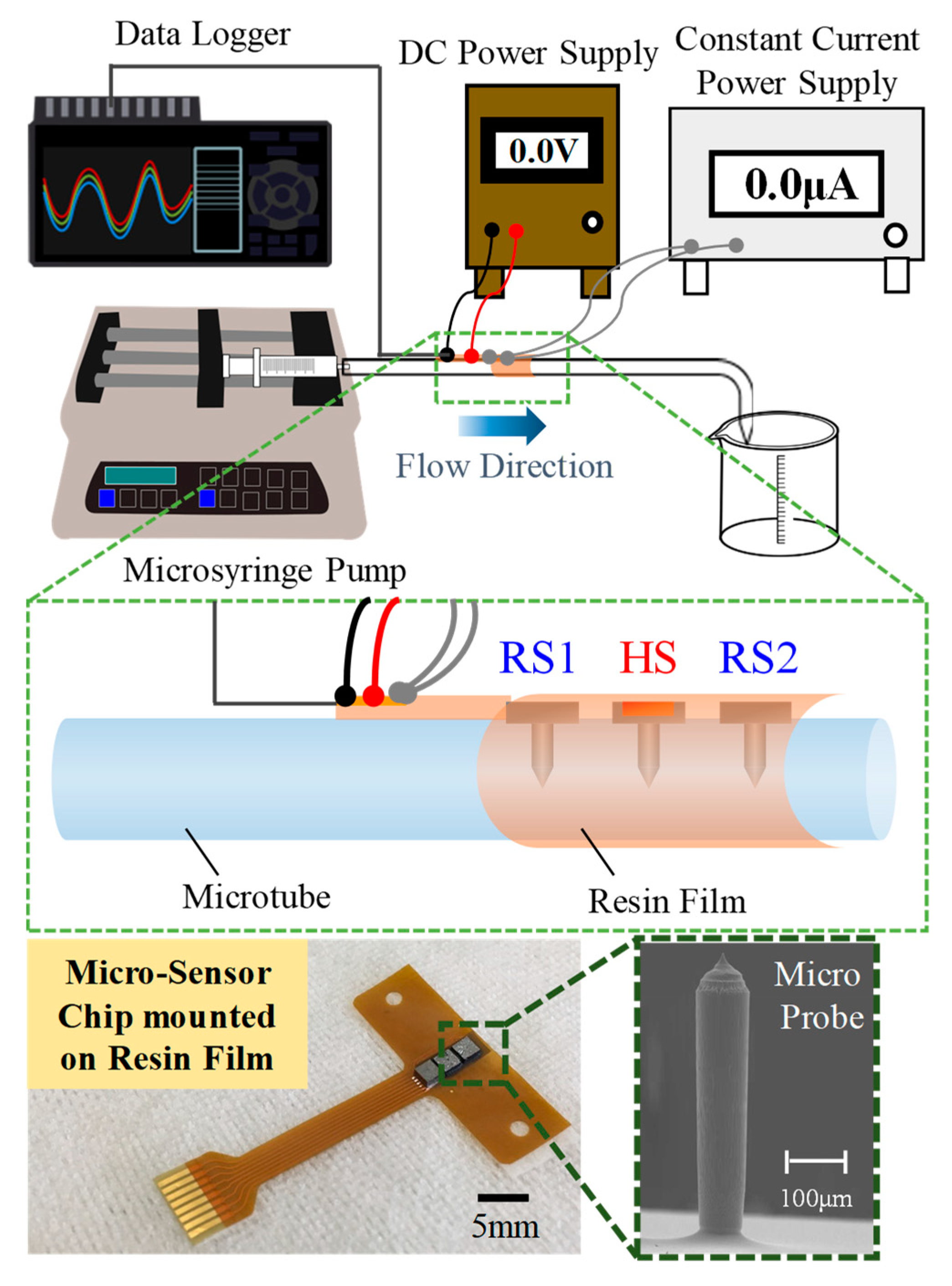

We measured the sap dynamics though experiments using mimicked plants.

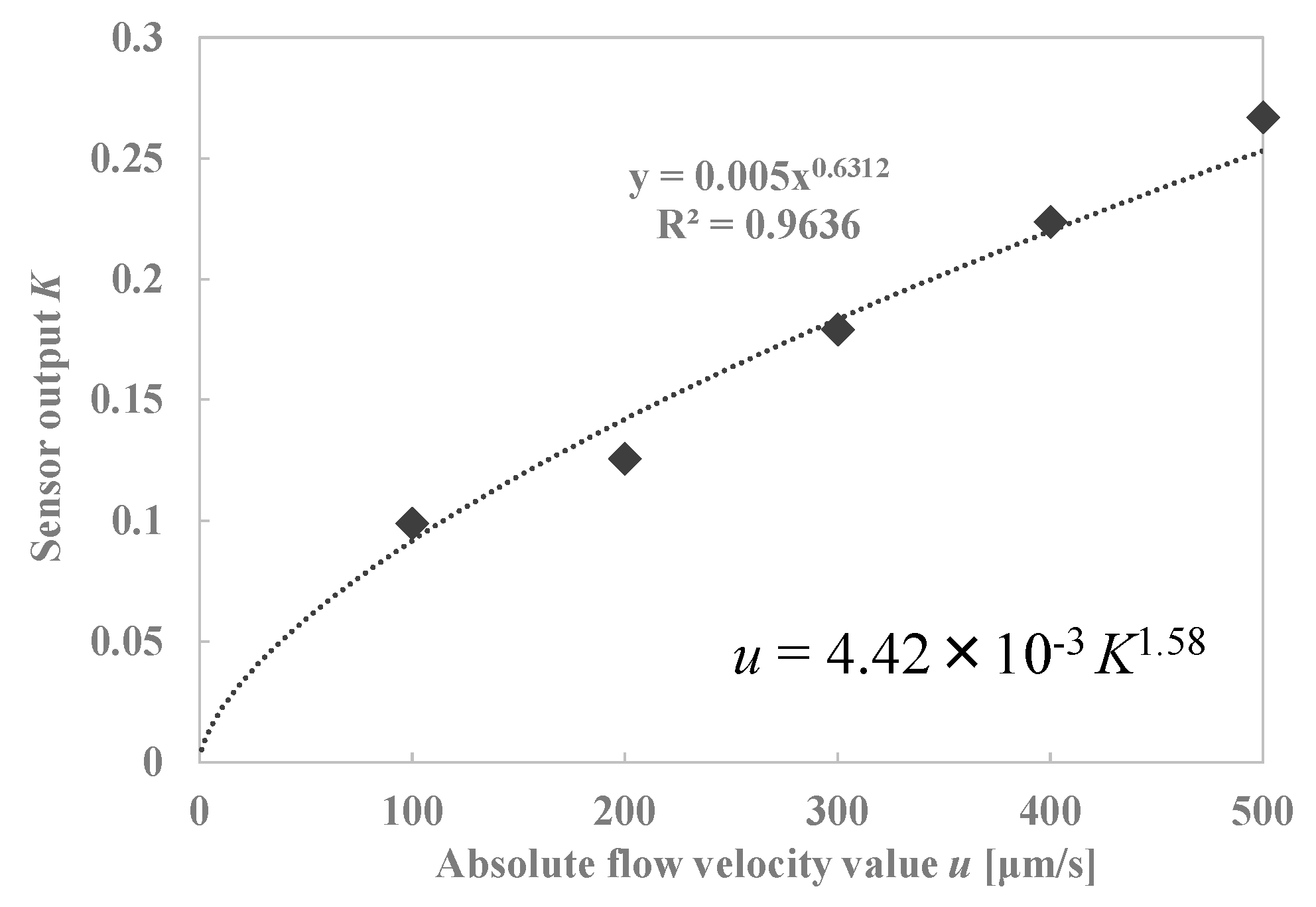

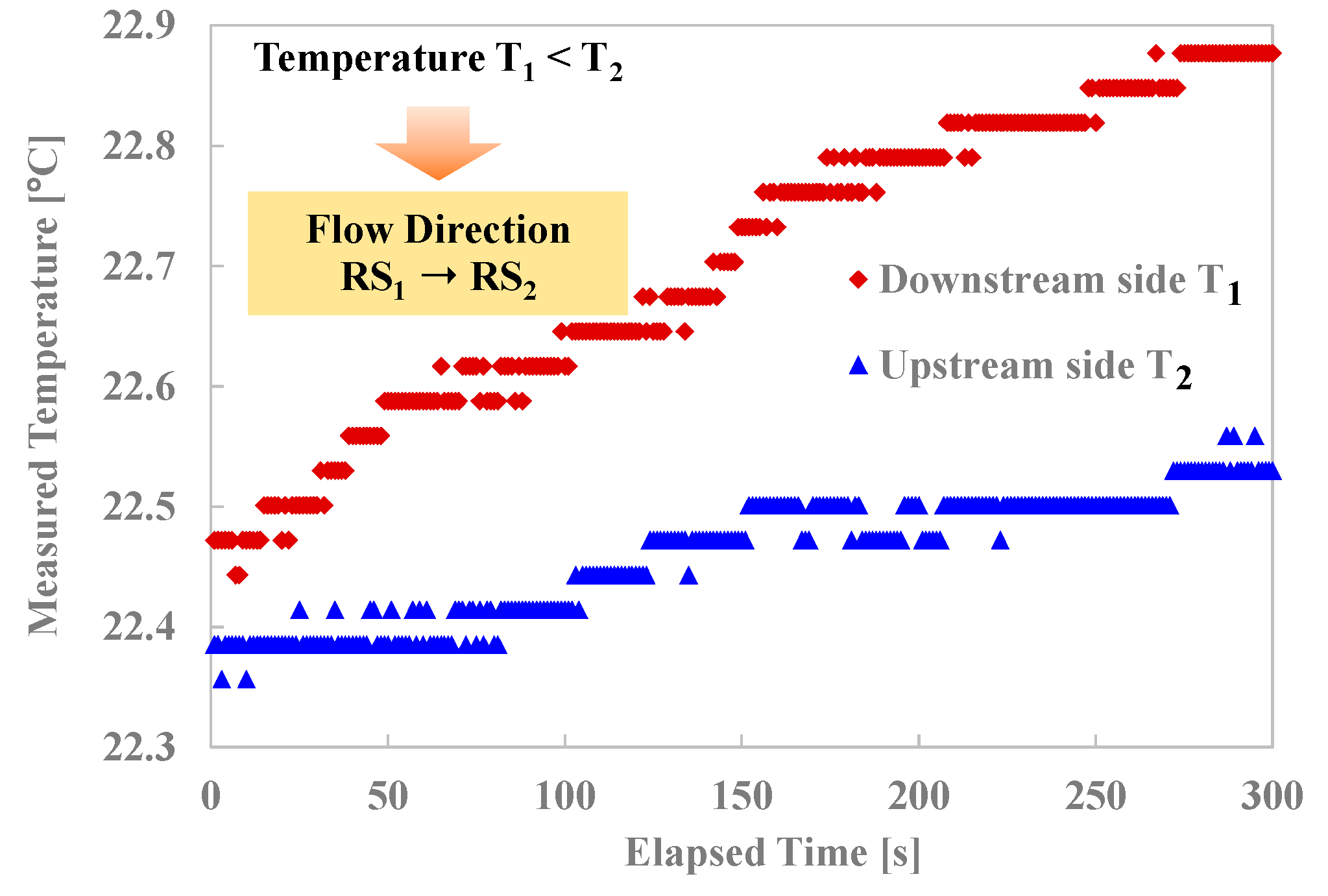

Figure 7 shows the mimicked plant experimental setup, comprising a microsyringe pump and microtube (outer diameter of the tube: φ0.6 mm and wall thickness: 0.16 mm). For the functional verification of the proposed sensor, we used perfectly separated sensor chips without thermal isolation structures, and assembled them on a resin film. We can calculate the flow velocity value

u flowing into the microtube using sensor output

K, in the range of 0–500 μm/s, which is known as the xylem sap flow velocity (

Figure 8). By comparing the temperature differences between these reference sensors (T

1<T

2), the flow direction was also determined to be from RS1 to RS2 (

Figure 9).

5. Conclusions

In this study, we newly proposed a microscale xylem sap flow sensor facilitating the simultaneous measurement of flow velocity and direction. We fabricated and evaluated the sensor chip incorporated in a microprobe, temperature sensor, and heater, and confirmed its functionality. Furthermore, we assembled it on a resin film, measured the sap dynamics by using an experimental setup, and succeeded in measuring the flow velocity (0–500 μm/s) and direction at the same time. In future works, we will try to quantitively measure the sap flow velocity and direction in an actual plant.