A Gradiometric Magnetic Sensor System for Stray-Field-Immune Rotary Position Sensing in Harsh Environment †

Abstract

:1. Introduction

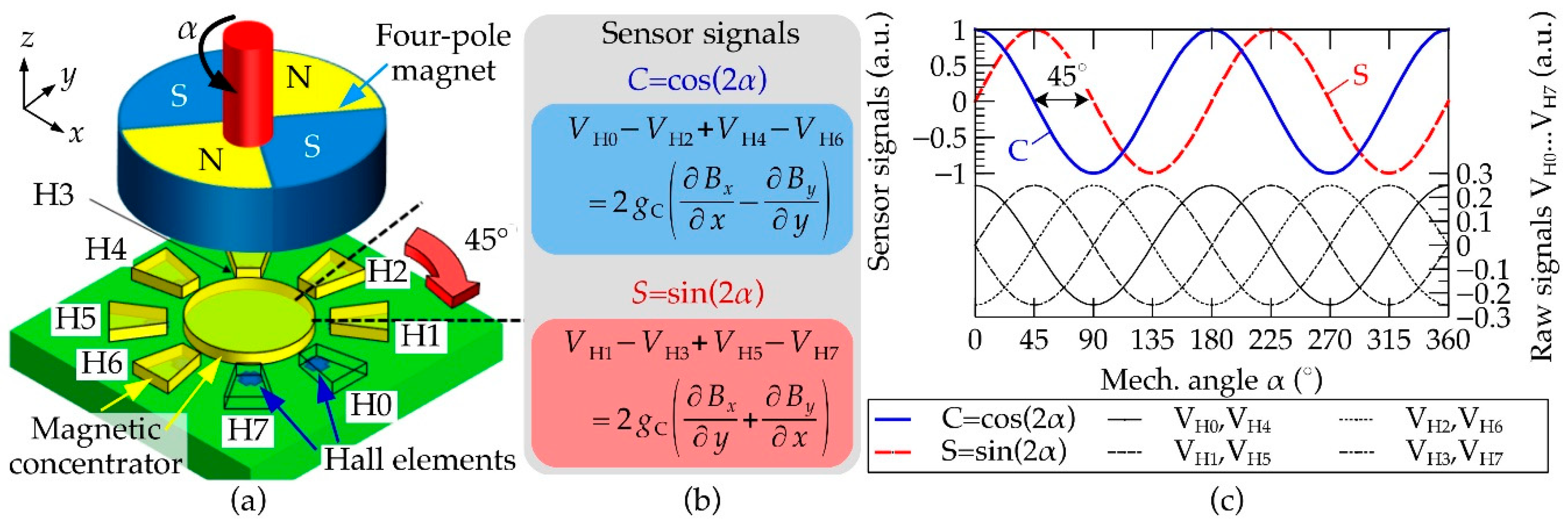

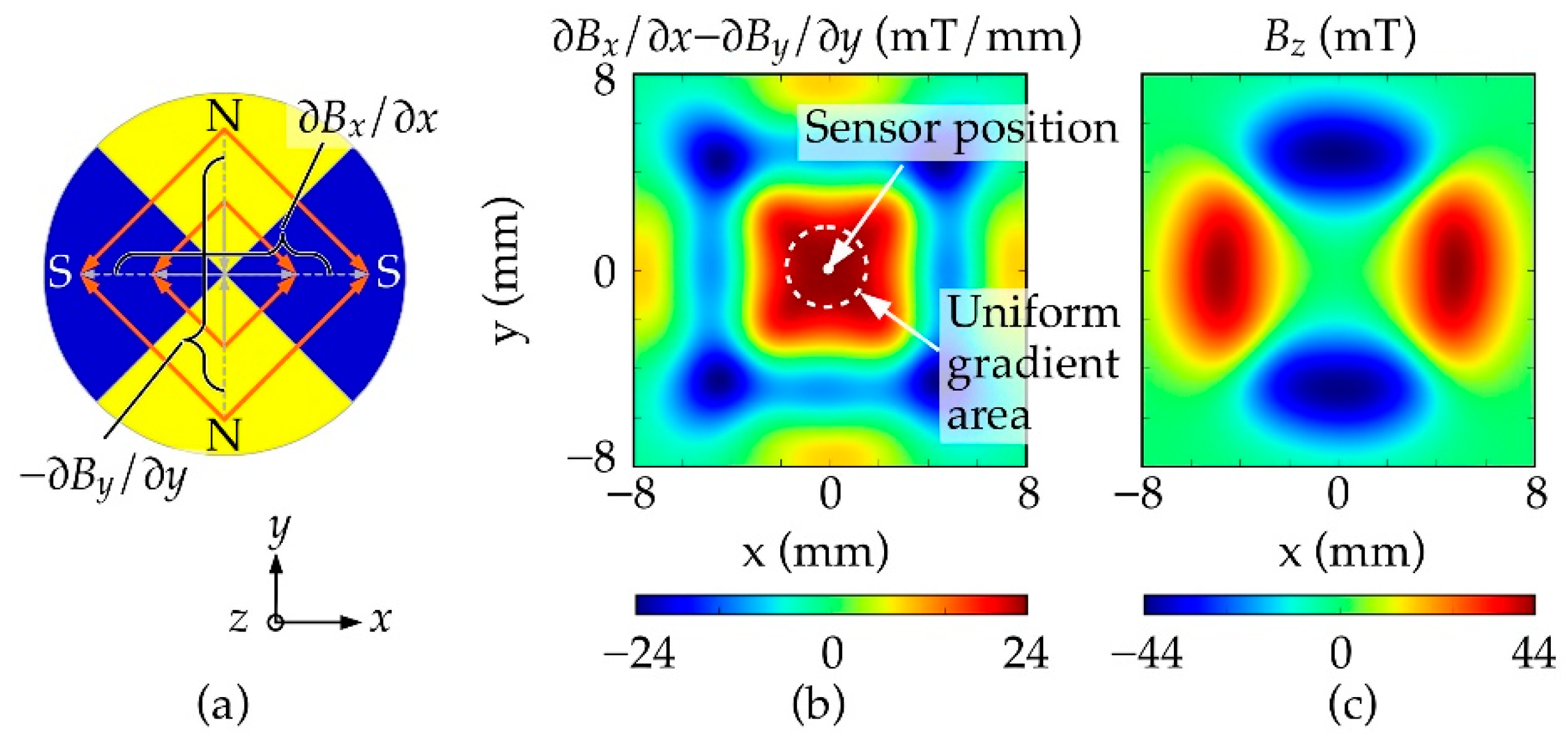

2. Concept

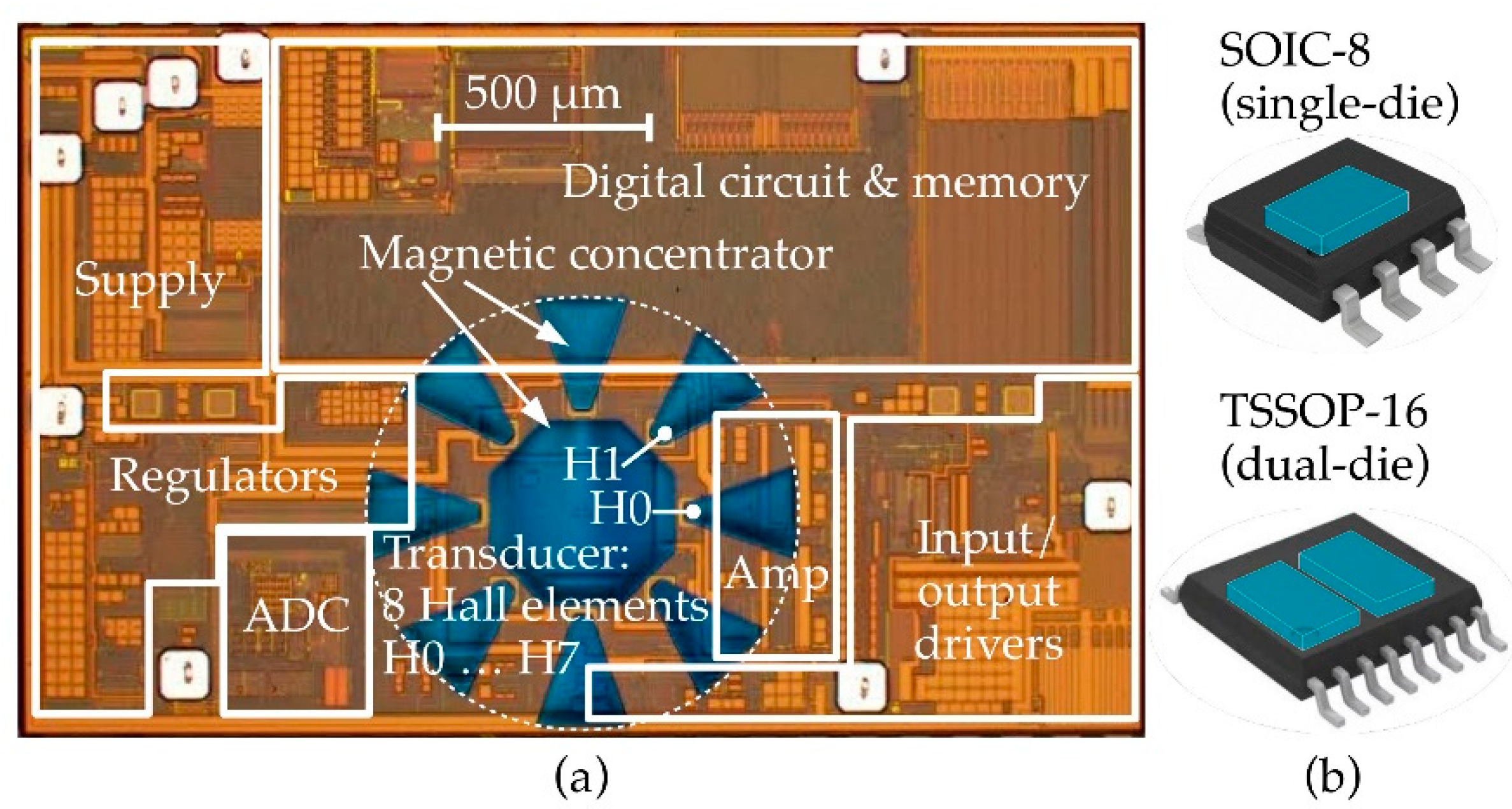

3. Materials and Methods

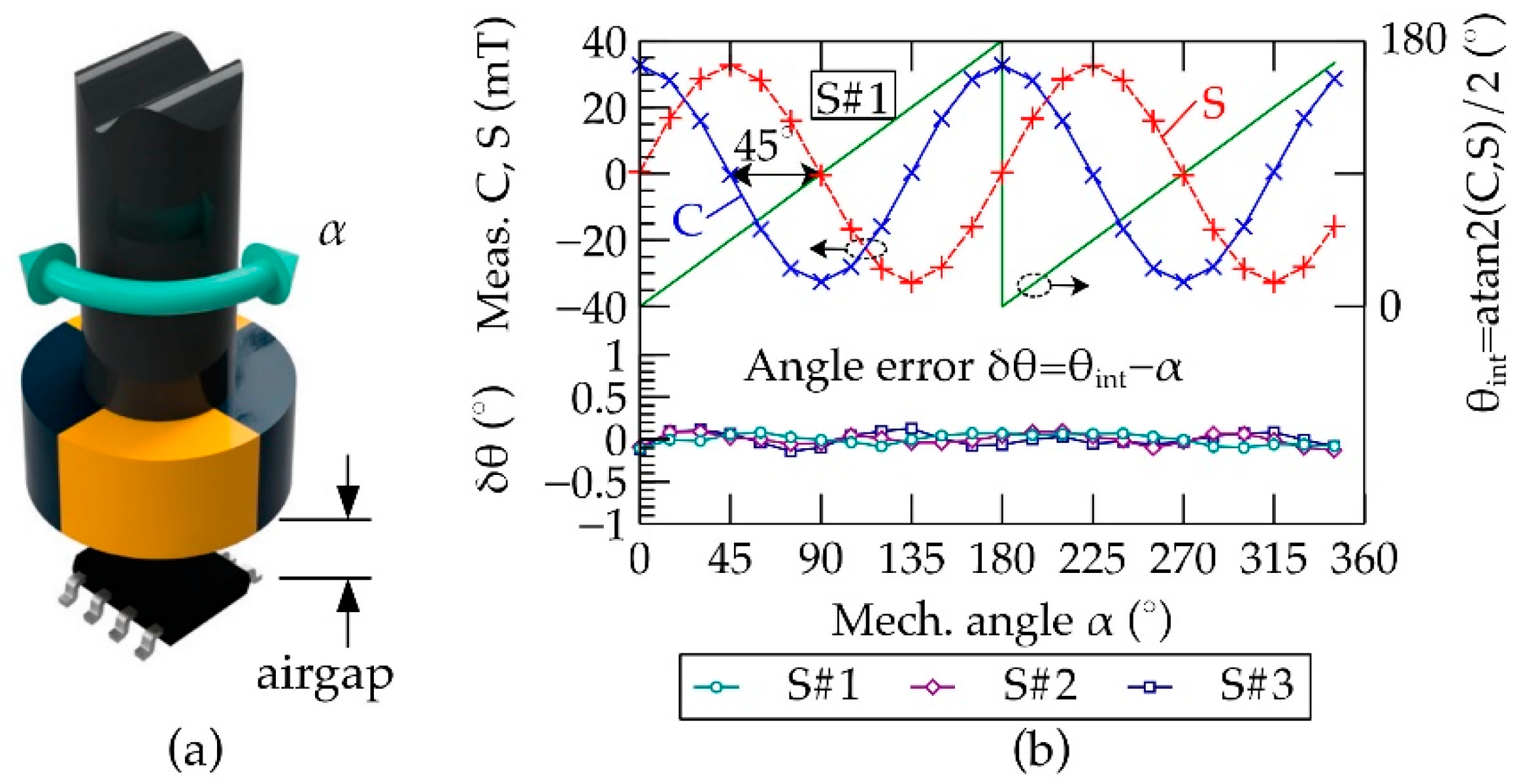

4. Results

5. Discussion and Conclusion

Acknowledgments

Conflicts of Interest

References

- Granig, W.; Hartmann, S.; Köppl, B. Performance and Technology Comparison of GMR Versus Commonly used Angle Sensor Principles for Automotive Applications; SAE Technical Paper 2007-01-0397; SAE International: Warrendale, PA, USA, 2007. [Google Scholar] [CrossRef]

- Hiligsmann, V.; Riendeau, P. Monolithic 360 degrees rotary position sensor IC [automotive applications]. In Proceedings of the IEEE SENSORS, Vienna, Austria, 24–27 October 2004. [Google Scholar] [CrossRef]

- Karabetsos, E.; Kalampaliki, E.; Tsanidis, G.; Koutounidis, D.; Skamnakis, N.; Kyritsi, T.; Yalofas, A. EMF measurements in hybrid technology cars. In Proceedings of the 6th International Workshop on Biological Effects of Electromagnetic, Bodrum, Turkey, 10–14 October 2010. [Google Scholar]

- Schneider, D.; Urban, M. Magnetic Position Sensors and Stray Field Interference; AMS AG: Premstätten, Austria, 2014. [Google Scholar]

- Schott, C.; Racz, R.; Huber, S. Smart CMOS Sensors with Integrated Magnetic Concentrators. In Proceedings of the IEEE SENSORS, Irvine, CA, USA, 30 October–3 November 2005. [Google Scholar] [CrossRef]

- Leroy, S.; Rigert, S.; Laville, A.; Ajbl, A.; Close, G.F. Integrated Hall-based magnetic platform for position sensing. In Proceedings of the ESSCIRC, 43rd IEEE European Solid State Circuits Conference, Leuven, Belgium, 11–14 September 2017. [Google Scholar] [CrossRef]

- Dupré, N.; Dubrulle, O.; Huber, S.; Burssens, J.-W.; Schott, C.; Close, G. Experimental Demonstration of Stray-Field Immunity beyond 5 mT for an Automotive-Grade Rotary Position Sensor. Proceedings 2018, 2, 763. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huber, S.; Burssens, J.-W.; Dupré, N.; Dubrulle, O.; Bidaux, Y.; Close, G.; Schott, C. A Gradiometric Magnetic Sensor System for Stray-Field-Immune Rotary Position Sensing in Harsh Environment. Proceedings 2018, 2, 809. https://doi.org/10.3390/proceedings2130809

Huber S, Burssens J-W, Dupré N, Dubrulle O, Bidaux Y, Close G, Schott C. A Gradiometric Magnetic Sensor System for Stray-Field-Immune Rotary Position Sensing in Harsh Environment. Proceedings. 2018; 2(13):809. https://doi.org/10.3390/proceedings2130809

Chicago/Turabian StyleHuber, Samuel, Jan-Willem Burssens, Nicolas Dupré, Olivier Dubrulle, Yves Bidaux, Gael Close, and Christian Schott. 2018. "A Gradiometric Magnetic Sensor System for Stray-Field-Immune Rotary Position Sensing in Harsh Environment" Proceedings 2, no. 13: 809. https://doi.org/10.3390/proceedings2130809

APA StyleHuber, S., Burssens, J.-W., Dupré, N., Dubrulle, O., Bidaux, Y., Close, G., & Schott, C. (2018). A Gradiometric Magnetic Sensor System for Stray-Field-Immune Rotary Position Sensing in Harsh Environment. Proceedings, 2(13), 809. https://doi.org/10.3390/proceedings2130809