Improvement Methods for Colorimetric Gas Sensor for Use in Indoor Livestock Farming †

Abstract

:1. Introduction

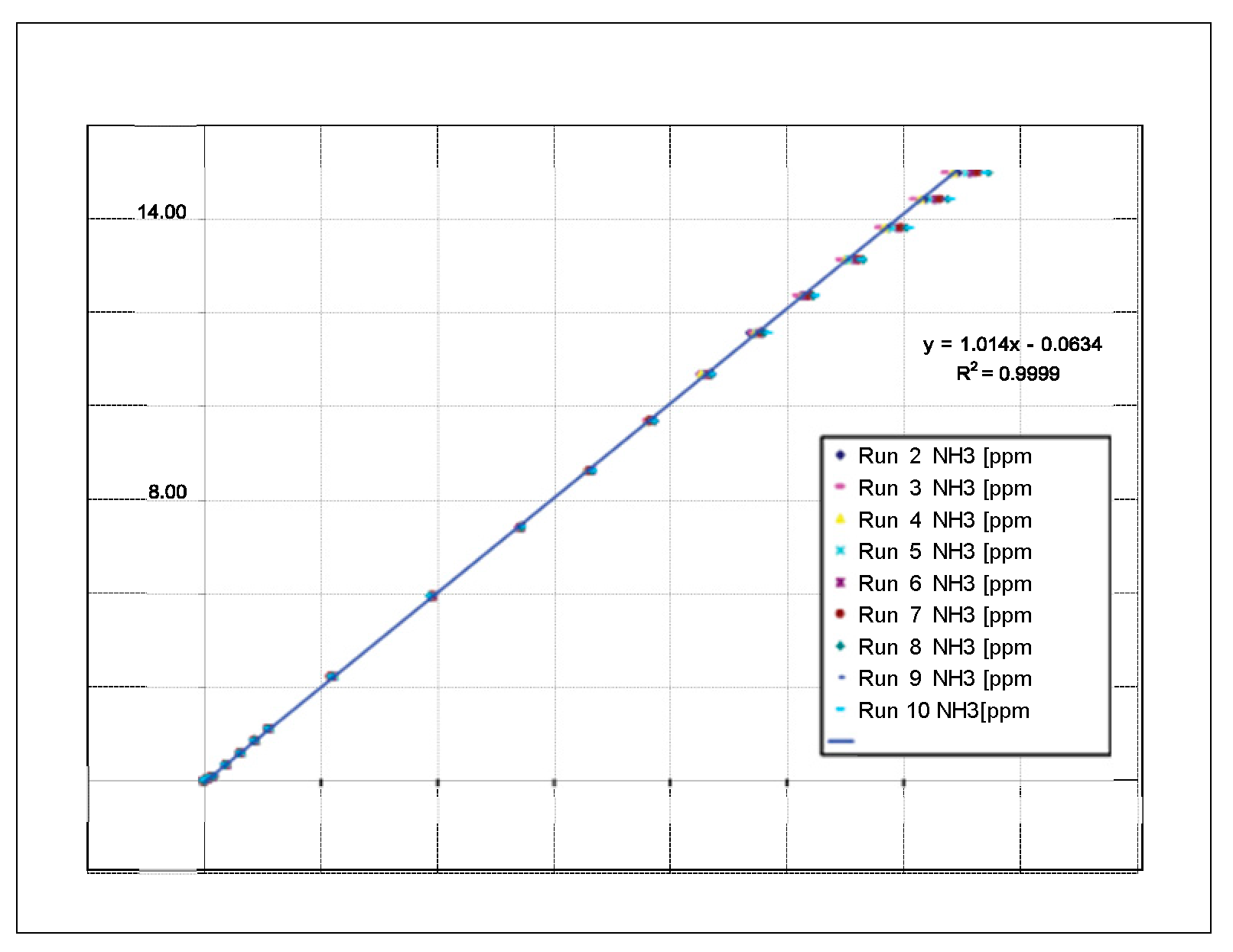

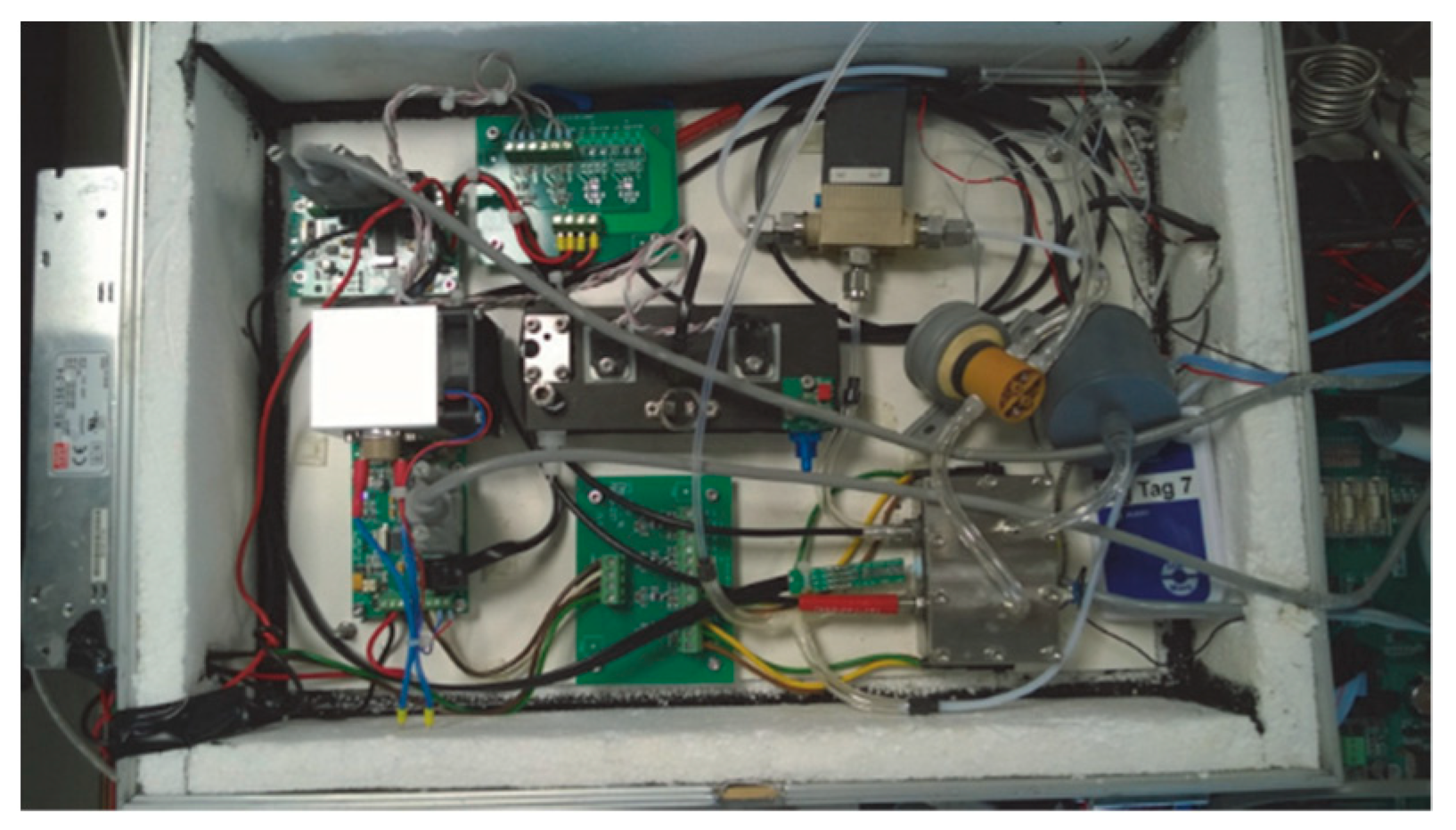

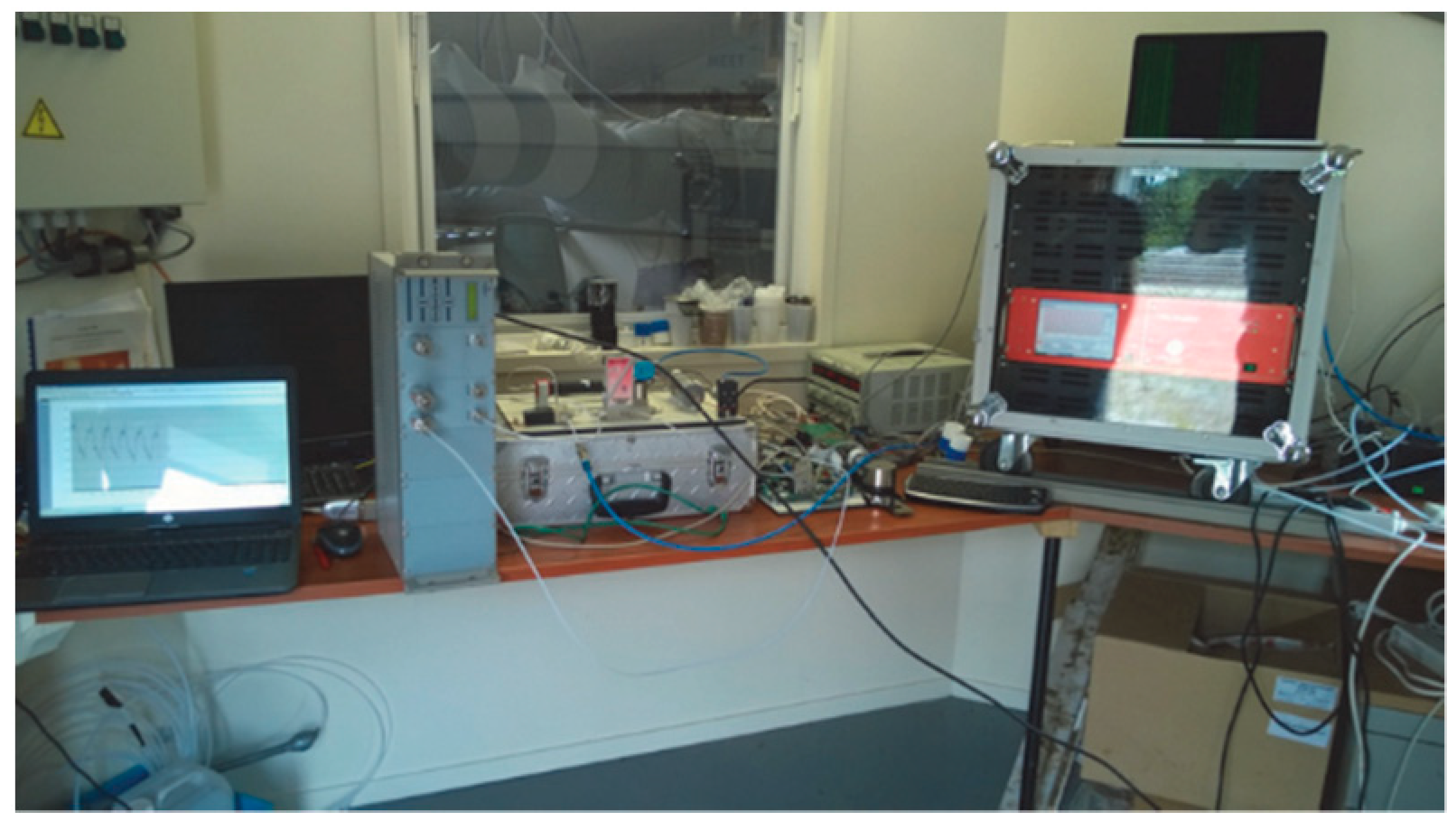

2. Materials and Methods

2.1. Dye

2.2. Substrate

2.3. Coating

2.4. Reference

2.5. Platinum (Pt) Catalyst

3. Results

4. Discussion and Conclusions

References

- Courbat, J.; Briand, D.; Wöllenstein, J.; de Rooij, N.F. Polymeric foil optical waveguide with inkjet printed gas sensitive film for colorimetric sensing. Sens. Actuators B Chem. 2011. [Google Scholar] [CrossRef]

- Courbat, J.; Briand, D.; Damon-Lacoste, J.; Wöllenstein, J.; de Rooij, N.F. Evaluation of pH indicator-based colorimetric films for ammonia detection using optical waveguides. Sens. Actuators B Chem. 2009. [Google Scholar] [CrossRef]

- Sjepherd, R.L.; Yerazunis, W.S. Low-Cost Surface Mount LED Gas Sensor. Sensors 2005, 6, 861–866. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boerman, J.-K.; van Harberden, J.-K.; Pannek, C.; Schmitt, K.; Tarantik, K.R.; Bauersfeld, M.-L.; Wöllenstein, J. Improvement Methods for Colorimetric Gas Sensor for Use in Indoor Livestock Farming. Proceedings 2018, 2, 769. https://doi.org/10.3390/proceedings2130769

Boerman J-K, van Harberden J-K, Pannek C, Schmitt K, Tarantik KR, Bauersfeld M-L, Wöllenstein J. Improvement Methods for Colorimetric Gas Sensor for Use in Indoor Livestock Farming. Proceedings. 2018; 2(13):769. https://doi.org/10.3390/proceedings2130769

Chicago/Turabian StyleBoerman, Jan-Kees, Jan-Kees van Harberden, Carolin Pannek, Katrin Schmitt, Karina R. Tarantik, Marie-Luise Bauersfeld, and Jürgen Wöllenstein. 2018. "Improvement Methods for Colorimetric Gas Sensor for Use in Indoor Livestock Farming" Proceedings 2, no. 13: 769. https://doi.org/10.3390/proceedings2130769

APA StyleBoerman, J.-K., van Harberden, J.-K., Pannek, C., Schmitt, K., Tarantik, K. R., Bauersfeld, M.-L., & Wöllenstein, J. (2018). Improvement Methods for Colorimetric Gas Sensor for Use in Indoor Livestock Farming. Proceedings, 2(13), 769. https://doi.org/10.3390/proceedings2130769