A Two-stage Energy Extraction Circuit for Energy Harvesting in Non-Sinusoidal Excited Environments †

Abstract

:1. Introduction

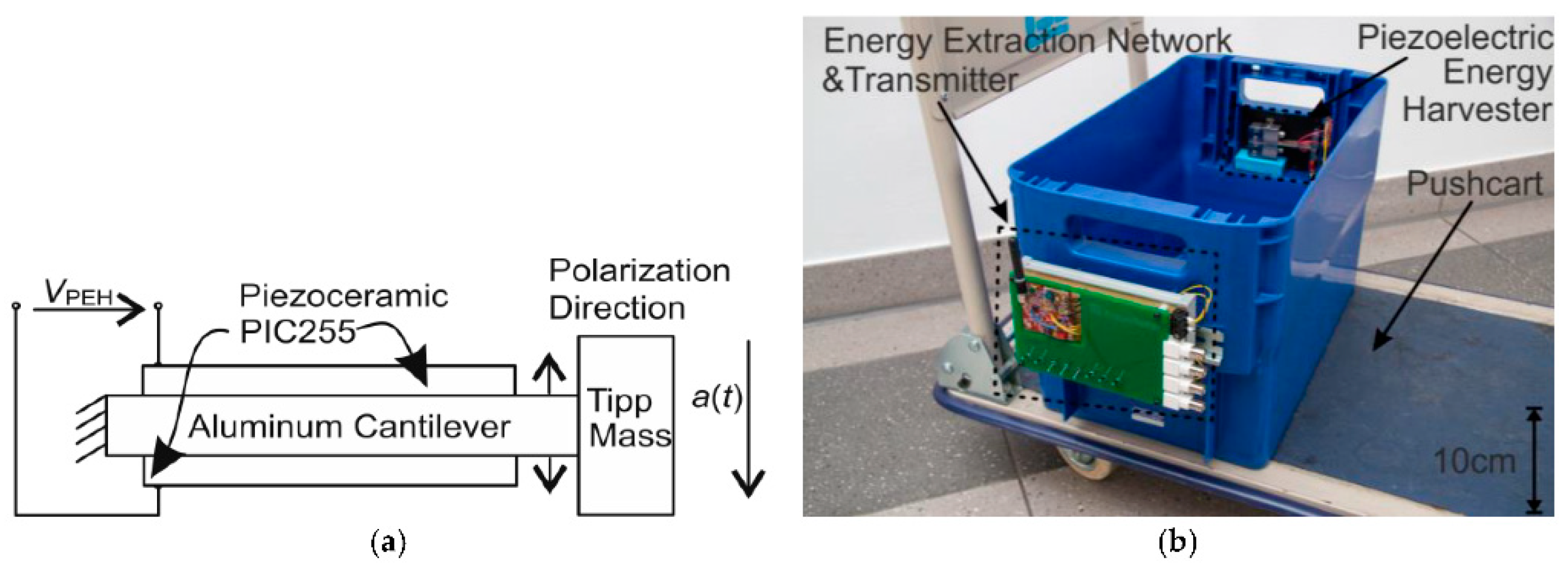

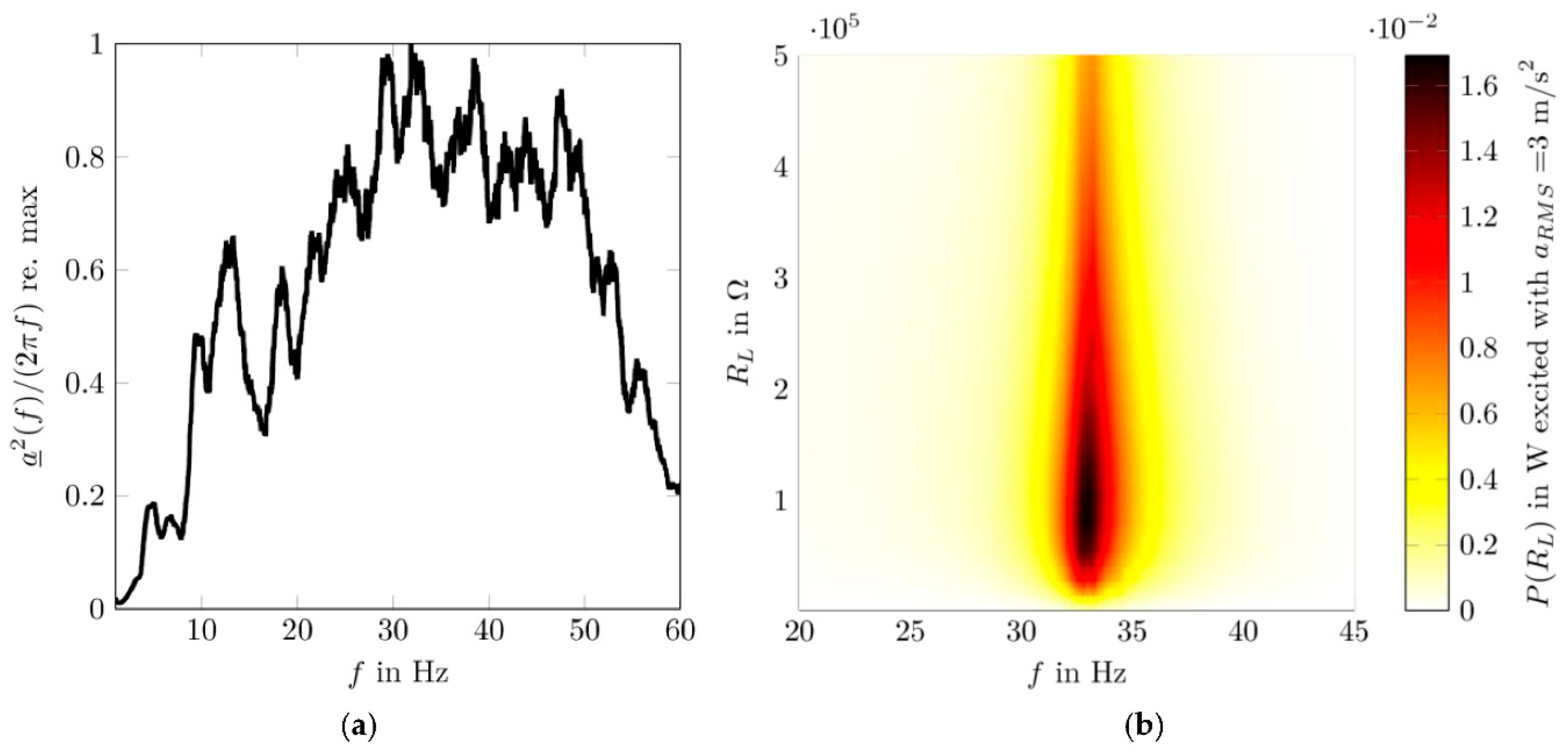

2. Characterization of the Excitation and the Piezoelectric Energy Harvester

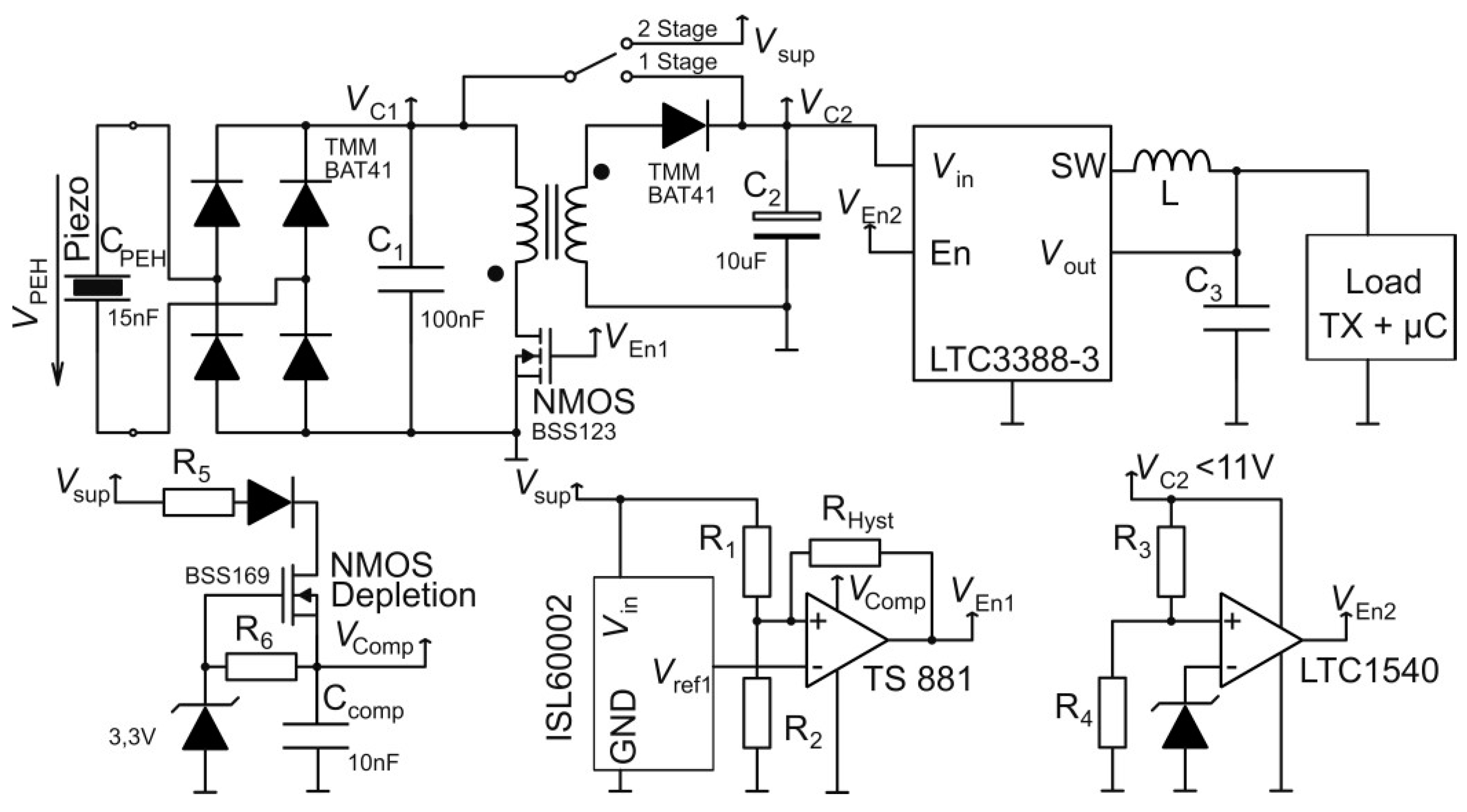

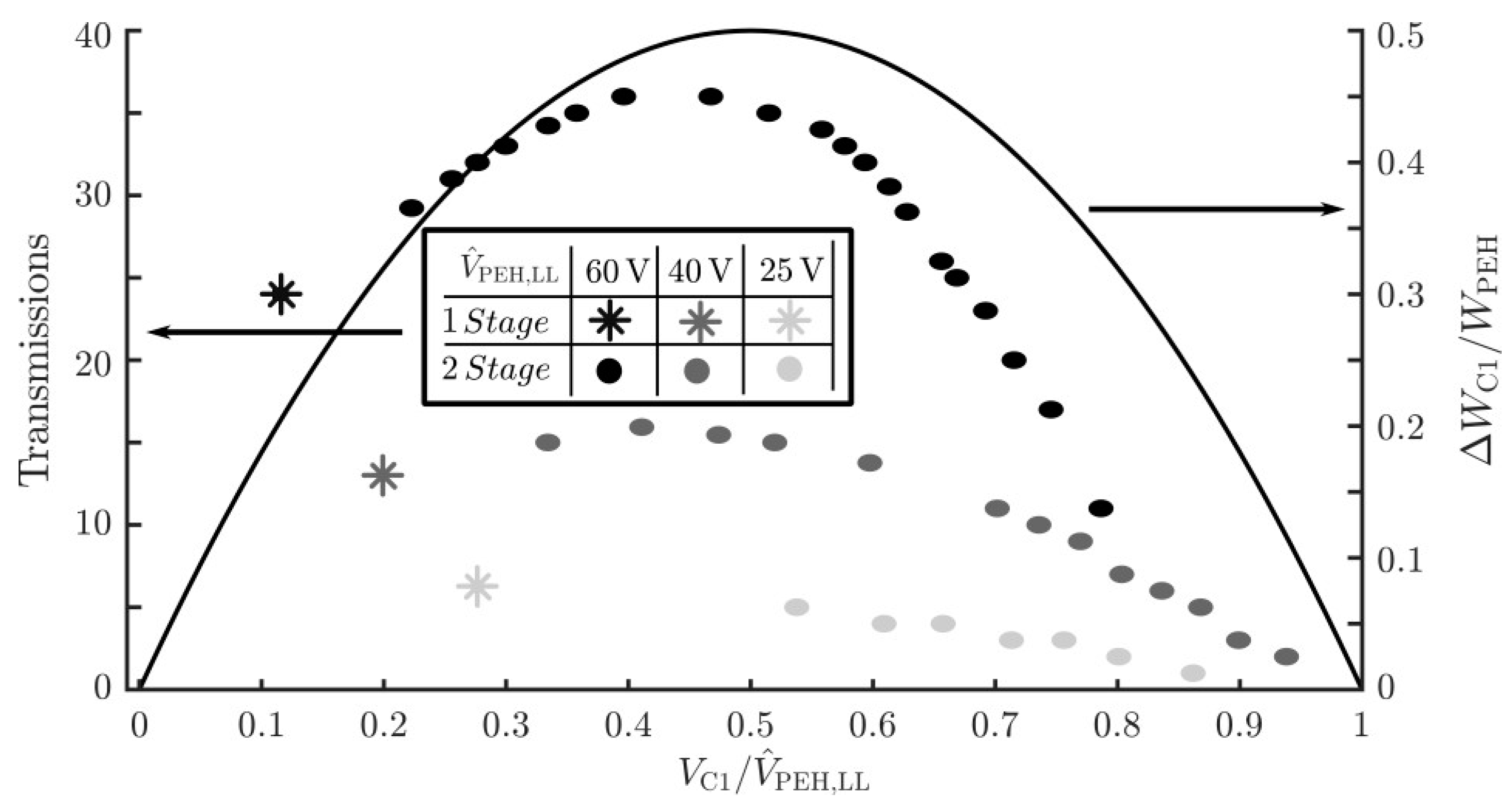

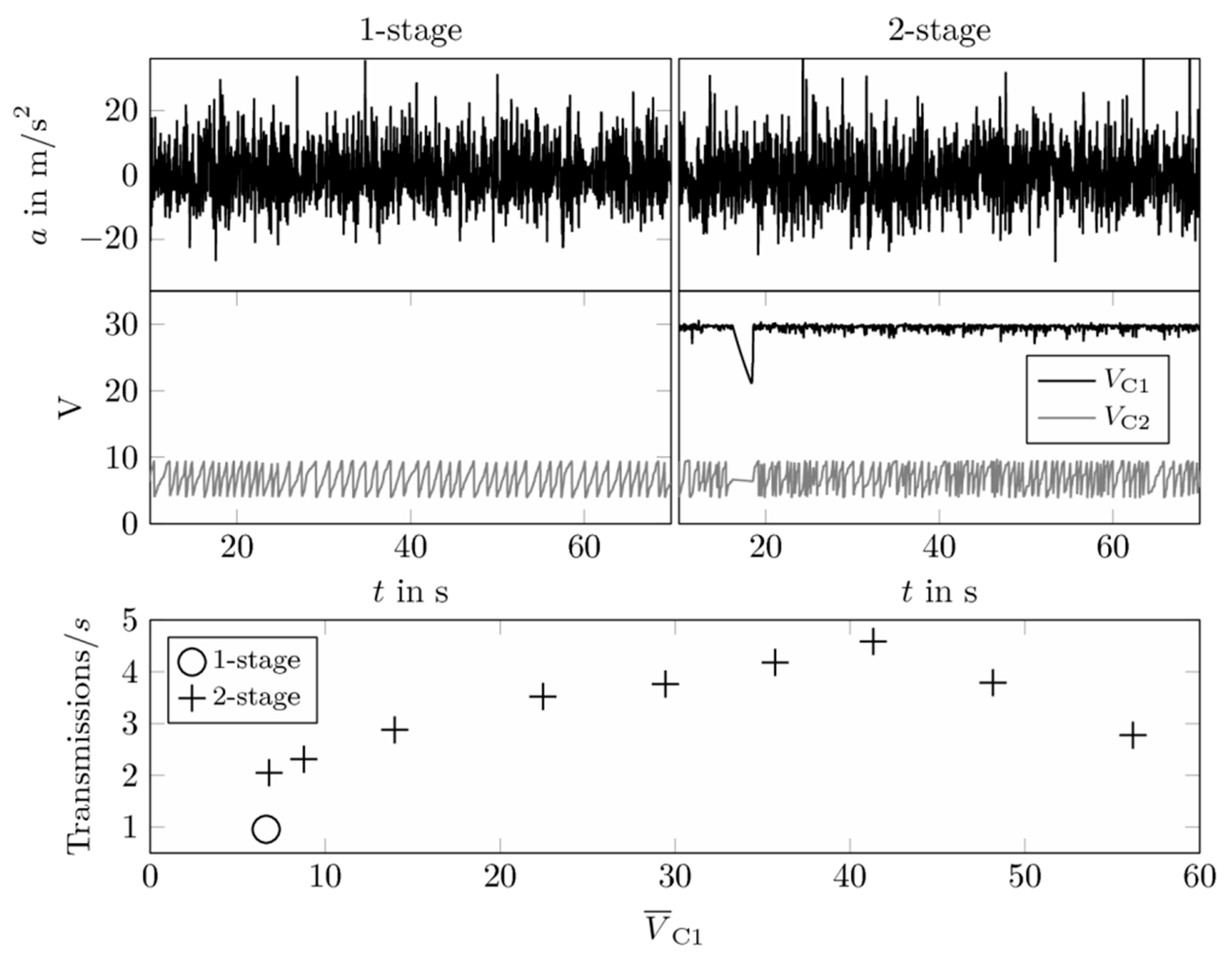

3. Two Stage Energy Extraction Network

4. Practical Evaluation of the Two-Stage Approach

Acknowledgments

Conflicts of Interest

References

- Dorsch, P.; Geyer, S.; Gedeon, D.; Hubert, F.; Rupitsch, S.J. Piezoelektrisches Energy-Harvesting in niederfrequenter Anregungsumgebung mittels kontaktbasierter Frequency-Upconversion. Tm–Technisches Messen 2018, 85, 275–290. [Google Scholar] [CrossRef]

- Rupitsch, S.J.; Ilg, J. Complete characterization of piezoceramic materials by means of wo block-shaped test samples. IEEE Trans. Ultrasonics Ferroelectr. Frequency Control 2015, 62, 1403–1413. [Google Scholar] [CrossRef]

- Lefeuvre, E.; Badel, A.; Richard, C.; Petit, L.; Guyomar, D. A Comparison between several vibration-powered piezoelectric generators for standalone systems. Sens. Actuators A Phys. 2006, 126, 4015–4016. [Google Scholar] [CrossRef]

- Guyomar, D.; Lallart, M. Recent Progress in Piezoelectric Conversion and Energy Harvesting Using Nonlinear Electronic Interfaces and Issues in Small Scale Implementation. Micromachines 2011, 2, 274–294. [Google Scholar] [CrossRef]

- Aguayo, A.E.; Paul, O.; Galchev, T. Integrated synchronous electrical charge extraction system for piezoelectric energy harvesters. In Proceedings of the IEEE International Symposium on Circuits and Systems (ISCAS), Lisbon, Portugal, 24–27 May 2015; pp. 1090–1093. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dorsch, P.; Bartsch, T.; Hubert, F.; Milosiu, H.; Rupitsch, S.J. A Two-stage Energy Extraction Circuit for Energy Harvesting in Non-Sinusoidal Excited Environments. Proceedings 2018, 2, 700. https://doi.org/10.3390/proceedings2130700

Dorsch P, Bartsch T, Hubert F, Milosiu H, Rupitsch SJ. A Two-stage Energy Extraction Circuit for Energy Harvesting in Non-Sinusoidal Excited Environments. Proceedings. 2018; 2(13):700. https://doi.org/10.3390/proceedings2130700

Chicago/Turabian StyleDorsch, Philipp, Toni Bartsch, Florian Hubert, Heinrich Milosiu, and Stefan J. Rupitsch. 2018. "A Two-stage Energy Extraction Circuit for Energy Harvesting in Non-Sinusoidal Excited Environments" Proceedings 2, no. 13: 700. https://doi.org/10.3390/proceedings2130700

APA StyleDorsch, P., Bartsch, T., Hubert, F., Milosiu, H., & Rupitsch, S. J. (2018). A Two-stage Energy Extraction Circuit for Energy Harvesting in Non-Sinusoidal Excited Environments. Proceedings, 2(13), 700. https://doi.org/10.3390/proceedings2130700