Miniature Twist/Rotation Fabry Perot Sensor Based on a Four-Core Fiber †

Abstract

:1. Introduction

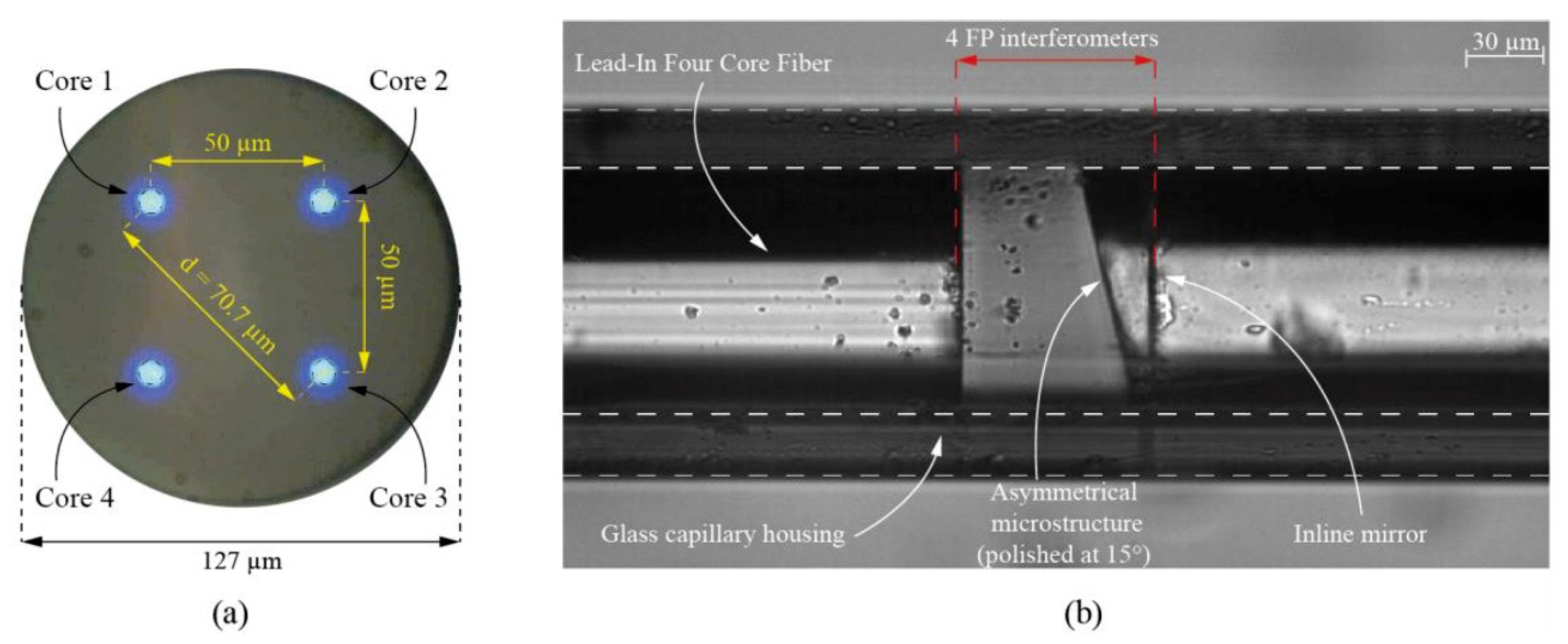

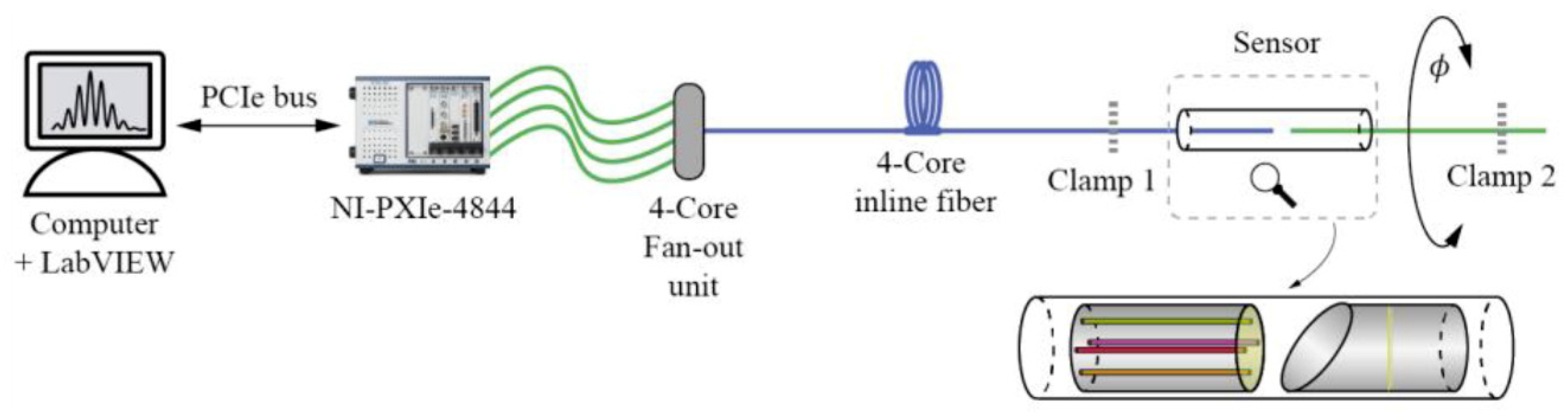

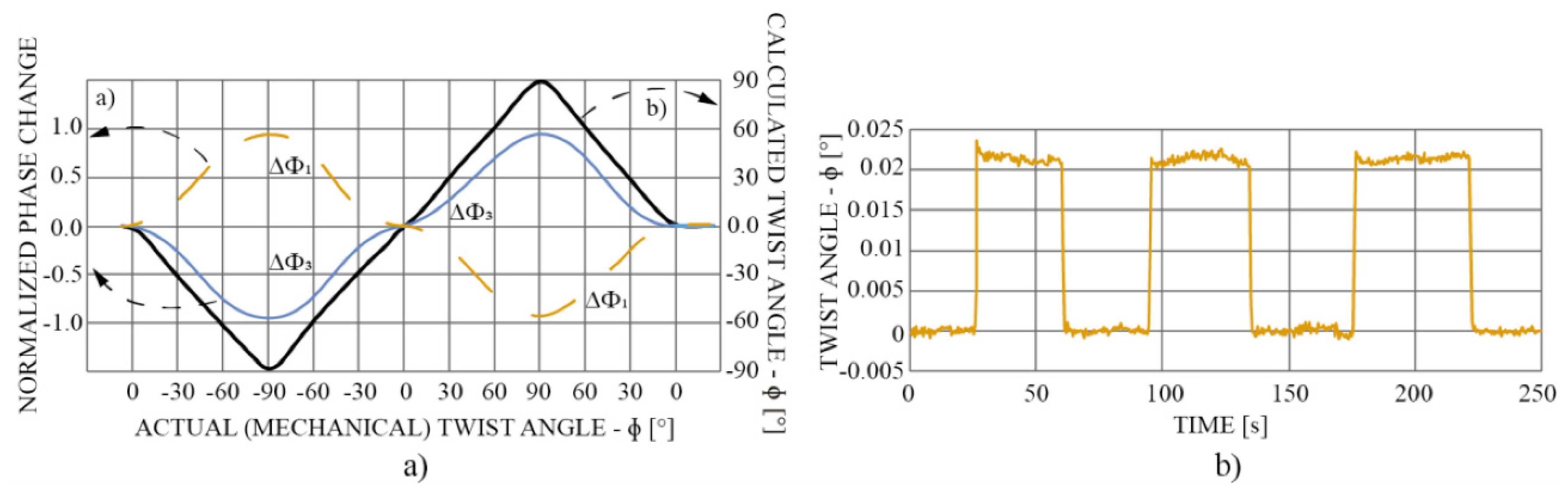

2. Sensor Design and Operation

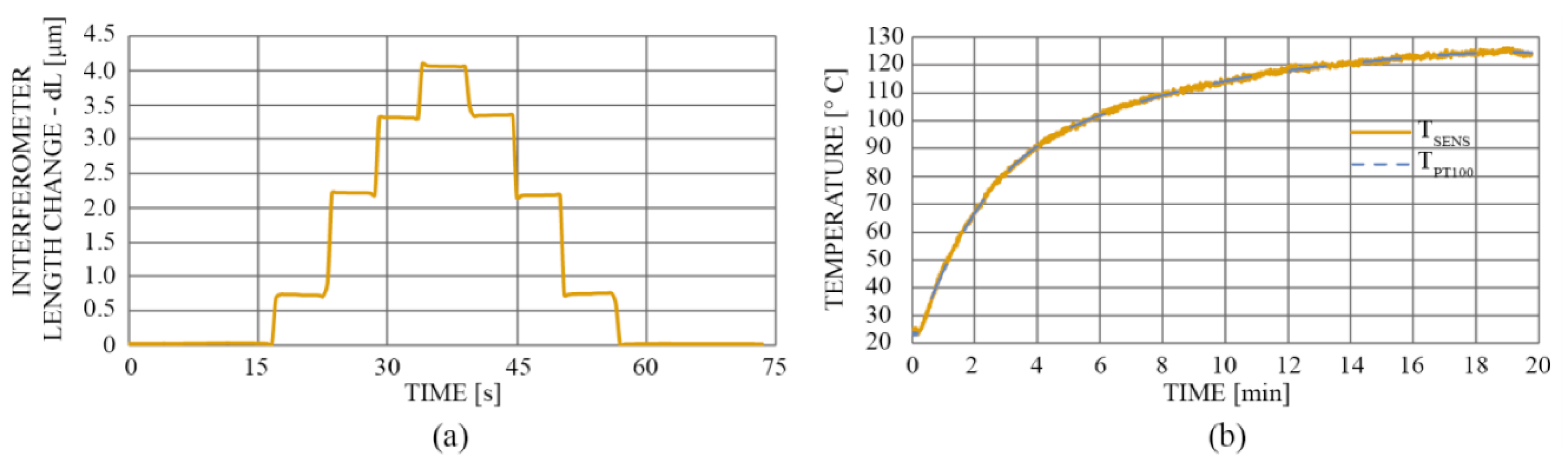

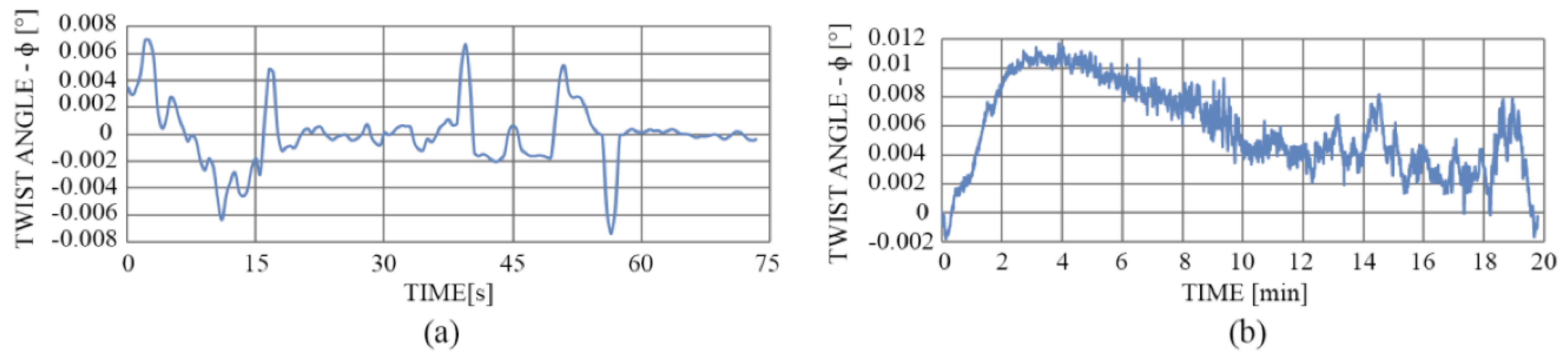

3. Experimental Results

4. Conclusions

References

- Budinski, V.; Donlagic, D. Fiber-Optic Sensors for Measurements of Torsion, Twist and Rotation: A Review. Sensors 2017, 17, 443. [Google Scholar] [CrossRef] [PubMed]

- Cibula, E.; Pevec, S.; Lenardic, B.; Pinet, E.; Donlagic, D. Miniature all-glass robust pressure sensor. Opt. Express 2009, 17, 5098–5106. [Google Scholar] [CrossRef] [PubMed]

- Heo, J.S.; Lee, J.J.; Lim, J.O. A Micro Total Reflective Extrinsic Fabry-Parot Interferometric Fiber Optic Pressure Sensor for Medical Application. Int. J. Mod. Phys. B 2003, 17, 1199–1204. [Google Scholar] [CrossRef]

- Pevec, S.; Donlagic, D. All-fiber, long-active-length Fabry-Perot strain sensor. Opt. Express 2011, 19, 15641. [Google Scholar] [CrossRef] [PubMed]

- Pevec, S.; Donlagic, D. Miniature all-fiber Fabry–Perot sensor for simultaneous measurement of pressure and temperature. Appl. Opt. 2012, 51, 4536. [Google Scholar] [CrossRef] [PubMed]

- Paulicka, I. Optical fibre Fabry-Perot sensor for the detection of small vibrations and displacements. In Proceedings of the SPIE—The International Society for Optical Engineering, Budapest, Hungary, 9–13 August 1993; pp. 1066–1067. [Google Scholar]

- J. S. Acceta, R. Arrathoon Ultra-sensitive optical sensors for robotic touch and hearing. In Proceedings of the Robotic Intelligence and Productivity Conference, Detroit, MI, USA, 18–19 November 1983; p. 75. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Budinski, V.; Donlagic, D. Miniature Twist/Rotation Fabry Perot Sensor Based on a Four-Core Fiber. Proceedings 2018, 2, 1091. https://doi.org/10.3390/proceedings2131091

Budinski V, Donlagic D. Miniature Twist/Rotation Fabry Perot Sensor Based on a Four-Core Fiber. Proceedings. 2018; 2(13):1091. https://doi.org/10.3390/proceedings2131091

Chicago/Turabian StyleBudinski, Vedran, and Denis Donlagic. 2018. "Miniature Twist/Rotation Fabry Perot Sensor Based on a Four-Core Fiber" Proceedings 2, no. 13: 1091. https://doi.org/10.3390/proceedings2131091

APA StyleBudinski, V., & Donlagic, D. (2018). Miniature Twist/Rotation Fabry Perot Sensor Based on a Four-Core Fiber. Proceedings, 2(13), 1091. https://doi.org/10.3390/proceedings2131091