Threshold Voltage Control to Improve Energy Utilization Efficiency of a Power Management Circuit for Energy Harvesting Applications †

Abstract

:1. Introduction

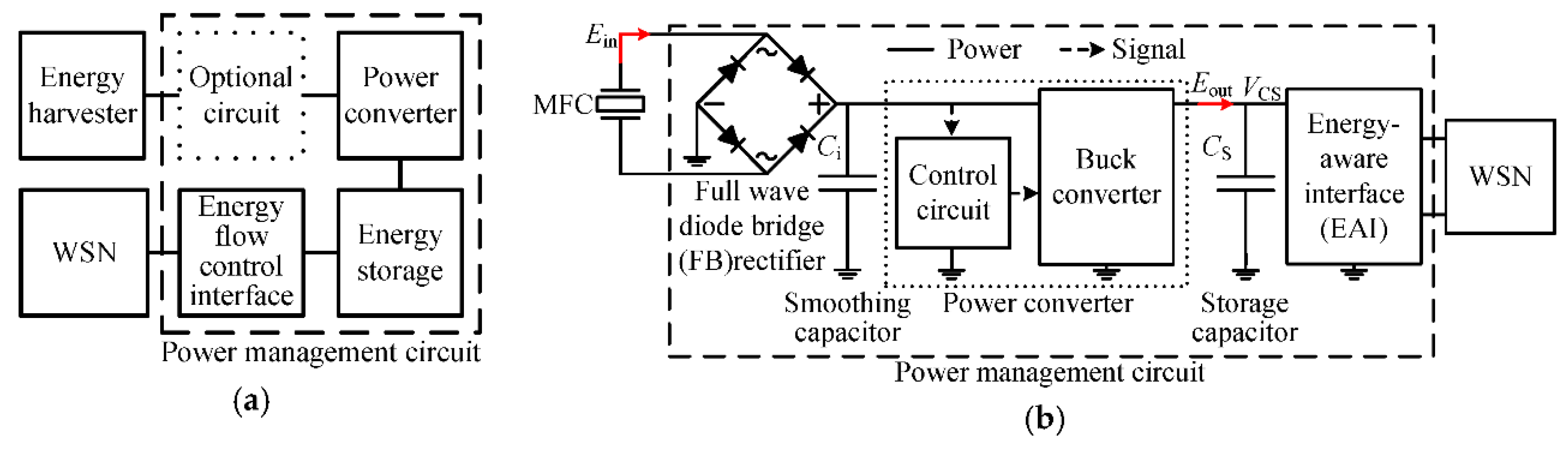

2. Threshold Voltage Control

3. Experimental Characterization

3.1. Experimental Setup

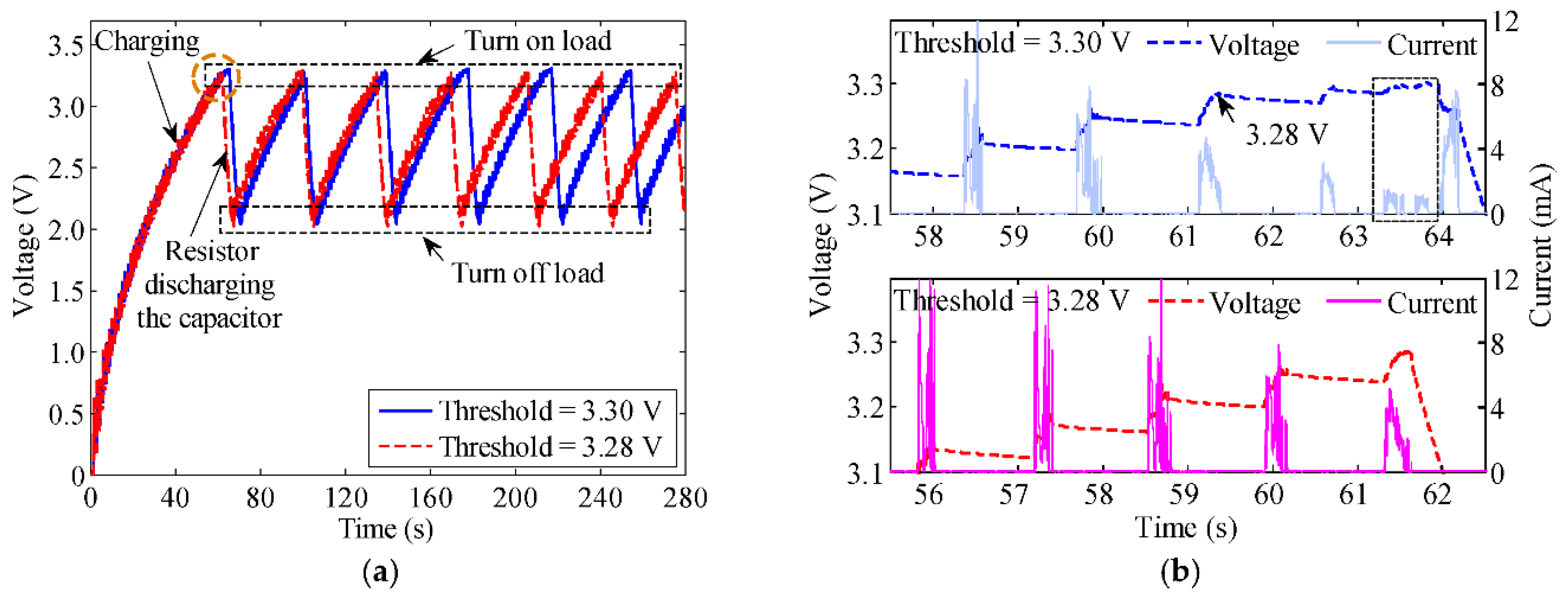

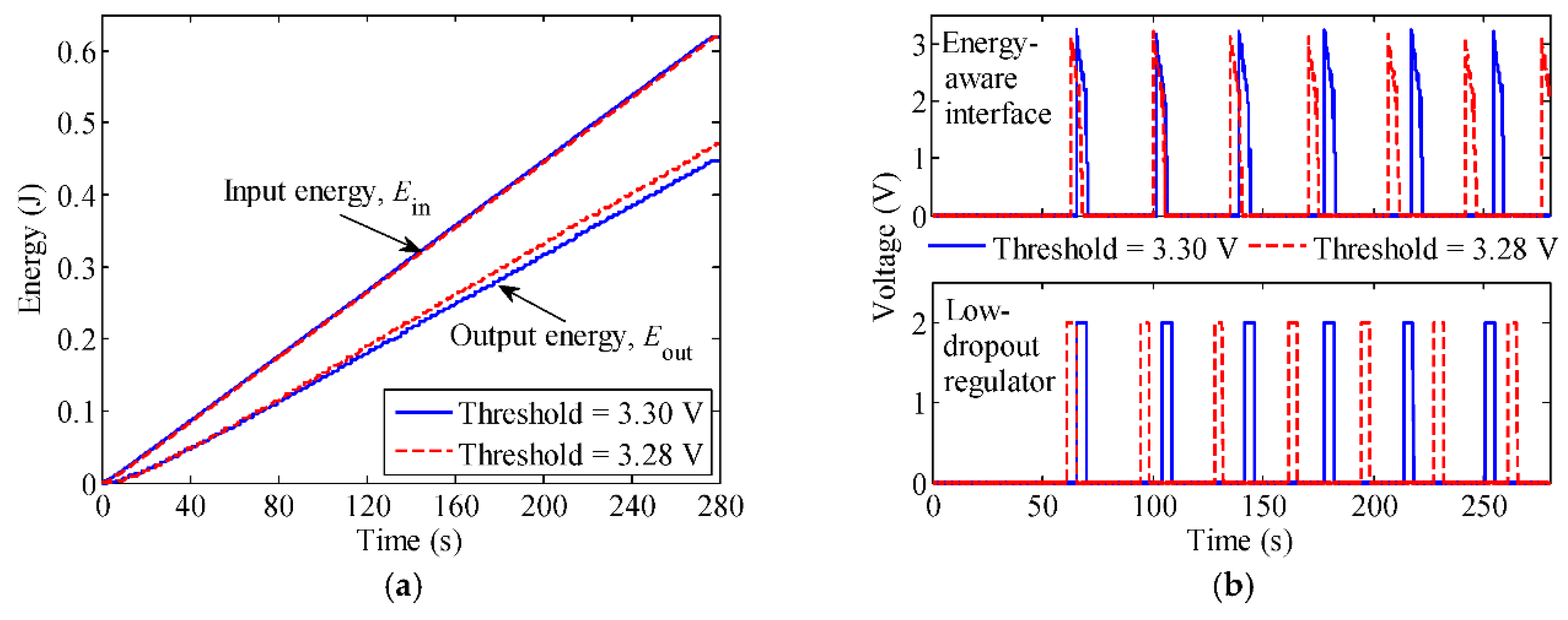

3.2. Results and Discussions

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Bogue, R. Wireless Sensors: A Review of Technologies, Products and Applications. Sens. Rev. 2010, 30, 285–289. [Google Scholar] [CrossRef]

- Magno, M.; Boyle, D.; Brunelli, D.; Flynn, B.O.; Popovici, E.; Benini, L. Extended Wireless Monitoring through Intelligent Hybrid Energy Supply. IEEE Trans. Ind. Electron. 2014, 61, 1871–1881. [Google Scholar] [CrossRef]

- Yu, H.; Zhou, J.; Deng, L.; Wen, Z. A Vibration-Based MEMS Piezoelectric Energy Harvester and Power Conditioning Circuit. Sensors 2014, 14, 3323–3341. [Google Scholar] [CrossRef] [PubMed]

- Chew, Z.J.; Ruan, T.; Zhu, M. Strain Energy Harvesting Powered Wireless Sensor System Using Adaptive and Energy-Aware Interface for Enhanced Performance. IEEE Trans. Ind. Inform. 2017, 13, 3006–3016. [Google Scholar] [CrossRef]

- Chew, Z.J.; Zhu, M. Adaptive Maximum Power Point Finding Using Direct VOC/2 Tracking Method with Microwatt Power Consumption for Energy Harvesting IEEE Trans. Power Electron. 2018, 33, 8164–8173. [Google Scholar] [CrossRef]

- Chew, Z.J.; Zhu, M. Combined Power Extraction with Adaptive Power Management Module for Increased Piezoelectric Energy Harvesting to Power Wireless Sensor Nodes. In Proceedings of the 2016 IEEE Sensors, Orlando, FL, USA, 30 October–3 November 2016; pp. 1–3. [Google Scholar]

- Katic, J.; Rodriguez, S.; Rusu, A. A Dual-Output Thermoelectric Energy Harvesting Interface with 86.6% Peak Efficiency at 30 μW and Total Control Power of 160 nW. IEEE J. Solid-State Circuits 2016, 51, 1928–1937. [Google Scholar] [CrossRef]

- Sanchez, D.A.; Leicht, J.; Hagedorn, F.; Jodka, E.; Fazel, E.; Manoli, Y. A Parallel-SSHI Rectifier for Piezoelectric Energy Harvesting of Periodic and Shock Excitations. IEEE J. Solid-State Circuits 2016, 51, 2867–2879. [Google Scholar] [CrossRef]

- Kong, N.; Ha, D.-S. Low-Power Design of a Self-Powered Piezoelectric Energy Harvesting System with Maximum Power Point Tracking. IEEE Trans. Power Electron. 2012, 27, 2298–2308. [Google Scholar] [CrossRef]

- Ruan, T.; Chew, Z.J.; Zhu, M. Energy-Aware Approaches for Energy Harvesting Powered Wireless Sensor Nodes. IEEE Sens. J. 2017, 17, 2165–2173. [Google Scholar] [CrossRef]

- Erickson, R.; Maksimovic, D. High Efficiency, Dc–Dc Converters for Battery Operated Systems with Energy Management; Department of Electrical and Computer Engineering, University of Colorado, Boulder, CO, USA, 1995, pp. 1–10. Available online: http://ecee.colorado.edu/~rwe/papers/EnergyMangmt.pdf (accessed on 2 May 2018).

- Carreon-Bautista, S.; Erbay, C.; Han, A.; Sanchez-Sinencio, E. An Inductorless DC–DC Converter for an Energy Aware Power Management Unit Aimed at Microbial Fuel Cell Arrays. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 1109–1121. [Google Scholar] [CrossRef]

| Threshold Voltage (V) | EAI | LDO 1 |

|---|---|---|

| 3.28 | 2477 | 2589 |

| 3.30 | 2266 | 2333 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chew, Z.J.; Zhu, M. Threshold Voltage Control to Improve Energy Utilization Efficiency of a Power Management Circuit for Energy Harvesting Applications. Proceedings 2018, 2, 1052. https://doi.org/10.3390/proceedings2131052

Chew ZJ, Zhu M. Threshold Voltage Control to Improve Energy Utilization Efficiency of a Power Management Circuit for Energy Harvesting Applications. Proceedings. 2018; 2(13):1052. https://doi.org/10.3390/proceedings2131052

Chicago/Turabian StyleChew, Zheng Jun, and Meiling Zhu. 2018. "Threshold Voltage Control to Improve Energy Utilization Efficiency of a Power Management Circuit for Energy Harvesting Applications" Proceedings 2, no. 13: 1052. https://doi.org/10.3390/proceedings2131052

APA StyleChew, Z. J., & Zhu, M. (2018). Threshold Voltage Control to Improve Energy Utilization Efficiency of a Power Management Circuit for Energy Harvesting Applications. Proceedings, 2(13), 1052. https://doi.org/10.3390/proceedings2131052