Development of Graphene Based Inks for Deposition via Inkjet Printing for Sensing Application †

Abstract

:1. Introduction

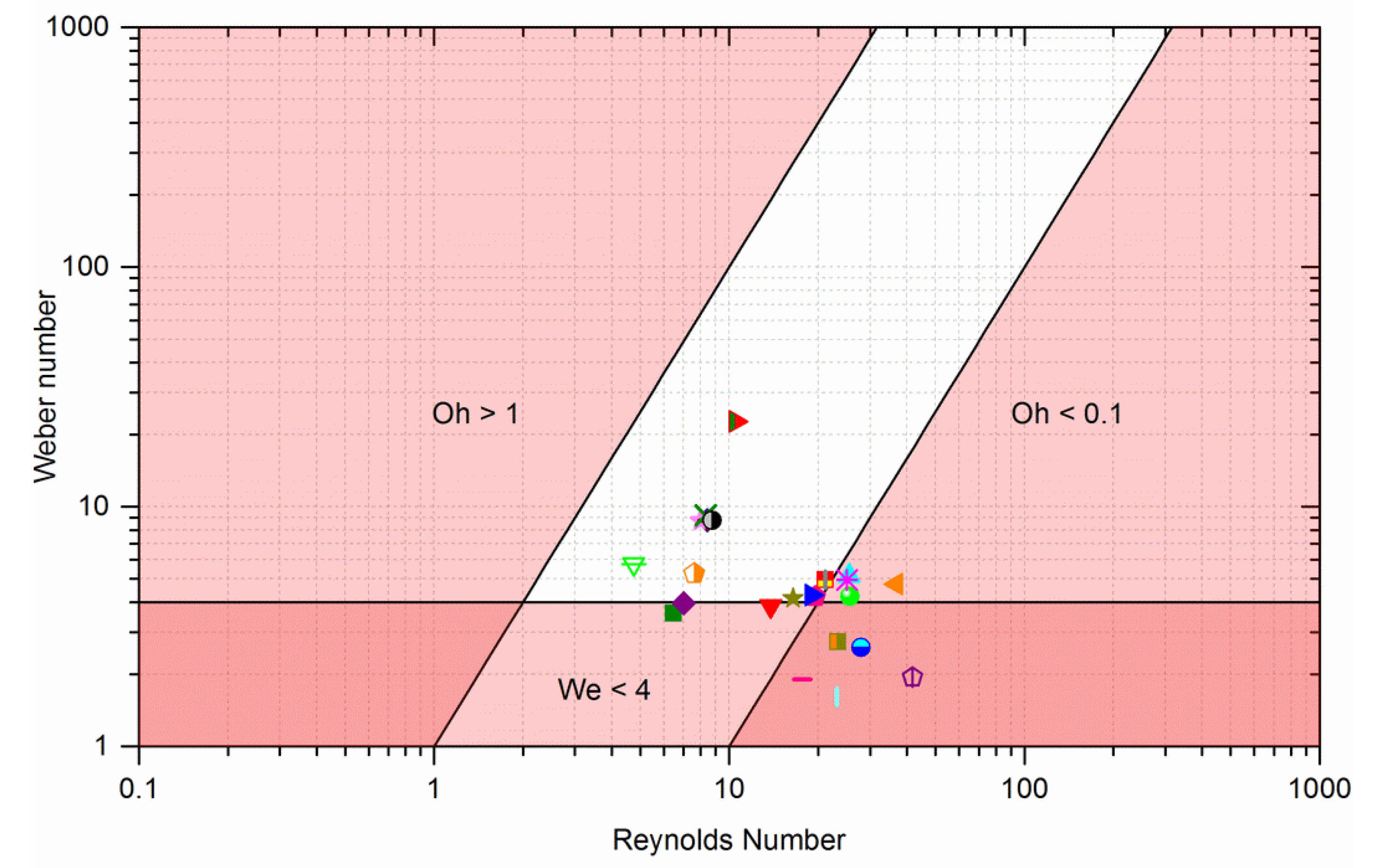

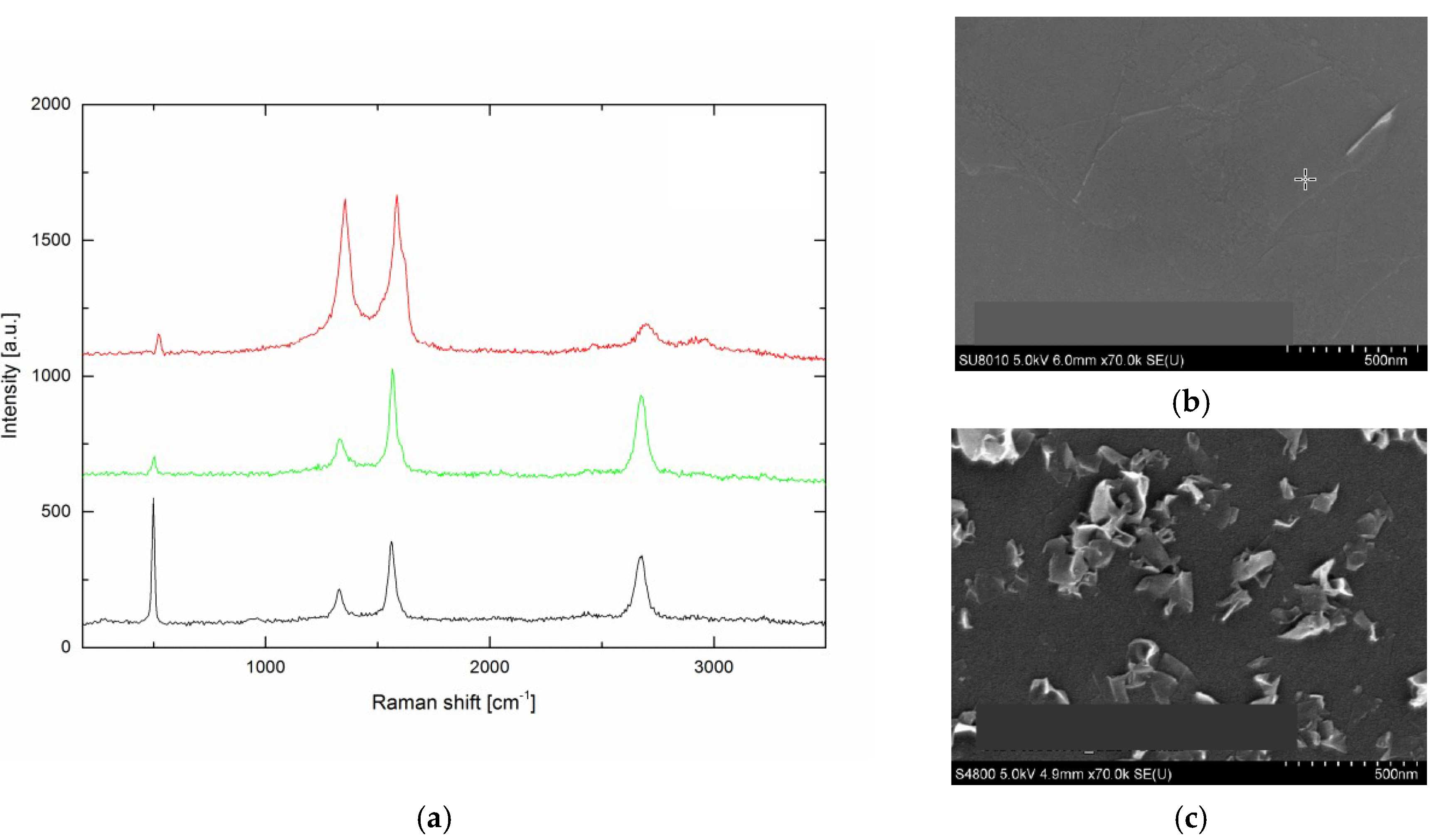

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Llobet, E. Gas sensors using carbon nanomaterials: A review. Sens. Actuators B Chem. 2013, 179, 32–45. [Google Scholar] [CrossRef]

- Ghaffarzadeh, K. Graphene, 2D Materails and Carbon Nanotubes: Markets, Technologies and Opportunities 2016–2026; IDTechEx: Cambridge, UK, 2016. [Google Scholar]

- Hutchings, I.M.; Martin, G.D. Martin, Inkjet Technology for Digital Fabrication, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Derby, B. Inkjet printing of Functional and Structural Materails: Fluid Property Requirements, Feature Stability and Resolution. Annu. Rev. Mater. Res. 2010, 40, 395–414. [Google Scholar] [CrossRef]

- Eckmann, A.; Felten, A.; Mishchenko, A.; Britnell, L.; Krupke, R.; Novoselov, K.S.; Casiraghi, C. Probing the nature of Defects in Graphene by Raman Spectroscopy. Nano Lett. 2012, 12, 3925–3930. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Travan, C.; Mischitz, M.; Zöpfl, A.; Krumbein, U.; Makaram, P. Development of Graphene Based Inks for Deposition via Inkjet Printing for Sensing Application. Proceedings 2018, 2, 1008. https://doi.org/10.3390/proceedings2131008

Travan C, Mischitz M, Zöpfl A, Krumbein U, Makaram P. Development of Graphene Based Inks for Deposition via Inkjet Printing for Sensing Application. Proceedings. 2018; 2(13):1008. https://doi.org/10.3390/proceedings2131008

Chicago/Turabian StyleTravan, Caterina, Martin Mischitz, Alexander Zöpfl, Ulrich Krumbein, and Prashant Makaram. 2018. "Development of Graphene Based Inks for Deposition via Inkjet Printing for Sensing Application" Proceedings 2, no. 13: 1008. https://doi.org/10.3390/proceedings2131008

APA StyleTravan, C., Mischitz, M., Zöpfl, A., Krumbein, U., & Makaram, P. (2018). Development of Graphene Based Inks for Deposition via Inkjet Printing for Sensing Application. Proceedings, 2(13), 1008. https://doi.org/10.3390/proceedings2131008