Circular Economy in Wastewater Treatment Plant–Challenges and Barriers †

Abstract

:1. Introduction

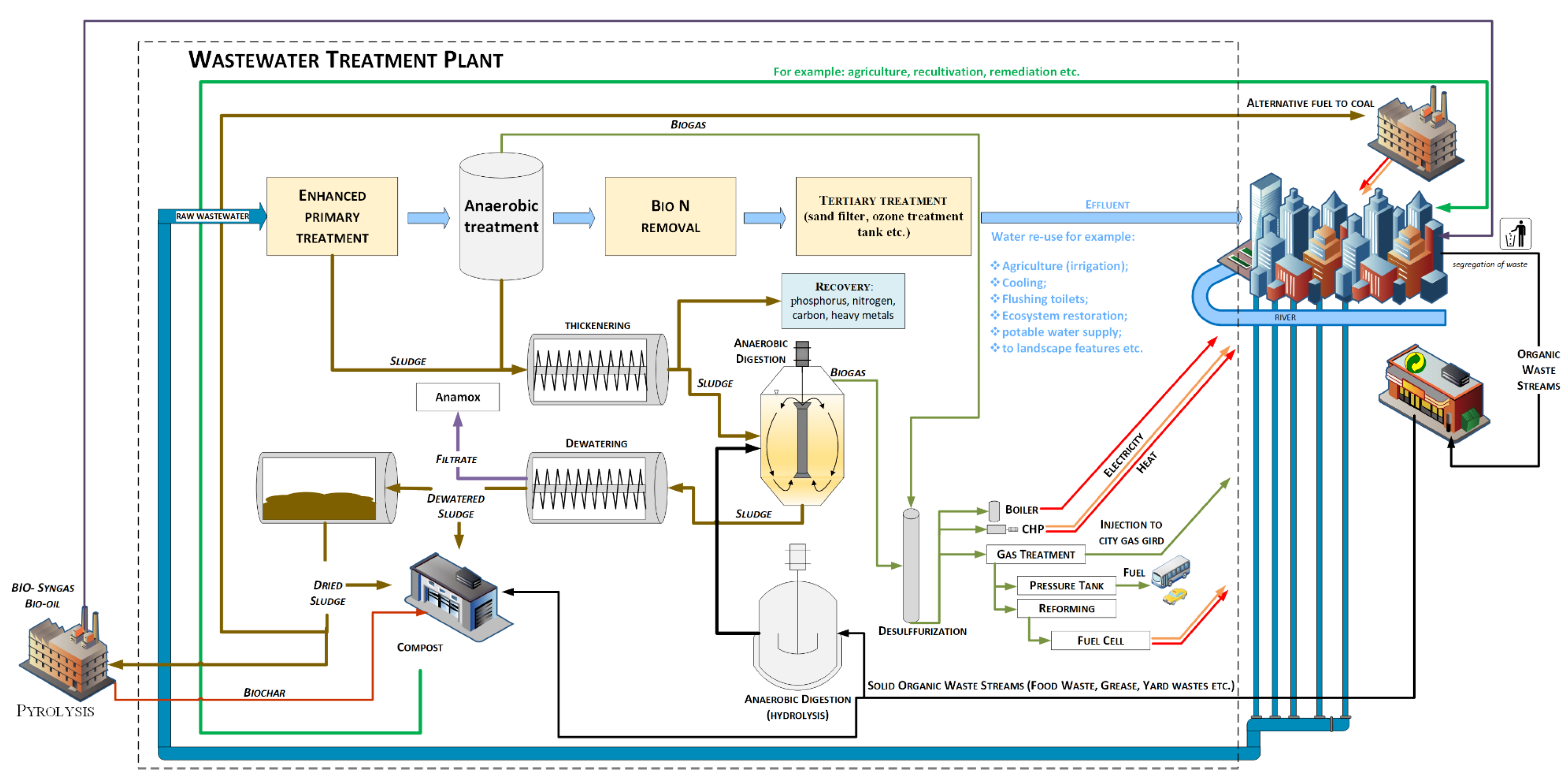

2. Resources Recovery at Wastewater Treatment Plant

2.1. Nutrient Recovery

2.2. Water Reuse

2.3. Energy Recovery

2.4. Other Resources

3. Wastewater Treatment Plants in SMART Cities

4. Challenges of the Future

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Rashidi, H.; GhaffarianHoseini, A.; GhaffarianHoseini, A.; Sulaiman, N.M.N.; Tookey, J.; Hashim, N.A. Application of wastewater treatment in sustainable design of green built environments: A review. Renew. Sustain. Energy Rev. 2015, 49, 845–856. [Google Scholar] [CrossRef]

- Mo, W.; Zhang, Q. Energy–nutrients–water nexus: Integrated resource recovery in municipal wastewater treatment plants. J. Environ. Manag. 2013, 127, 255–267. [Google Scholar] [CrossRef]

- Commission Staff Working Document. Summary of the Responses to the Consultative Communication on the Sustainable Use of Phosphorus [COM(2013) 517]. Available online: http://ec.europa.eu/environment/natres/pdf/phosphorus/SWD(2014)263%20final.pdf (accessed on 20 February 2018).

- Cordell, D.; Drangert, J.O.; White, S. The story of phosphorus: Global food security and food for thought. GEC 2009, 19, 292–305. [Google Scholar] [CrossRef]

- EU Reference Scenario 2016 Energy, Transport and GHG Emissions Trends to 2050. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/ref2016_report_final-web.pdf (accessed on 20 February 2018).

- WssTP. Water and Energy: Strategic Vision and Research Needs. The Water Supply and Sanitation Technology Platfor. Available online: http://www.danishwaterforum.dk/activities/WssTP_Water_and_Energy_Publication%2009_2011.pdf (accessed on 20 February 2018).

- Cantwell, J.; Dunning, J.H.; Lundan, S.M. An evolutionary approach to understanding international business activity: The co-evolution of MNEs and the institutional environment. JIBS 2010, 41, 567–586. [Google Scholar] [CrossRef]

- Zhang, Q.; Hu, J.; Lee, D.J.; Chang, Y.; Lee, Y.J. Sludge treatment: Current research trends. Bioresour. Technol. 2017, 243, 1159–1172. [Google Scholar] [CrossRef]

- Eurostat. 2017. Available online: http://ec.europa.eu/eurostat/web/products-datasets/product?code=env_ww_spd (accessed on 20 February 2018).

- Hukari, S.; Hermann, L.; Nättorp, A. From wastewater to fertilisers—Technical overview and critical review of European legislation governing phosphorus recycling. Sci. Total Environ. 2016, 542, 1127–1135. [Google Scholar] [CrossRef] [PubMed]

- Kabbe, C.; Kraus, F.; Remy, C. Review of promising methods for phosphorus recovery and recycling from wastewater. In Proceedings of the International Fertiliser Society, London, UK, 23–24 June 2015; pp. 1–29. [Google Scholar]

- Batstone, D.J.; Hülsen, T.; Mehta, C.M.; Keller, J. Platforms for energy and nutrient recovery from domestic wastewater: A review. Chemosphere 2015, 140, 2–11. [Google Scholar] [CrossRef]

- El-Shafai, S.A.; El-Gohary, F.A.; Nasr, F.A.; Van Der Steen, N.P.; Gijzen, H.J. Nutrient recovery from domestic wastewater using a UASB-duckweed ponds system. Bioresour. Technol. 2007, 98, 798–807. [Google Scholar] [CrossRef]

- Becerra-Castro, C.; Lopes, A.R.; Vaz-Moreira, I.; Silva, E.F.; Manaia, C.M.; Nunes, O.C. Wastewater reuse in irrigation: A microbiological perspective on implications in soil fertility and human and environmental health. Environ. Int. 2015, 75, 117–135. [Google Scholar] [CrossRef] [PubMed]

- Lyu, S.; Chen, W.; Zhang, W.; Fan, Y.; Jiao, W. Wastewater reclamation and reuse in China: Opportunities and challenges. J. Environ. Sci. 2016, 39, 86–96. [Google Scholar] [CrossRef]

- Pintilie, L.; Torres, C.M.; Teodosiu, C.; Castells, F. Urban wastewater reclamation for industrial reuse: An LCA case study. J. Clean. Prod. 2016, 139, 1–14. [Google Scholar] [CrossRef]

- Bertanza, G.; Canato, M.; Laera, G. Towards energy self-sufficiency and integral material recovery in waste water treatment plants: Assessment of upgrading options. J. Clean. Prod. 2018, 170, 1206–1218. [Google Scholar] [CrossRef]

- Zhen, G.; Lu, X.; Kato, H.; Zhao, Y.; Li, Y.Y. Overview of pretreatment strategies for enhancing sewage sludge disintegration and subsequent anaerobic digestion: Current advances, full-scale application and future perspectives. Renew. Sustain. Energy Rev. 2017, 69, 559–577. [Google Scholar] [CrossRef]

- Hagos, K.; Zong, J.; Li, D.; Liu, C.; Lu, X. Anaerobic co-digestion process for biogas production: Progress, challenges and perspectives. Renew. Sustain. Energy Rev. 2017, 76, 1485–1496. [Google Scholar] [CrossRef]

- Culha, O.; Gunerhan, H.; Biyik, E.; Ekren, O.; Hepbasli, A. Heat exchanger applications in wastewater source heat pumps for buildings: A key review. Energy Build. 2015, 104, 215–232. [Google Scholar] [CrossRef]

- Frijns, J. Intervention Concepts for Energy Saving, Recovery and Generation from the Urban Water Sytems D45-1. KWR Watercycle Reasearch Instutute. 2014. Available online: https://www.researchgate.net/profile/Nelson_Carrico/publication/275213940_Intervention_concepts_for_energy_saving_recovery_and_generation_from_the_urban_water_system/links/553576530cf20ea35f10d908.pdf (accessed on 15 February 2018).

- Smol, M.; Kulczycka, J.; Henclik, A.; Gorazda, K.; Wzorek, Z. The possible use of sewage sludge ash (SSA) in the construction industry as a way towards a circular economy. J. Clean. Prod. 2015, 95, 45–54. [Google Scholar] [CrossRef]

- Bengtsson, S.; Karlsson, A.; Alexandersson, T.; Quadri, L.; Hjort, M.; Johansson, P.; Magnusson, P.A. Process for polyhydroxyalkanoate (PHA) production from municipal wastewater treatment with biological carbon and nitrogen removal demonstrated at pilot-scale. N. Biotechnol. 2017, 35, 42–53. [Google Scholar] [CrossRef]

- Pandey, P.; Shinde, V.N.; Deopurkar, R.L.; Kale, S.P.; Patil, S.A.; Pant, D. Recent advances in the use of different substrates in microbial fuel cells toward wastewater treatment and simultaneous energy recovery. Appl. Energy 2016, 168, 706–723. [Google Scholar] [CrossRef]

- Gaur, A.; Scotney, B.; Parr, G.; McClean, S. Smart city architecture and its applications based on IoT. Procedia Comput. Sci. 2015, 52, 1089–1094. [Google Scholar] [CrossRef]

- Papa, M.; Foladori, P.; Guglielmi, L.; Bertanza, G. How far are we from closing the loop of sewage resource recovery? A real picture of municipal wastewater treatment plants in Italy. J. Environ. Manag. 2017, 198, 9–15. [Google Scholar] [CrossRef]

- Xie, M.; Shon, H.K.; Gray, S.R.; Elimelech, M. Membrane-based processes for wastewater nutrient recovery: Technology, challenges, and future direction. Water Res. 2016, 89, 210–222. [Google Scholar] [CrossRef]

- Swedish Utility Selects Veolia for Wastewater to Energy Project. Available online: https://www.metering.com/news/swedish-utility-selects-veolia-for-rollout-of-wastewater-project/ (accessed on 15 February 2018).

- Gu, Y.; Li, Y.; Li, X.; Luo, P.; Wang, H.; Robinson, Z.P.; Li, F. The feasibility and challenges of energy self-sufficient wastewater treatment plants. Appl. Energy 2017, 204, 1463–1475. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Neczaj, E.; Grosser, A. Circular Economy in Wastewater Treatment Plant–Challenges and Barriers. Proceedings 2018, 2, 614. https://doi.org/10.3390/proceedings2110614

Neczaj E, Grosser A. Circular Economy in Wastewater Treatment Plant–Challenges and Barriers. Proceedings. 2018; 2(11):614. https://doi.org/10.3390/proceedings2110614

Chicago/Turabian StyleNeczaj, Ewa, and Anna Grosser. 2018. "Circular Economy in Wastewater Treatment Plant–Challenges and Barriers" Proceedings 2, no. 11: 614. https://doi.org/10.3390/proceedings2110614

APA StyleNeczaj, E., & Grosser, A. (2018). Circular Economy in Wastewater Treatment Plant–Challenges and Barriers. Proceedings, 2(11), 614. https://doi.org/10.3390/proceedings2110614