Pressure Agglomeration Process of Bakery Industry Waste †

Abstract

1. Introduction

2. Aim of the Research

3. Materials and Methods

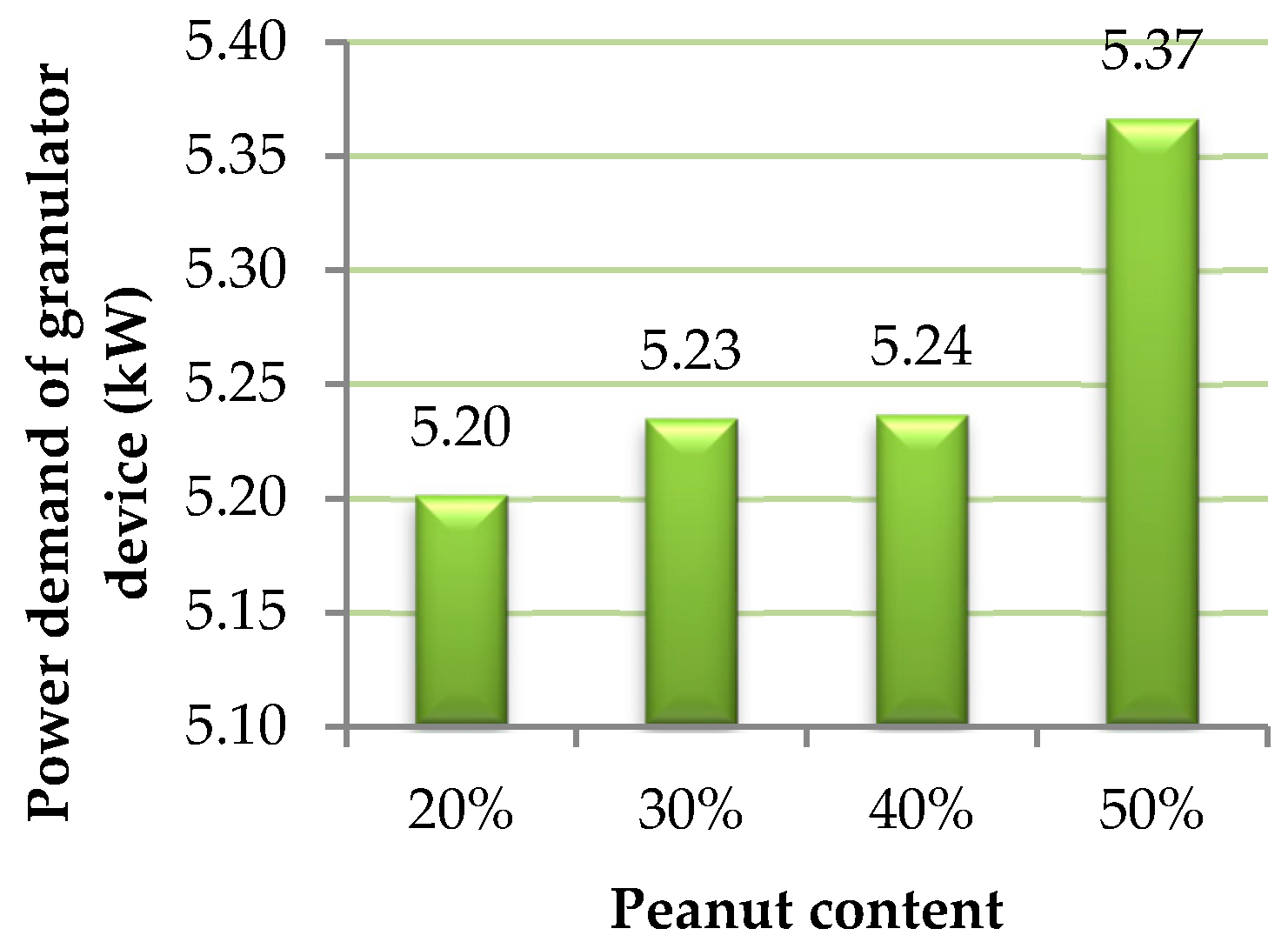

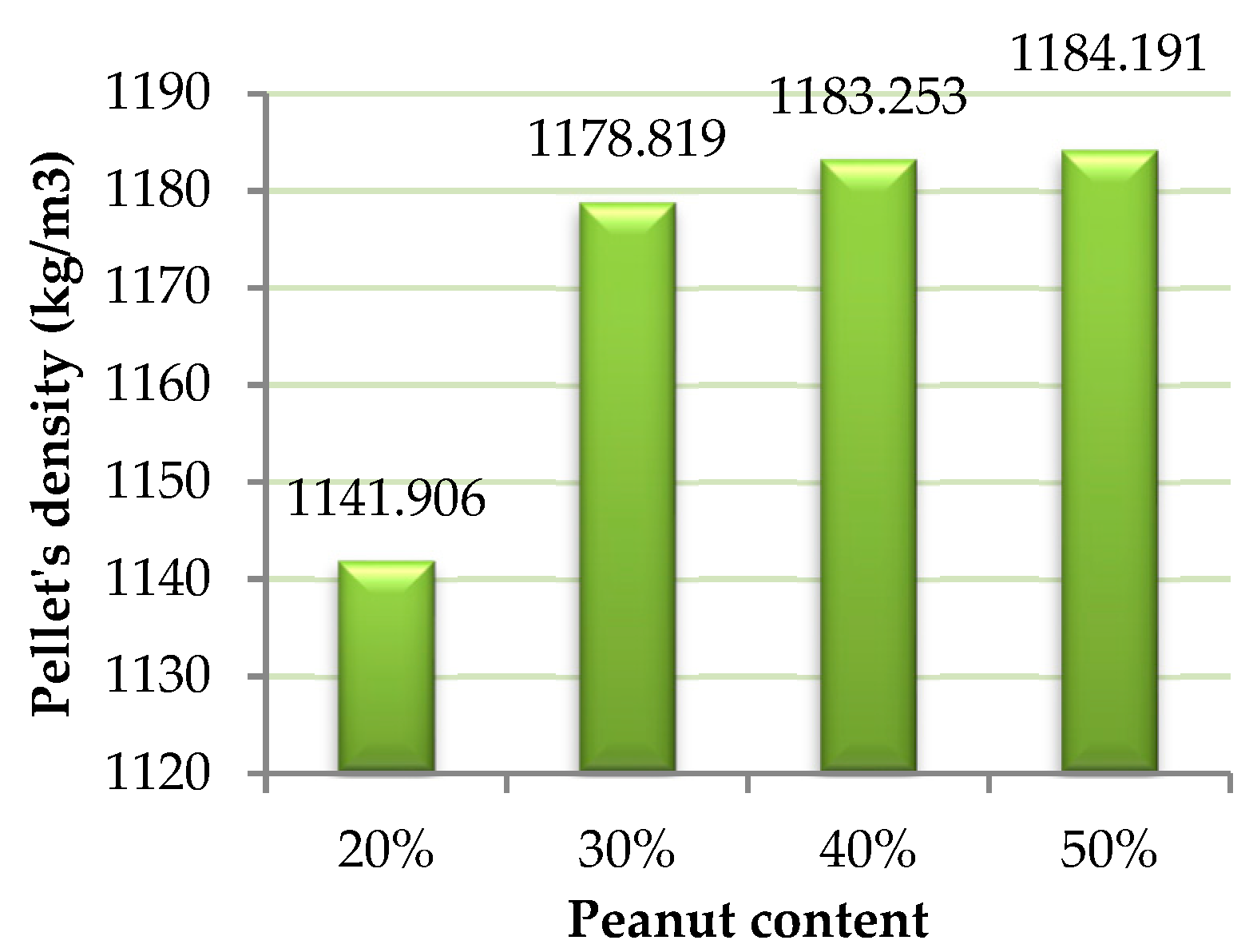

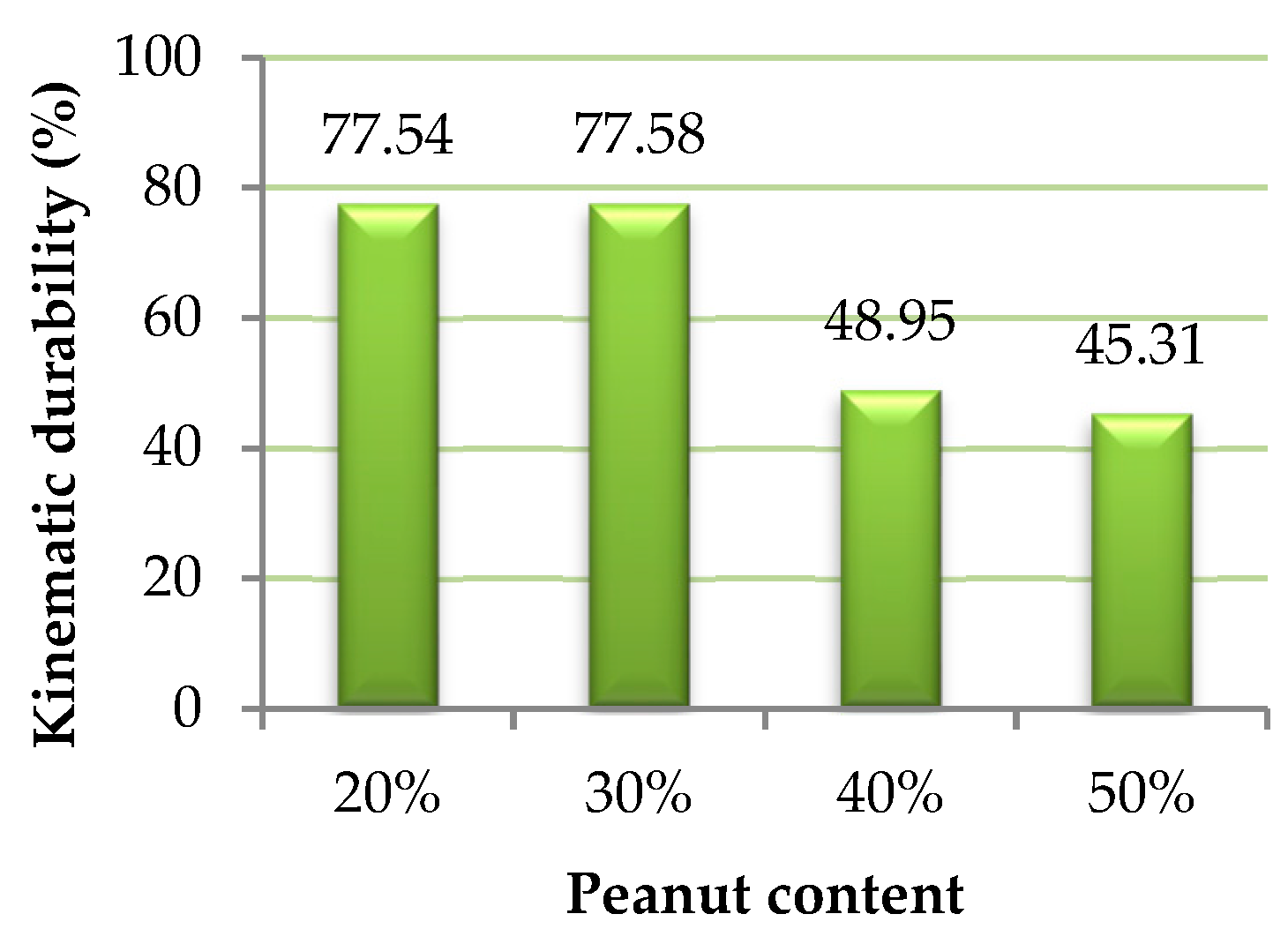

4. Results and Conclusions

Author Contributions

Conflicts of Interest

References

- Central Statistical Office (2016). Available online: https://stat.gov.pl/ (accessed on 5 July 2019).

- Obidziński, S. Pelletization of biomass waste with potato pulp content. Int. Agrophys. 2014, 28, 85–91. [Google Scholar] [CrossRef]

- Daniel, Z.; Juliszewski, T.; Kowalczyk, Z.; Malinowski, M.; Sobol, Z.; Paulina Wrona, P. Metoda szczegółowej klasyfikacji odpadów z sektora rolniczego i rolno-spożywczego; Infrastruktura i Ekologia Terenów Wiejskich: Kraków, Poland, 2010; pp. 141–152. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dołżyńska, M.; Obidziński, S.; Kowczyk-Sadowy, M.; Krasowska, M.; Karczewski, K.; Jóźwiak, D.; Buczyński, R. Pressure Agglomeration Process of Bakery Industry Waste. Proceedings 2019, 16, 37. https://doi.org/10.3390/proceedings2019016037

Dołżyńska M, Obidziński S, Kowczyk-Sadowy M, Krasowska M, Karczewski K, Jóźwiak D, Buczyński R. Pressure Agglomeration Process of Bakery Industry Waste. Proceedings. 2019; 16(1):37. https://doi.org/10.3390/proceedings2019016037

Chicago/Turabian StyleDołżyńska, Magdalena, Sławomir Obidziński, Małgorzata Kowczyk-Sadowy, Małgorzata Krasowska, Krzysztof Karczewski, Dorota Jóźwiak, and Radosław Buczyński. 2019. "Pressure Agglomeration Process of Bakery Industry Waste" Proceedings 16, no. 1: 37. https://doi.org/10.3390/proceedings2019016037

APA StyleDołżyńska, M., Obidziński, S., Kowczyk-Sadowy, M., Krasowska, M., Karczewski, K., Jóźwiak, D., & Buczyński, R. (2019). Pressure Agglomeration Process of Bakery Industry Waste. Proceedings, 16(1), 37. https://doi.org/10.3390/proceedings2019016037