The Possibilities of Paper Sludge Waste (PSw) Utilization in Cement Materials †

Abstract

:1. Introduction

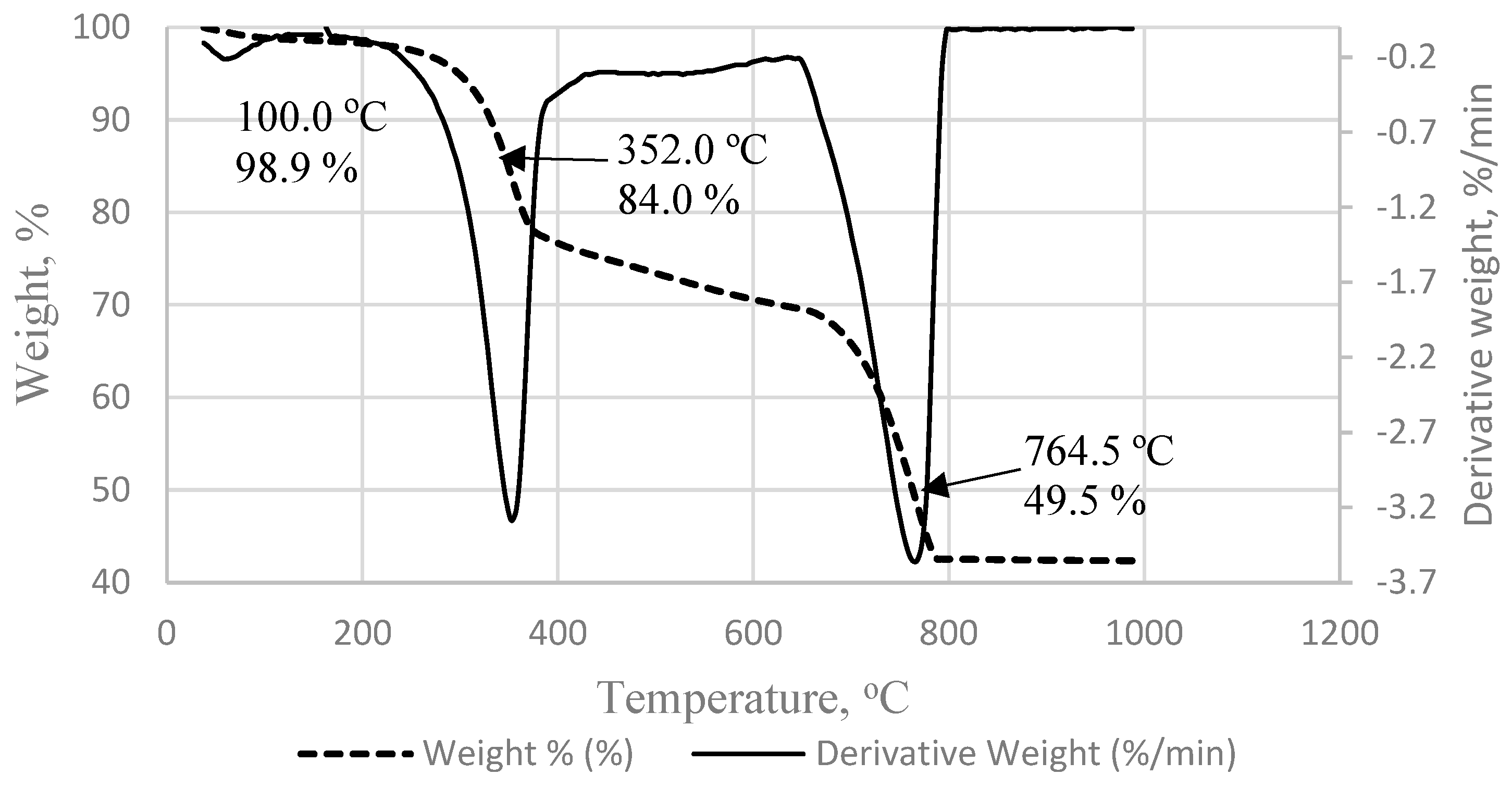

2. Materials and Methods

| C_O(org) | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | TiO2 | SO3 | Cl | Na2O | Others * |

|---|---|---|---|---|---|---|---|---|---|---|

| 34.08 | 58.21 | 3.48 | 2.36 | 0.52 | 0.64 | 0.10 | 0.18 | 0.06 | 0.09 | 0.28 |

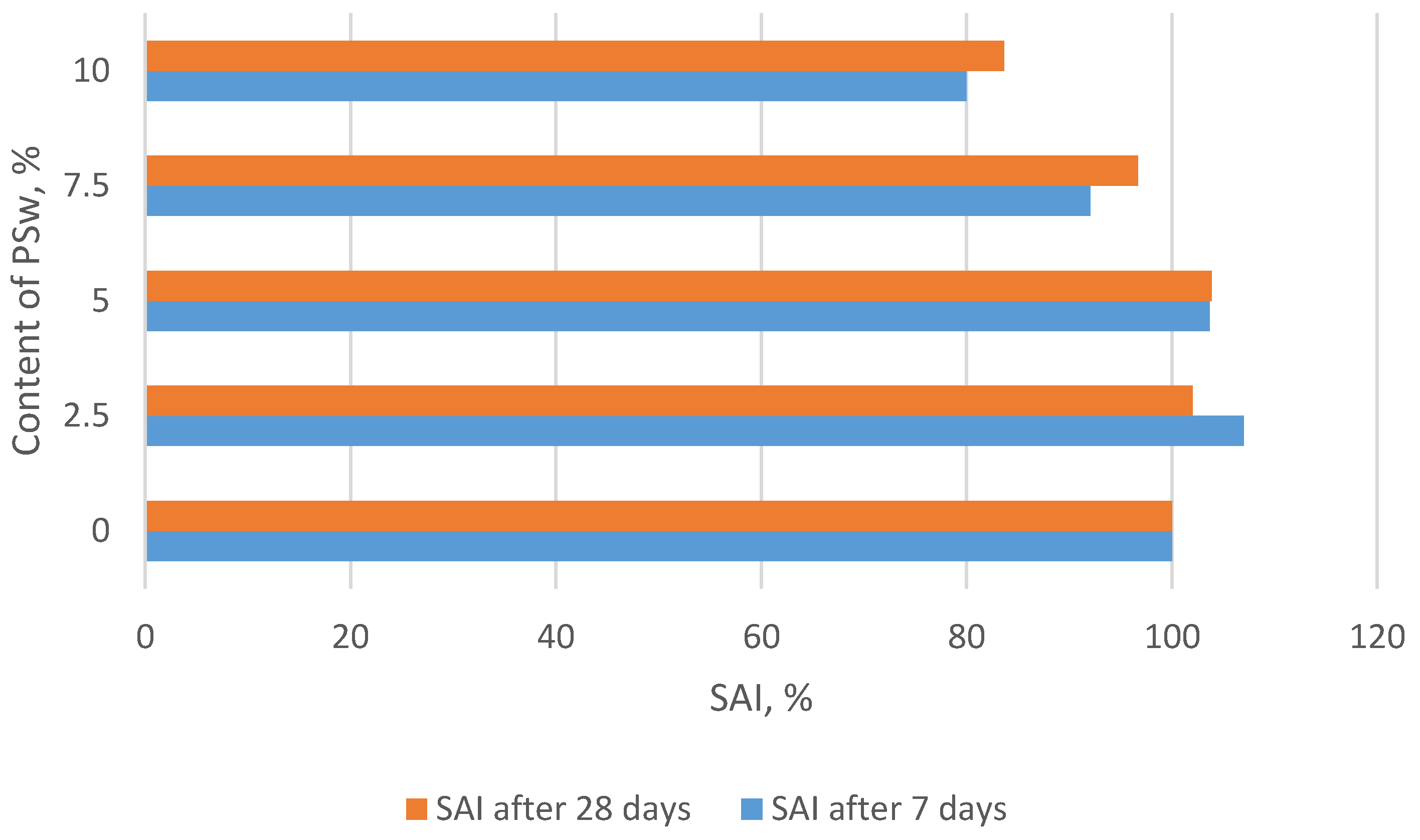

3. Results and Discussion

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Eurostat. Energy, Transport and Environment Indicators; Statistical books, Imprimerie Centrale: Luxembourg, 2018; pp. 148–164. [Google Scholar]

- Azevedo, A.R.G.; Alexandre, J.; Xavier, G.C.; Pedroti, L.G. Recycling paper industry effluent sludge for use in mortars: A sustainability perspective. J. Clean. Prod. 2018, 192, 335–346. [Google Scholar] [CrossRef]

- Martínez-Lage, I.; Velay-Lizancos, M.; Vázquez-Burgo, P.; Rivas-Fernández, M.; Vázquez-Herrero, C.; Ramírez-Rodríguez, A.; Martín-Cano, M. Concretes and mortars with waste paper industry: Biomass ash and dregs. J. Environ. Manag. 2016, 181, 863–873. [Google Scholar] [CrossRef] [PubMed]

- Buruberri, L.H.; Seabra, M.P.; Labrincha, J.A. Preparation of clinker from paper pulp industry wastes. J. Hazard Mater. 2015, 286, 252–260. [Google Scholar] [CrossRef] [PubMed]

- Seifi, S.; Sebaibi, N.; Levacher, D.; Boutouil, M. Mechanical performance of a dry mortar without cement, based on paper fly ash and blast furnace slag. J. Build Eng. 2019, 22, 113–121. [Google Scholar] [CrossRef]

- Ferrándiz-Mas, V.; Bond, T.; García-Alcocel, E.; Cheeseman, C.R. Lightweight mortars containing expanded polystyrene and paper sludge ash. Constr. Build. Mater. 2014, 61, 285–292. [Google Scholar] [CrossRef]

- Novais, R.M.; Carvalheiras, J.; Senff, L.; Labrincha, J.A. Upcycling unexplored dregs and biomass fly ash from the paper and pulp industry in the production of eco-friendly geopolymer mortars: A preliminary assessment. Constr. Build. Mater. 2018, 184, 464–472. [Google Scholar] [CrossRef]

- Saeli, M.; Tobaldi, D.M.; Seabra, M.P.; Labrincha, J.A. Mix design and mechanical performance of geopolymeric binders and mortars using biomass fly ash and alkaline effluent from paper-pulp industry. J. Clean. Prod. 2019, 208, 1188–1197. [Google Scholar] [CrossRef]

- Martínez, C.; Cotes, M.; Corpas, F.A. Recovering wastes from the paper industry: Development of ceramic materials. Fuel Proc. Technol. 2012, 103, 117–124. [Google Scholar] [CrossRef]

- Donatello, S.; Tyrer, M.; Cheeseman, C.R. Comparison of test methods to assess pozzolanic activity. Cem. Concr. Comp. 2010, 32, 121–127. [Google Scholar] [CrossRef]

- Weerdt, K.D.; Ben, H.M.; Saout, G.L.; Kjellsen, K.O.; Justnes, H.; Lothenbach, B. Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash. Cem. Concr. Res. 2011, 41, 279–291. [Google Scholar] [CrossRef]

- Kakali, G.; Tsivilis, S.; Aggeli, E.; Bati, M. Hydration products of C3A, C3S and Portland cement in the presence of CaCO3. Cem. Concr. Res. 2000, 30, 1073–1077. [Google Scholar] [CrossRef]

| Mineral | Amount at 2.5% PSw, a. u. | Amount at 7.5% PSw, a. u. |

|---|---|---|

| Portlandite | 344.9 | 410.8 |

| Ettringite | 276.4 | 260.6 |

| Calcite | 200.0 | 202.8 |

| Alite | 203.9 | 182.0 |

| Belite | 168.0 | 159.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banevičienė, V.; Malaiškienė, J.; Vaičienė, M.; Boris, R. The Possibilities of Paper Sludge Waste (PSw) Utilization in Cement Materials. Proceedings 2019, 16, 34. https://doi.org/10.3390/proceedings2019016034

Banevičienė V, Malaiškienė J, Vaičienė M, Boris R. The Possibilities of Paper Sludge Waste (PSw) Utilization in Cement Materials. Proceedings. 2019; 16(1):34. https://doi.org/10.3390/proceedings2019016034

Chicago/Turabian StyleBanevičienė, Vilma, Jurgita Malaiškienė, Marija Vaičienė, and Renata Boris. 2019. "The Possibilities of Paper Sludge Waste (PSw) Utilization in Cement Materials" Proceedings 16, no. 1: 34. https://doi.org/10.3390/proceedings2019016034

APA StyleBanevičienė, V., Malaiškienė, J., Vaičienė, M., & Boris, R. (2019). The Possibilities of Paper Sludge Waste (PSw) Utilization in Cement Materials. Proceedings, 16(1), 34. https://doi.org/10.3390/proceedings2019016034