Analysis of the Use of Radiant Floor Heating as a Cooling System †

Abstract

:1. Introduction

2. Materials and Methods

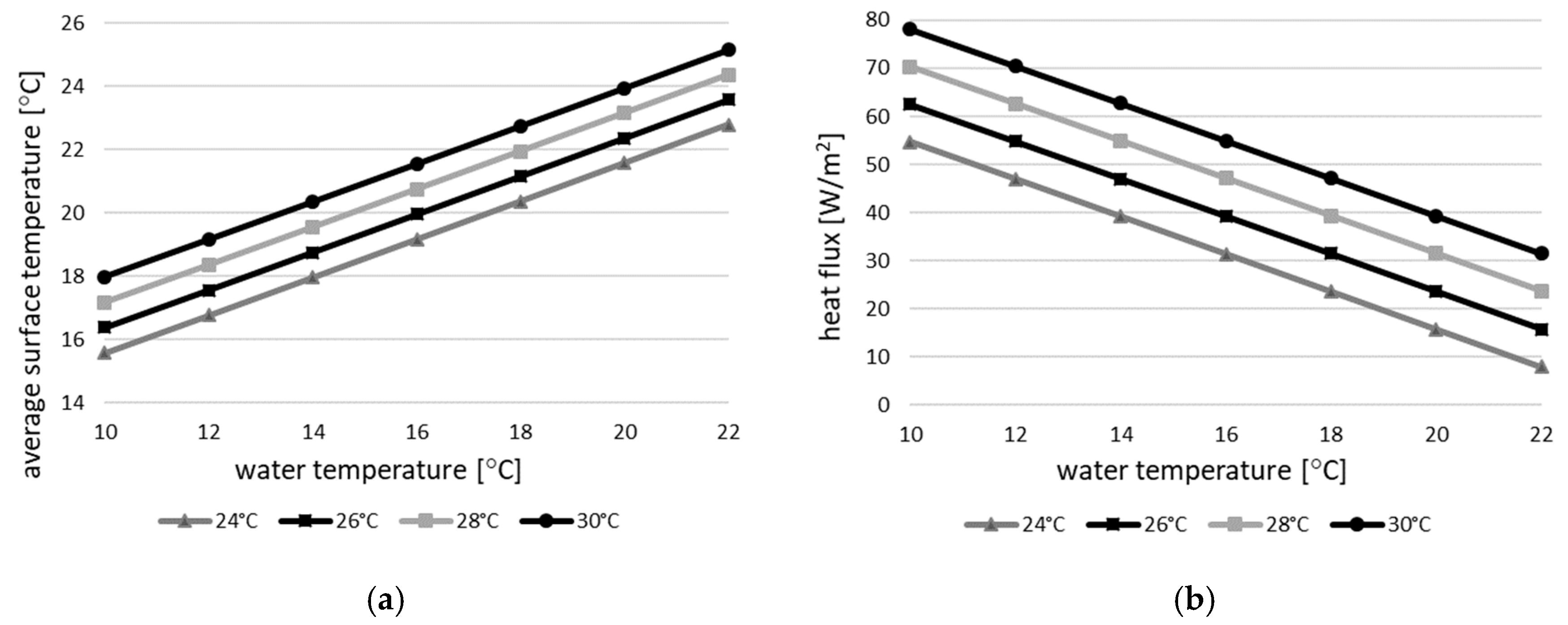

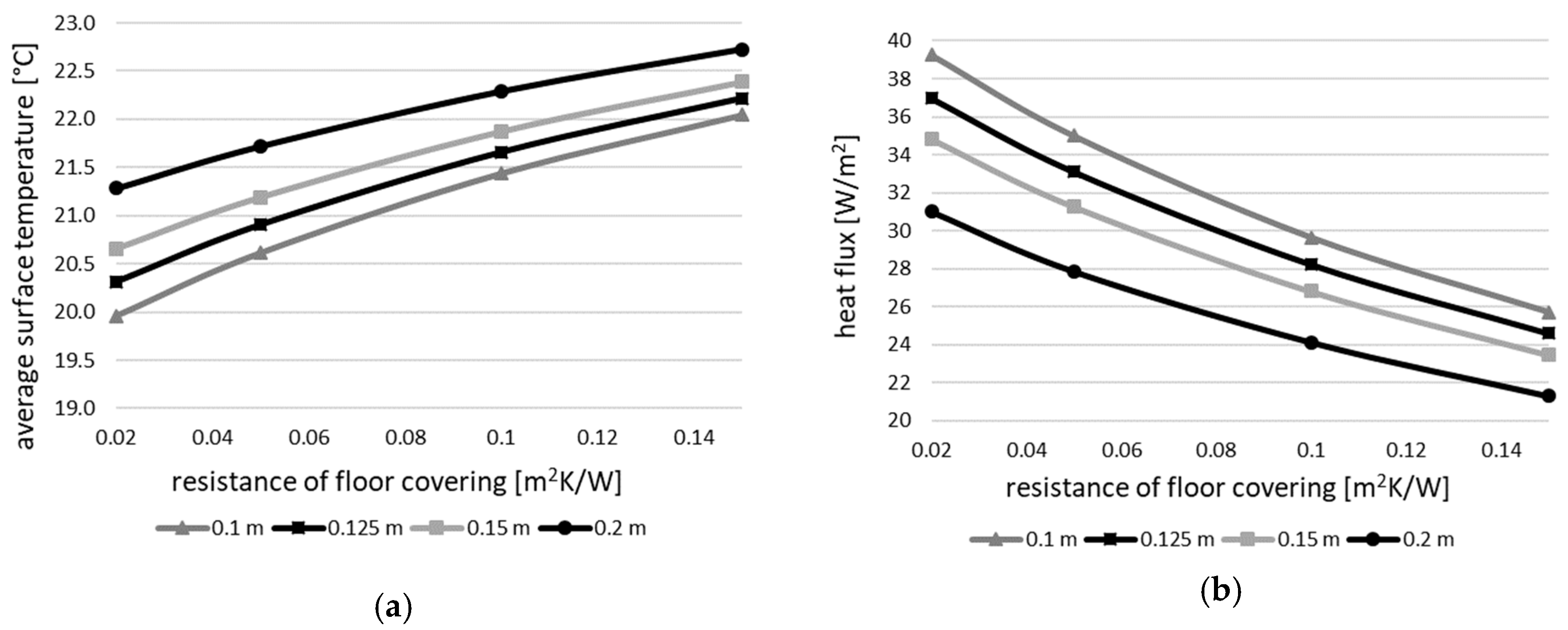

3. Results

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Cacabelos, A.; Eguía, P.; Míguez, J.L.; Granada, E.; Arce, M.E. Calibrated simulation of a public library HVAC system with a ground-source heat pump and a radiant floor using TRNSYS and GenOpt. Energy Build. 2015, 108, 114–126. [Google Scholar] [CrossRef]

- Villarino, J.I.; Villarino, A.; Fernandez, F.A. Experimental and modelling analysis of an office building HVAC system based in a ground-coupled heat pump and radiant floor. Appl. Energy 2017, 190, 1020–1028. [Google Scholar] [CrossRef]

- Song, D.; Kim, T.; Song, S.; Hwang, S.; Leigh, S.-B. Performance evaluation of a radiant floor cooling system integrated with dehumidified ventilation. Appl. Energy 2008, 28, 1299–1311. [Google Scholar] [CrossRef]

- Rhee, K.-N.; Kim, K.W. A 50 year review of basic and applied research in radiant heating and cooling systems for the built environment. Build. Environ. 2015, 91, 166–190. [Google Scholar] [CrossRef]

- Catalina, T.; Virgoe, J.; Kuznik, F. Evaluation of thermal comfort using combined CFD and experimentation study in a test room equipped with a cooling ceiling. Build. Environ. 2009, 44, 1740–1750. [Google Scholar] [CrossRef]

- Tian, Z.; Love, J.A. A field study of occupant thermal comfort and thermal environments with radiant slab cooling. Build. Environ. 2008, 43, 1658–1670. [Google Scholar] [CrossRef]

- Lim, J.-H.; Kim, K.-W. Set of Standards ISO 11855 on the Design, Dimensioning, Installation and Control of Embedded Radiant Heating and Cooling Systems. Available online: https://www.rehva.eu/knowledge-base/rehva-journal/chapter/iso-11855-the-international-standard-on-the-design-dimensioning-installation-and-control-of-embedded-radiant-heating-and-cooling-systems (accessed on 19 June 2019).

- Cholewa, T.; Rosiński, M.; Spik, Z.; Dudzińska, M.R.; Siuta-Olcha, A. On the heat transfer coefficients between heated/cooled radiant floor and room. Energy Build. 2013, 66, 599–606. [Google Scholar] [CrossRef]

- Olesen, B.W. Radiant floor heating in theory and practice. ASHRAE J. 2002, 44, 19–26. [Google Scholar]

- Jin, X.; Zhang, X.; Luo, Y.; Cao, R. Numerical simulation of radiant floor cooling system: The effects of thermal resistance of pipe and water velocity on the performance. Build. Environ. 2010, 45, 2545–2552. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Werner-Juszczuk, A.J. Analysis of the Use of Radiant Floor Heating as a Cooling System. Proceedings 2019, 16, 23. https://doi.org/10.3390/proceedings2019016023

Werner-Juszczuk AJ. Analysis of the Use of Radiant Floor Heating as a Cooling System. Proceedings. 2019; 16(1):23. https://doi.org/10.3390/proceedings2019016023

Chicago/Turabian StyleWerner-Juszczuk, Anna Justyna. 2019. "Analysis of the Use of Radiant Floor Heating as a Cooling System" Proceedings 16, no. 1: 23. https://doi.org/10.3390/proceedings2019016023

APA StyleWerner-Juszczuk, A. J. (2019). Analysis of the Use of Radiant Floor Heating as a Cooling System. Proceedings, 16(1), 23. https://doi.org/10.3390/proceedings2019016023