Abstract

In this work, we report a systematic investigation about the sensitivity of arc-induced Long Period Gratings in standard SMF28 fiber. Several gratings were fabricated with period Λ in range 330–630 µm and characterized towards changes in the surrounding refractive index (SRI), temperature and strain conditions. Wide tuning of the sensitivities is reported, with maximum values of -6391.7 nm/RIU, 95.5 pm/°C and 2.0 pm/με, respectively, for SRI, temperature and strain. These results permit the proper selection of the fabrication parameters in order to have the desired sensing features for a specific application.

1. Introduction

A Long Period Grating (LPG) consists of a periodic perturbation of the refractive index and/or the geometry of the optical fiber, with period between 100 µm and 1 mm. As a result, the transmission spectrum of the fiber shows attenuation bands centered at discrete wavelengths, each one corresponding to the coupling between the core mode and a different cladding mode. First demonstrations of gratings were through UV irradiation, nowadays alternative and simpler approaches, based on CO2 lasers and Electric Arc Discharge (EAD) are also proposed, since they enable the inscription in not photosensitive and unconventional fibers as well [1,2]. In the EAD procedure the perturbation is created by applying an electric arc to the fiber with a certain periodicity. Concerning the mechanisms of grating formation, several effects were studied so far, including: dopant diffusion, stress relaxation, geometrical deformations and changes in glass structure [1]. The LPG represents one of the most important fiber grating technological platform that finds wide application for the sensing of physical, chemical and biological parameters [3,4,5]. In fact, the shape of the LPG spectrum and the resonance wavelengths of the attenuation bands are sensitive to several parameters, as for example: temperature, strain, bending and surrounding refractive index (SRI) [6,7,8]. In this work, we report about a systematic investigation of the sensitivity of arc-induced Long Period gratings written in standard SMF28 fiber. Several gratings were fabricated by using the EAD technique with period Λ in range 330–630 µm and characterized towards changes in the SRI, temperature and strain conditions. Currently, there is no evidence of a such study on these gratings and the results permit the proper selection of the fabrication parameters in order to have the desired sensing features for a specific application.

2. Results

2.1. Fabrication of the LPGs

For the purpose of the work, we selected a standard Ge-doped core SMF28 optical fiber provided by OZ Optics (DCO = 8.2 µm, DCL = 125.0 µm, MFD = 10.4 ± 0.8 µm at 1550 nm, NA = 0.14). The gratings were achieved by using the setup reported in [2] and the following optimized fabrication parameters: arc power in range 15–20 step (proprietary unit), arc duration of 650–700 ms, weight of 12.0 g and 0.8 mm electrodes gap. LPGs were fabricated at different period in the range Λ = 330–630 µm, resulting in total lengths within 15–30 mm as consequence of maximum power coupling with the highest order cladding mode in the range 1100–1700 nm.

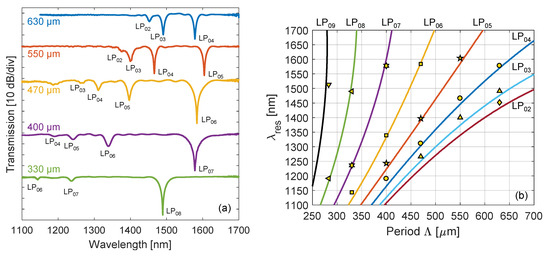

The transmission spectra of the LPGs are thus reported in Figure 1a, using offset for the sake of representation. Each spectrum presents different attenuation bands associated to the coupling between the core mode and cladding modes, which are indicated using the LP0i formalism. As the period is decreased, the highest order attenuation band changes from LP04 to LP08 in the wavelength window 1490–1610 nm, with very high depth comprised in 25–40 dB and insertion losses < 1 dB [9]. The resonance wavelength values are summarized in Table 1 for comparison.

Figure 1.

(a) Transmission spectrum of arc-induced LPGs in SMF28; (b) Phase-matching curves, comparison between numerical (solid lines) and experimental values (markers).

Table 1.

Sensitivity to SRI, temperature and strain of arc-induced LPGs in SMF28.

The attention is now focused on Figure 1b which reports the resonance wavelengths of the different modes versus the grating period (the phase-matching curves) [7], as obtained by using a numerical model based on the coupled-mode theory [10]. The experimental values from Figure 1a are also reported for comparison (as markers) and a good agreement was found, demonstrating the repeatability of the fabrication procedure.

A final comment should be made about the grating with Λ = 330 µm, since despite its period is close to the limit of the technique in standard fiber it presents high quality spectral features, in terms of attenuation band depth. In fact, even if there is evidence of arc-induced LPGs in the dispersion turning point (with Λ = 197 µm) [11], these results are still not satisfactory from the practical point of view, since as declared by the authors, a weak grating was obtained (depth of 1–2 dB) even after 400 arc discharges.

2.2. Characterization of the LPGs to SRI, temperature and strain

The response of the LPGs to surrounding refractive index, temperature and strain was experimentally investigated using the setups from [2] and by focusing the attention on the higher order band for each sample. It is the first time to our knowledge that a such systematic investigation is conducted on this kind of gratings.

Hence, the sensitivity characteristics to SRI are reported in Figure 2a, in terms of resonance wavelength shift . The values are reported with respect to SRI = 1.00 (when surrounding is air). As one can observe, for all the modes the shift is negative with SRI increasing, moreover the sensitivity increases with mode order and SRI [12]. The sensitivity values are reported in Table 1, considering three values for SRI (i.e. 1.342, 1.438 and 1.448), and it can be observed that for SRI = 1.342 the sensitivity increases from −1.9 nm/RIU of LP03 in LPG with Λ = 630 µm to -112.3 nm/RIU measured for LP08 in LPG with Λ = 330 µm. While for higher SRI = 1.438, the same increases from −67.4 to −2155.8 nm/RIU for the same modes. Finally, very high sensitivity of -6391.7 nm/RIU is recorded for LP08 at SRI = 1.448, this RI value being very close to cladding refractive index.

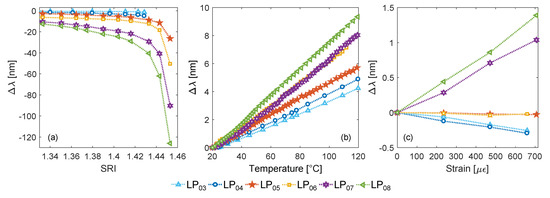

Figure 2.

Sensitivity characteristics of the LPGs to changes in (a) SRI, (b) temperature and (c) strain.

The temperature response of the same cladding modes is reported in Figure 2b, where the behavior has linear trend in the range under investigation, with red shift for temperature increasing. It should be recalled that the positive slope is associated to the fact that SMF28 has Ge-doped core whose thermo-optic coefficient is higher than silica one, with the result that the difference between core and cladding effective refractive index thermal sensitivities is positive (material contribution) [6]. In particular, the sensitivity passes from the value of 45.0 pm/°C of LP03 to 78.0 pm/°C for LP06, up to 95.5 pm/°C of LP08 (the other values can be found in Table 1).

The prediction of strain response is less straightforward since the cumulative wavelength shift is the contribution of both material and waveguide effect [6]. For lower order modes, the waveguide contribution (period change due to strain) prevails and thus the response is negative, as it can be observed from Figure 2c for LP03 and LP04; while for higher order modes (in this case LP07 and LP08) the material effect (strain induced change in effective indices) prevails and the response is positive. For intermediate periods, the two effects compensate each other and thus the response is very low, as for LP05 and LP06. As a result, a certain period exists for which a cladding mode can be strain-insensitive. In conclusion, as reported in Table 1, the sensitivity decreases from -0.5 pm/µε of LP04 to -0.1 pm/µε of LP05 and then rises to the value of 2.0 pm/µε for LP08.

3. Conclusions

Here, we have reported about the sensitivity of arc-induced LPGs in standard fiber to changes in the SRI, temperature and strain conditions. As a result, a wide tuning of the sensitivities was demonstrated, with maximum values of -6391.7 nm/RIU, 95.5 pm/°C and 2.0 pm/με, respectively, for SRI, temperature and strain. These results permit the proper selection of the fabrication parameters in order to have the desired sensing features for a specific application.

Author Contributions

experiment design and supervision, S.C. and A.I.; sensors fabrication, F.E.; sensors characterization, F.E. and A.S.; paper writing, F.E.; all the authors revised the paper.

Funding

This research was funded by the University of Naples “Parthenope”, through the “Bando di sostegno alla ricerca individuale per triennio 2015-2017, Annualità 2017”.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rego, G. Arc-Induced Long Period Fiber Gratings. J. Sensors 2016, 2016, 1–14. [Google Scholar] [CrossRef]

- Esposito, F.; Ranjan, R.; Campopiano, S.; Iadicicco, A. Arc-Induced Long Period Gratings from Standard to Polarization-Maintaining and Photonic Crystal Fibers. Sensors 2018, 18, 918. [Google Scholar] [CrossRef] [PubMed]

- Stancălie, A.; Sporea, D.; Neguţ, D.; Esposito, F.; Ranjan, R.; Campopiano, S.; Iadicicco, A. Long Period Gratings in unconventional fibers for possible use as radiation dosimeter in high-dose applications. Sensors Actuators A: Phys. 2018, 271, 223–229. [Google Scholar] [CrossRef]

- Esposito, F.; Zotti, A.; Palumbo, G.; Zuppolini, S.; Consales, M.; Cutolo, A.; Borriello, A.; Campopiano, S.; Zarrelli, M.; Iadicicco, A. Liquefied Petroleum Gas Monitoring System Based on Polystyrene Coated Long Period Grating. Sensors 2018, 18, 1435. [Google Scholar] [CrossRef] [PubMed]

- Esposito, F.; Sansone, L.; Taddei, C.; Campopiano, S.; Giordano, M.; Iadicicco, A. Ultrasensitive biosensor based on long period grating coated with polycarbonate-graphene oxide multilayer. Sensors Actuators B: Chem. 2018, 274, 517–526. [Google Scholar]

- Bhatia, V. Applications of long-period gratings to single and multi-parameter sensing. Opt. Express 1999, 4, 457. [Google Scholar] [CrossRef] [PubMed]

- Shu, X.; Zhang, L.; Bennion, I. Sensitivity characteristics of long-period fiber gratings. J. Light. Technol. 2002, 20, 255–266. [Google Scholar]

- Esposito, F.; Srivastava, A.; Iadicicco, A.; Campopiano, S. Multi-parameter sensor based on single Long Period Grating in Panda fiber for the simultaneous measurement of SRI, temperature and strain. Opt. Laser Technol. 2019, 113, 198–203. [Google Scholar] [CrossRef]

- James, S.W.; Tatam, R.P. Optical fibre long-period grating sensors: characteristics and application. Meas. Sci. Technol. 2003, 14, 49. [Google Scholar] [CrossRef]

- Del Villar, I.; Arregui, F.J.; Lalanne, P. Optimization of sensitivity in Long Period Fiber Gratings with overlay deposition. Opt. Express 2005, 13, 56–69. [Google Scholar] [CrossRef] [PubMed]

- Colaco, C.; Caldas, P.; Del Villar, I.; Chibante, R.; Rego, G. Arc-Induced Long Period Fiber Gratings in the Dispersion Turning Points. J. Light. Technol. 2016, 34, 1. [Google Scholar] [CrossRef]

- Iadicicco, A.; Esposito, F.; Ranjan, R.; Campopiano, S. Experimental Study of the Refractive Index Sensitivity in Arc-induced Long Period Gratings. IEEE Photon- J. 2017, 9, 1–10. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).