Elaboration and Characterization of CuO Thin Films by Spray Pyrolysis Method for Gas Sensors Applications †

Abstract

:1. Experimental

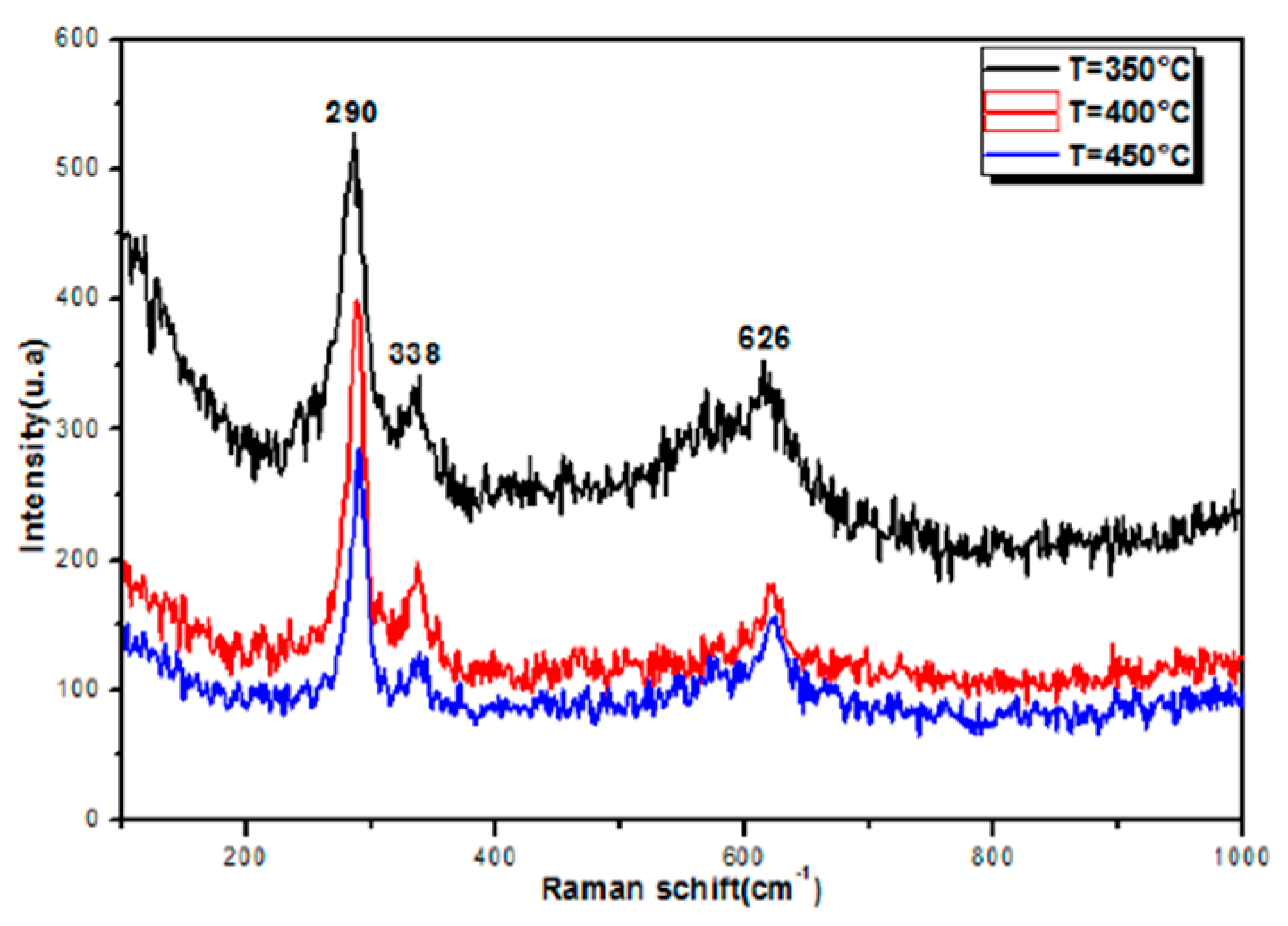

2. Characterization

3. Conclusions

Acknowledgments

Conflicts of Interest

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hinna, M.; Hartiti, B.; Batan, A.; Reniers, F.; Buess-Herman, C.; Segato, T.; Belouaggadia, N.; Fadili, S.; Siadat, M.; Thévenin, P. Elaboration and Characterization of CuO Thin Films by Spray Pyrolysis Method for Gas Sensors Applications. Proceedings 2019, 14, 55. https://doi.org/10.3390/proceedings2019014055

Hinna M, Hartiti B, Batan A, Reniers F, Buess-Herman C, Segato T, Belouaggadia N, Fadili S, Siadat M, Thévenin P. Elaboration and Characterization of CuO Thin Films by Spray Pyrolysis Method for Gas Sensors Applications. Proceedings. 2019; 14(1):55. https://doi.org/10.3390/proceedings2019014055

Chicago/Turabian StyleHinna, Maha, Bouchaib Hartiti, Abdelkrim Batan, François Reniers, Claudine Buess-Herman, Tiriana Segato, Naoual Belouaggadia, Salah Fadili, Maryam Siadat, and Philippe Thévenin. 2019. "Elaboration and Characterization of CuO Thin Films by Spray Pyrolysis Method for Gas Sensors Applications" Proceedings 14, no. 1: 55. https://doi.org/10.3390/proceedings2019014055

APA StyleHinna, M., Hartiti, B., Batan, A., Reniers, F., Buess-Herman, C., Segato, T., Belouaggadia, N., Fadili, S., Siadat, M., & Thévenin, P. (2019). Elaboration and Characterization of CuO Thin Films by Spray Pyrolysis Method for Gas Sensors Applications. Proceedings, 14(1), 55. https://doi.org/10.3390/proceedings2019014055