1. Introduction

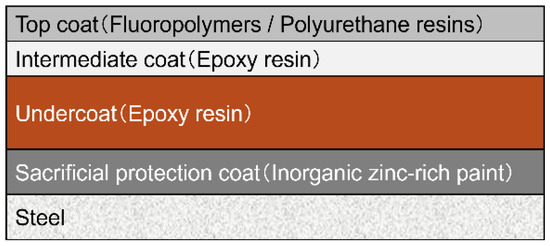

Long-span steel bridges are coated with heavy-duty anticorrosion coatings consisting of several layers of paint to prevent corrosion of steel materials, as shown in Figure 1. For the maintenance of heavy-duty anticorrosion coatings, it is important to detect the deterioration of the top coat early, in other words, the exposure of the intermediate coat, since deterioration progresses rapidly once the top coat is lost. However, current maintenance methods rely on visual inspection, and more efficient and accurate detection methods need to be developed. Furthermore, paints of similar colors are often employed for the top and intermediate coats for the purpose of color matching; it is difficult to distinguish them in the visible range. Therefore, researchers proposed an evaluation method of the deterioration state of heavy-duty anticorrosion coatings based on the difference in the near-infrared spectral characteristics between the top coat with a weather-resistant paint, such as a fluorine resin paint, and the intermediate coat with an epoxy resin paint [1,2]. However, the evaluation method proposed by these authors requires that the spectral characteristics of each paint are measured in advance. We employed the near-infrared hyperspectral imaging system to obtain the spectral characteristics of the top and intermediate coats, and identified the wavelength range where the spectral characteristics of each paint differed. Next, we employed a near-infrared camera with a band-pass filter attached that transmitted only the wavelength range and cut other wavelength ranges, and we obtained near-infrared images.

Figure 1.

Schematic illustration of heavy-duty anticorrosion coating.

2. Near-Infrared Hyperspectral Imaging System

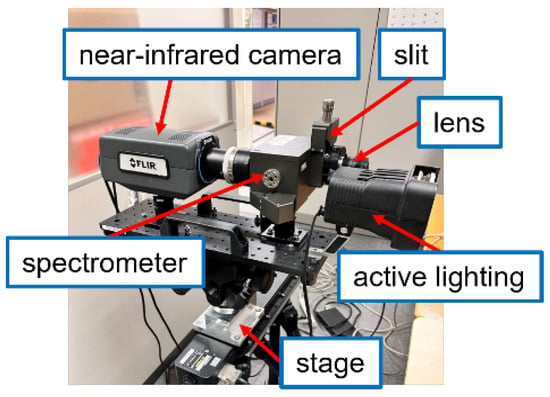

The near-infrared hyperspectral imaging system is a technology that combines spectroscopic and image measurements. Figure 2 shows the appearance of the measurement system employed in this study. The system is composed of a lens, a slit, a spectroscopic meter, a near-infrared camera, a stage, and active lighting. Light entering the lens passes through the slit and becomes a vertical line of light, which is then split by the spectrometer. The split light is measured by horizontal pixel rows of the infrared image sensor, each assigned to a different wavelength. The horizontal range that can be measured at the same time is limited by the width of the slit, so the stage is used to move the system horizontally while continuously scanning to measure a specified range. In this way, a three-dimensional data cube consisting of two-dimensional position information (x, y) and wavelength spectral information (λ) of the pixel is constructed. By analyzing this data cube, the infrared spectral characteristics at specific points within the measurement range can be obtained. Furthermore, it is possible to construct an image that emphasizes the differences in the absorption and reflection characteristics of paints at an arbitrary wavelength within the sensitivity wavelength range. Using this system, it is possible to obtain infrared intensity data for each wavelength, which is divided into 640 parts in the near-infrared range from 900 to 1700 nm. During measurement, active lighting is used to illuminate the measurement target to compensate for the lack of infrared intensity.

Figure 2.

The near-infrared hyperspectral imaging system.

3. Results and Discussion

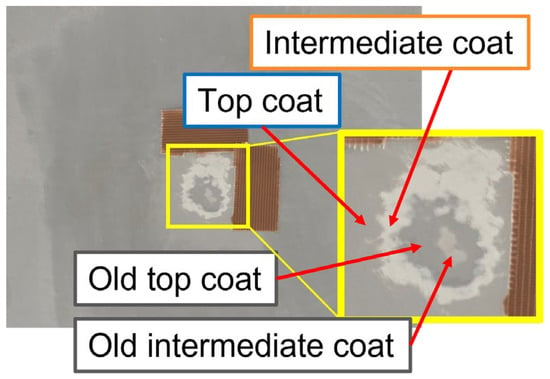

The measurement subject was the underside of the main girder of the long-span steel bridge. Figure 3 shows a visible image of the measurement location. The white areas in the visible image are the exposed areas of the intermediate coat.

Figure 3.

Visible image of the measurement location.

3.1. Measurement Results from the Near-Infrared Hyperspectral Imaging System

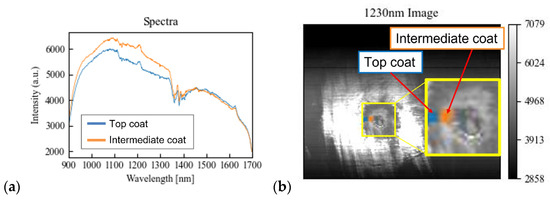

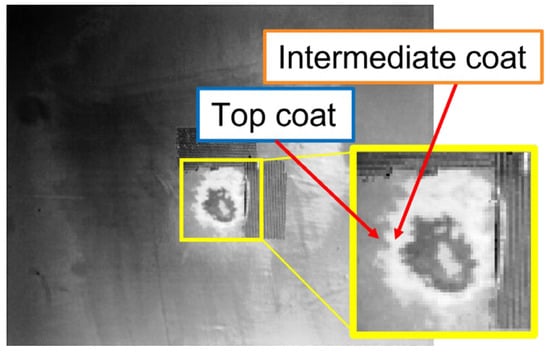

Figure 4a shows the spectra of the infrared reflection intensity of the top and intermediate coats at the measurement location, obtained using a near-infrared hyperspectral imaging system. There is a large difference in the spectra between the top coat and the exposed areas of the intermediate coat at around 1230 nm. Figure 4b shows a spectral image at 1230 nm constructed from the data cube for comparison with the wavelength range of the band-pass filter described below. From the spectral image, it is easier to detect the exposed areas of the intermediate coat compared to the visible image. The near-infrared hyperspectral imaging can be used to clearly detect the exposed areas of the intermediate coat by selecting the optimum wavelength at which the difference in infrared reflection intensity between the top and intermediate coats is large.

Figure 4.

(a) Spectra of infrared reflection intensity for the top and the intermediate coats. (b) Spectral image at 1230 nm.

3.2. Verification Using the Near-Infrared Camera Attached a Band-Pass Filter

Next, based on the results of the near-infrared hyperspectral imaging system, a band-pass filter that transmits only a specific wavelength range was attached to the near-infrared camera to obtain a near-infrared image. The band-pass filter has a central wavelength of 1230 [nm] and a half-width of 40 [nm]. Figure 5 shows the measurement result obtained using the near-infrared camera with the band-pass filter. In this image, it can be seen that the exposed areas of the intermediate coat are emphasized as bright areas.

Figure 5.

Infrared image obtained using the band-pass filter.

4. Conclusions

This experimental study showed that it is possible to detect exposure of an intermediate coat using a near-infrared hyperspectral imaging system and a near-infrared camera with a band-pass filter attached. These results can contribute to more efficient and appropriate maintenance of heavy-duty anticorrosion coatings of long-span steel bridges.

Author Contributions

Conceptualization, A.T., S.H., Y.O., D.S., T.S., K.F., H.K. and H.T.; methodology, A.T., S.H., Y.O., D.S., T.S., K.F., H.K. and H.T.; software, A.T. and S.H.; validation, A.T., S.H., Y.O., D.S., T.S., K.F., H.K. and H.T.; formal analysis, A.T. and S.H.; investigation, A.T., S.H., Y.O., D.S., T.S., K.F., H.K. and H.T.; resources, A.T., S.H., Y.O., D.S., T.S., K.F., H.K. and H.T.; data curation, A.T., S.H., Y.O., D.S. and T.S.; writing—original draft preparation, A.T. and Y.O.; writing—review and editing, A.T., S.H., Y.O., D.S., T.S., K.F., H.K. and H.T.; visualization, A.T., S.H., Y.O., D.S. and T.S.; supervision, A.T., Y.O. and T.S.; project administration, Y.O., D.S., T.S., K.F., H.K. and H.T.; funding acquisition, T.S., K.F., H.K. and H.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by a Grant-in-Aid for Scientific Research (B) JP 21H01213 and (c) JP 24K07216 from the Japan Society for the Promotion of Science.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are not publicly available.

Conflicts of Interest

Authors Kenji Fujita, Haruhiko Kono and Hiroto Tamura were employed by Honshu-Shikoku Bridge Expressway Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Sakata, T.; Kishigami, S.; Ogawa, Y.; Arima, N.; Nishitani, M.; Shiozawa, D.; Sakagami, T. Quantitative assessment of heavy-duty anticorrosion coating thickness via near-infrared measurements. NDT E Int. 2023, 138, 102893. [Google Scholar] [CrossRef]

- Kishigami, S.; Mizokami, Y.; Sakata, T.; Ogawa, Y.; Shiozawa, D.; Sakagami, T. Detection of heavy-duty anticorrosion coating deterioration using near-infrared spectral characteristics. NDT E Int. 2022, 132, 102708. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).